Snap Fresh BBT-POB04 User manual

CORDLESS IMPACT DRIVER

User Manual

BBT-POB04

geprufte

Sicherheit

Read all safety rules and instructions carefully before operating this tool.

+1 833 635 0955

Please scan the QR CODE for more services.

CONTENTS

Contents ......................................................................................................................................................................................... 2

..............................................................................................................................................................................................

Safety instructions ................................................................................................................................................................ 4-7

3

..............................................................................................................................................................8-9Machine information

.........................................................................................................................................................................................9-11

..................................................................................................................................................................................

........................................................................................................................................................................................

11

12Warranty

Maintenance

Operation

Symbols

3

The rating plate on your tool and the manual cover may show certain symbols. These represent important information

about the product or instructions on its use.

Hearing, sight and respiratory

protection must be worn.

Double insulated for additional

protection.

Conforms to relevant safety standards.

Do not dispose of batteries in fire.

They will explode and cause injury.

Polarities of DC connector.

Indoor use only.

Waste electrical and electronic

equipment(WEEE), should not be

disposed of with household waste.

please recycle where facilities exist.

check with your local authority or

retailer for recycling advice.

130℃thermal fuse.

Short-circuit proof safety isolating

transformer.

Do not expose the battery pack to heat

in excess of 40℃.

Do not dispose of batteries in water.

Danger, take care.

Dangerous voltage.

Contains lithium-ion.

1h charging time.

Before use, read the handbook carefully.

Li-ion

SYMBOLS

4

SAFETY INSTRUCTIONS

Read the enclosed safety warnings, the additional safety warnings and the instructions. Failure to follow the safety

warnings and the instructions may result in electric shock, fire and/or serious injury. Save the safety warnings and the

instructions for future reference.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions. Failure to follow the warning and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

.

.

.

.

.

.

.

.

.

Keep the work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

2) Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric

shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from

heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a Residual Current Device (RCD) protected supply.

Use a RCD to reduces the risk of electric shock.

.

.

3) Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool

while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection

.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

5

.

.

.

.

.

.

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or

battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in

unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts.

Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust related hazards.

.

.

.

.

.

.

.

.

4) Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjust-

ments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting

the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

Keep cutting tools sharp andclean. Properly maintained cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the

working conditions and the work to be performed. Use of the power tool for operations different from those intended

could result in a hazardous situation.

.

.

.

5) Battery tool use and care

Recharge only with the charger specifed by the manufacturer. A charger that is suitable for one type of battery pack

may create a risk of fire when used with another battery pack.

Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of

injury and fire.

When the battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails,

screws or other small metal objects that can make a connection from one terminal to another. Shorting the battery

terminals together may cause burns or a

fi

re.

.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush

with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause

irritation or burns.

Do not let familiarity gainedfrom frequent use of tools allow you to become complacent and ignore tool safety principles.

A careless action can cause severe injury within a fraction of a second.

Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do

not allow for safe handling and control of the tool in unexpected situations.

6

ADDITIONAL SAFETY RULES FOR DRIVERS

• Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

• Wear ear protectors when impact driving. Noise exposurecan cause hearing loss.

• Always use an auxiliary handle for maximum control over torque reaction or kick back. Loss of control can cause

personal injury.

• Ensure the power source conforms to the requirements stated on the name plate on the charging adaptor.

• Never change the direction of the chuck rotation while the tool is still running. Ensure the chuck has come to a

complete stop before changing the rotation of the driver.

• Do not lay the tool down unless the tool is switched off and the chuck has come to a complete stop.

• Keep hands and other body parts well away from the work area whist the tool is in use.

• Keep hands well away from the underside of the work piece during use.

• Do not use your hands to remove any dust, chips or other waste while the tool is in use.

• Do not touch the driver bit after operation. The bit will be HOT and will burn!

• When an extension power cord is required ensure that it has the correct ampere rating for your driver and that it is

in a safe electrical condition.

• Fully unwind the extension cable if the extension cable is supplied with a cable drum. This will avoid overheating.

•

.

.

.

6) Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure

that the safety of the power tool is maintained.

•

Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or

authorized service providers.

Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredi-

ctable behaviour resulting in fire, explosion or risk of injury.

Do not expose a battery pack or tool to

fi

re or excessive temperature. Exposure to

fi

re or temperature above 130 °C

may cause explosion. NOTE The temperature „130 °C“ can be replaced by the temperature „265 °F“.

Follow all charging instructions and do not charge the battery pack or tool outside the temperature range speci

fi

ed

in the instructions. Charging improperly or at temperatures outside the speci

fi

ed range may damage the battery and

increase the risk of

fi

re.

7

ADDITIONAL SAFETY RULES FOR CHARGERS

• Before using the charger, read all instructions and cautionary markings on the charger and battery pack as well as

the instructions on using the battery pack.

• Only charge your batteries indoors as the charger is designed for indoor use only.

• DANGER. If the battery pack is cracked damaged in any other way, do not insert it in the charger. There is a danger

of electric shock or electrocution.

• WARNING. Do not allow any liquid to come into contact with the charger. There is a danger of electric shock.

• The charger and the battery packs supplied with are specifically designed to work together. Do not attempt to charge

the battery pack with another charger than the one supplied.

• Pull on the charger transformer to disconnect it from the power source. Do not pull the lead.

• Do not use the charger if it has been subjected to a heavy knock, dropped or otherwise damaged in any way. Take the

charger to an authorised service centre for a check or repair.

• Do not disassemble the charger. Take it to an authorised service centre when service or repair is required. Incorrect

re-assembly may result in the risk of fire, electric shock or electrocution.

• To reduce the risk of electric shock, unplug the charger from the power supply before attempting to clean it.

Removing the battery alone does not reduce the risk.

ADDITIONAL SAFETY RULES FOR THE BATTERY PACK

• The battery pack for this tool has been shipped in a low charge condition. You should charge the battery pack fully

before use.

• Do not incinerate the battery pack if it is seriously damaged or can no longer hold a charge. The battery pack can

explode in a fire.

• A small leakage of liquid from the battery pack may occur under extreme usage or temperature conditions. This does

not necessarily indicate the failure of the battery pack. However, if the outer seal is broken and this leakage comes

into contact with your skin wash the affected area quickly with soap and water. If the leakage gets in your eyes flush

your eyes with clean water for a minimum of 10 minutes and seek immediate medical attention, inform the medical

staff that the liquid is a 25-35% solution of potassium hydroxide.

• Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks open or

cracks, immediately discontinue its use and do not recharge it.

• Do not store or carry a spare battery pack in a pocket or toolbox or any other place where it may come into contact

with metal objects. The battery pack may be short-circuited causing damage to he battery pack, burns or a fire.

8

COMPONENTS AND CONTROLS

1. 1/4” Hex Chuck

2. Lock/ Forward/ Reverse Knob

3. Handle

4. Variable Speed Trigger Control

5. LED Light

6. Belt Clip

7. 20V 2.0Ah Battery

1 x Carry Bag

1 x 20V Charger

1 x 2.0Ah Battery

7 x Screwdriver Bits

4 x Socket Adapters

1. 1/4” Hex Chuck

5. LED Light

4. Variable Speed Trigger Control

2. Lock/ Forward/ Reverse Knob

3. Handle

6. Belt Clip

7. 20V 2.0Ah Battery

MACHINE INFORMATION

9

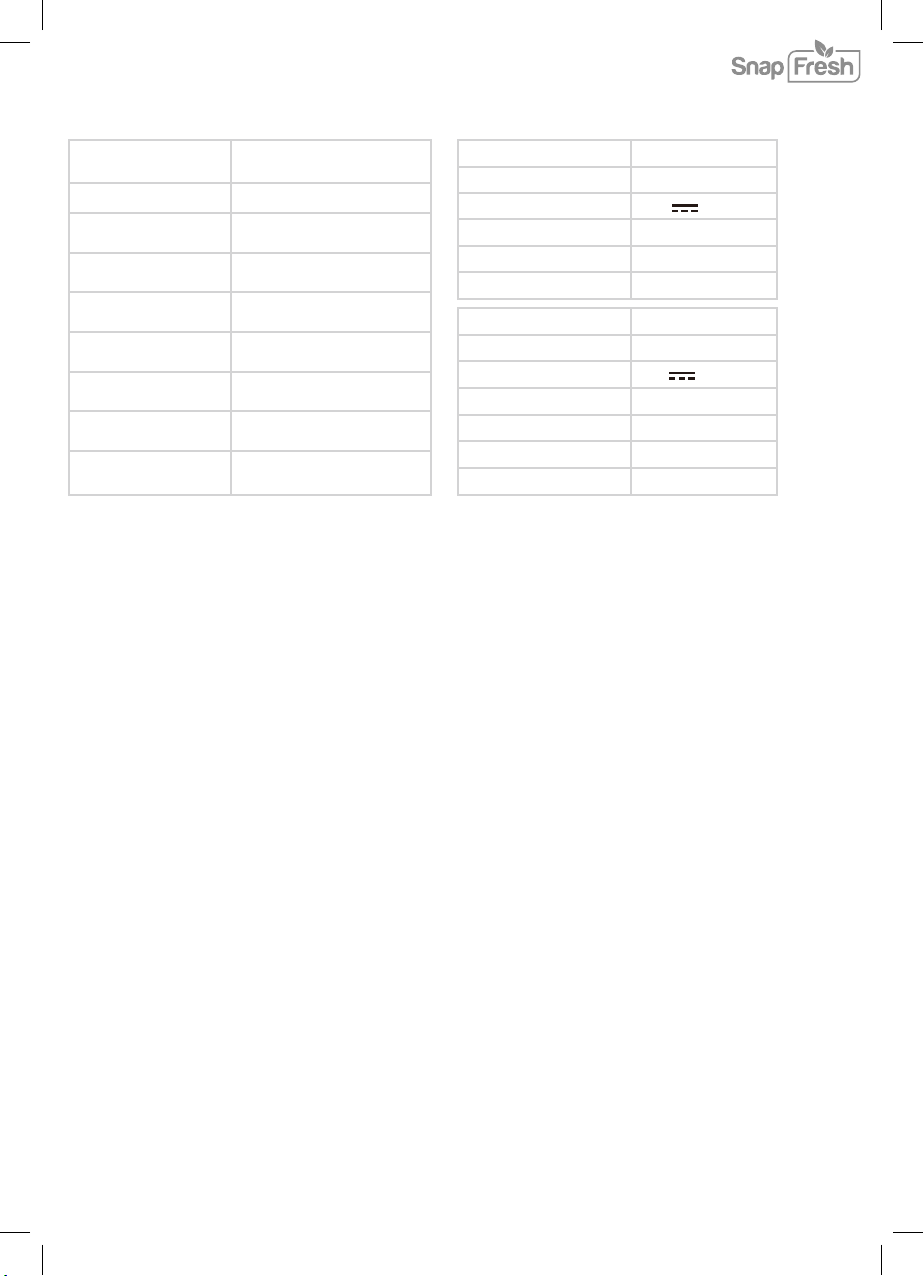

TECHNICAL SPECIFICATION

0-2200 rpm

0-3000 bpm

Impact rate

Max torque

Drive

Sound power level

Vibration level

Sound pressure level

1/4" hex chuck

150 Nm

LpA: 93.8 dB (A)

LpA: 104.8 dB (A)

11.156 m/s²

Charging the battery

The battery pack for this tool has been shipped in a low charge condition and must charged fully charged before the

first use. To obtain maximum energy, ensure the batteries are fully discharged of all power before re-charging for the

first 5 or 6 charges. The batteries must also be charged for a full hour during this time.

.Remove the battery pack from the driver. To do this press both battery release buttons simulta neously and pull down.

.Place the charging stand onto a bench or table near a power supply point.

.Push the charging plug of the AC adaptor into the battery.

.Connect the AC adaptor to the power supply point. The light will be red when unit is plugged in and during the battery

pack is being charged.

.When the battery is full charged, the red light turns to green.

Model No. BBT-POB04

Rated voltage

No load speed

20V

Model Number BBT-DC20A

Battery Type Lithium-ion

Voltage 20V

Capacity 2.0 Ah

Recommended charger BBT-YFT20V

Weight 0.3 kg

Model Number BBT-YFT20V

Charger input 100-120V~60Hz 65W

Charger output 21V 2.5A

Charging time 2Ah battery 60 minutes

Charging time 4Ah battery 120 minutes

Recommended batteries BBT-DC20A, BBT-DC40A

Weight 0.36 kg

OPERATION

10

Selecting correct driver bit/socket bit

.Always use the correct size driver bit/socket bit. Use only the driver bit/socket bit shown in below

picture. Do not use any other driver bit/socket bit.

.An incorrect size bit will result in inaccurate and inconsistent fastening torque and /or damage to

the bolt or nut.

Installing or removing driver bit

.To install the driver bit, pull the sleeve in the direction of the arrow and insert the driver bit into the sleeve as far

as it will go.

.Then release the sleeve to secure the driver bit.

.To remove the driver bit, pull the sleeve in the direction of the arrow and pull the driver bit out.

Switching on/off

The impact driver is started and stopped by depressing and releasing the ON/OFF switch trigger.

Switch lock

.The switch trigger can be locked in the center position.

.This helps to reduce the possibility of accidental starting when not in use.

.To lock the switch trigger, place the direction of rotation selector in the center position.

Direction of rotation

.Direction of rotation is controlled by the direction of rotation selector located above the switch trigger.

.Clockwise rotation—right: to select forward rotation, release the on/off switch and push the forward/reverse lever

to the left side of the tool.

.Anticlockwise rotation—left: to select reverse rotation, push the lever to the right side of the tool.

0.39in 0.35in

11

Variable speed

.This tool has a variable speed switch that delivers higher speed and torque with increased trigger pressure.

.Speed is controlled by the amount of switch trigger depression.

LED light

The LED work-light can light prior to motor running if you press the switch lightly, which keep the work area to be

lighted for checking clearly at first, and it lights also during your operation.

WARNING: Do not stare directly at the light beam. Never aim the beam at any person or an object other than the work

piece.

WARNING: Do not deliberately aim the beam at personnel and ensure that it is not directed towards the eye of a

person for longer than 0.25s.

MAINTENANCE

.Store the tool, instruction manual and accessories in a secure place. In this way you will always have all the

information and parts ready to hand.

.Keep the tool’s air vents unclogged and clean at all times.

.Remove dust and dirt regularly. Cleaning is best done with compressed air or a rag.

.Never use caustic agents to clean plastic parts.

CAUTION: Do not use cleaning agents to clean the plastic parts of the tool. A mild detergent on a damp cloth is

recommended. Water must never come into contact with the tool.

WARRANTY

Ningbo Babytec Technology Co., Ltd (Hereinafter referred to as Babytec) warrants this product against defects in

materials and/or workmanship under normal use for a period of ONE (1) YEAR from the date of purchase by the

original purchaser(’Warranty Period’).

If a defect arises and a valid claim is received within the Warranty Period, at its option, Babytec will either 1) repair

the defect at no charge, using new or refurbished replacement parts, or 2) replace the product with a new product

that is at least functionally equivalent to the original product, or provide a store credit in the amount of the purchase

price of the original product. A replacement product or part, including a part installed in accordance with instructions

product by Babytec, assumes the remaining warranty of the original product. When a product or part is exchanged,

any replacement item becomes your property and the replaced item becomes Babytec’s property. When a store

credit is given, the original product must be returned to Babytec and becomes Babytec’s property. To obtain

to describle the product that needs service and the nature of the problem.

Allrightsreservedby Ningbo Babytec Technology Co.,Ltd

The following circumstances are excluded from this guarantee:

.Repairs and or alterations have been made or attempted to the machine by unauthorized service centers;

.Normal wear and tear;

.The tool has been abused, misused or improperly maintained;

.Non-original spare parts have been used.

12

(Monday - Friday 9 a.m. - 5 p.m. EST 6 a.m. - 2 p.m. PST)

+1 833 635 0955

Table of contents