Snow Business SB200 Booster User manual

Snow Business International Ltd

The Snow Mill, Bridge Road, Ebley, Stroud,

Gloucestershire, GL5 4TR

Tel: +44 (0) 1453 840077

www.snowbusiness.com

Reg in England, Co # 3188135. VAT # GB618344930

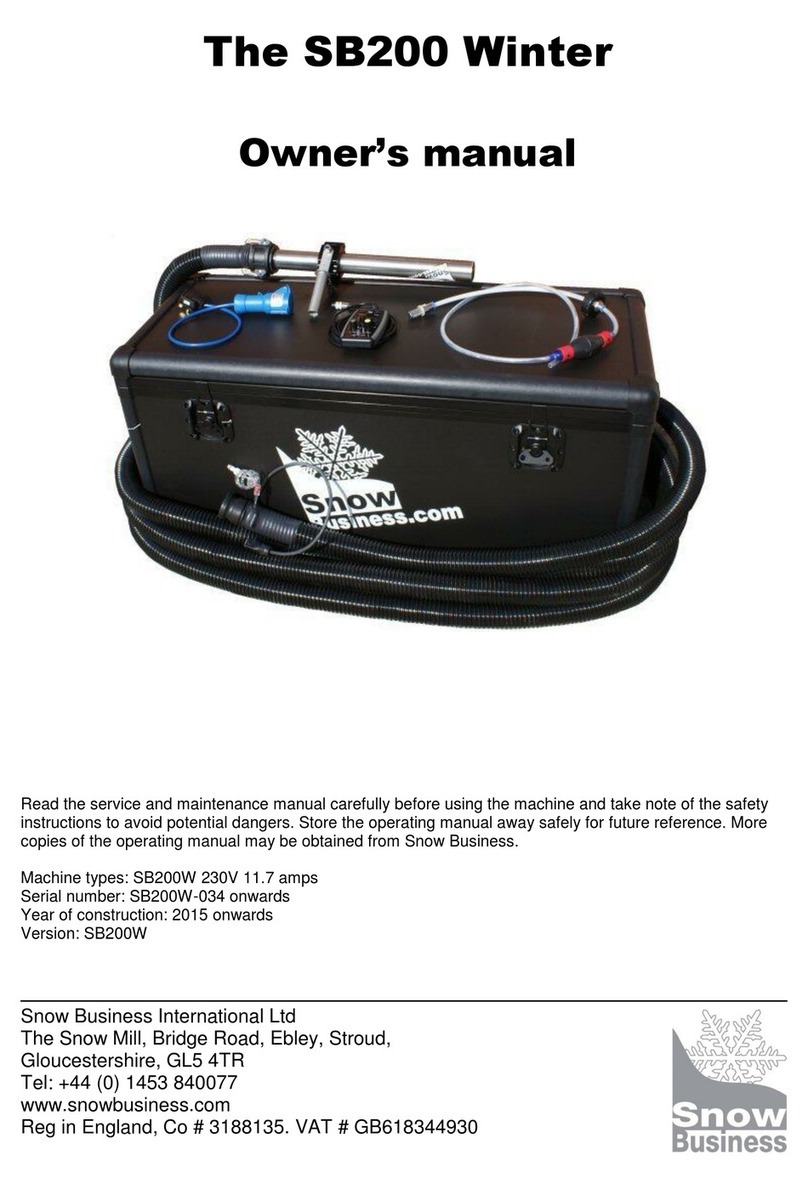

The SB200 Booster

Owner’s manual

Read the service and maintenance manual carefully before using the machine and take note of the safety

Instructions to avoid potential dangers. Store the operating manual away safely for future reference. More

copies of the operating manual may be obtained from Snow Business.

Machine types: SB200B 230V 4 amps

Serial number: (see name plate)

Year of construction: 2014 onwards

Version: SB200B

2

Contents

1 General safety instructions............................................................................................3

1.1 Obligations of the end user ........................................................................................3

1.2 Dangers involved with use of machine.......................................................................4

1.3 Intended use ..............................................................................................................4

1.4 Guarantee and liability................................................................................................4

2 Safety instructions, standard information....................................................................4

2.1 General ......................................................................................................................4

2.2 Explanation of symbols and instructions ....................................................................5

2.4 Informal safety measures...........................................................................................6

2.5 Training of operators..................................................................................................6

2.7 Dangers of electrical energy.......................................................................................6

2.8 Maintenance and service, trouble elimination ............................................................6

2.10 Cleaning of the machine...........................................................................................7

2.11 Operating noise........................................................................................................7

2.12 Copyright..................................................................................................................7

2.13 Taking possession of the machine...........................................................................7

2.14 Registration..............................................................................................................7

2.15 General ....................................................................................................................7

2.18 Foreign objects.........................................................................................................8

2.19 Electrical connection ................................................................................................8

3 General information........................................................................................................9

3.1 Description of the machine.........................................................................................9

3.2 External view SB200 Booster & SB200 Winter ..........................................................9

3.2 The control panel SB200B .......................................................................................10

Remote (dust cover in place)...................................................................................10

4 Operating the machine.................................................................................................10

4.2 Moving and setting up of machine............................................................................11

4.4 Manual operation......................................................................................................11

4.5 Wired remote operation............................................................................................11

4.6 Operation, SB200W not powered or switched off.....................................................11

4.7 Testing correct operation..........................................................................................11

5 Maintenance..................................................................................................................12

5.1 As needed................................................................................................................12

5.2 Before every use......................................................................................................12

6 Trouble shooting guide................................................................................................12

7 FAQ’s .............................................................................................................................13

8 WEEE Take back scheme.............................................................................................13

9 Technical Data ..............................................................................................................14

10 Declaration of conformity. .........................................................................................15

3

1 General safety instructions

The falling snow machine in question is assembled with moving and electrical parts. Misuse or non-

observance of the safety instructions may have serious consequences for the operator and his/her health

and could result in injury

Maintenance should be carried out by suitably qualified persons only, In addition, they must have

read the service and maintenance section of the manual accurately and must adhere to the safety

instructions:

•Read and comply with the instructions in the service and maintenance section of the

manual.

•Comply with all warning and safety instructions on the machine and in the operating manual.

•This machine should only be used for the intended purpose the machine was designed for.

•Disconnect the mains supply before assembly/disassembly.

•Only use the recommended snow fluid. Use of the wrong fluid may result in poor

performance and/or damage to internal parts of the machine.

•To avoid the inappropriate use of the machine by strangers, or children do not leave a

machine which is ready to operate unsupervised in an unsecure location.

•Do not place the machine on an unstable surface.

•Only use the machine with a 230 volt mains supply protected by a 20 amp Circuit breaker.

•Ensure that the machines air intake grill is not obstructed before operation otherwise

performance will be impaired and parts of the machine could be damaged.

•Provide for sufficient supply of fresh air, to avoid damage through overheating of the blower.

•Only qualified personnel may disassemble service and repair the machine. The opening of

the machine, removal of the outer cover, or similar parts, as well as the wrong assembly of

the machine, increases the risk of dangerous electrical shocks and other risks.

•Only use the machine within the authorised operating temperature range (see section 9) to

avoid damage.

•Do not make any changes to the machine. A change may lead to new safety risks and the

loss of the claim on guarantee.

•Observe the rules and regulations of the Health and Safety at Work Act to avoid accidents.

1.1 Obligations of the end user

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure they do not play with the appliance.

All people who work with or who have been instructed to work with the machine must commit themselves,

before they start working, to:-

•Adhere to the standard instructions of the health and safety at work act.

•To read the chapter on safety and the warnings in this operating manual and to

subsequently confirm with their signatures to their employer (if applicable) that they have

understood these.

4

1.2 Dangers involved with use of machine

This machine has been designed to be safe in normal operation, however misuse of the machine may render

it unsafe to use. Should the operator suspect that the machine has been misused or damaged in any way

they should cease operation of the machine and report their concerns either to their own maintenance team

or to Snowbusiness international Ltd.

1.3 Intended use

This machine is to be used for the purpose of creating an artificial falling snow effect using only fluids

recommended by Snow business.

1.4 Guarantee and liability

Guarantee related claims and demands of liability following injury to people and damage to property are

invalid when they are traced back to one, or more of the following causes:

•Use of the machine for a purpose other than the intended use.

•Improper assembly, putting into service, use and maintenance of the machine.

•Non-observance of the instructions in the operating manual related to transport, storage,

assembly, putting into use, operation, maintenance and preparation of the machine.

•Self-conceived structural changes to the machine.

•Repairs carried out improperly.

•Interference of foreign objects or acts of nature

2 Safety instructions, standard information

2.1 General

You have acquired a “state of the art”falling snow machine. This machine has been constructed in line with

European guidelines and standards. It carries a CE-identification plate. This ensures the long-term

availability of spare parts and guarantees that European safety standards have been met in its design and

construction. This handbook contains information about the use and handling of your machine type SB200B

including technical detail on the operation, maintenance and safety.

To get the maximum performance out of your machine and get to know all the safety-technical aspects, a

fundamental study of this operating manual is imperative. As with any machine which is used improperly, or

serviced incorrectly, this machine could be dangerous if so used, or serviced. Therefore, you should please

give special attention to our safety instructions. The SB200B offers you the following features and

advantages:-

•A tough case with wheels, handles and a noise reducing out-put nozzle.

•Manual or Wired remote control.

•Quiet operation.

•Ability to use a wide range of fluids.

•Ability to propel snow 15 meters (in favourable wind conditions) thus allowing the snow to be

distributed over a large area.

5

Snow Business International offers reliable and fast after sales service with every machine delivered. For

answers to technical questions, or questions about servicing, please contact us during our office hours which

can be found on our website.

2.2 Explanation of symbols and instructions

For greater clarity and to emphasize instructions related to safety, the following icons will be used:

This symbol indicates real danger threatening the lives and health of people. Non-observance of these

instructions may lead to serious injury.

This symbol indicates possible danger threatening the lives and health of people. Non-observance of these

instructions may seriously damage the health of people and may even result in life-threatening injury.

This symbol indicates a real danger of electrocution. Non-observance may seriously damage the health of

people and may even result in life threatening injury.

This symbol indicates that the user should refer to this operator’s manual.

This symbol indicates a temperature limitation.

Separate collection, handling and disposal for waste electrical and electronic equipment and its components

This symbol indicates important information.

6

2.4 Informal safety measures

The operating manual must be stored at the place of operation at all times. In addition to the operating

manual, the generally prevailing and local rules for accident-prevention and environment protection must be

kept at hand and observed. All safety and danger instructions on the machine must be kept in a condition

which ensures their legibility.

2.5 Training of operators

Please read the manual before:-

•Operating the machine

•Mounting and rigging the machine.

•Servicing, cleaning and maintaining the machine.

This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand the hazards involved. Children

shall not play with the appliance. Cleaning and user maintenance shall not be made by children without

supervision.

2.6 Safety measures with normal use

Before starting the machine, check the security of electrical connections and the fluid level.

2.7 Dangers of electrical energy

Only an authorised electrician may execute electrical work. The electrical equipment of the machine must be

checked regularly. Defects such as, loose connections, scorched/damaged cable, or broken connectors

must be repaired immediately.

2.8 Maintenance and service, trouble elimination

Carry out the prescribed adjustments, maintenance work and inspections timely. The machine must remain

disconnected from the power supply during all maintenance, inspection and repair work (See section 5).

2.9 Structural changes to machine

No changes, additions, or modifications may be made to the machine, without the permission of Snow

Business International Ltd. Only use spare parts and parts subject to wear which are original. It cannot be

guaranteed that parts bought from third parties were manufactured and finished to the required standards for

use and safety.

7

2.10 Cleaning of the machine

Disconnect the machine from the power supply before cleaning. The machine should be cleaned with a

damp soapy cloth only.

2.11 Operating noise

The normal on-going noise level of the machine measured outside the case, amounts to

a maximum of 72 db @ 1 meter.

2.12 Copyright

Copyright on this operating manual remains with Snow Business Ltd. The operating manual is

intended for the use of the operator and his/her staff only. It contains information and instructions which may

not be:- •Faxed

•Distributed

•Or otherwise communicated to others, either in full or in part without express permission of

Snow Business International Ltd.

2.13 Taking possession of the machine

When the machine is delivered, it must be checked for completeness against the delivery note.

Please check if the machine has been damaged in transit. Possible damage must be reported in

writing to us within 8 days of delivery.

2.14 Registration

The buyer of a used machine, in other words, a machine which was not obtained directly from Snow

Business International Ltd, is obliged to provide their address, with the data on the machine plate, to the

manufacture, or his assignee, in writing within 4 weeks after the date of buying the machine.

2.15 General

Safety instruction: All cleaning and assembly work, including the transport of the machine, should only be

executed with the power supply disconnected. Non-observance of this safety instruction may result in

serious dangers from inadvertent start-up, or other sources of danger.

8

2.16 Installation site

Inside the casing of the machine are many different electrical units. While these are waterproof It is best that

the machine is stood on dry ground, not only while it is working, but also when it is switched off and resting. It

is advisable in hot weather not to stand the machine in direct sunlight as this may cause overheating of the

internal parts of the machine. It should also be ensured that the air supply at the installation site is sufficient.

When the air supply is insufficient overheating of the motors may take place. Air-intake grills which are partly

blocked will impair the air supply to the machine. The machine is designed to create large volumes of falling

snow. When used indoors small rooms will quickly become saturated with snow if the flake size is too large.

The flake size should be turned down so as to match the snow production with the volume of the space into

which it is being blown.

2.17 Place of machine use

The machine was conceived for use on film sets, in theatres and at live events. Compliance with the

permitted operating temperatures is a precondition for the secure and trouble-free use of the machine. In the

Chapter Technical data (section 9) you may read what the permitted operating temperatures are.

2.18 Foreign objects

Contamination of the snow fluid may lead to blocking of the snow generating gauze. If the gauze has

become blocked it should be removed from the snow gun assembly and back flushed with clean water or

compressed air to clear it, after which it can be returned. The grills built into the machines sides are sufficient

to stop large objects being sucked into the air intake of the machine. However dust and small objects may

get past the grills. These objects should not cause any great problem however it is advisable to clean the

machine periodically.

2.19 Electrical connection

The machine may only be connected to a power supply of 230V / 50Hz alternating voltage with

a UK 3 pin plug fitted with a 13 amp fuse or a Euro C-form type 3 pin plug. As a C-form plug is not fitted with

a fuse there is a separate fuse holder on the machine’s control panel which is fitted with a 10 amp 240V

fuse. The power supply should be protected by a 16 amp circuit breaker. Deviations in voltage and frequency

of ±5 % poses no danger of damage to the machine and is permitted. While the machine is used, the

electricity cable must not be rolled up on a drum, or similar object, but should be completely unrolled to

prevent it overheating.

Please comply with the manufacturer’s instruction when using this device in conjunction with electrical

generator equipment.

9

3 General information

3.1 Description of the machine

The SB200 Booster when used in conjunction with an SB200 Winter base unit produces an artificial falling

snow effect by combining snow fluid, water and air together to form dry foam. The SB200 Booster machine’s

booster fan is designed to be activated via a wired remote control driven from the SB200 Winter base unit or

manually via the 3 position selector switch on the SB200 Boosters control panel.

When the machine is switched to manual the blower will automatically come on. If switched to

remote the blower will be activated by the SB200Winter and may start at any time, without

warning.

3.2 External view SB200 Booster & SB200 Winter

10

3.2 The control panel SB200B

Remote (dust cover in place)

Main fuse 10 amp 240 V

Auto/Off/On selector switch

4 Operating the machine

4.1 Loading and unloading of machine

The machine may be moved using the handles on the main part of the outer case of the machine and its

casters or by grasping the machine by both handles and lifting N.B. the machine should be classed as a two

person lift.

11

4.2 Moving and setting up of machine

The machine can be stood on a flat surface with its output nozzle vertical, at 45 degrees, or horizontal. When

the machine is stood on a flat surface it must be in a place which satisfies the following conditions:-

Solid, dry ground.

Free from dust and loose objects which may be sucked into the air intakes.

The machine can easily be maneuverer on its casters.

The machine weights 44 KG’s. Lifting the machine should not be attempted by a single person. To lift this

weight safely you should ask for assistance.

4.4 Manual operation

To operate the machine in manual mode, connect the fluid line and air hose from the SB200Winter to the

back of the machine. Connect the power lead to a suitable supply (see 2.19) and then switch the

Manual/off/auto switch to manual. The booster fan will now run continuously and snow will be produced

every time the SB200Winter is operated.

4.5 Wired remote operation

To operate the machine in remote mode, connect the fluid line and air hose from the SB200Winter to the

back of the machine. Connect the power lead to a suitable supply (see 2.19) and then switch the

Manual/off/auto switch to Auto. The booster fan will now run only when the SB200Winter is operated.

4.6 Operation, SB200W not powered or switched off

Snow will still be made in this situation however without the SB200B’s fan engaged there will be no boost

effect.

4.7 Testing correct operation

Operate the machine as in 4.5 if the machine is operating correctly there should be a good amount

of evenly sized snowflakes emitted from the nozzle whenever the flake size control on the SB200W is turned

up and the machine is running. If this is not the case please refer to the trouble shooting guide under section

6.

12

5 Maintenance

The machine is designed to give a long and low maintenance life. In order to ensure this is the case, please

undertake the following tasks at the intervals given. (Always insure the machine is disconnected from the

power supply before undertaking any maintenance task).

5.1 As needed

Wipe the machine over with a damp soapy cloth to clean it.

5.2 Before every use

Ensure that there is no visible damage to any part of the machine. Pay special attention to the power lead

and connection. If the power lead has become damaged in any way the machine should not be used. Please

contact Snow Business to arrange a repair. Check all air intakes and the nozzle for obstructions or

blockages; if any are found remove them before operating the machine. Look down the nozzle (with the

machine switched off) and inspect the gauze for damage. If the gauze is damaged it will need to be replaced,

ring Snow Business to order a replacement.

5.3 At least once a year

Remove the machine’s gauze (inside the nozzle) by removing the nozzle and then undoing the self-tapping

screw holding the gauze cover in place. Pull the gauze off by grasping the end and pulling. Once removed

inspect for contamination or damage. The gauze can be cleaned with water and or a compressed air line. If

the gauze is damaged it will need to be replaced. In dusty areas or when used in conjunction with artificial

snow or set dressing materials of any kind it may become nessacery to remove and clean the gauze more

often. A drop off in snow production and quality is a sure indicator that the gauze has become contaminated.

There are no internal parts that can be maintained by the owner of an SB200B. In the event of a

failure of any of the internal parts of the machine please contact Snow Business to arrange for repair.

Unauthorised repairs will invalidate the machines warrantee and may place the operator in danger.

6 Trouble shooting guide.

If the machine appears to be dead:-

With the Manual/Off/Auto switch, in position Manual, the blower should run.

Inspect the power lead for signs of damage, if it is damaged do not use the machine and insure

others can’t too. Contact Snow Business to arrange repairs.

If the power flex and plug are ok, check there is power to the machine and it is switched on at the

plug.

Check the circuit breaker on the external power supply panel and then the fuse in the plug and the

control panel. If both are OK or if the supply continually trips or the fuse(s) continually blow then the

machine will need to be returned to Snow Business for repair.

If the machine works in Manual mode but not Auto check that the wired remote cable is properly

connected.

If it is and the machine is not working then please contact Snow Business.

If the machine turns on and the blower runs but there is no snow.

Check that the fluid conection at the rear of the machine inside the 2” air hose is not leaking.

If it is then the fault is most likely with the SB200Winter machine. Refer to the SB200Winter owners

manual.

13

7 FAQ’s

1. Can I use non recommended fluids with an SB200B? Snow business spends a lot of time testing the

snow fluid it sells to insure that it won’t damage clothing, painted surfaces, the machine itself or the

people using it. We accept no responsibility for any damage caused by using non specified fluid.

2. How much fluid will my SB200B Winter use? That all depends on how much you use the machine, if

left to run continuously on a high flake size it will drain the fluid tank quickly and produce very large

flakes of foamy snow.

3. Can I leave my SB200B out in cold weather? If connected to an SB200W machine warm air from the

hose heater should protect the SB200B from freezing down to about -7 Deg C.

4. I have left my SB200B out all night and the fluid has frozen what should I do? De-frost the boosters

gun with a hair-drier directed into the gun tube (machine switched off). While the SB200B is likely to

be ok if the SB200W has been switched off all night it will most likely have damaged internal parts

and will need repair.

5. My SB200B isn’t working properly what should I do? See trouble shooting section 6.

6. Is it safe to use my SB200B in the rain? The SB200B has been tested to IP rating-.-.

7. Is it ok to use my SB200B in very hot weather? Exposing the machine to direct sunlight in very hot

weather may result in the machine overheating, in extreme cases the thermal fuse in the motor may

blow resulting in the failure of the machine requiring repair by Snow Business. It is advisable to

shade the machine from direct sunlight and the machine should not be used above 40 deg C

ambient temperature.

8. What area will the SB200B cover with falling snow? This is entirely dependent on wind speed and

direction.

9. How do I replace the gauze? See section 5.3

10. Can I control the machine via DMX? Although the SB200B cannot itself be controlled directly be

DMX it must be used in conjunction with an SB200W which can.

11. Will the machine run on 110 volts? No the machine is designed to run on 230 volts AC only.

12. Will the machine work on a slope? Yes, but you will need to secure it properly.

13. Can I change the flake size during operation? Flake size adjustment is carried out using the

SB200W hand controller or via DMX.

14. Can the machine be left to run on its own? Yes but remember to keep checking the fluid level in the

tank of the SB200W.

8 WEEE Take back scheme.

Under the European WEEE directive (Waste Electrical and Electronic Equipment) provided you purchase

another piece of equivalent machinery from Snow Business, Snow Business will collect and dispose of your

old machine free of charge at the end of its life. If you do not wish to purchase a new machine from Snow

Business then you should dispose of your old machine in accordance with local regulations.

14

9 Technical Data

Weight 44 kg

Machine Dimensions (SB100T & TXT) 690cm long x 530cm wide x 1230cm high

Current 4.0 Amps

Power 900 Watts

Voltage 220- 240 volt

Noise Output Base unit 70 db, Gun 75db to 80db depending on fan setting.

Permissible snow fluids Bioflake or Snowboy fluid

Ingress protection IP14

Operating temperature range Event -5 to +40 deg C (used with an SB200W)

Operating modes Manual, off and wired remote.

Plug fuse 13 amp

Control panel fuse 10 amp

15

10 Declaration of conformity.

16

Table of contents

Other Snow Business Dj Equipment manuals