7

Introduction

SETUP

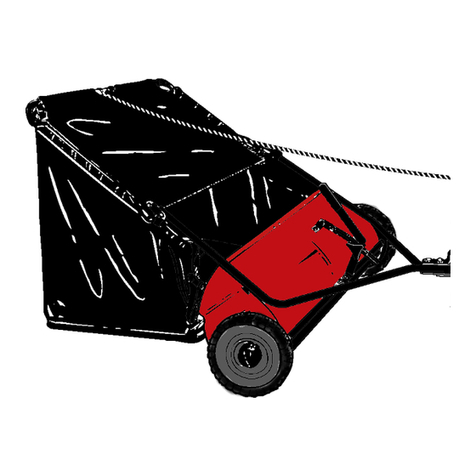

The Big Vac arrives from with some setup required.

1. The PTO shaft and the rubber boot that goes around the blower and the reel need to be installed.

2. You will need a 40 HP (minimum) tow vehicle to remove the Big Vac from the trailer.

a. Clevis Hitch - You will need a 3/4diameter by 4" pin with some type of lock.

b. Ball Hitch (optional) - You will need a 25/16" ball and a locking pin for the coupler.

3. Crank the jack on the Big Vac up so you can hook to tow vehicle.

4. Check the tire pressure. Big Vac: 18 psi (1.3 bar) Castor Wheels: 20 psi (1.4 bar).

5. Check hydraulic fluid level in tank. Look at the sight gauge on the front left side of the tank.

The oil level should be at 90°C (194°F). If level is low, add SAE 10W-40API Service SJ or

higher motor oil.

6. Machine should be greased before starting. See Maintenance part of manual.

7. Lower reel all the way down. Place rubber boot onto the bottom of the blower housing.

Raise the reel up 3/4 of the way. Stretch rubber boot around lip on reel. Lift and lower

several times to ensure boot is on properly.

8. When installing PTO shaft be sure the end with the tractor decal (72-087) goes to the tow

vehicle. If PTO Shaft is put on wrong it will bust when engaged.

9. Read operating instructions before starting.

OVERLOADINGDEBRISHOPPERANDWEARONVACUUMHOUSING

OVERLOAINGDEBRIS HOPPER

Smithco Sweeper-Vacs are designed to carry the following maximum loads:

Model 72-000 Big Vac 1500 lbs. (608 kg)

PLEASENOTETHEFOLLOWING:

1. Loads heavier than that will damage the unit.

2. Such damage is not covered by warranty.

3. Overloading is particularly easy when collecting aerifier cores.

4. The hoppers on the Big Vac and V62 are large in order to hold 7 and 4 cubic yards respectively, of thatch, grass

clippings, leaves and trash.

5. They will not hold 7 or 4 cubic yards of aerifier cores.

6. The maximum depth (in the debris hopper) of aerifier cores is:

Model 72-000 Big Vac 12 in. (30 cm)

VACUUM HOUSING WEAR

The Big Vac & V62 are fitted with a wear resistant liner in the vacuum housing. This will provide additional husing life.

Be sure the following points are explained to the user:

1. The vacuum housing and impeller must be cleaned each time the unit is used so the housing liner is inspected

daily. Only Smithco Sweeper-Vacs provide a clean out/inspection port for easy inspection and cleaning.

2. When bare steel is visible at any point in the housing lining, the lining must be replaced. It is expected the liner

will wear and be replaced. It is a vast improvement over competitive units with no liners.

3. Replacement of the liner or the vacuum housing due ti wear is normal and is not covered by warranty.

4. Collection of aerifier cores causes extreme wear on the liner (and if unchecked, on the housing).

5. Caution users that, while Smithco Sweeper-Vacs do an excellent job collecting cores, the lining (and the

housing) will wear quickly in such use.

RUBBERIZED BOOT

The rubberized boot between main unit and sweeper head is subject to wear and damage from debris. Unless

defecetive, replacement of this boot is not covered by warranty.