SlowBipe Air SlowBipe Instructions for use

SlowBipe ARF Construction Manual

This manual will illustrate the construction of the SlowBipe airplane from kit to flight.

Go to www.slowbipe.com/products.asp for a full color version of this manual.

The magnets are already installed. Some of the assembly on this kit is already done. This

manual documents setting up the SlowBipe using the Power Pack and Servo Pack from

SlowBipe.com.

Warning: Do not use CA or Super Glue. Even some “foam safe” cyanoacrylate glues

will attack the blue foam in this kit.

For this build I used Gorilla Glue for everything. Once you learn how much of it to use,

it is one of the strongest and lightest glues you can use. If you have not used it before, do

some test glues on something that you can throw away. Be sure to spread a thin film of

the glue all the way to the edges of what you want to glue. I spread roughly over the

entire surface to be glued, then wipe it to a thin film with a wiper. I am supplying several

pieces of scrap foam to be used as a wiper during construction.

Fuselage Construction

•Using your glue of choice, do the following steps

oInsert the 4 included plywood keys into the slots in the 4- one inch thick

fuselage core pieces. The keys then align the core pieces to the locations

they go on the depron fuselage sides. Please see the picture. You can glue

them onto one side now. The four pieces are as follows:

Servo block – Place this so that the slots cut for the servo wires is

on the opposite side of the fuselage from the cutout for the servo’s.

Top Wing Saddle – This piece already has the two magnets glued

into it.

Bottom Wing Saddle – This piece already has a landing gear block

glued in.

Firewall Core Piece – This piece already has the plywood firewall

and a landing gear block glued in.

2

oNow glue the one half inch

thick tail block assembly to the

depron fuselage side. There are

4 alignment tabs to place it

correctly. See picture.

oNext are the battery trays top

and bottom core pieces. These

are cut from 6mm depron foam

and will be glued in on one

side.

oAt this point I would allow

these pieces to dry, but that

really depends on the type of

glue you choose to use.

oIncluded with your kit is a

depron spacer from 6mm foam

that is about 4 x 4 inches. Use

this spacer to raise the tail on

the flat surface to make the

tapered tail. See picture.

oIt is now time to glue in the

6mm depron tail spar. This is

the tapered spar that is tabbed.

Apply glue to the areas that

touch the one fuselage side and

press into place.

oNow apply glue to all of the

surfaces that will touch the

second fuselage side when

installed. Be sure to use the

spreader to make sure that the

Gorilla glue is applied with a

thin film across every surface.

oIf using Gorilla glue I would

then spray the entire surface

with a mist of water and align

and press down the second

fuselage side. Once this is

down apply some form of

weight to the surface of the

plane so that the joint is tight.

oAllow to dry

3

Other Fuselage Items

oGlue the Plywood Pushrod Guide

into slot in fuselage side.

oUsing a sanding block, sand the wing

saddle so that the depron and blue

foam are at the same level. This will

ensure that you get good contact for

the magnets that hold the wing on.

You can also sand any other surfaces

that are not even to create a better

finished plane.

oGlue hatch back plate to back side of hatch door. There is a recessed area

in the 1/32 inch plywood plate for alignment on one edge of the foam

door. See picture.

oGlue hatch door handle in slot in

front of battery hatch door.

oGlue 1/8 inch light ply retainer to

end of fuselage nose hatch. See

picture for placement. There is a

mark milled in the surface of this

foam part. You can align the

plywood retainer to this mark. This

piece slides into the nose block of

the plane to make the hatch cover a

tight fit.

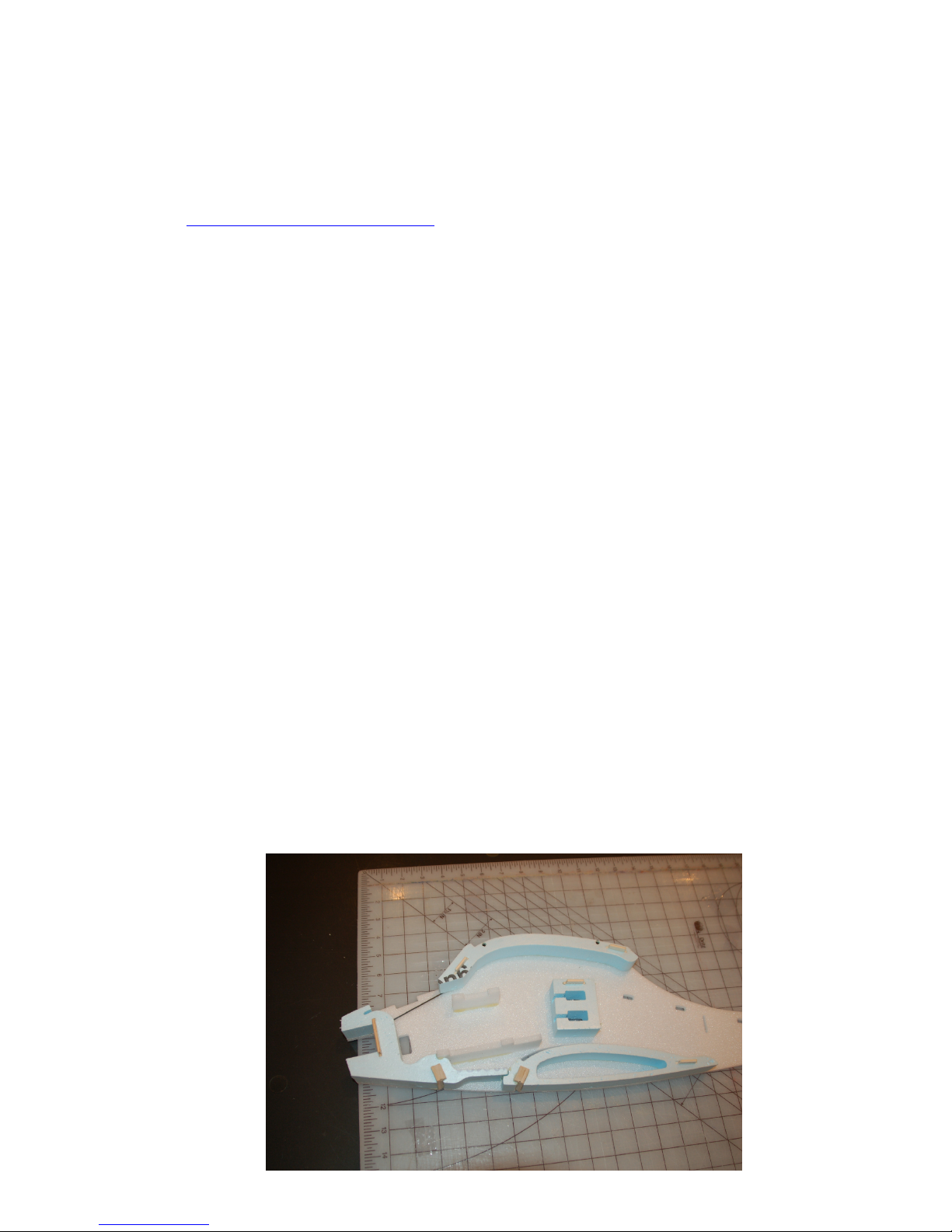

Paint Fuselage

•Optionally paint the fuselage at this time.

The paint that I have found to work the best

that doesn’t eat the foam is Krylon Short

Cuts. I have found this paint locally at

Michaels Craft store as well as Hobby

Lobby.

ohttp://www.krylon.com/products/short_cuts_aerosol_paints/

oSpray one or two light coats and allow to dry over night

4

Battery Hatch Door

oThere is a piece of self adhesive

¼” foam in the kit to go on the

inside of the battery door. When

applied it will hold the door shut

from pressure on the battery pack

inside.

oI would place the Velcro on the

bottom of the battery compartment

floor and on the side of your

battery pack. This makes it easier

to get the battery in and out

without pulling the Velcro off the

surface. It also leaves more space

for the battery pack. See picture 8.

Rudder Assembly

•Using 5 minute epoxy glue rudder shaft into milled slot in foam rudder. 5 minute

epoxy is available at most home improvement stores and at Walmart.

oRudder shaft is oriented so that the hole for retainer clip is at the bottom

and so that the clip when inserted is parallel to the rudder. If you have the

landing gear option, you can use the tail wheel wire here to make sure that

the holes are parallel to the rudder. Tail wheel wire will install through

this hole to make the tail wheel steerable.

•When the rudder shaft is dry in the

rudder, slide rudder control horn onto

rudder shaft from bottom

oRudder control horn is oriented

so that it extends to the right of

rudder when viewed from behind

•Using 5 minute epoxy glue rudder

control horn to shaft and bottom of

rudder

oSee illustration for position of

rudder control horn

oThe control horn will be perpendicular to rudder or 90 degrees

5

Elevator Control Horn Installation

•Using Epoxy glue, glue the control horn

into the two 1/16

th

inch holes on the

bottom of the horizontal stabilizer

oSecure by gluing the retainer on

the other side. The magnet to

retain the stabilizer to the fuselage

is already installed for you.

Windshield Installation

•Remove backing from vinyl windshield

•Apply vinyl windshield to fuselage

•Press windshield sides around fuselage

and press firmly

Servo Installation

•Feed servo wire from servo slot through fuselage and into radio compartment

•Press servo into servo holes by rocking the

servo gently until seated. Be carful not to

crush the foam on either side when

starting servo into hole. The servo's install

with the wires facing front of fuselage.

Control Rod Installation

•Connect your receiver up to the ESC

(Electronic Speed Control) and two

servo’s.

oThe top servo is for rudder and the

bottom is for elevator

oConnect your battery pack to the ESC

oTest that your radio is functioning and allow servo’s to center

6

•Install servo arms onto servo’s with both arms facing down. If you purchased the

servo pack from us, we have attempted to align these for you already.

•Slide horizontal stabilizer into slot in fuselage tail until the magnets align and it

snaps into place

•Insert control rod into rudder control

horn as you install the rudder. Retain

rudder with supplied body clip at bottom

of fuselage, or the tail wheel wire.

•Install wire control rods through pushrod

guide and into EZ Links on servo horns

•Insert control rod into elevator control

horn so that the side of the fuselage

holds the rod in place

7

Prop Saver Installation

•Assemble prop saver by inserting

two screw into prop adapter hub

•Slide prop saver onto motor shaft

per illustration and tight screws

with Phillips head driver.

Wing Assembly

•Drop top wing onto top of

fuselage. It will snap into place

from magnets. After flying, you

can adjust the wing on the magnets

to get the plane to fly straight and

level.

•Be sure to press the leading edge

magnet down firm each time you

assemble the plane to make sure

the magnets have good contact.

•Plug one of each lower wing into

each side of fuselage lower wing

slot. These will snap into place

with the magnets that are already installed in these wings.

•Carefully slide wing struts onto ends of wing panels.

Other Flight Items

•CG location is about 1.5 inches behind the leading edge of the lower wing.

•Go to www.SlowBipe.com for flight instructions

8

Landing Gear Installation

•Install main wheels onto axle shafts

on landing gear legs. Slide ½ inch

fuel tubing onto axes and up against

wheel to retain main wheels.

•Insert landing gear legs into each

side of fuselage by carefully sliding

each rod into the holes in fuselage

gear blocks. They should go in

approximately 7/8 inch.

•Snap gear retaining blocks onto front

set of gear rods by aligning the rods

to the gear pushing the block on

from the front. Slide rear gear

retaining block onto rear set of gear

rods by pushing the block on from

the rear. Gear legs pull down to

align and snap into the blocks. This

ensures that the legs will not pull out

during landing. See picture.

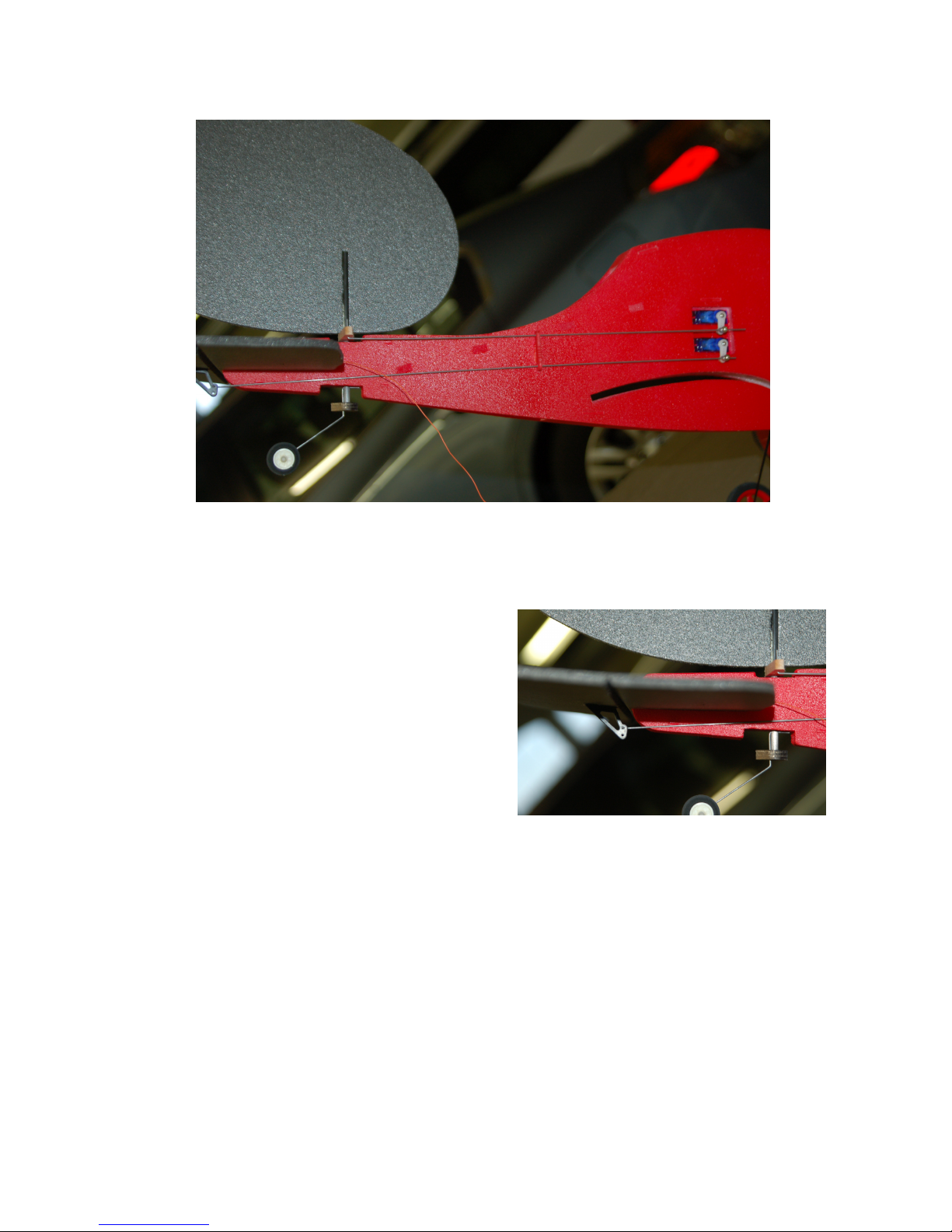

Rudder Installation

•Slide Rudder Assembly into rudder

bearing blocks in tail

•Insert rudder control rod into control horn through pushrod guide and into bottom

of rudder horn

•Retain rudder control rod at bottom with either the body clip or landing gear tail

wire if you are using the landing gear option. See Picture.

Table of contents

Popular Toy manuals by other brands

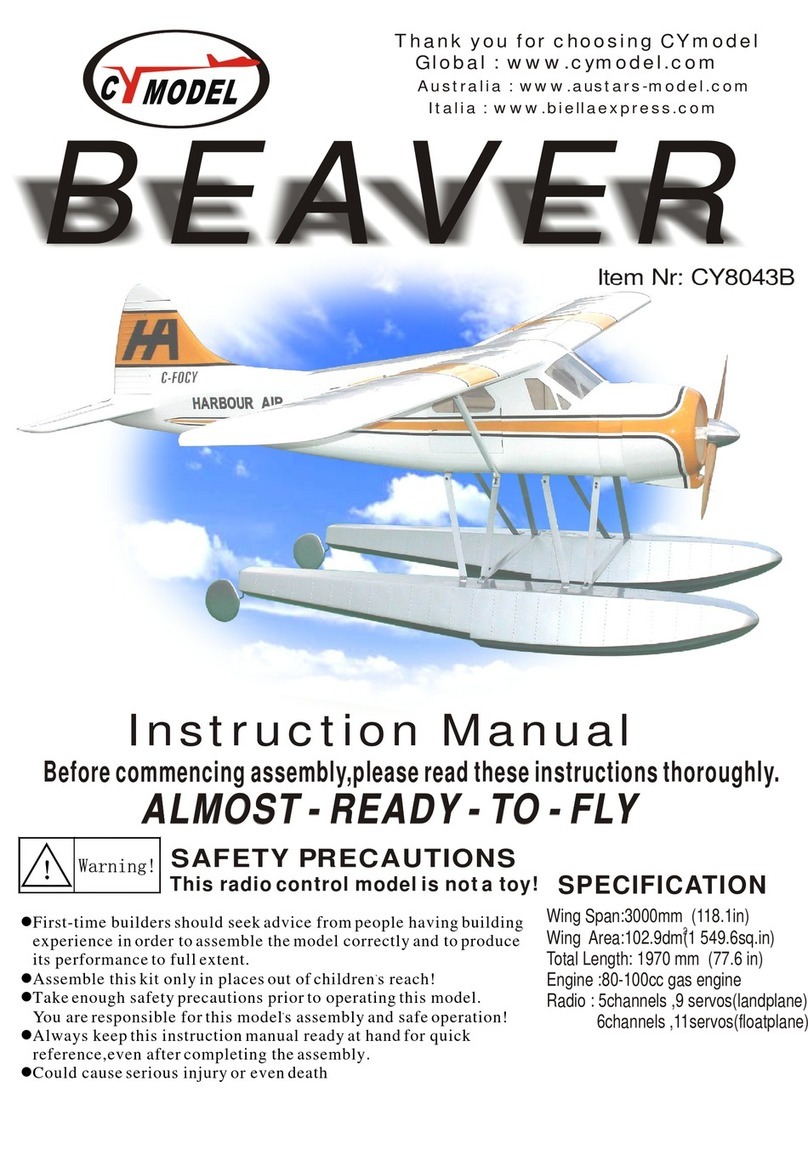

CYmodel

CYmodel BEAVER CY8043B instruction manual

SAB Heli Division

SAB Heli Division Goblin Kraken Urukay Genesis manual

Carl Goldberg Products

Carl Goldberg Products Stinson 108 ARF user guide

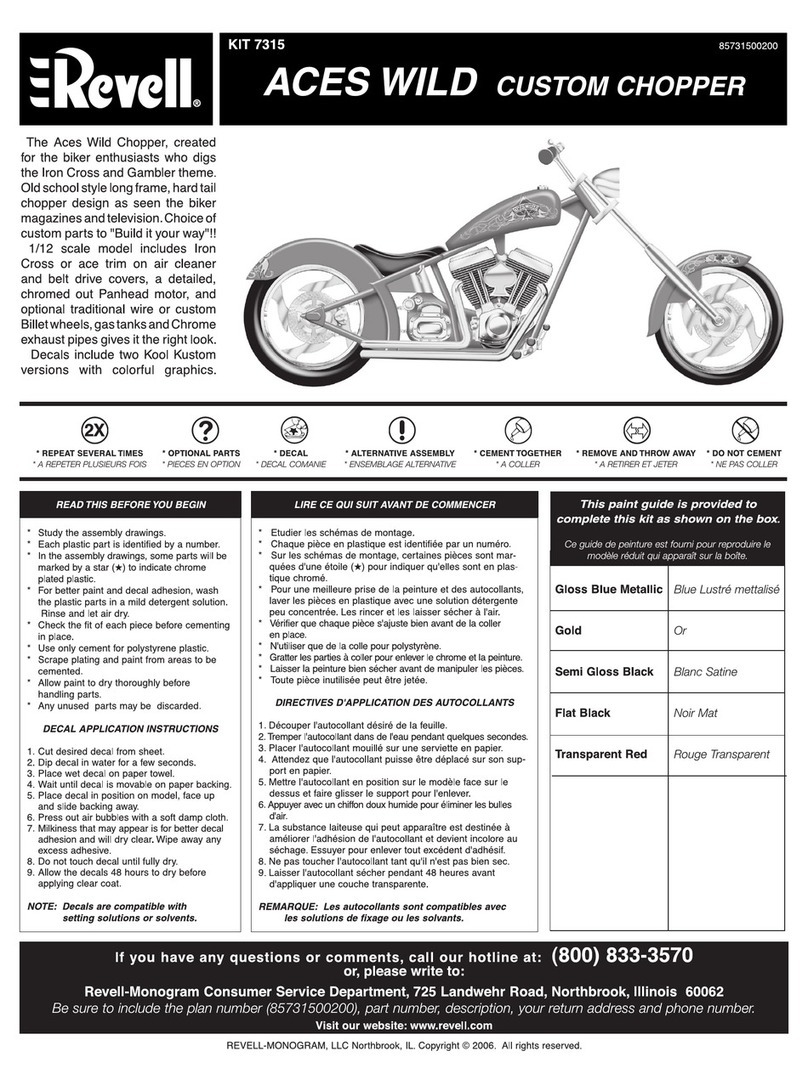

REVELL

REVELL Aces Wild Custom Chopper Assembly manual

POLA G

POLA G Madulain Station manual

Gualala Gadget

Gualala Gadget Small Gear Assembly instructions