Skyflo Wireless Liquor Management System User manual

Wireless Liquor Management System

User

Guide

2

PREFACE

The purpose of assembling this Skyflo User Manual is to provide basic information

required to use and configure our products.

This manual is a “work in progress” – if you see corrections, or would like to suggest

additions or other changes which will make this reference more useful to yourself

and others, please let us know.

Our products are being constantly improved and modified for extra functionality as

well as for individual clients specific needs. For this reason this manual will need to

be updated regularly.

This updated manual has been compiled and published by Linda Zhou & Andrew Ferrett

Updated 9/7/2010

3

INDEX

Page

4 Using SKYFLO Pour Spout

6 Using the Washing Key

7 Using a Charging Key

9 Calibration Key for SKYFLO Pour Spout

11 Beerflo – Wireless Beer Monitor

13 Beerflo Box – Wireless Beer Monitor

18 Optic pearl

21 Skytag

22 FAQ Frequently Asked Questions

4

Using SKYFLO™ POUR SPOUT

Important – when shipping Skyflo always ensure you put it to

Sleep using the washing key. RF devices must always be

switched off in transit!

Preparation

zUnpack the box and check contents as per the packing list.

zFor security reasons the Spout is deactivated with access

to Cleaning Mode (Spout open) during transportation.

Touch the sensitive button with your finger and you will see

the top 2 LEDs light blue.

zTo activate the Spout take the Washing Key, push the button

until you see ‘Close’ light green, then within 4 seconds you

must put it on the top of the Spout with contact to the metal part.

You will hear the motor run once. The Spout then closes and is

activated.

zTake the Spout and insert the air valve tube.

Pouring

zTake a bottle ensuring it contains liquid.

Nb. This Spout is not recommended for syrup product.

zInsert the Spout fully onto the bottle to make bottle presence sensor

activate. You should hear the motor run once,

The Spout opens & closes and air is released from the bottle.

zIncline the bottle quickly but smoothly to at least a 160

degree angle and pour.

Cleaning Mode Washing Key ‘Close’ light green - Spout Closes

Bottle

presence

sensor

Air Valve

SKYFLO Spout

Spout registers

on bottle

5

Changing Serving Sizes

zAfter the bottle presence sensor is activated by inserting the

Spout into the bottle the default pour size is usually set as 30ml.

zTrigger the Spout with a simple finger touch on the sensor pad

to choose the size you want to pour. The blue LEDs from top to

bottom stand for 50ml, 40ml, 30ml & 20ml respectively. After

choosing a size you can incline the bottle to pour. If you keep the

bottle inclined it will continue to pour measures of the set quantity

until you return the bottle to upright.

zUsing SKYMAN to configure the Spout, you can fix a different

default size, block the optional sizes, or select a free pour mode.

Liquid Detection & Bottle Change

zThe Spout will not pour when the bottle runs empty, as no liquid is detected.

4 LEDs blink in blue and flash off from bottom to top, if you keep the bottle inclined they repeat 2

times then flash off completely.

zRemove the Spout and attach it to a new full bottle of the same size and brand.

zChanging of bottles is printed on your report.

Low Battery Indication

zWith a tiny Li-ion battery inside the Spout can pour 10,000 drinks before recharging.

zIf you do not pour at all, a Spout on a bottle can stand by for up to 3 months.

zWhen the Spout top LED blinks RED it indicates low battery and needs to charge.

zLow battery status is printed on your report.

Technical Comments

The Skyflo Spout is currently designed to transmit pour data to the Master immediately, and if it

gets no response, to continue sending after 2/4/8/16/30/60/120/240/480 seconds, then attempt to

transmit every 8 minutes until it succeeds.

The Spout synchronises with the Master Unit once every hour to check connection, whether the

Spout is pouring or at rest.

If the Spout is unable to transmit the data immediately it is able to store more than 50 pours.

Change size

6

Charging the Washing Key

zIf you depress the Washing Key button and no LED blinks it needs charging.

Plug the Washing Key to the power supply and the ‘open’ light will turn red.

This signifies normal charging progress.

zWhen the Washing Key battery is full the Washing Key ‘open’ light turns green.

Recharge can be done in two hours.

Cleaning the Spout

zTake the Washing Key. Push the button to light the ‘open’ light

turn green. Put it on the Spout. You will hear the motor run once.

Spout opens and is ready for cleaning.

During cleaning mode the Spout will not send any signal.

If you touch the sensor pad on the Spout no LED blinks.

zBriefly rinse the Spout in warm/cold water and shake to dry.

zDo not keep the Spout submerged in water.

zDo not wash the Spout more than once a day.

zDo not wash with water that is too hot to touch.

zDo not bleach or use abrasive cleaners.

zDo not leave the Spout soaking in water.

zDo not put the Spout in a dishwasher.

zWhen cleaning is finished push the Washing Key button

until you see the ‘Close’ light turn green, then within 4 seconds

place it on the top of the Spout with contact to the metal part.

You will hear the motor run once. The Spout then closes and is

activated.

Changing Cork

zCut the old cork with a knife and replace with the new cork.

zDifferent cork sizes are available to fit the Spout.

Spout LED Blinking Instructions

zIf the bottle is inclined and all blue LEDs flash On, Off, then ON again this means no liquid is

detected.

zTop blue LED and last Bottom blue LED blinks; RF communication with master is in error.

zTop blue LED flashes all the time, in configuration mode with Master via SKYMAN.

zTop blue Led flashes and then all blue LEDs flash off from bottom to top, The Spout has been reset;

Washing Key/Charger reset button

zUse a pin to push the hole by the Washing Key /Charger button to reset the device.

Open Spout

Close Spout

7

Using a Charging Key to charge a Spout

zCharging the Charger:

A full charger can charge approximately 1.5 Skyflo Spouts.

The Charging Key should be fully charged before charging a Spout.

Plug in the Charging Key and wait for the “Charger” red light to go out.

However the charger can feed the spout meanwhile it is getting charged.

zBefore charging Spout:

Press the Key button once to activate and place the Key on the Spout.

Light reference;

“Charger” LED Green = Key battery OK;

“Charger” LED Red = Key battery empty.

zDuring charging:

When the key is placed on a Spout the key will detect how much power is present.

It continues to detect every 1 to 3 minutes during the charging process.

(When key is detecting spout the “Spout” LED blinks green once.)

8

zSigns of proper charging process:

¾“Spout” LED blinks blue, meanwhile Spout “top LED” blinks red.

Nb. When the Spout runs completely out of power, the “top LED” will not immediately blink red

after the Key is placed on it. It wakes up the Spout = Spout “top LED” blinks blue and the motor

runs - opening and closing one time.

Take the Key off the Spout and re-place on it. The Spout will then immediately blink red.

¾When Key battery becomes flat the Key “Charger” LED will turn red.

This alerts the operator to plug power to charge the Key.

¾Error notice: If the Key loses contact with the Spout or a program error occurs the Key

“Charger” LED will turn green automatically.

After “Charger” LED turns green the Key stops charging.

This alerts the operator to take the Key off the Spout and re-place it back on the Spout.

If the error persists you can use a pin to push RST (Reset) to reset Key.

zCharging Complete:

Once the Charging Key detects that the Spout has enough power (more than 90%) the Key “Spout”

LED will turn green, and will then stop charging.

Take the Charging Key off the Spout and press the Key button to exit alert status.

9

Calibration Key for Skyflo™ Spout

The Calibration Key has the same housing as the Charger and Washing Key. It adjusts the pour

rate and refines the pour size. This can also be done through our Skyman software.

Push the Calibration Key button once and you will see both LEDs light Green.

How to Use:

1. Sit Skyflo Spout on the bottle, but ensure the bottle presence sensor is not depressed. Put the

Calibration Key on Spout.

2. Adjust Pour size to smaller:

1) Push the Key button for 1 second and the ‘decrease LED’ light will turn green; Push Key

button once and the same key light blinks once. This means the Spout pour rate is

reduced 0.5%; each push should follow with the ‘decrease LED’ blinking green once.

2) When you have finished leave the key on Spout for about 3 seconds, you will then see

the ‘decrease LED’ light blink blue. Spout top LED will then blink blue and follows with 4

LEDs flashing from bottom to top twice. Spout saves the setting and exits. You may hear

the Spout open and close once with the motor running.

decrease LED

increase LED

10

3. Adjust Pour size bigger:

1) Push the Key button for 1 second and ‘increase LED’ light will turn green. Push the Key

button once and see same key light blinks once. This means the Spout pour rate is

increased 0.5%; each push should follow with the ‘increase LED’ blinking green once.

2) When you have finished leave the key on Spout for about 3 seconds, you will then see

the ‘decrease LED’ light blink blue. Spout top LED will then blink blue and follows with 4

LEDs flashing from bottom to top twice. Spout saves the setting and exits. You may hear

the Spout open and close once with the motor running.

Note:

1. The Calibration Key helps to adjust the pour size but it is based on the size previously set in

Skyman.

For example, the original size is 20ml, after adjustment Spout will continue to signal as 20ml to

Master Unit.

2. Spout does not require adjusting for each size. After adjustment, all 4 optional sizes will follow the

change.

3. After calibration the spout, the initial pour need to be ignored as spout was previously reset by the key

to execute the calibration, the second pour should be ok.

11

LED1LED2

Skyflo™ Wireless Beerflo

Brief Instructions to use the Wireless Beerflo

For security reason during transportation, the Beerflo was

previously entered Cleaning Line mode to avoid sending signal.

After unpack it for install, the first thing is to exit Cleaning Line mode,

refer below steps.

Note: when RF module and Flow meter are separate, do always remember to enter RF module into

Cleaning Line mode to avoid Huge Power Consumption from the RF module with attempt looking for flow

meter pins connection.

Put Washing Key on the ring (for add device, exit and enter cleaning line mode and etc.)

1. Press washing key OPEN, Flowmeter LED 1 blinks red & green alternatively, Wireless Beerflo stops

counting the pulses. This message can be treated as “Clean Line” or “Change Keg”. In order to

separate this two messages, application software need to accumulated the volume from the keg to tell.

2. Press washing key CLOSE, Beerflo LED 2 blinks red & green alternatively, Wireless Beerflo will send

signal as to “Add Device” in the master via SKYMAN or other application software.

This is also used to EXIT “Cleaning Line” or “Change Keg”.

3. When LEDs 1 & 2 flash green, it means no master in responding to this Wireless Beerflo.

4. When LED 1 blinks red weakly, it means battery low.

Battery can last 2 years as per calculation in theory. Battery is replaceable.

12

Mind how the RFModule is connected to the Flow Meter.

(RF Module “+V” hole to Flow Meter “+V” pin)

Attention: wrong connection is prohibited as it may lead beerflo over heated and battery flat!!

13

Skyflo™ Wireless Beerflo Monitor

Beerflo Monitor Box is able to connect to 8 kegs (beer lines).

With LCD display, touch keypad, and 8 beer line LEDs

1. Power is DC12 volts. **Do not connect this power supply to any other Skyflo product.

2) Open Beer Monitor housing. Mind not to break the FPC

connection to the touch Keypad.

8 flowmeter connections, RS485 port (not in use) & DC power 12V (though silkscreen is 24V).

1) Screw here 9to open the housing at 4 corners at the back

housing. (Inside the deep-hole screws)

Do not unscrew the covered PCB screws.

14

Red cable = “V” for Power

Blue cable =“S” for signal

Black cable = “G” for Ground

“V” for Power

“S” for signal

“G” for Ground

•Printed Circuit Board:

•Titan Beverage Meter 300-010:

•Note the Switch Direction:

Make sure below 8 Switches pointing to “ON” after connection to Titan Meter 300-010.

* Only when an infrared flowmeter such as SF800-Swiss Flow is connected, the 8

switches should point OFF (the opposite position of ON).

4) Once you have connected the flowmeter to the beer monitor, after power up the beerflo monitor box,

the relevant channel LED will turn ON.

2. Connecting the Beerflo Monitor to a Master Unit through RF

1) Note: before add device, make sure minimum one channel is wired to the connector.

Ex-work hardware may have one channel connected with resistance for easy add device.

Screw off the resistance after one channel is wired to the connector.

2) After you have installed SKYMAN on your PC go to Program – Configuration - Master and

Click Add Device.

3) Connect the flowmeter cable to the Beerflo PCB.

15

LED indicators 1 ~ 8 under the LCD:

Off: no flow meter.

Red: flow meter is connected.

Blue: flowing.

Blink Red-Blue: washing.

Blink Red: changing keg.

LED indicator left to the LCD:

On: “Fn” function key is activated.

Off: normal condition.

LED indicator right to the LCD:

Blink blue: attempt to transmit recorded pulses.

3) Connect the Beerflo Monitor power line, enter Menu and find “Remove keg”, input your beer

line channel (numbered from 1 to 8). Touch button “Enter” on Beer Monitor Keypad, you will

be able to see the Beerflo device ID on the Skyman screen, input a name for this Beer

Monitor (maximum 5 digits).

4) Open the page Skyman ÆManagerÆDevice. Give each of the connected channels a

product name for each beer line. Products have previously been set inside Products page of

Skyman ÆManagerÆProduct.

5) You must also configure the pour rate of each connected channel/beer line in the R1,

R2, R3 etc. column.

For Titan Beverage Meter 300-010 you should enter 1420 (‘K’ Factor) as per its specification

1420 pulses = 1 liter.

For example if the Titan Beverage Meter 300-010 shows pulses 1164 Skyman will give

819ml. (819ml = 1164/1420*1000).

Skyman will now show measurements in ml. You can test this if you wish by blowing gently

into the flowmeter before connecting it to the beer line.

If you want the Master Unit to show pulses instead of ml, input 1000 for each channel rate

inside Skyman ÆManagerÆDevice page after you add the Beerflo device.

3. LED, LCD and keypad functions:

zFront Panel LED display:

zLCD default display

[ ……. ]

[->3….235 _ öX_ __ ]

Power up beerflo: “…….” no pulses recorded.

Recorded pulses: “3” is beer line/channel, “235” is pulses, maximum display 16 events.

touch keypad “arrow up” or “arrow down” to turn page.

Channel Off: ‘ ‘ (blank) no flow meter is detected.

Channel On: ‘_’ (underline) the flow meter is connected;

Washing line: “ö” in washing mode, flow does not count.

Changing keg: “X” in changing keg mode, flow does not count.

Flowing: “ “ dynamic height to indicate the flow speed.

zSystem information

16

In “LCD default display” mode, touch “Fn”+”#” to display system information

1. Version

2. Device ID

3. Time (auto synchronize with Master) Format: “Month-Day Hour:Minute:Second”

4. 6,7,8,9. Some debug data

5. Pour data in the buffer; “A-X-X”: A is saved events in the memory, X for debug.

A. Hardware flags.

zDefinitions of menu

In “LCD default display” mode, touch ‘Menu’ to enter the menu. Touch keypad “arrow up”

or “arrow down” to turn page:

Start clean (F1) = clean beer line

Stop clean (F2) = stop clean beer line

Remove keg (F3) = take out empty keg

Restore keg (F4) = Install a new full keg

Memory = Manage the eeprom and ram memory, only for debug.

Admin = Set Admin ID and password; set the waiter ID and password,

support max 8 waiters.

Clean time = setup clean time

NOTE: Only the admin has the authorization to use the functions of ‘Memory’, ‘Admin’

and ‘Clean time’.

zStart and Stop cleaning beer line

1) In “Menu” mode, move the arrow to “Start clean (F1) ”, touch “Enter”; or In “LCD

default display” mode, touch “F1”.

[Start 9_ _ öX _ _ 9]

[ Clean 2 3 * 7 ]

‘ö’ –the channel 4 is already in washing mode.

‘X’--the channel 5 is changing keg.

‘_’—the channel is in normal work mode, channel 2, 3, 6,7.

‘9‘—no flow meter is connected. Channel 1 & 8.

‘2’, ‘3’,’7’ – channel 2,3,7 can go to washing mode.

“*”— channel 6 already been selected.

Only the displayed channel numbers are ok for further operation. Select the channel to

be cleaned by touch “0” to “8”, touch “0” for reverse the selection, then touch “Enter” ;

2) To exit clean Line mode, In “Menu” mode move arrow to “Stop clean (F2) ”, touch

“Enter”; or In “LCD default display” mode, touch “F2”. Select the channel then touch

“Enter”.

[Stop 9_ _ öX _ _ 9]

[ Clean 4 ]

17

Note:

If the beer line is left running with water without entering cleaning mode previously,

Beerflo will send every 10,000 pulses to Master Unit. Application software must treat

those big readings plus final small readings as cleaning events. Otherwise it will

influence the accuracy of dispense record.

zRemove and Restore keg

Enter “Remove keg (F3)” and “Restore keg (F4)”, follow the same principle as above “Start and

Stop cleaning”.

zSet Admin ID

In “Menu” mode, move the arrow to “Admin”, input the code “100000” and touch “Enter”; it

will show “Admin” “0” “pswd” “100000”; move arrow to “admin” input number to give a

different admin ID, not forget to touch “Enter” and save it; follow the same principle for a

different password setting. (Please remember your new password!)

The Admin ID is with the top level of authorization for change keg and clean line.

There are total 8 waiter IDs with password, it is not in use yet.

zSetup Clean time

In “Menu” mode, move the arrow to “Clean time”, input the code “100000” and touch “Enter”;input

the number of minutes you wish to have the line exit cleaning mode automatically.

18

Wireless Optic Pearl

Economic Liquor Control Solution

The system comprises of:

Standard Measure Brackets, pearl, wireless pearl counter, bottle inserts.

Standard Measure Brackets

Pearl & bottle inserts. Available pearl: 25ml, 35ml, 50ml; bottle insert for 75cl & 1 liter bottle.

Wireless pearl counter

19

Insert the optic into the support

Replace your old support with

the Skyflo Optic Pearl support

Replace your old support with

the Skyflo Optic Pearl support

Sk

y

flo O

p

tic Pearl su

pp

ort

Bottle switch

Dis

p

ensin

g

switch

Optic Pearl

Once the bottle is removed it automatically

signals a bottle change to the Master Unit

Using the Optic Pearl

20

How to Replace Pearl Counter Battery

Button Cell Battery: CR2032, 3V 200mAH

1. Screw off the Cover of Pearl Counter.

2. Take Battery Holder PCB out of Counter Housing

4. Use a non-metallic tool to push battery completely out of the holder.

5. Replace with a full battery, insert LEDs to the plastic cover, push back the Battery Holder PCB and screw on

Cover of Counter Housing.

Important – when shipping this product always isolate the battery.

RF devices must always be switched off in transit!

Table of contents

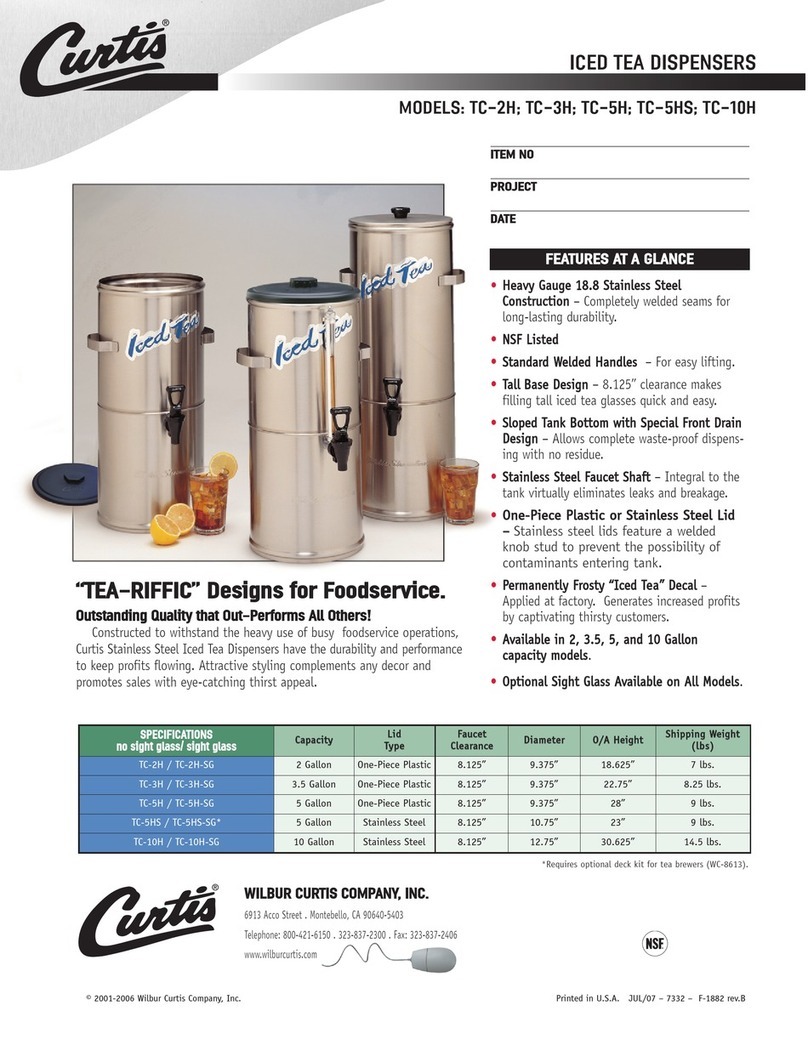

Popular Beverage Dispenser manuals by other brands

CDA

CDA BVB4 Manual for installation, use and maintenance

Kenmore

Kenmore 564.8815022 Owner's instructions

Ice-O-Matic

Ice-O-Matic Hotel Dispenser CD300 Service & installation manual

Silver King

Silver King SKMCD1P/C1 Routine Maintenance Tasks

lancer

lancer FLAVOR SELECT 22 Installation and service manual

Cornelius

Cornelius Enduro ED-250 BCP installation manual