smaco Heap 1 User manual

LANGUAGE CATALOG

English language

français

Deutsche

русский

Español

italiano

日本

中文

EN

FR

IT

DE

RU

ES

JP

P 01

P 14

P 27

P 40

P 53

P 66

P 79

P 92

CN

01

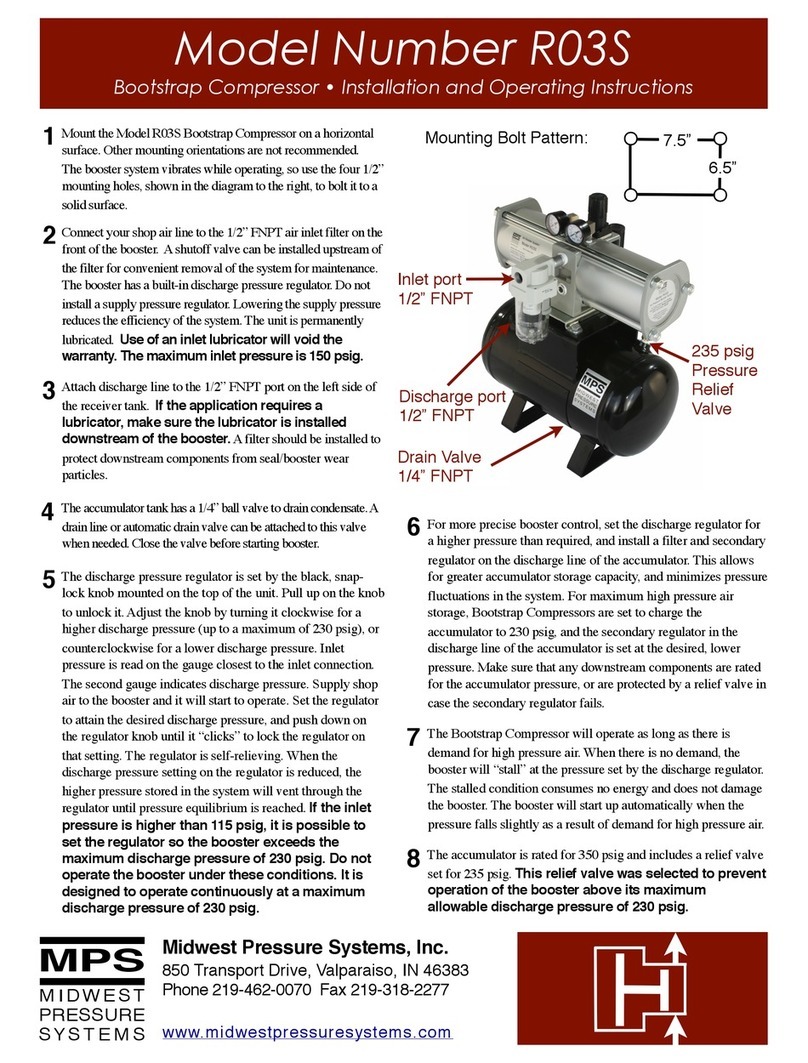

01 PRODUCT INTRODUCTION

02 WARNING

03 PRECAUTIONS

04 LIST OF ACCESSORIES

05 PRODUCT STRUCTURES AND THEIR NAMES

06 OPERATION INSTRUCTIONS OF HOUSEHOLD POWER SUPPLY

07 OPERATION INSTRUCTIONS OF VEHICLE POWER SUPPLY

08 COMMON PROBLEM HANDLING

09 Analysis and troubleshooting of common failures

10 DISCLAIMER

TABLE OF CONTENTS

P02

P03

P04

P05

P06

P07

P09

P11

P12

P13

Model

Power

Operating voltage

Motor speed

Air output

Dimensions

Weight

Maximum working pressure

Maximum current

HEAP 1

250W

DC 12V-15V

2700 r / min

11 L/min

24cm×22cm×25.6cm

9.7 KG

310bar

25 A

1.1 THANK YOU FOR PURCHASING SMACO PRODUCTS

The manual is prepared for the operators of SMACO air compressor “HEAP 1”. The basic operations

of the air compressor are introduced herein. Please read the manual carefully before using the

machine to guarantee correct and proper usage.

• Any of the contents in the manual may be modified without further notice;

• We have done our utmost to make the manual accurate, but any uncertainties or mistakes may

exist. Please feel free to contact us if you find any of such uncertainties or mistakes;

• Some products specified herein may not be included in the equipment you have purchased.

1.2 PRODUCT DESCRIPTION

• Working pressure: 0-310Bar (0-31MPa) It can achieve accurate automatic stop and control,

guarantee all pressures are accurate and consistent;

• Oil-free design, clean and pollution-free;

• Air cooling is used, no need to equip water cooling;

• Long service life, low maintenance rate;

• Low noise and low vibration, and an oil-water separator is equipped;

• Premium quality, space-saving, easy transport and storage.

1.3 TECHNICAL PARAMETERS

02

PRODUCT INTRODUCTION

01

2.1 Intended purpose

The product is intended for no purposes other than filling compressed air

2.2 Disassembling is prohibited

Disassembling may result in failures or electric shocks. Except for those parts that can be disassem-

bled, it’s not allowed to disassemble any other part. Please contact us immediately if any failure is

found. Don’t repair it by yourself to avoid dangers.

2.3 Confirming input voltage

If AC power supply is used:

First of all, confirm whether the input voltage for the machine is consistent with local supply voltage

(remove the voltage shifter dust cover at the top for confirmation, see the first item on page 7 for

details). Make the input voltage consistent with local supply voltage if they are inconsistent. A short

circuit or fire may be caused and the machine may be damaged in case incorrect input voltage is used.

If DC power supply is used:

Be sure to connect the red wire to the positive pole and the black wire to the negative pole.

2.4 Power cable:

If the power cable is damaged, please use those with the following specifications for replacement. A

fire or damage may be caused if an incorrect power cable is used. Note that the machine is level-I

protection, so it must be connected with grounding terminals.

For areas with supply voltage of 100 – 120V:

UL certified, three-core cable (one is ground wire), American wire gauge No.18, maximum length: 3m,

minimum rated voltage: 125V.

For areas with supply voltage of 220 – 240V:

Conforming to EU/EN and 3C standards, three-core ground cable, maximum length: 3m, minimum rated

voltage: 250V.

2.5 Avoiding electric shocks:

• Don’t unplug or plug the power plug with a wet hand to avoid induced current or electric shocks.

• Be sure to turn off the power switch (“O” position) before unplugging or plugging the cable to prevent

electric shocks.

03

WARNING 02

3.1 Overheating

• The recommended air inflation period is less than 30 minutes otherwise the internal parts may be

damaged as a result of overheating.

• Please turn off the machine immediately after air inflation is finished, and make the cooling fan work

for 2 – 4 minutes before it is turned off.

• When the machine is operated, the thermovent and air inlet of the fan should not be completely

blocked.

3.2 Stabilizing the machine during operation

The machine must be placed at a stable place, and the surroundings should be clean, dry with good

ventilation.

3.3 Don’t turn off the air inflation switch by unplugging

For the operation may damage the internal circuits.

3.4 In case abnormal sound is heard during operation, the machine should be turned off immediately

For troubleshooting otherwise the machine cannot work properly, or it may have any more serious

failure.

3.5 High temperature, high humidity, and acid-soluble oil, basic oil, insecticides, harmful gases, and

other easily absorbed substances should be avoided during operation

Prevent them from damaging internal components or affecting air inflation quality.

3.6 When the machine is unattended or not used, the power supply should be turned off and the power

plug should be unplugged

Avoid accidents resulting from electric circuit failures

3.7 Stored in room temperature to avoid humidity

The internal parts of the machine may be subject to oxidation if it is in humid conditions for an

extended period, making the machine fail to work properly. More seriously, failures like electric leakage,

short circuit may be caused.

04

PRECAUTIONS

03

NO

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

×1

×1

×1

×1

×1

×1

×1

×1

×2

×1

×1

×10

×1

×1

×1

NAME OF PARTS

Oil-water separator

360° air inflation extension pipe

7mm hexagon wrench

6mm hexagon wrench

5mm hexagon wrench

3mm hexagon wrench

2.5mm hexagon wrench

2mm hexagon wrench

Spring

19mm socket spanner

First-level piston ring

Anti-explosion diaphragm

#12-14 spanner

#14-17 spanner

Pull rod

QUANTITY

05

LIST OF ACCESSORIES

04

01 0302

04 06 08 09 10 11 12

05 07

13 14

15

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

PART NAME

360° air inflation extension pipe

Vehicle power supply alligator clip

Wire spool

Pressure Gauge

8mm air inflation inlet

Start button

Stop button

Pressure relief valve

Thermovent

Power cable port

Power switch

Blow vent

Explosion-proof valve

Plastic handle

Voltage shifter dust cover

Thermovent

Thermovent

04 05

06

07

08

09

10

11

12

13 14 15

16

17

02 0301

NO

06

PRODUCT STRUCTURES AND THEIR NAMES

05

6.1 First of all, make the voltage of the machine consistent with local supply voltage (1).

And correctly connect the power cable and plug the power plug (2).

6.2 Loosen the pressure relief valve (1), and correctly connect the 360° air inflation extension

pipe of the oil-water separator to the object to be inflated (2).

6.3 Adjust the rotary knob on the surface of the pressure gauge (1), adjust the pointer to the

required pressure, and the maximum pressure shall be no larger than 310bar (2).

OPERATION INSTRUCTIONS OF HOUSEHOLD POWER SUPPLY06

07

6.4 Turn on the power switch (“II” position) (1),

when the sound of the cooling fan is heard, press the start button to start the machine (2).

After everything is normal, tighten the pressure relief valve (3),

and wait for the completion of air inflation. Please keep a safe distance during air inflation.

6.5 When the pressure gauge reaches the preset pressure, the machine will stop air inflation

automatically (1). Or press the stop button to make the machine stop air inflation (2).

The cooling fan keeps working at the moment; after the fan works for 2 – 4 minutes,

the power switch can be turned off (“O” position) (3), and the power plug can be unplugged.

6.6 Unscrew the pressure relief valve to discharge air and water from the blow vent (1),

and remove the oil-water separator from the object inflated (2).

OPERATION INSTRUCTIONS OF HOUSEHOLD POWER SUPPLY06

08

7.1 First of all, ensure the power switch of the machine is off (“O” position) (1), and

loosen the pressure relief valve (2).

7.2 Take out the vehicle power supply alligator clip from the wire spool to connect the

positive and negative poles correctly (1). Correctly connect the 360° air inflation

extension pipe of the oil-water separator to the object to be inflated (2).

7.3 Adjust the rotary knob on the surface of the pressure gauge (1), adjust the pointer to

the required pressure, and the maximum pressure shall be no larger than 310bar (2).

OPERATION INSTRUCTIONS OF VEHICLE POWER SUPPLY07

09

7.4 Turn on the power switch (“I” position) (1), when the sound of the cooling fan is heard, press the

start button to start the machine (2). After everything is normal, tighten the pressure relief valve (3),

and wait for the completion of air inflation. Please keep a safe distance during air inflation.

7.5 When the pressure gauge reaches the preset pressure, the machine will stop air inflation

automatically (1). Or press the stop button to make the machine stop air inflation (2). The cooling

fan keeps working at the moment; after the fan works for 2 – 4 minutes, the power switch can be

turned off (“O” position) (3), and remove the alligator clip and put it into the wire spool.

7.6 Unscrew the pressure relief valve to discharge air and water from the blow vent (1), and remove

the oil-water separator from the object inflated(2).

OPERATION INSTRUCTIONS OF VEHICLE POWER SUPPLY07

10

The explosion-proof valve will relieve pressure if the safe pressure is exceeded.

The anti-explosion diaphragm should be replaced with a new one at the moment.

The schematic diagram below helps you know the replacement:

Unscrew the anti-explosion

nut by rotating it

counterclockwise;

Take out the damaged

anti-explosion diaphragm;

Put the spare anti-explosion

diaphragm in it and tighten it up.

11

08 COMMON PROBLEM HANDLING

12

09 Analysis and troubleshooting of common failures

Failures Analysis of causes Troubleshooting

The machine does

not work

(household power

supply)

The machine

does not work

(vehicle power supply)

The machine works

normally, but the object

cannot be fully inflated;

The power plug is not plugged

properly

The current voltage of the machine

is inconsistent with local supply

voltage

The power switch mode is incorrect

The positive and negative poles are

incorrectly connected

Connect the red and black

wires to the positive and

negative poles respectively

Check the vehicle power

supply

Adjust the power switch to

the “I” position

Adjust the power switch to the

“II” position

Correctly connect to the power

supply

Open the voltage shifter

dust cover at the top for

adjustment

The power switch mode is incorrect

The vehicle power supply is off

The pressure relief valve is not

tightened before air inflation

The working environment is

polluted, making the air smelly

Change the working

environment for the machine

The filter element of the oil-water

separator is invalid

Replace the filter element or

the oil-water separator

Tighten the pressure relief

valve

The machine is manually

or accidentally turned

off during operation,

and it fails to restart the

machine

The internal pressure of the

machine makes it impossible

to start the machine

Loosen the pressure relief

valve and tighten it to restart

the machine

The gas has

peculiar smell

13

10 DISCLAIMER

Thank you for purchasing/using the SMACO HEAP 1 air compressor. The contents

below concern your safety, legal rights, and duties.

To protect the legitimate rights and interests of the users, please carefully read the user’s manual,

legal disclaimer and precautions provided with this product before use. Shenzhen CP-Link

Electronic Co., Ltd. reserves the right to update the aforesaid documents. Please use this product

in accordance with the instructions and precautions;

The product is not intended for the uses by minors and those without full capacity for civil

conducts. We are not responsible for any accident, injury, or death resulting from any operation by

anyone who is not a target user;

Once you start to use this product, it’s deemed that you have read, understood, approved and

accepted all the terms and contents of the user’s manual, precautions and legal disclaimer. The

user has promised to be responsible for his/her own actions and all the consequences arising

therefrom. The user has promised to use this product only for legitimate purposes, and agreed to

the terms and any related policies or guidelines that may be formulated by Shenzhen CP-Link

Electronic Co., Ltd.;

When use this product, please make sure to strictly abide by and implement the requirements

including but not limited to the user’s mannual and precautions. All per-sonal injuries, accidents,

property losses, legal disputes and all other conflicts of in-terest caused by user’s behaviors which

violate the contents of the user’s manual or force majeure factors, the user shall bear the relevant

responsibilities and losses and Shenzhen CP-Link Electronic Co., Ltd. will be free from any legal

re-sponsibility;

Shenzhen CP-Link Electronic Co., Ltd. will not bear any responsibility for any violation of the

law which occurs directly or indirectly by using this product.

Address: 201 west, 2F, 1 Building, Jianghao Industrial Park, No. 430 JiHua Road, BanTian Street,

Longgang District, Shenzhen city, Guangdong Province, China.

Shenzhen CP-Link Electronic Co., LTD

+86 755-28483655

www.smacodive.com

+86 755-28483655

Table of contents

Popular Air Compressor manuals by other brands

Doosan

Doosan P600WJD T3 Operation & maintenance manual

Powermate

Powermate PA0601512 parts manual

OMEGA COMPRESSORS

OMEGA COMPRESSORS NOBEL 30 DV CSA Instruction & maintenance manual

Sullair

Sullair 20/12 Series Operator's manual and parts list

Ozito

Ozito ACP-2419 instruction manual

Waterous

Waterous 80-P Operation guide