2

SUMMARY

1. Introducon ...................................................................................... 3

1.1 Safety .................................................................................................................... 3

1.2 Main Components ................................................................................................. 6

1.3 Technical Characteriscs ........................................................................................ 6

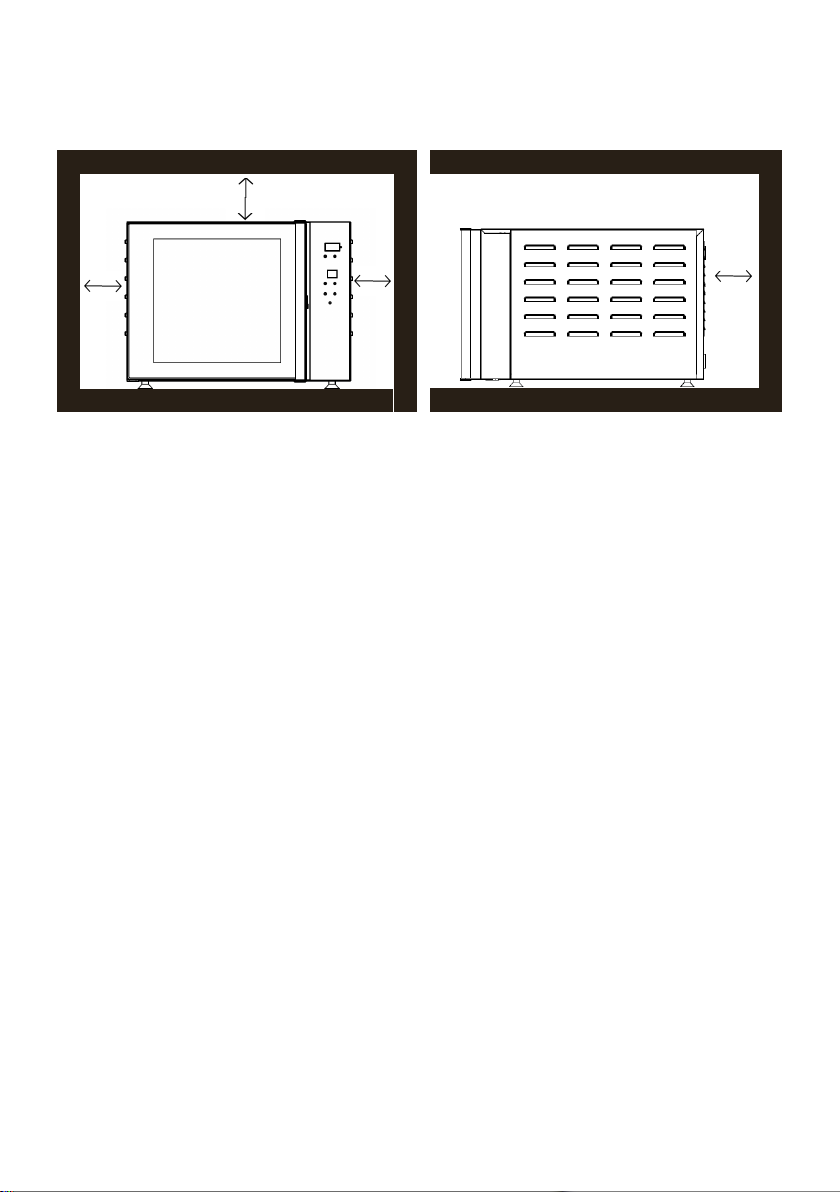

2 Installaon and Pre-Operaon............................................................7

2.1 Installaon ............................................................................................................ 7

3. Operaon ........................................................................................ 12

3.1 Acvaon .............................................................................................................12

3.2 Operaon Procedure ............................................................................................14

3.3 Cleaning and Sanizing ........................................................................................15

3.4 Cauons with Stainless Steels...............................................................................16

3.5 Products Guide Chart ...........................................................................................17

4. General Safety Noons .................................................................... 18

4.1 Basic Operaon Pracce .......................................................................................18

4.2 Cauon and Observaons before Turning on the Appliance ..................................19

4.3 Roune Inspecon................................................................................................20

4.4 Operaon .............................................................................................................20

4.5 Aer Finishing The Work.......................................................................................20

4.6 Maintenance........................................................................................................20

4.7 Advice ..................................................................................................................21

5. Analysis and Problems Solving......................................................... 22

5.1 Problems, Causes and Soluons............................................................................22

6. Maintenance ................................................................................... 24

7. Electrical Diagram............................................................................ 25