Soham Impex 200 User manual

GMAW WELDING MACHINE

MANUAL

Vavdi Survey no. 28, Shivam Industrial Area, Street No.3 Plot No.7, Near Sunny Raj Metal,

USER MANUAL

GMAW WELDING

MACHINE

Safety notices

For the sake of your and other's safety, please read the manual

carefully before installation or operation of the equipment!

The people operating the equipment or nearby should fully know about

safety measures. The safety will be fulfilled through everyone's common

effort.

The complete equipment should be securely grounded.

All operations must be performed:

In accordance with the operating instructions

By the special operator

Incorrect operation is likely to cause an accident. injure the operator,

and damage the equipment.

When operating the equipment, every operator must know about:

Control of the equipment

Operation of the equipment

All effective safety rules

For its convenient use, every selection switch, knob, button, ampere

meter, and voltmeter is marked. Its function and usage are described

clearly.

Safety information:

Be sure to use appropriate personal safety outfit, for example,

protective goggle, mask, and gloves. Do not wear a tie, bracelet, and loose

clothing that are easy to twine the equipment.

Put the fire extinguishers in the specially marked position (the fire

extinguishers shall be provided by the user).

Keep the arc-welding rectifier a certain distance away from flammable

substances such as waste oil and clothing.

The splashing can cause a fire and burn your skin. The arc light would

damage your eyes and skin.

Smoke and dust produced during the welding process are harmful to

your body. Please try to remove them or avoid inhaling them.

Check the emergency and safety devices every day.

Be sure to cut the power off after finfish your work and/or when leave

the welding site temporarily.

Be sure to check the arc-welding rectifier before and after use of it. Be

sure to find out the reason and correct the abnormality when any

abnormality occurs. Do not use the equipment before correct the

abnormality.

Be sure to cut the power off before check the welder. Do not open the

case before cut the power off to avoid an electric shock.

1. Main purposes and features

1.1 Main purposes

IGBT inverter gas-shielded welders of GMAW/MIG series include Model

200, 300, and 400. They are mainly applicable to CO2-shielded welding,

consumable electrode argon arc-welding (GMAW/MIG), and mixed gas-

shielded welding (GMAW/MAG). They conform to safety requirements

of arc-welding equipment technical requirements of the welder

The model description of the series conforms to standards of model

description for the arc welder.

1.2 Features

IGBT high frequency inverter technology is used. Up to 20KHz inverter

frequency provides fast dynamic response.

Use of current control mode provides high quality and reliable

performance.

Total digital presetting and display of welding current/voltage provides a

visual and convenient operation.

Current self-adaptation within 30mm dry extension is applicable to all-

position welding.

Perfect protection circuit and fault display function provides safety,

reliability, and convenience to locate a fault.

Metal transfer waveform control provides stable electric arc, little

splashing, and well-shaped welding lines.

Arc-striking and ball removal circuit is added to guarantee the arc-

striking success rate.

Small dimension, low weight, high efficiency, energy saving, high duty

cycle, and no noise

Reasonable structure and concise layout provides convenient

maintenance.

Applicable to CO2 /MIG/MAG welding with solid/flux-cored welding

wire of different welding specifications

Stable welding process and strong immunity against power grid

fluctuation ( 280~480V)

2. Normal operating conditions

Environmental temperature

-10°C ~ 40°C

Elevation

≤1000 meters

Relative humidity

At 40°C: relative humidity ≤50%

At 20°C: relative humidity ≤90%

Power requirements

Power supply: three-phase, 415V, 50Hz

Imbalance rate of

the

three-phase voltage : <±0.5%

Voltage fluctuation of the power grid : <±10%

Frequency fluctuation : <±1%

Others

In the working site, there are no gas, vapor, chemical sediment,

dust, dirt, mildew, and other flammable/corrosive substance, which

severely affect the use of the arc-welding rectifier. In addition, avoid

violent shake and jolt of it.

Put the equipment in a dry and ventilated place. Avoid direct

exposure to sunlight and rain.

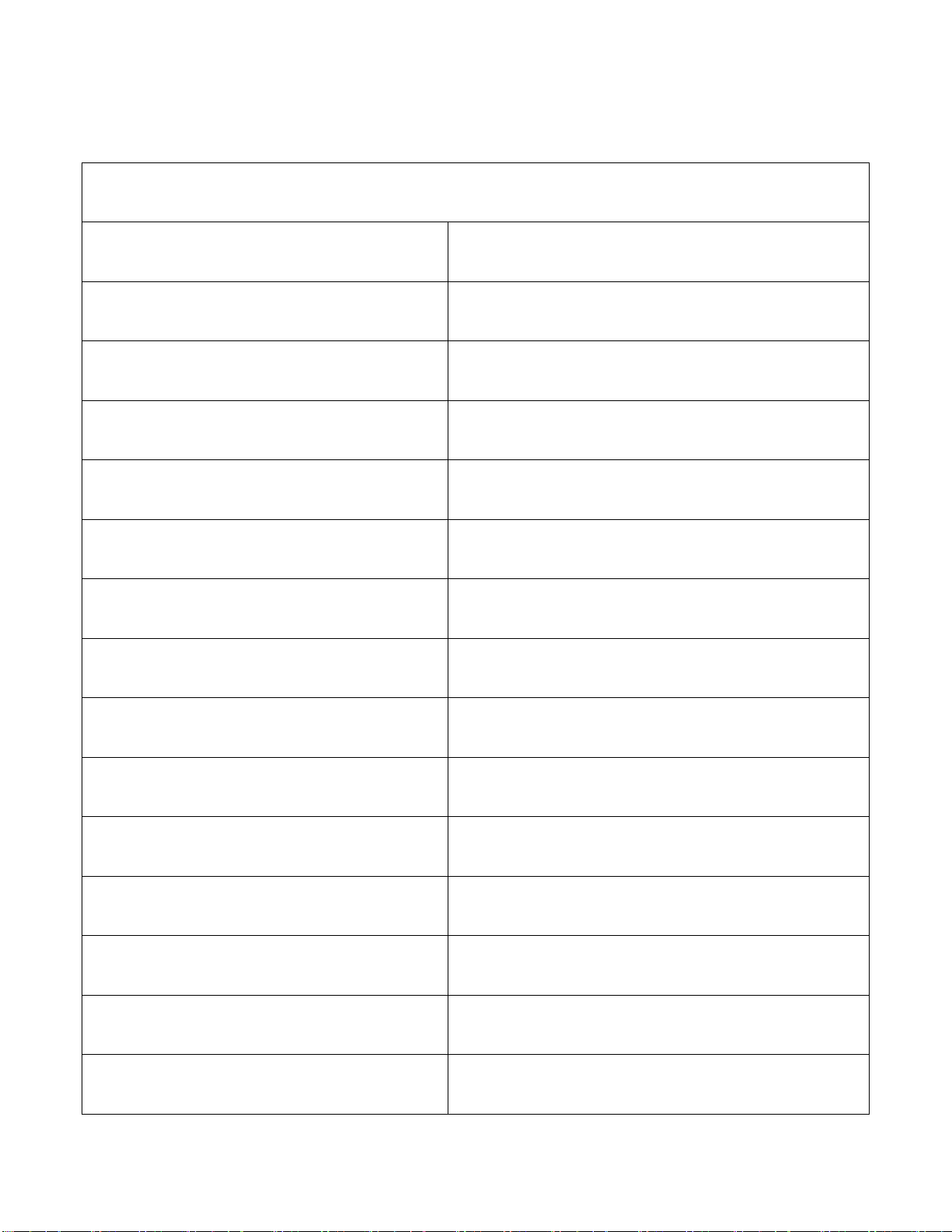

Technical Specification

GMAW WELDING MACHINE 300AMP MOSFET BASED

Type of power Source

MOSFET based

Current capacity of GMAW welding set

300MM

Current rating at 40 % Duty Cycle

340MM

Current rating at 100 % Duty Cycle

210MM

Welding current range

300AMP

Power Input

Single Phase (215 ± 15% V AC, 1 Phase, 50 Hz)

Open circuit voltage, DC

80 VOLT

Type of Metal which can be welded

Mild Steel

Open Circuit Power

5WATT

Protection Class

IP23

Di�erent type of insulation class

F

Type of cooling

Forced air cooling

Type of Wire feeder drive

2 roll drive

Wire Feeding rate

18

Type of welding Torch

WELDING TORCH

4. Hoist and storage

There are two handles on the top of the arc-welding rectifier for

hoisting purpose.

The arc-welding rectifier and wire feeder are packed with the carton.

It can be transferred manually or with a forklift. However, be sure to

avoid its hit or fall.

The arc-welding rectifier and wire feeder should he stored in a dry,

ventilated, and rainproof place. The storage temperature is -25~ 55'C.

5. Installation and attention

First, please read the user's manual carefully. Check if the

product and accessories are complete and in good condition.

Put the arc-welding rectifier in a dry, dustproof, rainproof, and

anticorrosive place. Make the installation and connection in the

following ways (refer to Diagram 2). Put the arc-welding rectifier in a

well-ventilated environment to facilitate heat dissipation. Air outlet opening

should be not less than 800mm away from the wall, and not less than 100mm

away from the right and left wall.

The three-phase power cable must go to the arc-welding rectifier through the

air switch. Select the capacity of the air switch in accordance with technical

parameter requirements of the welder.

Attention:

The case of the arc-welding rectifier must be securely grounded

(in the place with a grounding mark) to avoid an electric shock.

The arc-welding rectifier must be securely connected to the three-

phase power cable. Otherwise, the equipment would function improperly,

or the local area of the joint be heated and damaged.

It is strictly prohibited to pull the air switch when the load is

applied to avoid the damage.

The "+" output of the arc-welding rectifier should be connected to the wire-

feeder, and the "-" output to the to-be-welded workpiece.

One end of the gas hose is connected to the gas outlet opening of the gas

adjuster, and the other end to the inlet opening of the gas valve of the

wire feeder.

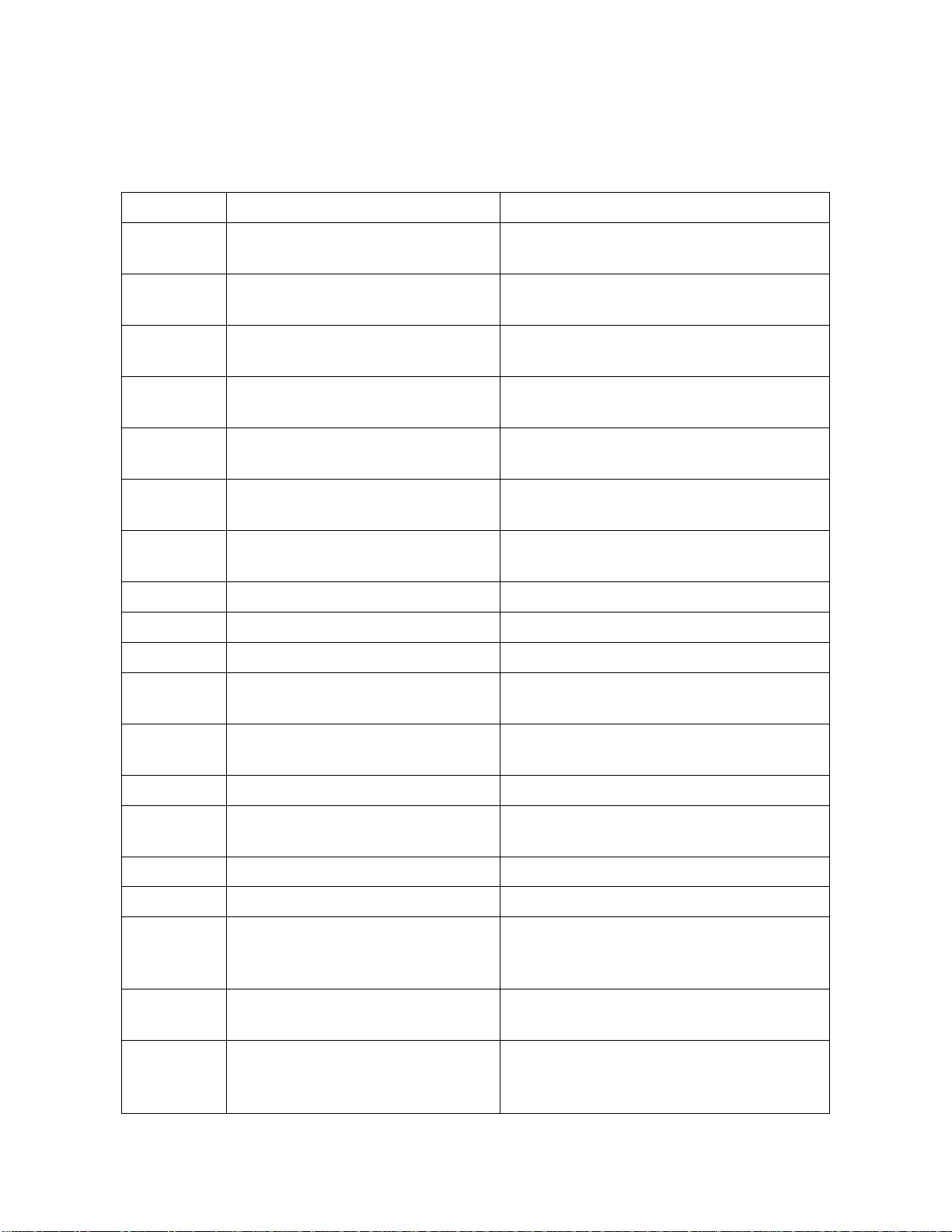

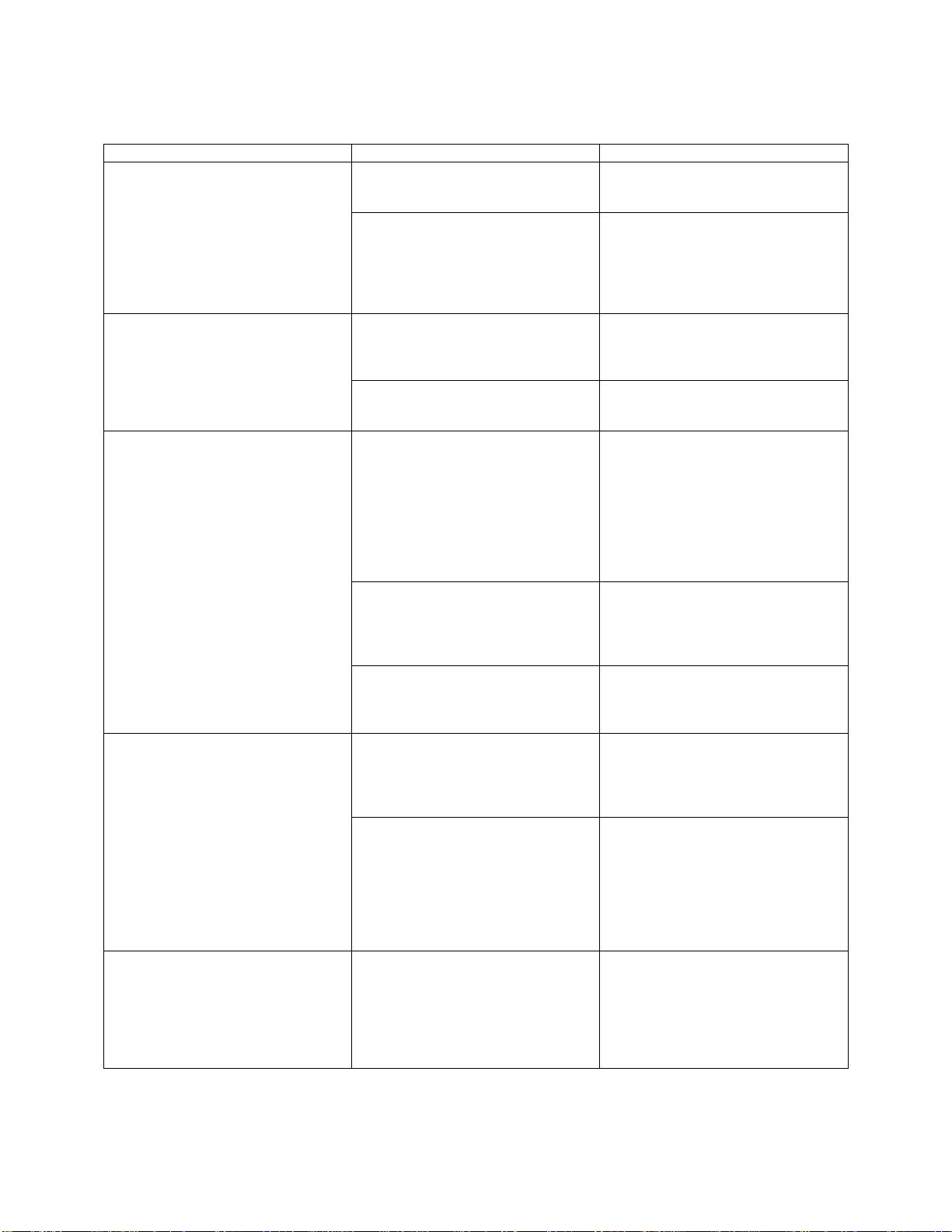

6. Function description

Function description of the front/rear panel of the arc-welding rectifier

No.

Name

Description

1

Amperemeter

Preset and display the output current of the

welder

2

Voltmeter

Preset and display the output voltage of the

welder

3

Power indicator light

Indicate if the power supply of the welder is

turned on/off.

4

Abnormality indicator light

The abnormality indicator light is on when

an abnormality occurs

5

Adjustment knob of

arc-receiving current

Set the arc-receiving/manual welding current

6

Adjustment knob of arc-receiving

voltage

Set the arc-receiving voltage for welding

7

Arc-receiving On/Off switch

Make sure if the arc-receiving specification is

required

8

Gas check switch

Check gas flow and pre-adjust gas flow rate

9

Wire-selection switch

Select the welding-wire diameter

10

Function switch

Select manual/gas-shielded welding

11

Plug of the control cable

Connected to the control cable of the wire

feeder

12

Output anode

Connected to the welding power cable of the

wire feeder

13

Output cathode

Connected to the workpiece

14

Input terminal box

Connected to the input power cable of three-

phase, 415V/AC, and 50Hz

15

Plug of the heater

Connected to the heater of the CO2 adjuster

16

Control power fuse

Protect the control circuit

17

Air switch

When the welder functions improperly, or is

overloaded for a long time, protection

function of the air switch is activated.

18

Nameplate

Indicate the related technical parameters and

information of the welder

19

Grounding terminal

Be sure to connect it to the welding ground

when use the welder to ensure safe use of

electricity.

7. Use and operation

7.1 Preparation before use

Connect the input power cable of the welder to the power grid according

to the requirements. (Refer to 5. Installation and attention)

Attention: The three relatively thick wires are connected respectively to the

phase wire of the three-phase power supply. Do not need to identify the phase

sequence. The relatively thin wire is connected to the welding ground. The

connection must be secure. Be sure not to make any wrong connection.

Otherwise, the equipment would be damaged and human safety be

endangered.

The air switch on the rear panel of the welder is put in closed state ("On"

position), and the power switch in the power board is put in opened state

("Off" position).

Attention: The air switch should be normally closed. When the load is

applied, it is strictly prohibited to pull it to avoid the damage.

Check if the circuit connection is correct and secure and the power

supply of the power grid meets the requirements. Turn on the power switch in

the power board after make sure all connections are correct.

Attention: At this time, the fan runs and the power indicator light is on.

The preset voltage and current value (a minus value) is displayed in the

voltmeter and arnperemeter.

Put the "Gas check" switch to the "Gas check" position and adjust the gas

flow rate. Then, put the "Gas check" switch to the "Welding" position.

Load the wire with the "Inching" button on the operating panel of the wire

feeder.

Attention: The width of the wire groove of the wire-feeding reel should

match with the diameter of the used welding wire. The pressure of the

wire-pressing roller should be adjusted to be just appropriate to dispense

the welding wire.

Attention: The aperture of the contact tip of the welding gun and the wire-

feeding hose should match with the diameter of the used welding wire.

Put the "Wire-selection" switch of the welding power panel to a correct

position, which is the one to match the diameter of the welding wire.

Attention: If the "Wire-selection" switch is put to a incorrect position,

the welding current will not match with the preset value.

The "Function" switch position is incorrect.

When the contact tip is burned or in a poor contact, it is

necessary to replace it to avoid affecting the welding stability.

When the diverter or nozzle of the welding gun is damaged, it is

necessary to replace it to avoid affecting the gas shielding effect.

When the wire-feeding hose of the welding gun is blocked, it is

necessary to replace or clean it to avoid affecting the welding stability.

7.2 Welding

When perform the gas-shielded welding, turn the adjustment knob of

the welding voltage and current to the desired value according to process

requirement (The minus value displayed in the ampere meter and voltmeter

is the present value, and the plus value is the actual output value. The

preset voltage value is actual output value and the preset current value is

percent of the wire-feeding speed. The maximum value is 100%).

When the arc-receiving specification is required, it is necessary to

put the "Arc-receiving On/Off" switch in the welding power panel to the

"On" position, and turn the adjustment knob of the arc-receiving voltage and

current to the desired value.

Attention: When the "Arc-receiving On/Off' switch is put to the "Off"

position, press and hold the switch of the welding gun to start the

welding, and release it to stop the welding.

When the "Arc-receiving On/Off' switch is put to the "On"

position, press the switch of the welding gun to start the welding. Press

the switch again and hold it to enter arc-receiving state, and release it

to stop the welding.

When make sure the arc-welding rectifier can function properly after

adjustment, you can use and operate the welder according to your desired

welding process requirements and methods.

When perform the manual welding, turn the arc-receiving current knob in

the welder panel to preset the output current. The actual output current is

the maximum output current of the welder multiplied by your preset

percent.

7.3 Shutdown

When complete the welding and need to turn the welder off, put

the power switch in the power board to the "Off" position.

8. Maintenance and troubleshooting

8.1 Maintenance

After the arc-welding rectifier is used for a period of time, it is necessary to

remove dust and dirt in the equipment with the dry compressed air or in

other way to ensure the arc-welding rectifier functions properly for a long

time, and prolong its service life.

Check the fasteners and connections in the equipment to see if any is loose

or broken. If yes, it is necessary to correct it in time.

Attention:

* Be sure to cut off the power supply of the arc-welding rectifier

when remove dust and dirt.

* Do not fiddle with the connections in the equipment

when

remove dust and dirt to avoid damaging the component.

Check the grounding of the case of the arc-welding rectifier at all times to

avoid an electric shock.

Check if the arc-welding rectifier is securely connected with the three-

phase power supply of the power grid at all times to avoid the arc-welding

rectifier functioning improperly or the local area of the joint being heated

and damaged.

Check if the external bolts of the arc-welding rectifier is secured at all times

to avoid the arc-welding rectifier functioning improperly or the local area of

the joint being heated and damaged.

Clean the wire feeder at all times to keep it clean and well insulated.

Make sure no foreign substance exists in the wire groove of the wire-feeding

reel to ensure smooth wire feeding.

Clean the wire-feeding hose of the welding gun at all times to ensure its

smoothness and intactness.

8.2 Troubleshooting

8.2.1 Make the following checks first when the arc-welding rectifier functions

improperly:

Is the three-phase supply voltage between 340V~420V?

Does the three-phase power supply have a phase lacking fault?

Is the input power cable of the arc-welding rectifier securely connected?

Is the output power cable of the arc-welding rectifier correctly connected

and in a good contact?

Is any component burned, or any connection broken or loose in the

equipment?

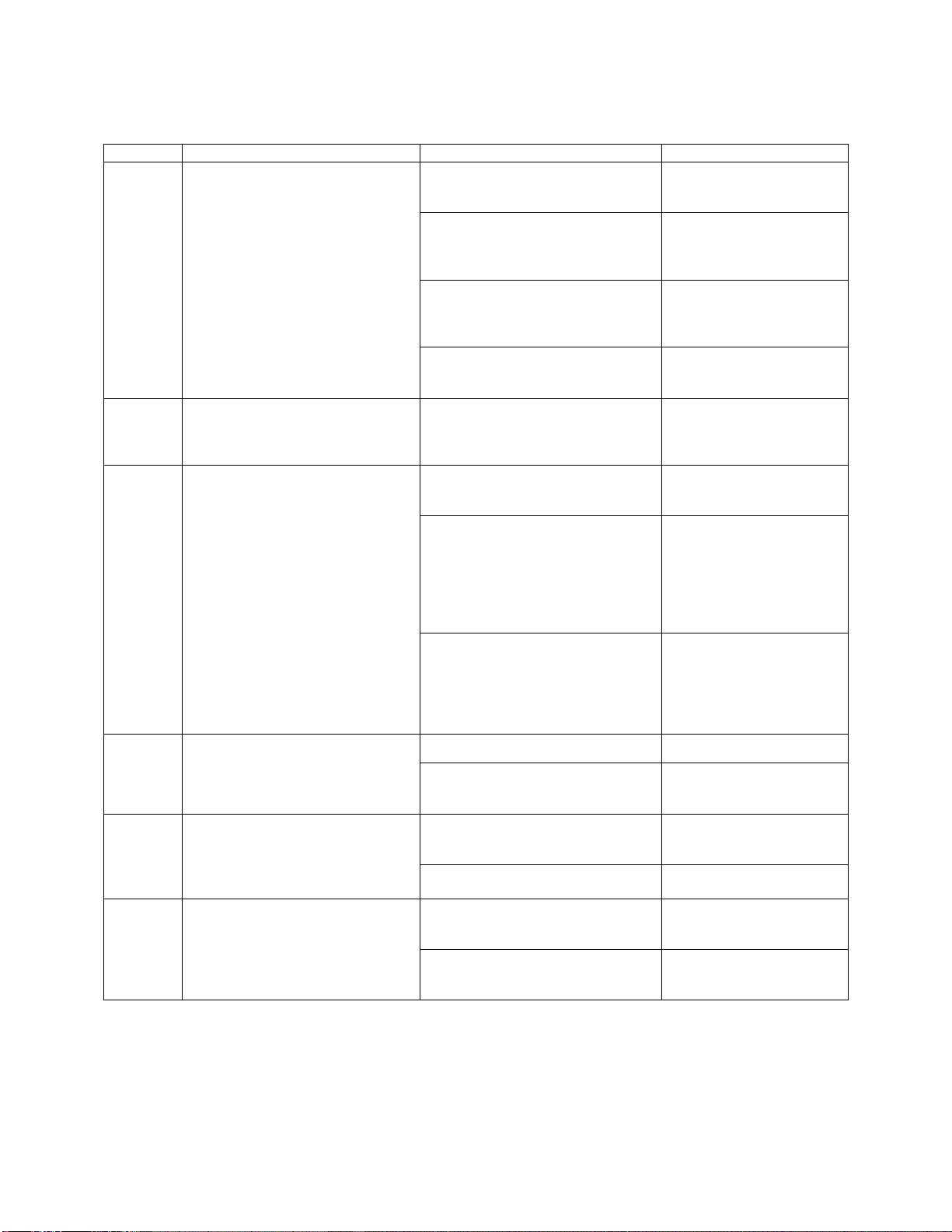

Table 3: Troubleshooting

No.

Trouble

Reason

Remedy

1

The power indicator

light is not on and the

fan doesn't run. There

is no display in the

voltmeter and

amperemeter.

The external power

supply has a phase-

lacking fault

Check the three-

phase power

supply circuit

The automatic air

switch is unclosed or

damaged

Close the

automatic air

switch or replace

it

The input connection

is

broken

Check the

connection or

replace the

damaged part

The control

transformer is

damaged

Replace the

transformer

2

The fan doesn't run

The fan or the fan

capacitor is damaged,

or the related

connection has a fault

Replace the

damaged part, or

check the

connection

3

The protection

indicator light is not

on and the welder

doesn't work

The control board has

a fault. The part is

damaged

Please contact

with our

company

The voltage of the

power grid is too high.

The arc-welding

rectifier is in automatic

protection state.

It will resume

work

automatically

after the voltage

of the power grid

returns to

normal

Internal temperature of

the arc-welding

rectifier is too high, the

arc-welding rectifier is

in automatic protection

state

Ventilate the arc-

welding rectifier

for a while. It will

resume work

automatically

4

The heater doesn't

work

The fuse is burned

Replace the fuse

The heater is damaged

Replace the

heater or the gas

adjuster

5

The wire feeder doesn't

work

properly

The control cable is

broken or in a poor

contact

Check the

connection

The main control board

has a fault

Replace the main

control board

6

The air switch trips

The component is

damaged

Please contact

with our

company

The automatic air

switch is damaged

Replace the

automatic air

switch

Attention:

" Turn the equipment off immediately if any other fault occurs

and can't be corrected, and give notice to our company or the local

vendor as soon as possible. Be sure not to repair it on your own to

avoid worsening the problem and causing unnecessary loss.

* When give notice to our company, please describe the problem as

detailed as possible so that you problem can be handled in time.

9. Possible problems during the welding process

The problems listed here are related to the fittings, welding materials,

environmental factors, and power supply. Please try to improve the

environment and avoid the problems occurring.

A. Difficult in arc starting and prone to arc breaking:

1)

Check

if the welding ground clamp and the workpiece are in a good contact.

2)

Check if all the joints are in a good contact.

B. The output current can't reach the rated value:

The supply voltage diverges from the rated value so that the output current

value is not the same as the preset value. When the supply voltage is lower than

the rated value, the maximum output current of the welder is likely to be

lower than the rated value.

C. During the welding process, the current can't be kept stable:

The problem may be related to the following factors:

1) The voltage of the power grid has changed.

2) There is severe interference from the power grid or other electric

equipment.

D Gas holes exist in the welding lines.

1) Check if gas leakage exists in the gas supply loop.

2) Check if any foreign substance such as oil, dirt, rust, or paint exists in the

surface of the base material.

10. Daily check

Daily check is very important in making full use of the welder's

performance and ensuring daily safe operation.

In a daily check, especially see if various parts in the welding gun and wire

feeder are worn away or distorted and if the gas holes are blocked. Check the

following parts one by one. When necessary, clean and replace some parts. Be

sure to replace the parts with Hitronic original ones of the welder to maintain

the original performance.

WARNING: Be sure to cut off the power supply of the switch cabinet and ensure

the safety before make a daily check unless there is a special demand. Failure to

following the above rule may cause a severe human accident such as electric

shock or burn.

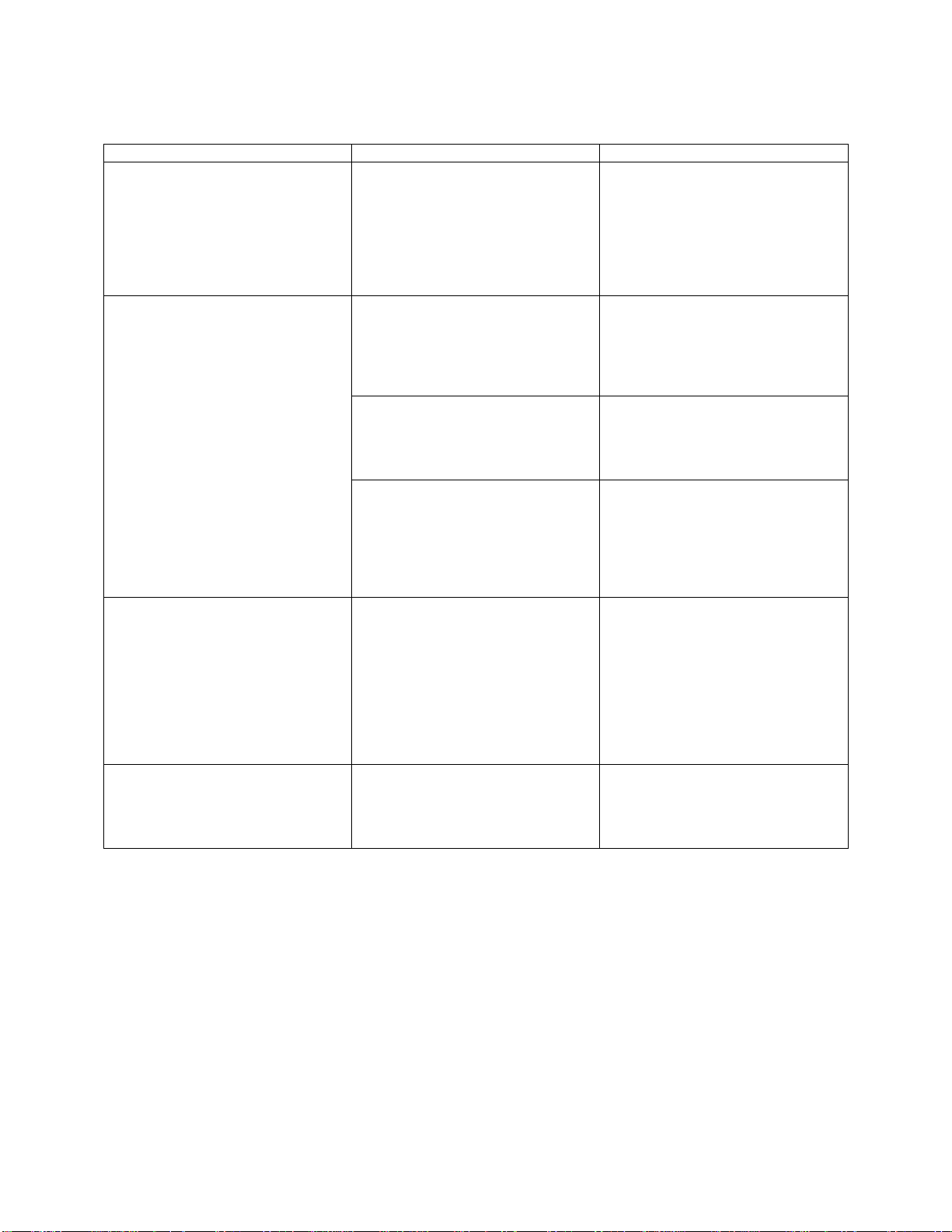

10. I Welding power source

Part

Check point

Remarks

Operating control panel

1. Check the operation,

switching, and

installation of the

switches.

2. Check if the power

indicator light turns

on/off correctly.

Cooling fan

1. Check if there is a

current of air the air

and the sound is

normal

If the running sound is

unheard or abnormal, it is

necessary to check the

inside.

Power section

1. When the power

supply is turned on,

check if there is any

abnormal vibration or

buzz.

2. When the power

supply is turned on,

check if there is any

peculiar smell.

3. Check if there is any

external color change

or heating sign.

Peripheral

1. Is the gas supply loop

damaged, or the joint

loose?

2. Is the case or other

fastened part loose?

10.2Welding gun

Part

Check point

Remarks

Nozzle

1. Is it securely

mounted? Is its

front end distorted?

It is the reason to cause

gas holes

2. Is it stuck with the

splashing?

It is the reason to cause

the welding gun to be

damaged (using anti-

splash agent is a useful

way to avoid it occurring)

Contact tip

1. Is it securely

mounted?

It is the reason to cause

the screw thread of the

welding gun to . be

damaged

2. Is the tip damaged,

or the hole worn

away or blocked?

It is the reason to cause

unstable arc or arc

breaking

Wire-feeding hose

1. Measure the

extension length of

the

wire-feeding hose.

Replace the wire-feeding

hose when the length is

less than 6mm. A too

small length would cause

unstable arc (it is better to

use a new one with the

extension length slightly

longer than the specified

one)

2. Does the diameter

of the welding wire

match the inner

diameter of the

wire-feeding hose?

The mismatch is the

reason to cause unstable

arc. Replace the welding

wire hose with a suitable

hose.

3. Local bending and

elongation

It is the reason to cause

poor wire feeding and

unstable arc. Replace the

wire-feeding hose.

4. Blocked by dirt and

welding-wire

residue

It can cause poor wire

feeding and unstable

arc(wipe it with kerosene

or replace it with a new

wire-feeding hose)

5. The wire-feeding

hose is damaged.

The “O” shaped ring

is worn away.

It can cause splashing:

1. The heat-

shrinkable tube is

damaged. Replace it

with a new one.

2. Replace the worn

ring with a new

one.

Gas diverter

Forgot to insert it, or the

hole is blocked, or the

component of other

manufactures is used.

It can cause the welding

defect (splashing) or the

burn of the welding gun

body(the arc in the gun

body) due to poor gas

shielding, please handle

the problem correctly.

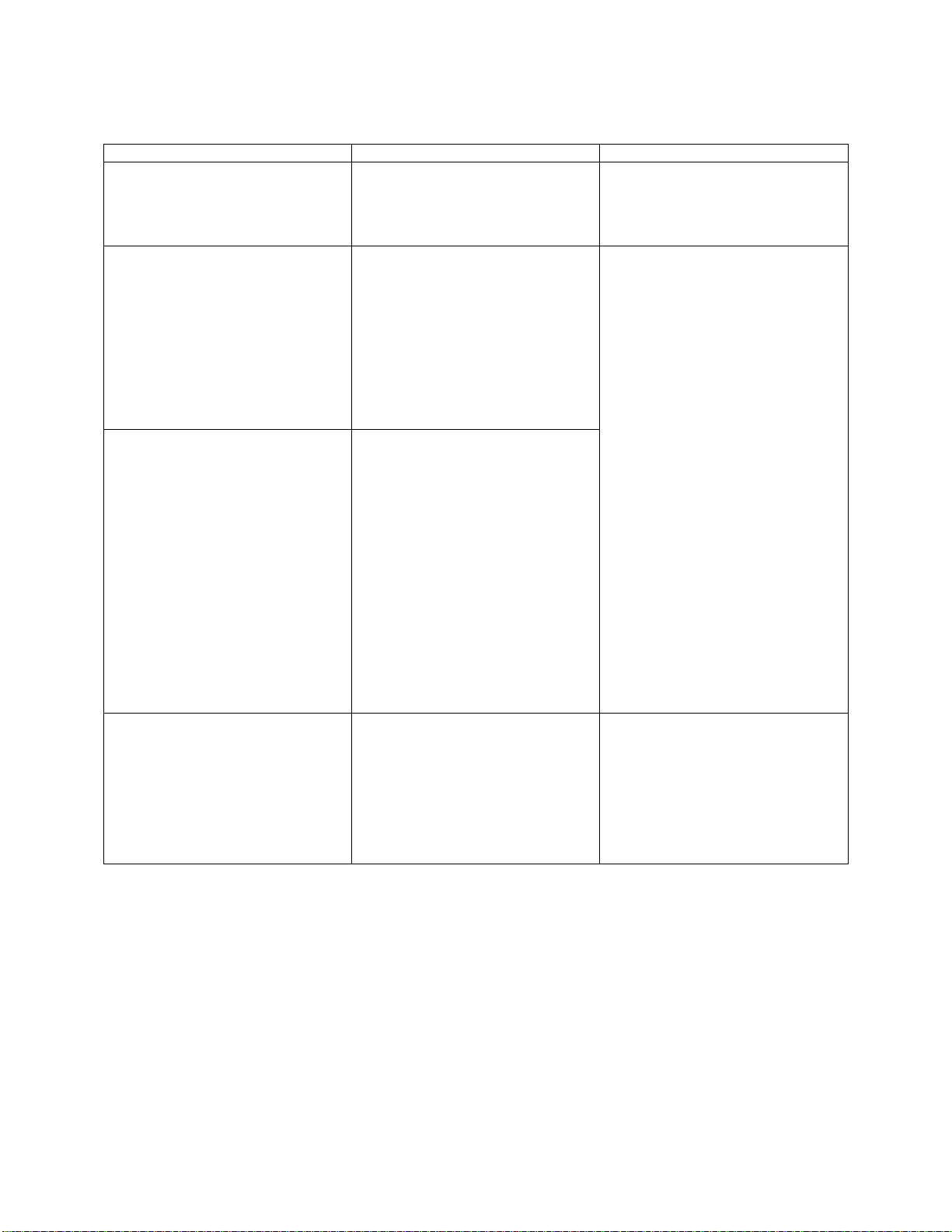

10.3 Wire feeder

Part

Check point

Remarks

Pressing handle

Is the pressing handle

adjusted to an

appropriate pressure-

applied indicator line?

(Special attention : it is

strictly prohibited to damage

the welding wire under

1.2mm)

It will cause unstable wire

feeding and arc.

Wire-guide tube

1. is the cut powder

and scrap

accumulated in the

end of the wire-guide

tube and the rim of

wire-feeding reel?

Clean the cut powder and

scrap. Check the reason and

correct the problem

thoroughly.

2. Does the diameter of

the welding wire

match the inner

diameter of the wire-

guide tube?

The mismatch would cause

unstable arc, or the cut

powder and scrap.

3. Check if the end

center of the wire-

guide tube is aligned

with the groove

center of the wire-

feeding reel (visual

inspection).

The misalignment would

cause the cut powder and

unstable arc.

Wire-feeding reel

1. Does the diameter of

the welding wire

match the nominal

diameter of the wire-

feeding reel?

2. Check if the groove of

the wire- feeding reel

is blocked.

1. It would cause the

welding wire to

produce the cut

powder, the wire-

feeding hose to be

blocked, and the arc

to be unstable.

2. Replace it with a new

one if any

abnormality occurs.

Pressing wheel

Check the running stability.

Check if the pressure-

applied side of the welding

wire is worn away and the

contact side is narrowed.

It would cause poor wire

feeding and unstable arc.

10.4 Cables

Part

Check point

Remarks

Cable of the welding gun

1. Is the cable of the

welding gun over-

bended?

2. Is the metal joint of

the fast plug loose?

It would cause poor wire

feeding.

The over-bended cable

would cause unstable arc.

Output cable

1. The cable insulation

is worn away and

damaged

2. The cable joint is

exposed (the

insulation is

damaged) and loose.

(the welded area of the

power terminal, and the

joint of the base material

and the cable)

In order to ensure human

safety and stable welding,

please use appropriate

check methods according to

the working site.

Daily check General

and simple

Regular check

Thorough and

detailed

Input cable

1. Is the input and

output terminal of

the input protection

device of the switch

cabinet securely

connected?

2. Is the safety device

securely connected?

3. Is the cable in the

input terminal of the

welding power source

securely connected.

4. Is the input cable

exposed as its

insulation is worn

away or damaged

during the wiring.

Grounding cable

1. Is the grounding

cable of the welding

power source

broken? Is it securely

connected?

2. Is the grounding

cable of the base

material broken. Is it

securely connected?

Be sure to make daily check

in order to prevent the

current leakage and ensure

the safety.

Early diagnosis of abnormalities

Even if an abnormality happens, for example, the welding can't be conducted, the arc is

unstable, or the welding effect is not good, do not make a judgment too early that the welder

has a fault.

Even when the welder works normally, the above mentioned abnormalities may occur due to

some problems far from faults, for example, fastener loosening, forgetting to turn a switch

on/off, incorrect setting, cable breaking, and gas hose cracking. Therefore, please try to

make a check before make a fault determination and send the welder for repair. Quite a few

problems can be readily solved.

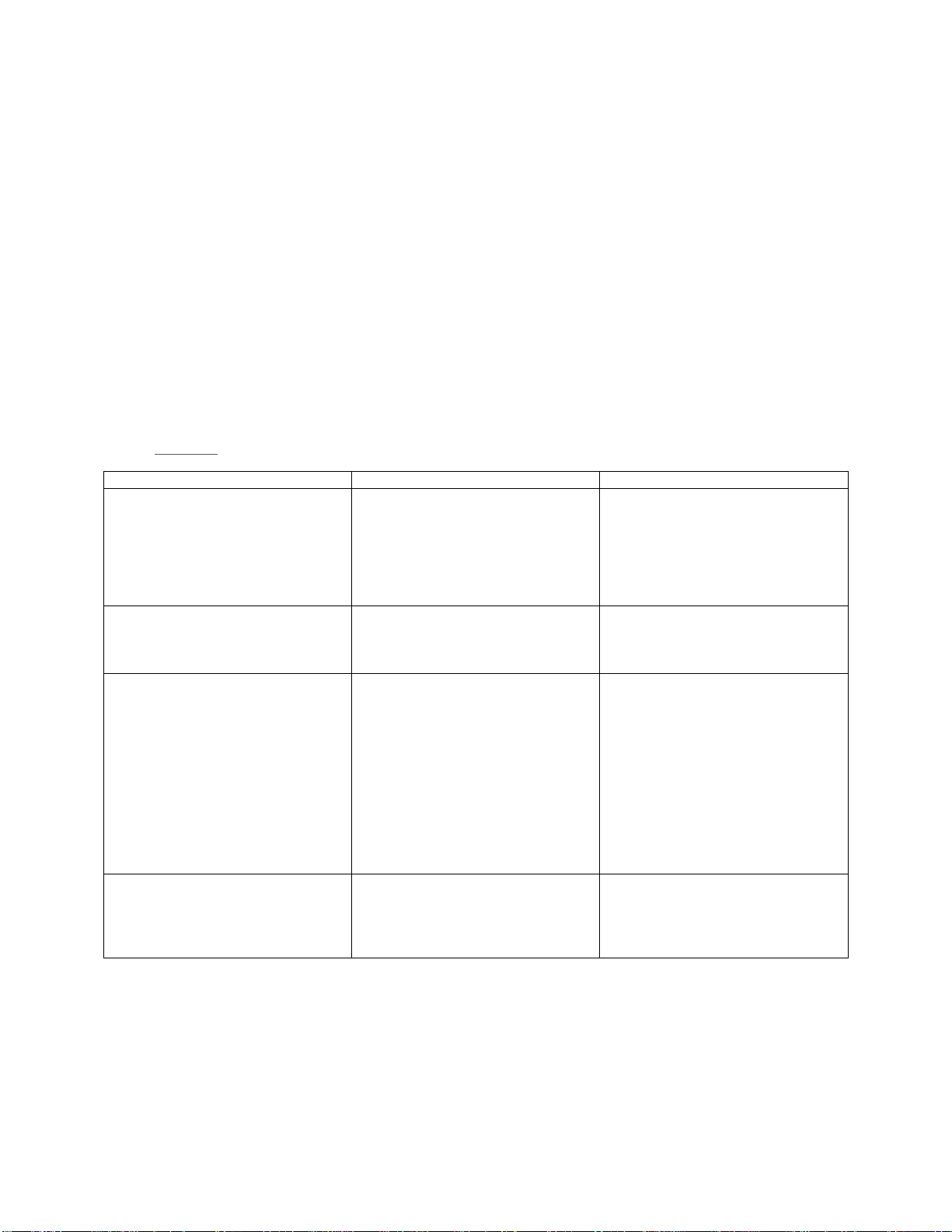

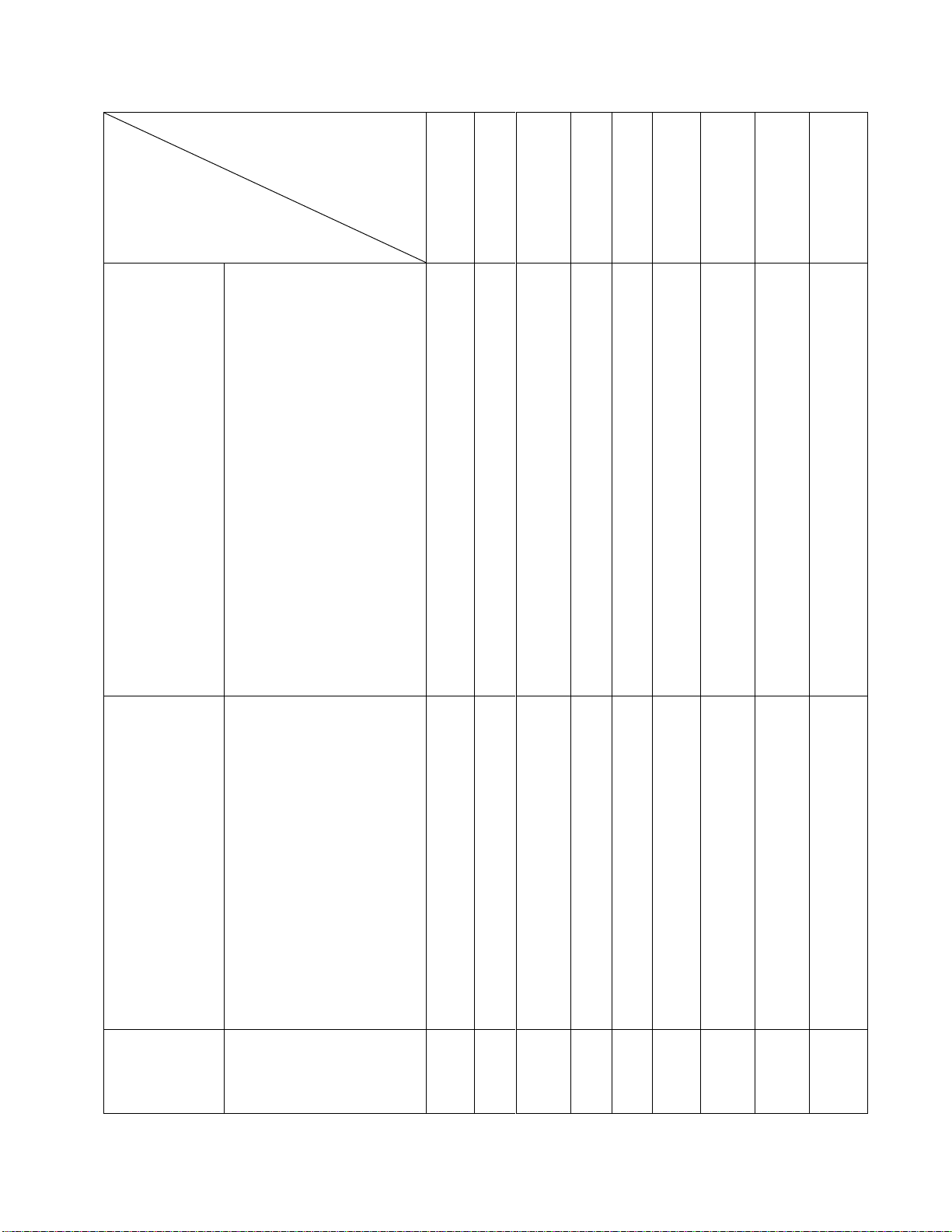

The following are early diagnosis tables of common welding

abnormalities. Find the problem in the abnormality columns in the

upper right corner of the table. If there is a "0" under the problem,

please make a check and maintenance according to related items in the

table.

Early diagnosis of welding abnormalities (1)

Abnormalities

Check parts and items

The arc can’t

be struck

No gas flows

out

No welding

wire goes out

Poor arc

starting

Unstable arc

Unclean rim

of the welded

lines

Welding wire

stuck to the

base

Welding wire

stuck to the

Gas holes are

produced

Switch

cabinet

(input

protection

device)

1. Is it

connected?

2. Is the fuse

burned?

3. Is the joint

loose?

O

O

O

O

O

O

Input

cable

1. Is the cable

broken?

2. Is the joint

loose?

3. Is there

heating sign?

O

O

O

O

Operation

of the

welding

power

source

1. Is the switch

turned on?

2. Is there a

phase-lacking

fault?

O

O

O

O

O

O

O

O

Gas

cylinder

and gas

adjuster

1. Is the lid of

the cylinder

opened?

2. Check the

remaining

quantity of

the gas

3. Check the set

value of the

flow rate

4. Is the joint is

loose?

O

O

Gas

supply

hose (the

full path

from the

high

pressure

gas

cylinder

to the

welding

gun)

1. Is the joint

loose?

2. Is the gas

hose

damaged?

O

Abnormalities

Check parts and items

The arc can’t

be struck

No gas flows

out

No welding

wire goes out

Poor arc

starting

Unstable arc

Unclean rim

of the welded

lines

Welding wire

stuck to the

base

Welding wire

stuck to the

Gas holes are

produced

Wire

feeder

1. Does the

diameter of

wire-feeding

reel match

that of the

wire-guide

tube?

2. Is the wire-

feeding reel

cracked, or

the groove

blocked?

3. Is the

pressing

handle too

tight or

loose?

4. Is the cut

powder of

the welding

wire

accumulated

in the

entrance of

the SUS

tube?

O

O

O

O

O

Welding

gun and

its cable

1. Is the power

cable of the

welding gun

folded and

over-bended

2. Is the

diameter of

the contact

tip, wire-

feeding hose,

and welding

wire

matched?

Are the

contact tip

and wire-

feeding hose

worn away,

blocked, or

distorted?

O

O

O

O

Body of

the

welding

gun

1. Are the

contact

tip,nozzle,

and nozzle

connector

O

O

loose?

2. Is the body

connector of

the welding

gun properly

inserted and

fastended?

The power

cable of

the

welding

gun and

the switch

control

cable

Broken (bending

fatigue)

Damaged by a

heavy object

O

O

O

O

O

The

surface

condition

of the

base

material

and the

extension

of the

welding

wire

There is oil, dirty,

rust, and or paint

membrane on it.

The welding wire is

over-extended

O

O

O

O

O

Output

cable

The cross-

sectional area of

the cable

connected to the

base material is

insufficient.

The joint of the (+)

and (-) output

cable is loose.

The electrical

conductivity of the

base material is

poor.

O

O

O

Extended

cable

The cross-

sectional area of

the cable is

insufficient

The cable is folded

or over-bended

O

O

O

O

Welding

operating

conditions

Check the welding

current and

voltage, the angle

of the welding gun,

the welding speed,

and the extension

length of the

welding wire once

again

O

O

O

O

O

This manual suits for next models

2

Table of contents

Other Soham Impex Welding System manuals