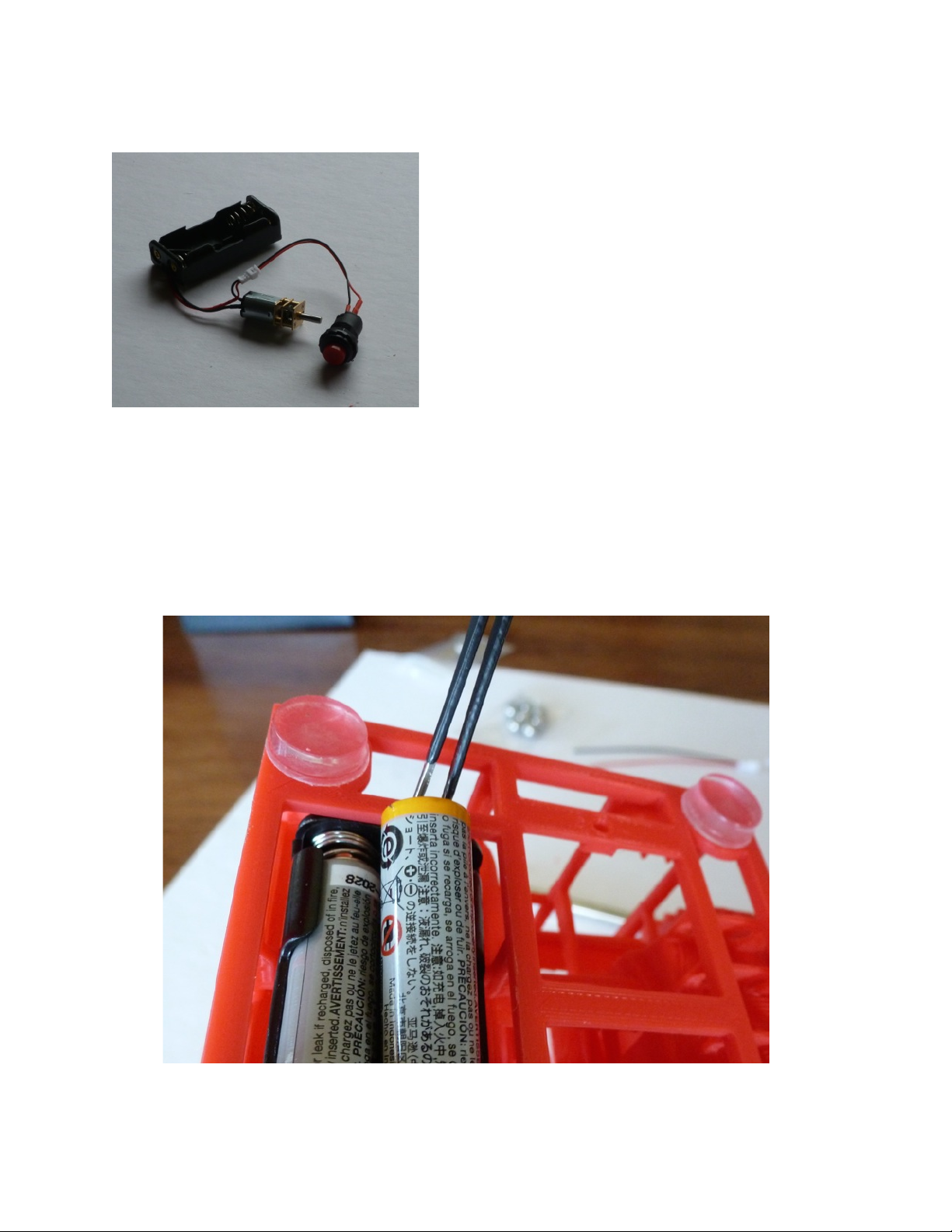

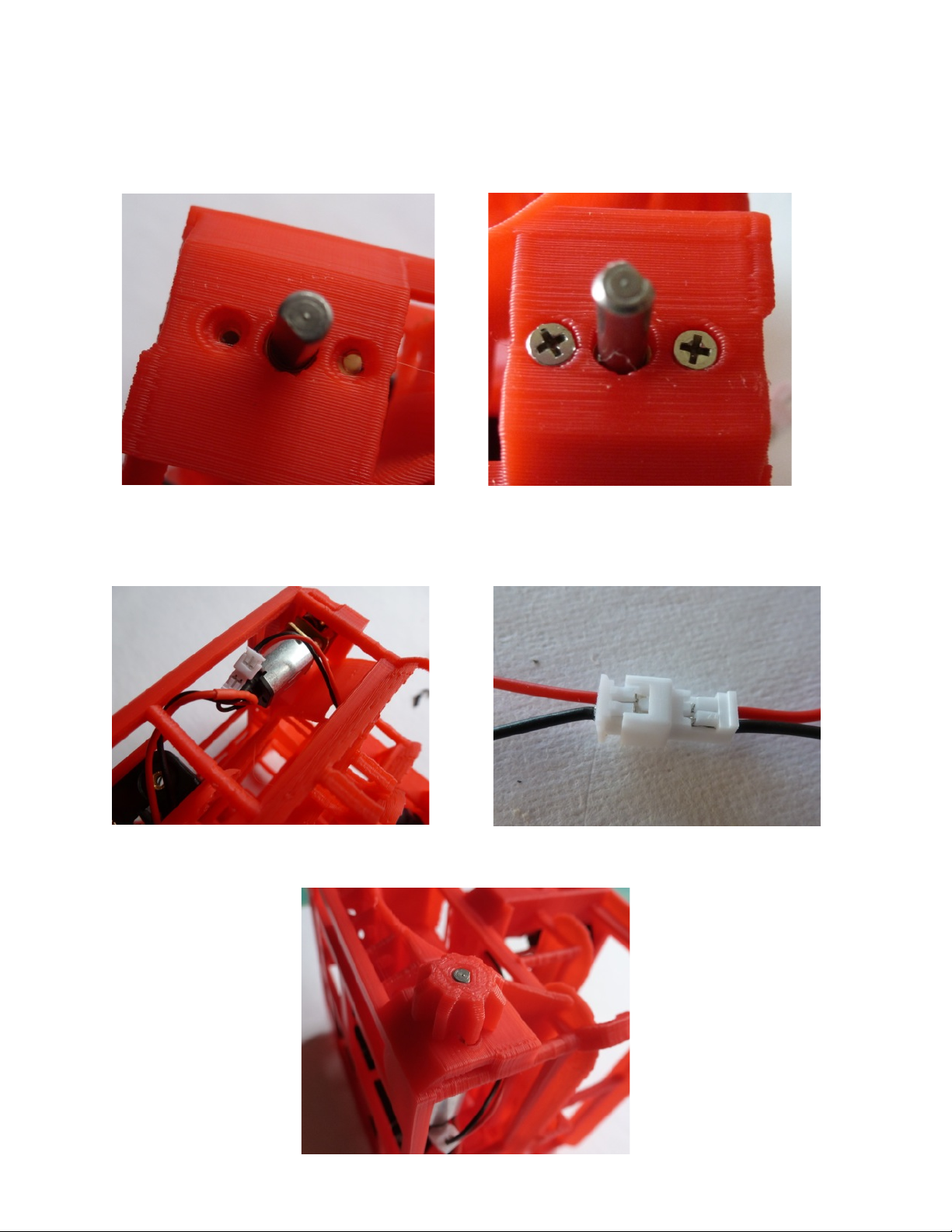

Step 3: Test the electric parts.!!

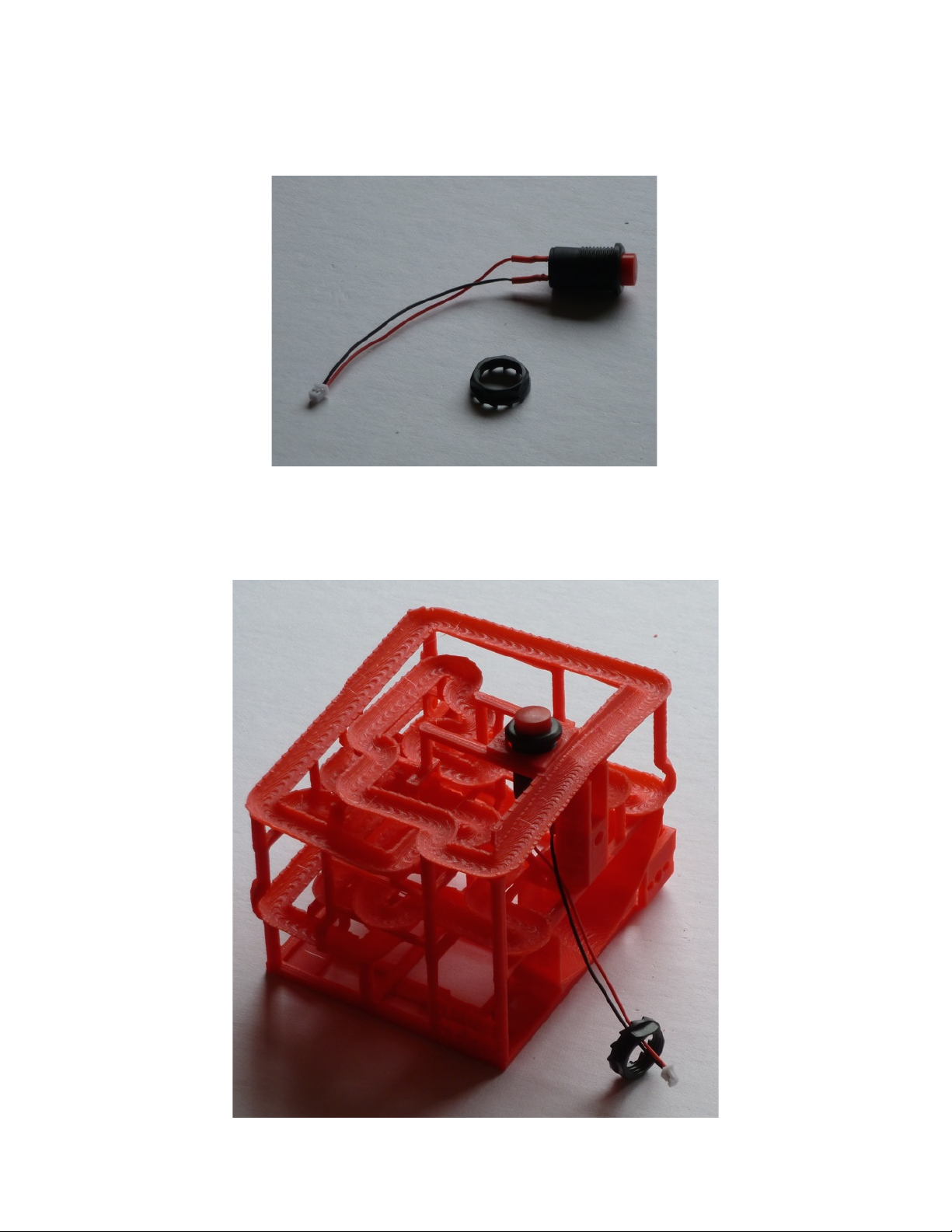

Carefully connect the motor/battery and button,

insert two AAA batteries and press the button. Make

sure the motor is rotating in the clockwise direction. !

!

You may find it necessary to use the tweezers to

connect or disconnect the small JST connector. This

is an especially tricky step — you need to be very

careful with this connector. Don’t force it. If you’re

having trouble inspect the socket side and make

sure the pins are properly aligned for the plug side.!

!

If the motor is running backwards make sure the

batteries are correctly inserted.!

!

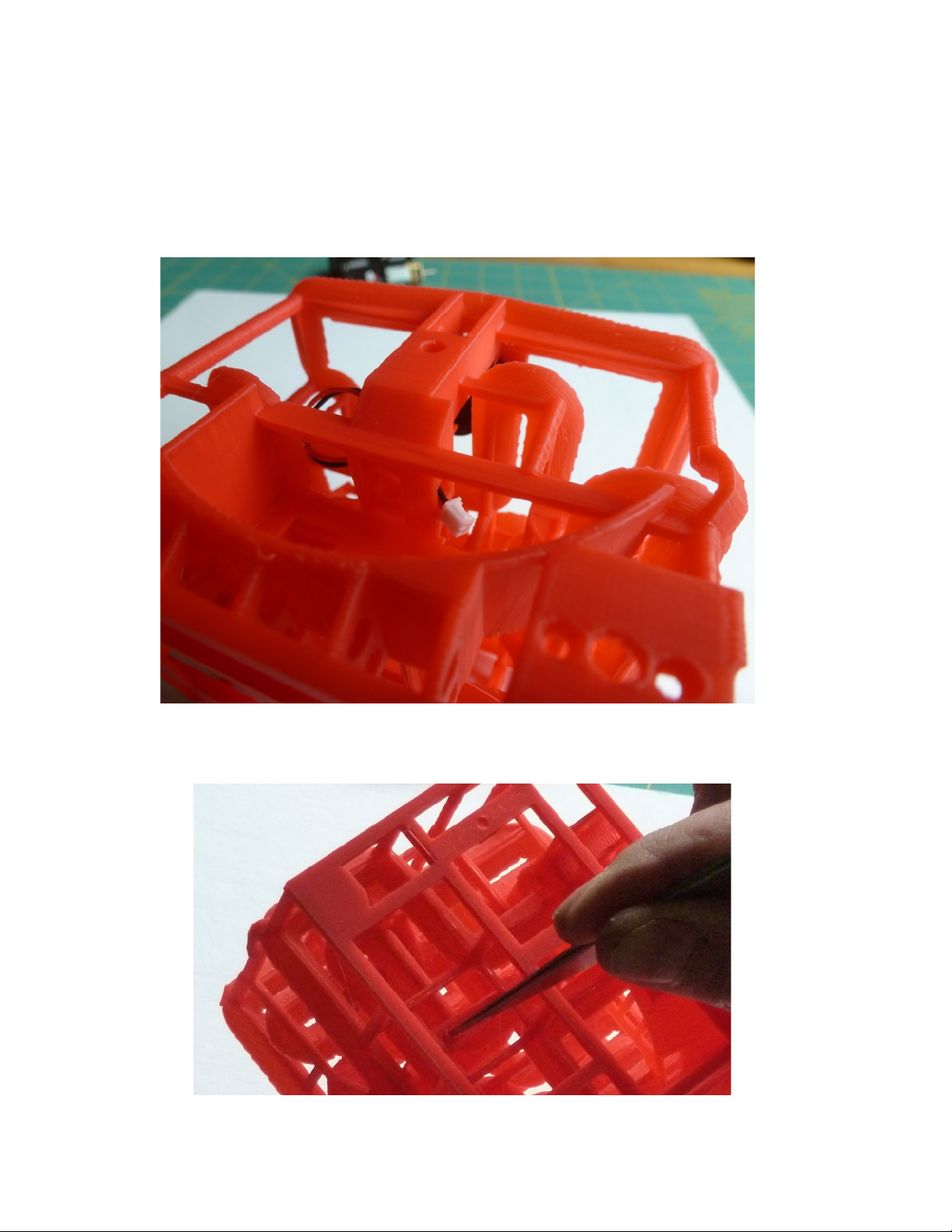

If the motor doesn’t run at all check that the batteries are seated in the holder properly, and use

the tweezers to “kickstart” the motor by spinning the gear closest to the motor in the tiny

gearbox. (Sometimes the motors arrive from the factory in a “stalled” condition, but kickstarting

them seems to solve the problem).!

!

Once you have completed this step, remove the batteries and disconnect the two components.

You can use the tweezers to help remove the batteries. !

!

!