Snapper LT Series Manual

Other Snapper Lawn Mower manuals

Snapper

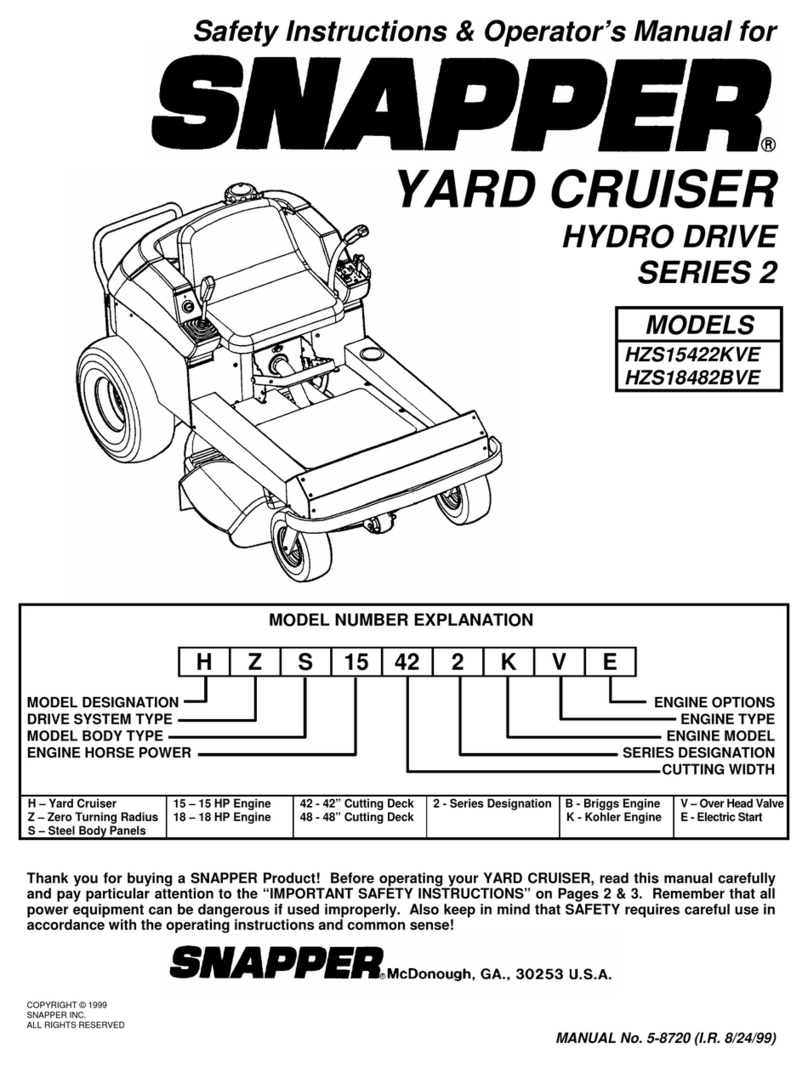

Snapper YARD CRUISER HYDRO DRIVE 2 Series Operation and maintenance manual

Snapper

Snapper Comet 2650S User manual

Snapper

Snapper CP216017RV, CP215017KWV, CP215017HV,... Operation and maintenance manual

Snapper

Snapper 7900925 User manual

Snapper

Snapper 375ZB2050CE User manual

Snapper

Snapper 6413 User manual

Snapper

Snapper 411611BVE Operation and maintenance manual

Snapper

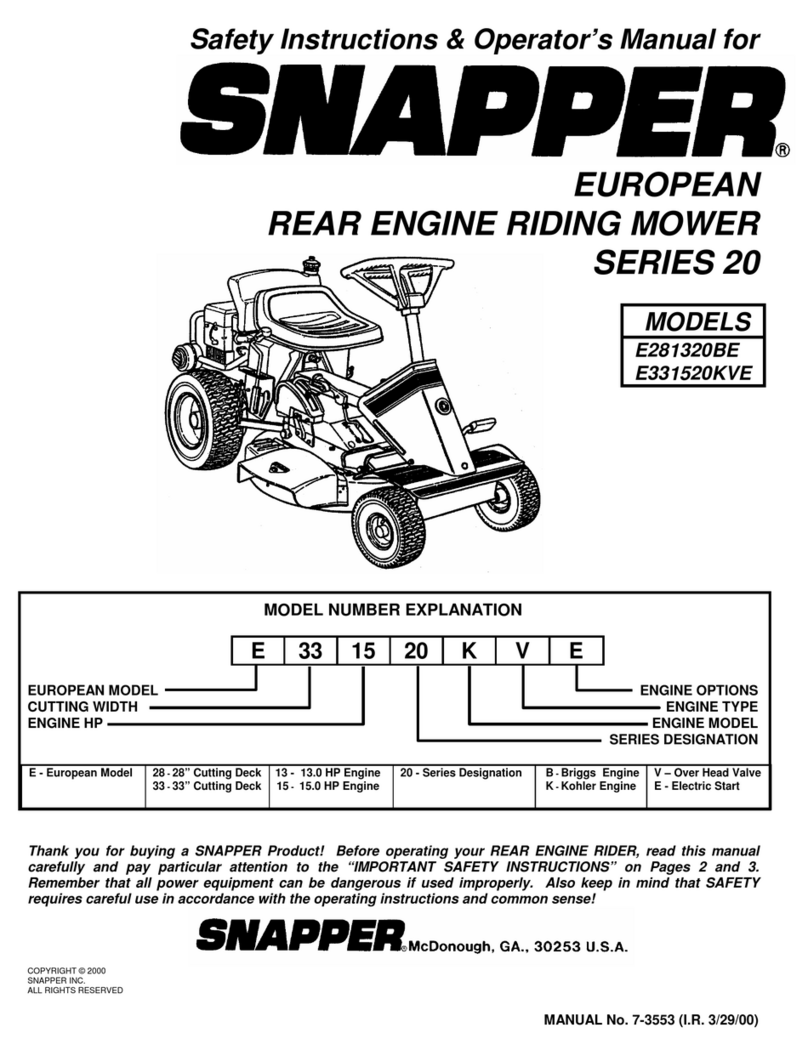

Snapper E281320BE, E331520KVE Operation and maintenance manual

Snapper

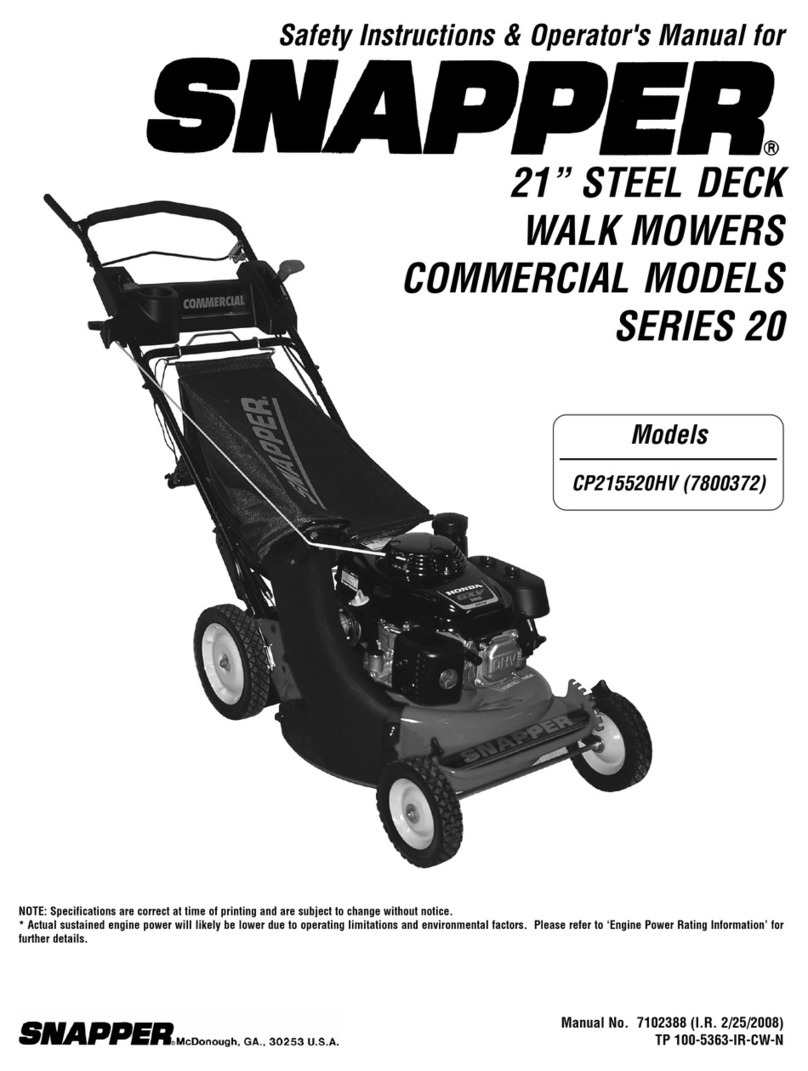

Snapper CP215520HV Operation and maintenance manual

Snapper

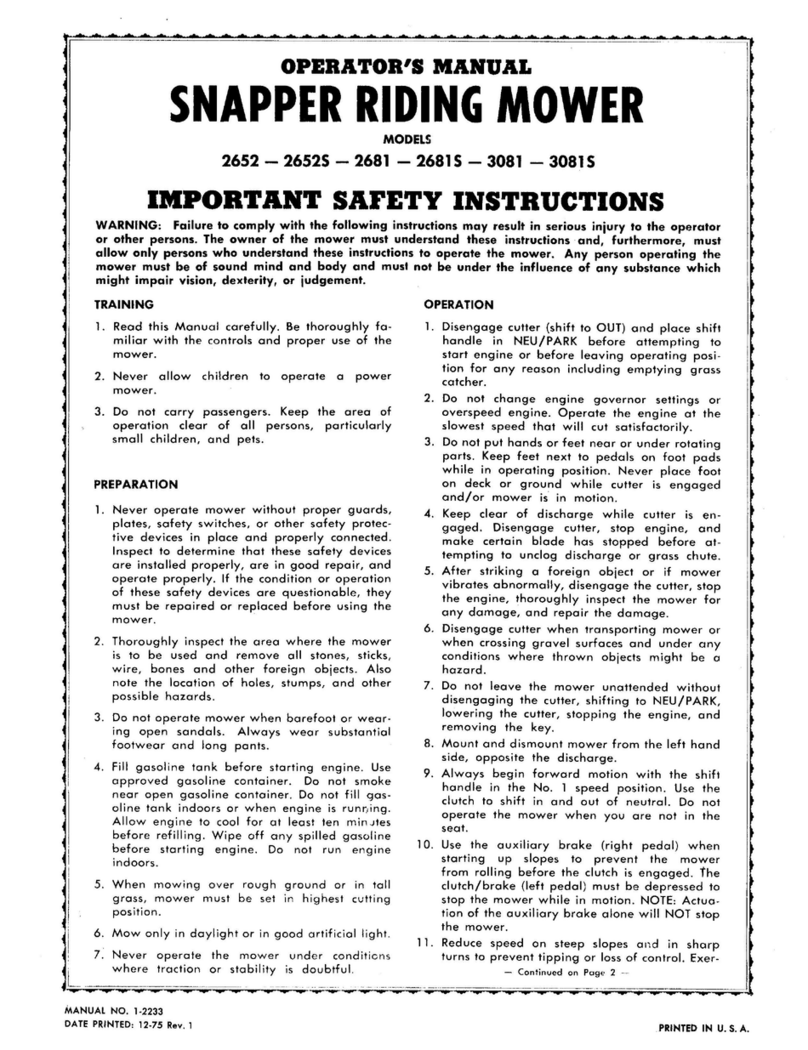

Snapper 2652 User manual

Snapper

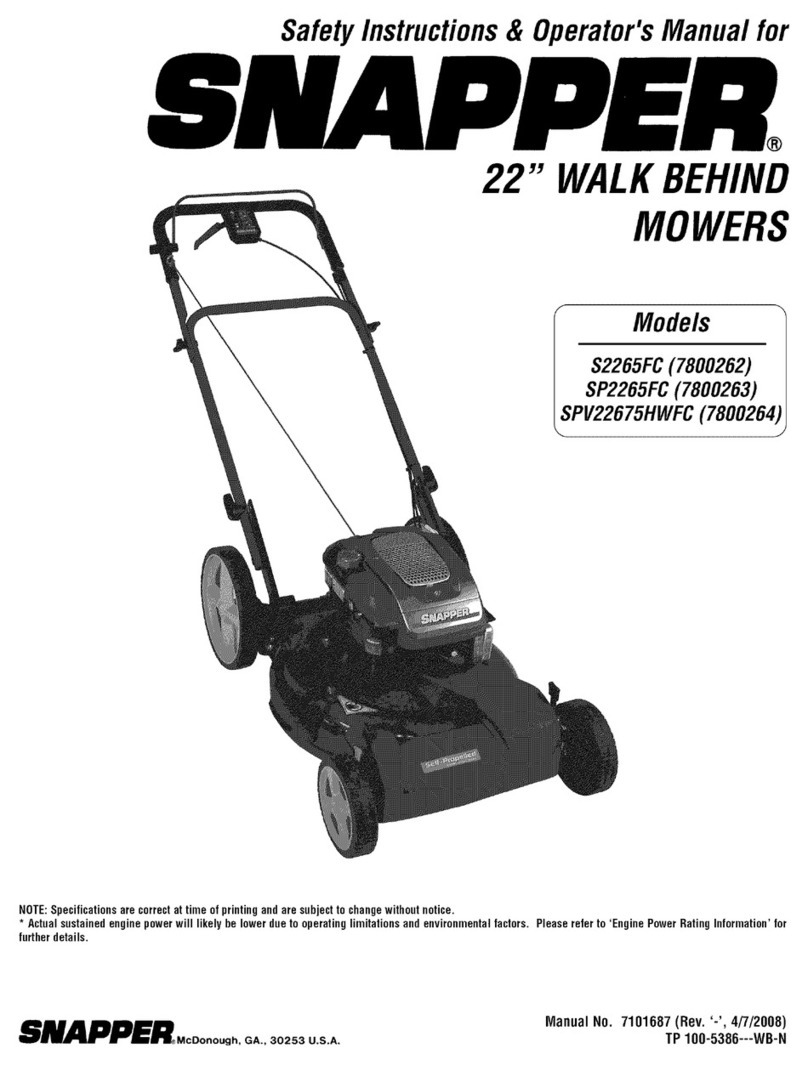

Snapper S2265FC Operation and maintenance manual

Snapper

Snapper CP215518HV Operation and maintenance manual

Snapper

Snapper McDonough Operation and maintenance manual

Snapper

Snapper SPV2270HW User manual

Snapper

Snapper C21400R2, CP21400R2, CP21550V Operation and maintenance manual

Snapper

Snapper 355Z Series User manual

Snapper

Snapper ELT18540 User manual

Snapper

Snapper 200Z User manual

Snapper

Snapper WLT160H42HBV Operation and maintenance manual

Snapper

Snapper 19300-2 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual