Introduction Service Diagrams Parts Accessories Reference

CONTENTS

Introduction .........................................1-10

Introduction...................................................................................1-3

SafePractices.............................................................................2

Specifications ..............................................................................3

OptionalEquipment .....................................................................3

Service ........................................................................................ 4-11

Maintenance.............................................................................4-6

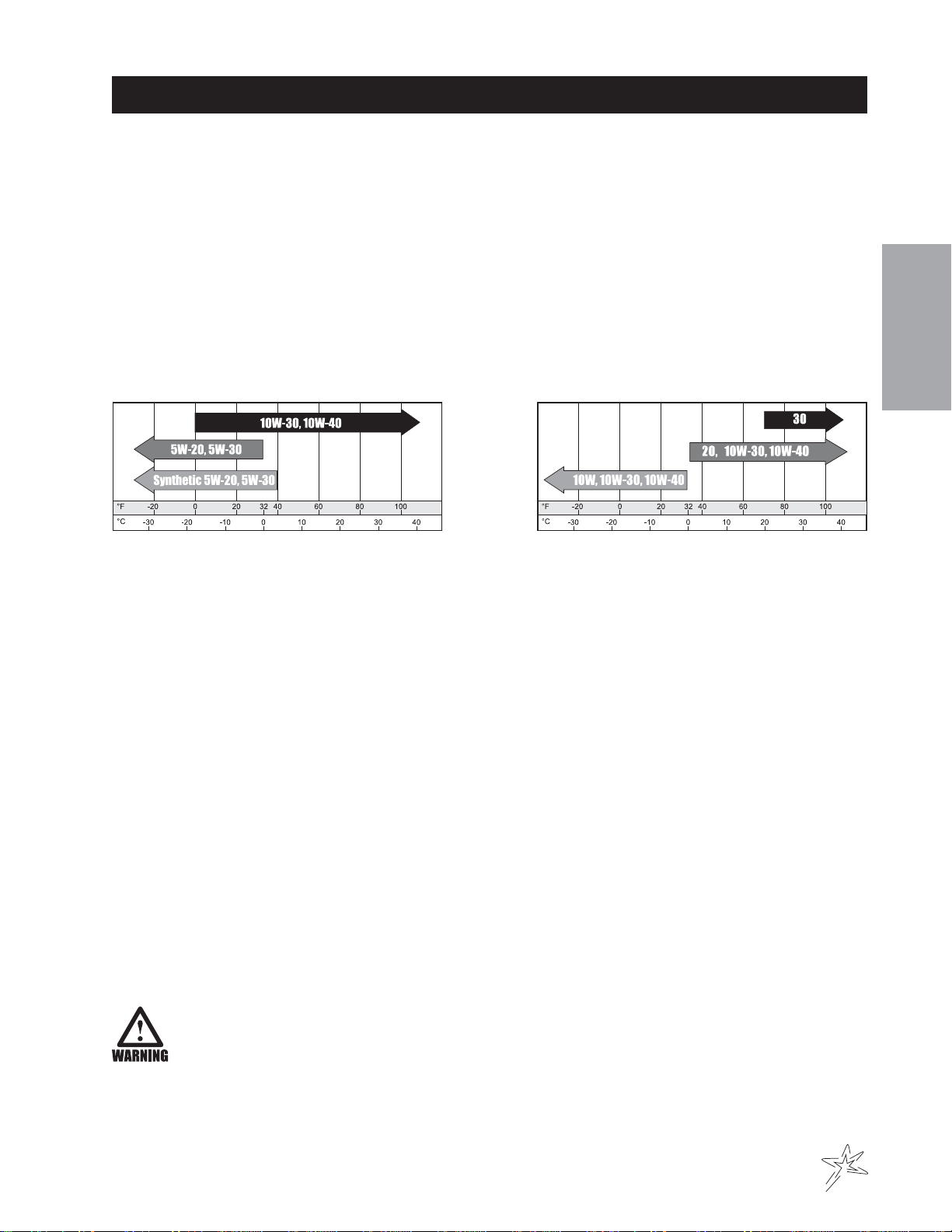

ServiceChartKohlerCommand 25 hp .........................................7

ServiceChartKubotaDiesel18.8hp............................................8

EndUser’s Service Chart.............................................................9

Adjustments ..............................................................................10

Storage ......................................................................................10

Notes ........................................................................................ 11

Diagrams ................................................................................... 12-17

DieselWiringDiagram .......................................................... 12-13

GasWiring Diagram ............................................................. 14-15

HydraulicDiagram ................................................................ 16-17

Parts .......................................................................................... 18-65

Bodyand Frame ................................................................... 18-19

RollOver Protection(ROPS)................................................. 20-21

Steering ................................................................................ 22-23

FrontFork ............................................................................ 24-25

GasolineLinkage.................................................................. 26-27

DieselLinkage ...................................................................... 28-29

GasConsole ........................................................................ 30-31

DieselConsole ..................................................................... 32-33

Fuel Tank and Oil Tank ......................................................... 34-35

Oil Filter ............................................................................... 36-37

HydraulicLift Cylinder........................................................... 36-37

ReelLift Cylinder .................................................................. 38-39

TailgateCylinder ................................................................... 38-39

KohlerGas Engine and Exhaust........................................... 40-41

KubotaDieselEngine and Exhaust ...................................... 42-45

ElectricClutch Driven BeltDrive............................................ 46-47

FingerReel ........................................................................... 48-49

RearAxle.............................................................................. 50-53

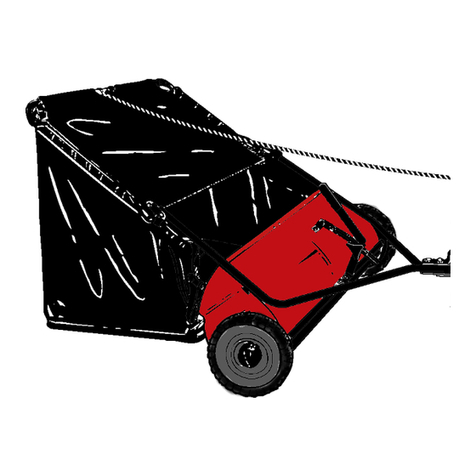

Hopper.................................................................................. 54-55

Tailgate................................................................................. 56-57

77-239Eaton Hydrostatic Pump ........................................... 58-59

76-197Eaton GearPump ..................................................... 60-61

76-238Rear WheelMotor ..................................................... 62-63

76-0233-Bank HydraulicValve ............................................. 64-65

Accessories ............................................................................... 66-67

76-271 Dust/Dirt Filtration Pack........................................... 66-67

Reference.................................................................................. 69-70

Decal List .................................................................................. 69

QuickReference Replacement Parts .........................................70