GW2145 - GW1160 - GW4060 - GW4190

CONTENTS

1INTRODUCTION................................................................................................................................................... 6

1.1 GW FAMILY - INTENDED USE .............................................................................................................................. 7

1.2 DEFINTITION: “RESPONSIBLE AUTHORITY” IN RELATION TO THE DEVICE.......................................................... 7

1.3 WASHING TROLLEYS AND ACCESSORIES............................................................................................................. 8

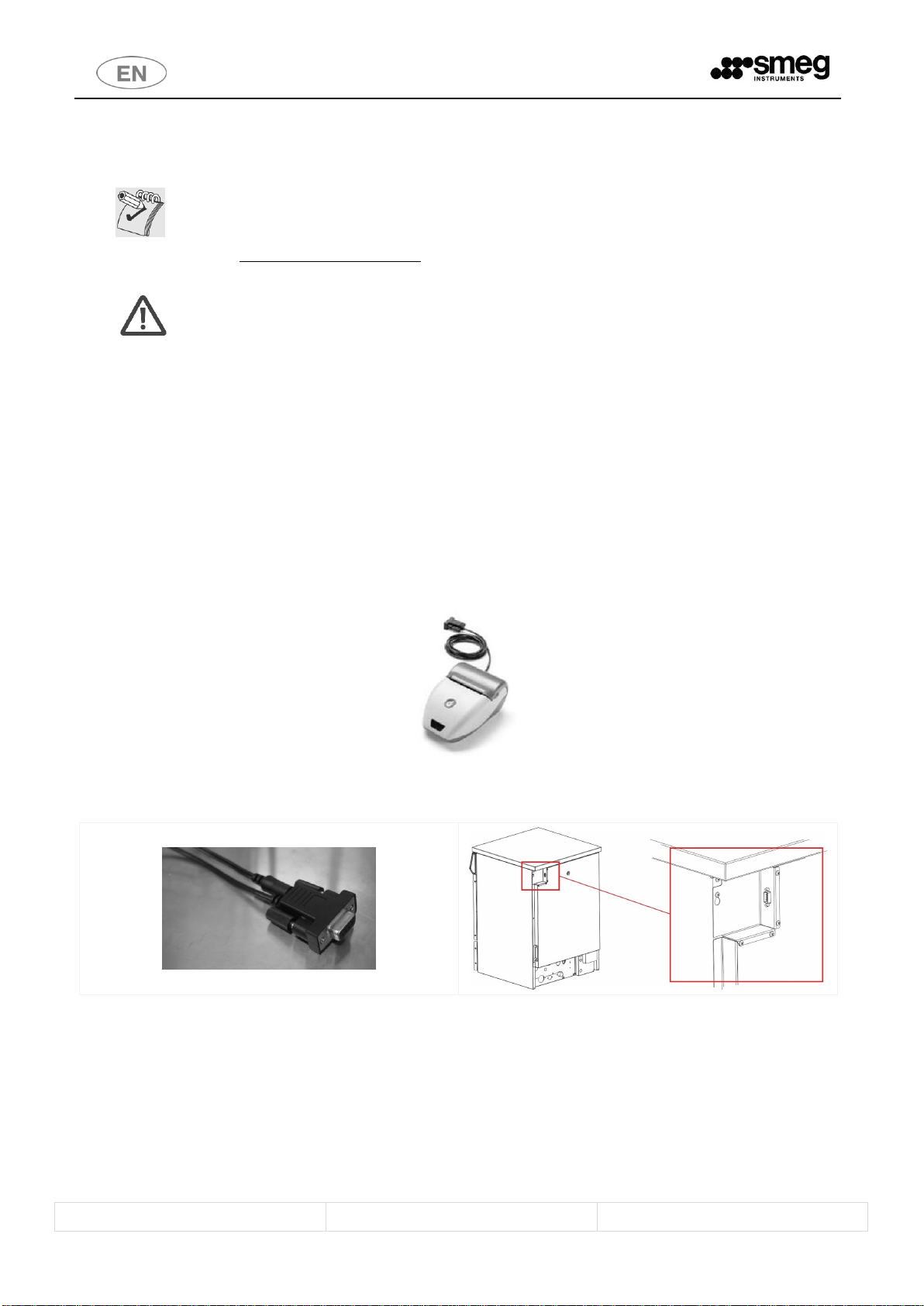

1.3.1 Smeg WD-PRINTE printer –GW2145, GW1160, GW4060 series................................................................ 8

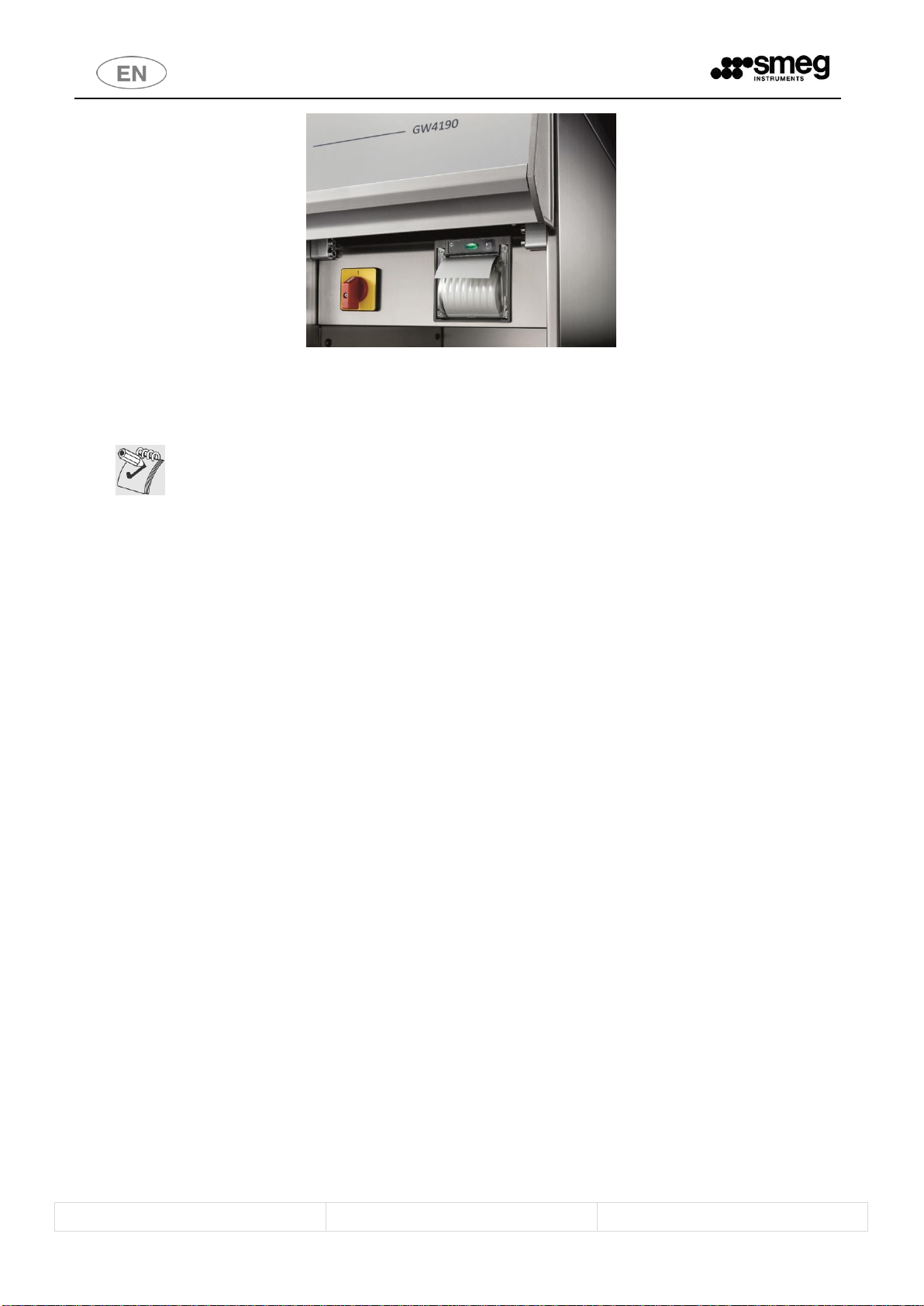

1.3.2 Smeg WD-PRINT9 Printer –GW4190 Series .............................................................................................. 8

1.4 PERISTALTIC PUMP P3 (NOT INSTALLABLE ON GW2145) ................................................................................... 9

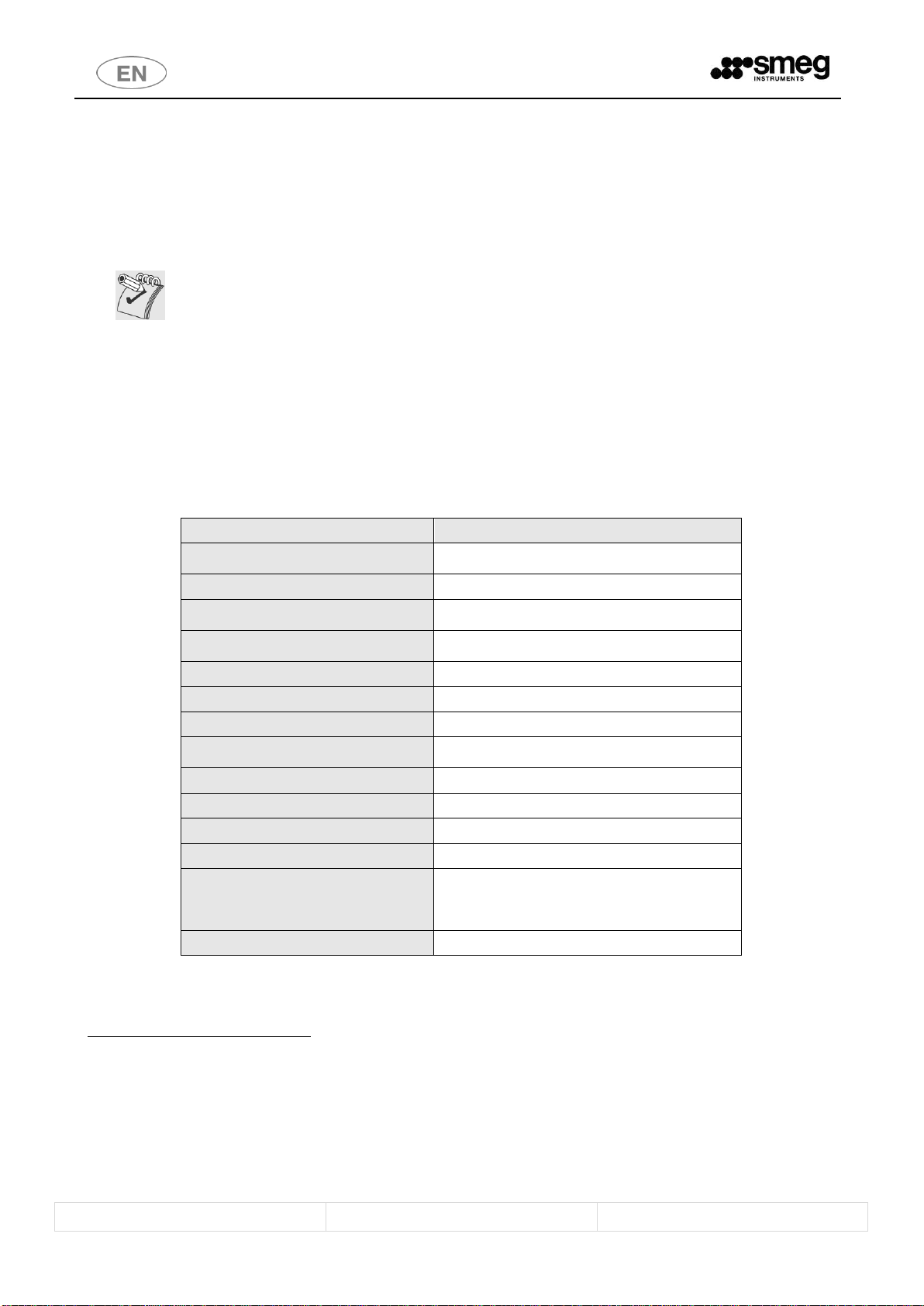

1.5 LIST OF MODELS................................................................................................................................................ 10

2KEY TO THE SYMBOLS USED IN THE MANUAL AND ON THE APPLIANCE .............................................................11

3GENERAL WARNINGS .........................................................................................................................................12

3.1 ACCESSING AND REUSING THE DEVICE AFTER AN INCOMPLETE CYCLE ........................................................... 13

3.2 DOOR OPENING ................................................................................................................................................ 14

3.3 MANUAL DOOR RELEASE PROCEDURE ............................................................................................................. 15

3.4 GW4190 OPENING THE DOOR OF THE SIDE CABINET - SERIES GW4190 ONLY ................................................ 15

4DESCRIPTION OF CONTROLS AND PROGRAMS...................................................................................................17

4.1 CONTROLS......................................................................................................................................................... 17

4.2 CONTROLS - DETAILED DESCRIPTION ............................................................................................................... 18

4.2.1 A0 PARAMETER DISPLAY........................................................................................................................... 19

4.3 INDICATOR LEDS - INTRODUCTION................................................................................................................... 20

4.4 INDICATOR LEDS - DETAILED EXPLANATION..................................................................................................... 21

4.5 SELECTING THE WASHING PROGRAMME ......................................................................................................... 23

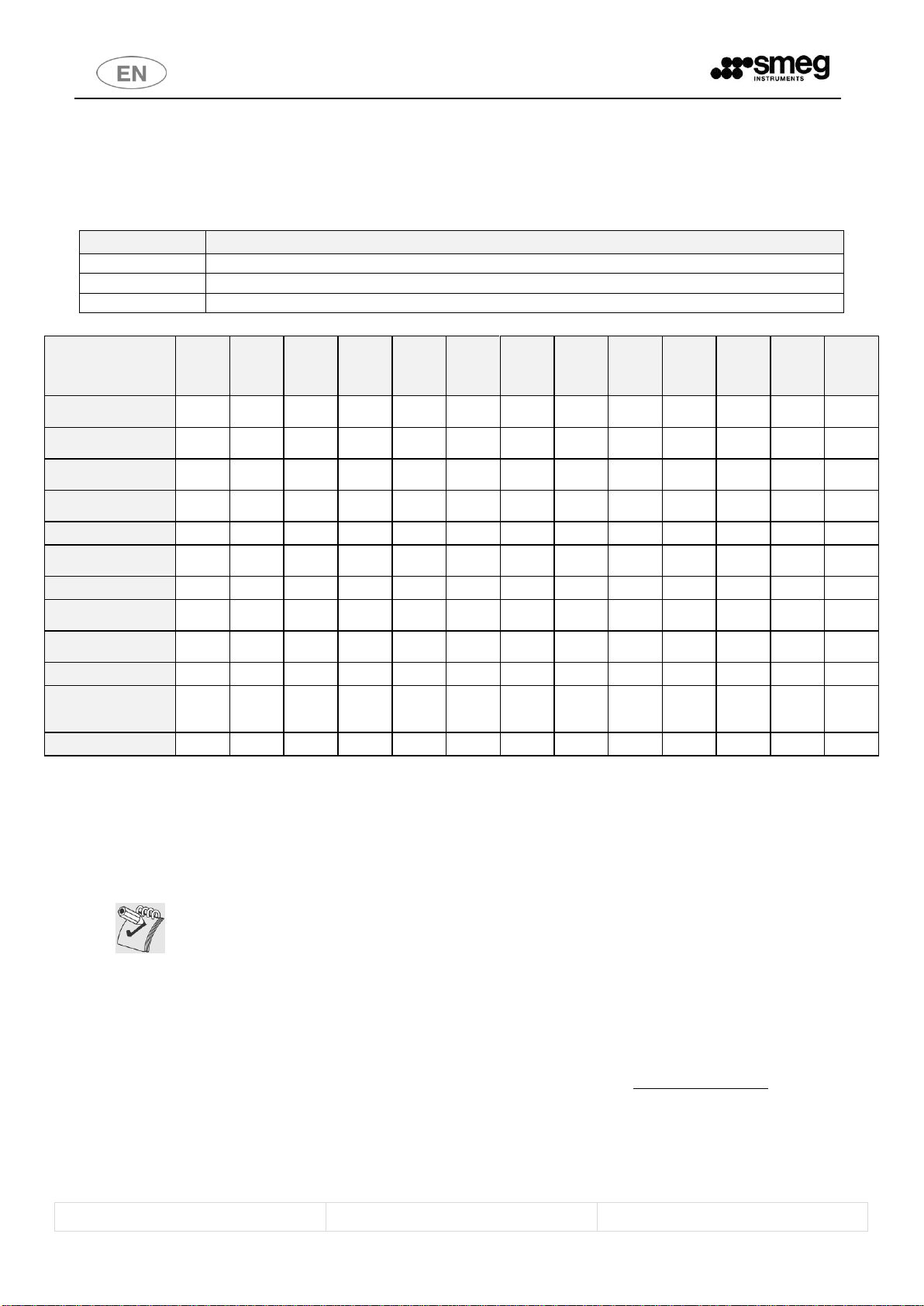

4.6 BRIEF TABLE OF THE PROGRAMS INSTALLED.................................................................................................... 25

4.6.1 RESINS - SOFTENER, REGENERATION AND WASHING PHASE ................................................................... 26

4.6.2 DRYING PHASE –Only for GW4060, GW4190 series ................................................................................ 26

4.6.3 CUSTOM PROGRAMS ................................................................................................................................ 28

4.7 A0 THERMAL DISINFECTION PARAMETER ........................................................................................................ 29

4.8 PREPARING THE LOAD FOR WASHING AND DISINFECTION.............................................................................. 30

4.9 END OF CYCLE ................................................................................................................................................... 31

4.10 INTERRUPTING A PROGRAM IN EXECUTION .................................................................................................... 32

4.11 PROGRAM SPECIAL OPTIONS............................................................................................................................ 33

4.11.1 DELAYED START - Setting the hours.......................................................................................................... 33

4.11.2 DELAYED START - Starting the program and display................................................................................. 33

4.11.3 TEMPORARY DISABLING OF DEMI WATER................................................................................................ 34

4.11.4 Deleting “Delayed start” - “No Demi” settings ......................................................................................... 35

4.12 RESET PROCEDURE............................................................................................................................................ 36

4.13 PRINTING THE CYCLE AND APPLIANCE PARAMETERS....................................................................................... 37

5SETUP MODE - “FUNCTIONS” .............................................................................................................................37

5.1 ACCESSING THE SETUP MODE / ENTERING THE PASSWORD ........................................................................... 38

5.2 ACCESS AND PARAMETER MODIFICATION ....................................................................................................... 39

5.3 “SET“ PARAMETERS .......................................................................................................................................... 41

5.3.1 APPLIANCE DATA STORAGE, OVERWRITING, “Set -b” .............................................................................. 44

5.4 “CLOC” – DATE AND TIME PARAMETERS.......................................................................................................... 46

5.5 SETTING THE “PrEn” “PROGRAM ENABLING” FUNCTION................................................................................. 46

6INSTALLATION INSTRUCTIONS ...........................................................................................................................49

6.1 USE OF THE WATER SOFTENER......................................................................................................................... 49

6.2 USING DETERGENT AND NEUTRALISING AGENT .............................................................................................. 50

6.2.1 LIQUID DETERGENT INTAKE SYSTEM ........................................................................................................ 50

6.2.2 DETERGENT LEVEL SENSORS - OPTIONAL ................................................................................................. 52