Soham Impex SI-TIG-300 User manual

AC/DC GTAW WELDING MACHINE

MANUAL

Vavdi Survey no. 28, Shivam Industrial Area, Street No.3 Plot No.7, Near Sunny Raj Metal,

OPERATING MANUAL

AC/DC GTAW WELDING MACHINE

MODEL : SI -TIG - 300

Works :- Soham Impex,

Vavadi survey no.28, Plot no.7, Near Sunny Raj Metal, Rajkot City,

Gujarat –360004

AC/DC GTAW

WELDING MACHINE

CONTENTS

1. INTRODUCTION OF TIG WELDING MACHINE........................................................................................ 1

2. SAFETY INSTRUCTIONS......................................................................................................................... 3

3. INSTALLATION & COMMISSIONING OF AC/DC TIG WELDING MACHINE.............................................8

4. OPERATING INSTRUCTION..................................................................................................................13

5. COMPONENT DETAILS OFWELDING PLANT ..................................................................................... 15

6. WELDING PARAMETER SELECTION AND SETTING [FRONT PANEL]................................................ 16

7. MAINTENANCE......................................................................................................................................21

8. TROUBLE SHOOTING .......................................................................................................................... 24

9. TIG WELDING TORCH DETAILS........................................................................................................... 28

10. ARGON FLOWMETER REGULATOR DETAILS .....................................................................................30

11. WATER COOLING UNIT DETAILS .........................................................................................................32

12. TECHNICAL SPECIFICATION OF MACHINE......................................................................................... 34

13. BASIC WELDING TECHNIQUE ..............................................................................................................37

[1]

This series of power sources apply IGBT soft switch inverter technology. Its internal control system

applies digital signal processor which ensures quick response to any change during the welding

process so as to achieve precise control of welding process and ensure optimal welding results.

Power source features

This series of power sources are microprocessor controlled and apply MCU + DSP control technology

to improve the control precision. The strong ability of arc self-adjustment ensures a highly stable

welding current against grid fluctuation and arc length change to get optimal results.

Highlights as follows:

- User friendly interface, synergic, easily control;

- Embedded welding expert database, automatic intelligent combination of parameters

- To achieve beautiful ripple pattern of welding seam with the function of Pulse TIG

- Perfect functions of starting arc and reducing melting ball while stopping arc

- Special 4-step mode is suitable for welding metal with good thermal conductivity, with

perfect welding quality when starting arc and stopping arc

- Multiple protection functions

- TIG torch with quick and convenient adjustment of welding current at Torch handle

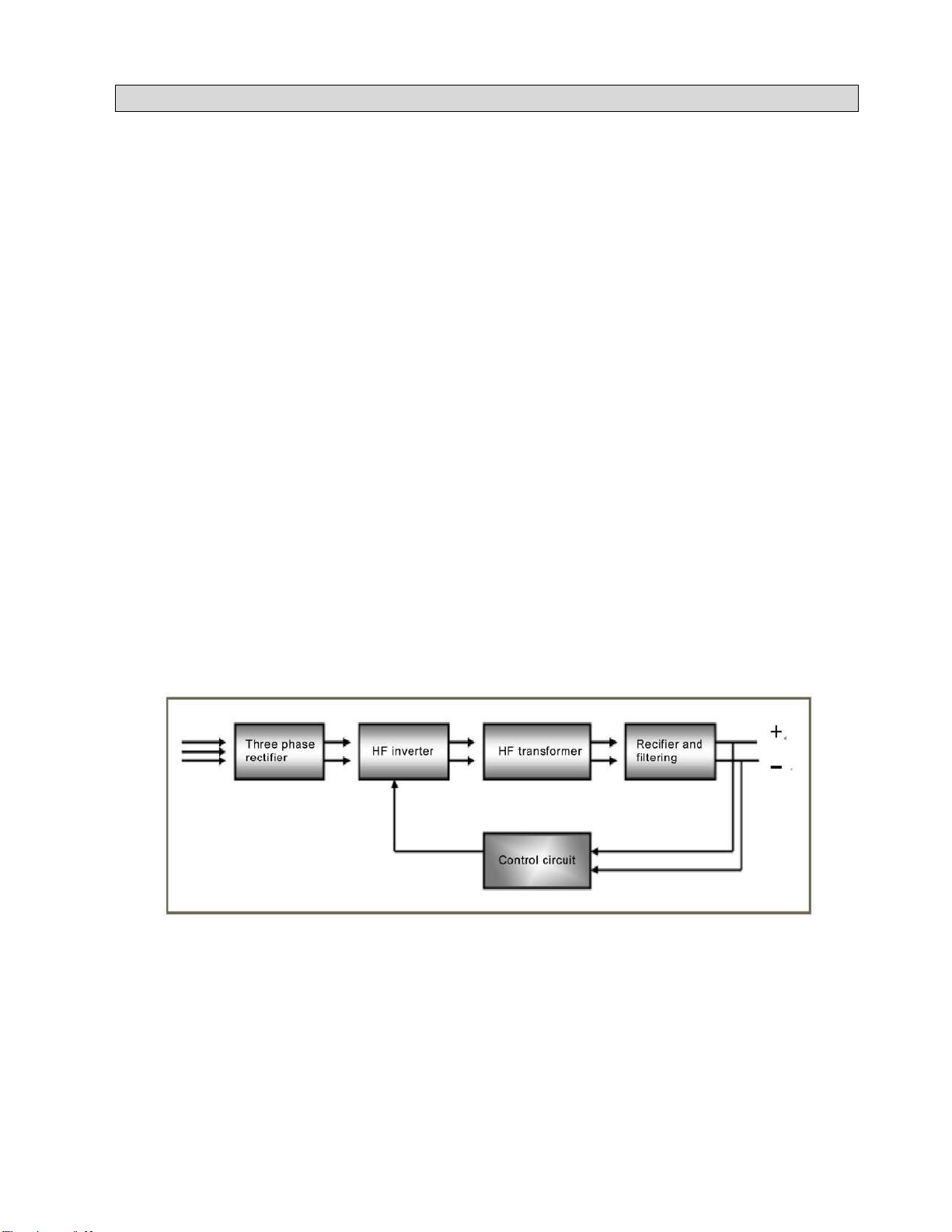

Functional principle

This series of power sources adopt IGBT soft switch inverter technology to improve the dynamic

response rate and make the machines with small size and light weight. The control circuit's closed-loop

control makes the power source enjoy strong ability against power grid fluctuation and perfect welding

performance. The schematic diagram is as shown in Fig. 1-2-1:

Schematic diagram

1. Introduction of GTAW welding machine

[2]

Note!

Exceeding duty cycle can damage the machine and greatly reduce its lifespan

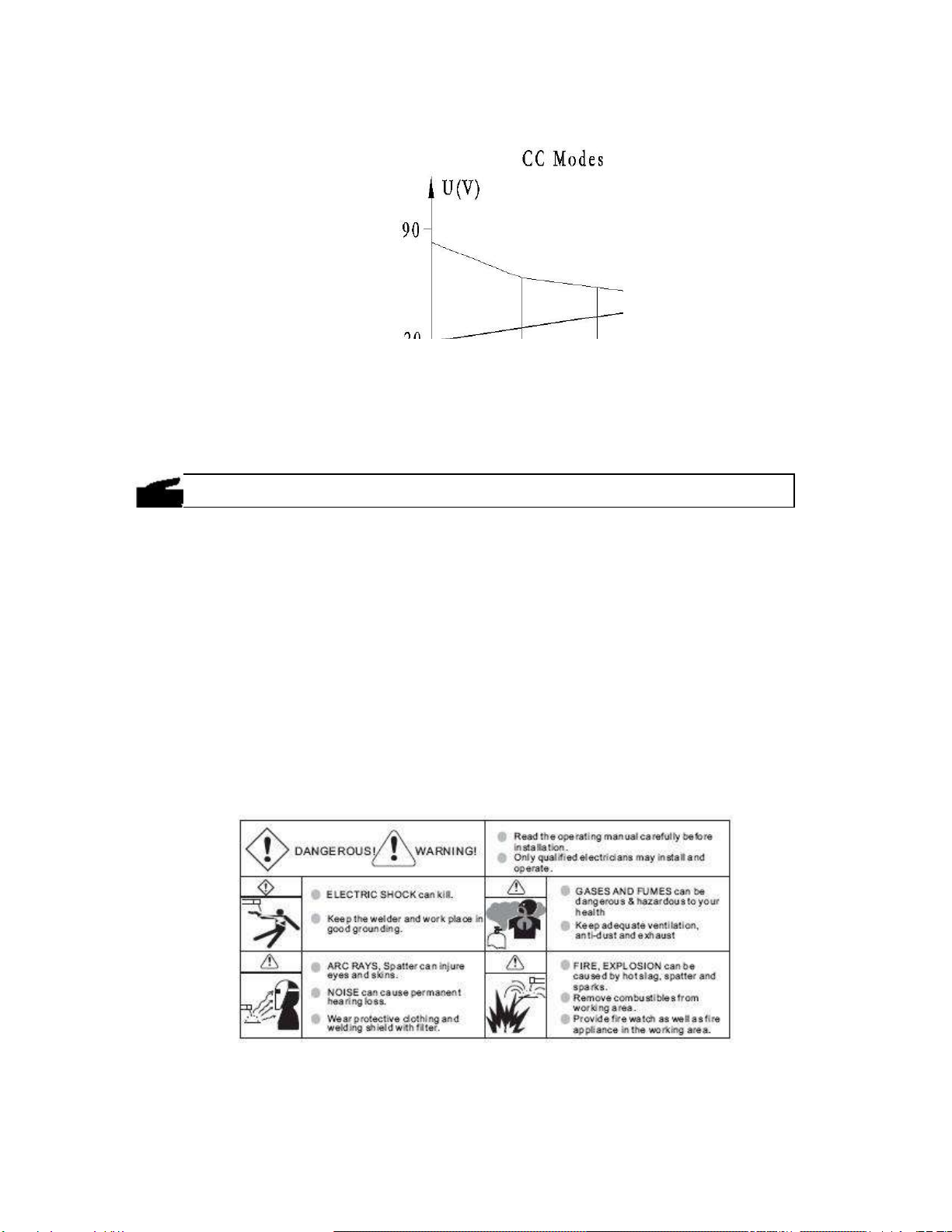

Output characteristics

Output characteristics

Duty cycle

Duty cycle is percentage of 10 minutes that a machine can weld at rated load without overheating. If

overheats, thermostat(s) will open, output stops. Wait for fifteen minutes for the machine to cool down.

Reduce amperage or duty cycle before welding.

Applications

This series of machines have many welding processes and can weld most of the metal materials,

including carbon steel, stainless steel, aluminum and Al-Mg alloy, copper and alloy, etc.

Recommended areas of use as follows:

- Automobile and car manufacture industry

- Chemicalstructure andengineering

- Boiler pressurevesselmanufacture

- Shipbuilding and offshore engineering

- Electric power construction

- Vehicle manufacturing

- Mechanical industry

- Other industries

Warning

Warning

[3]

Danger! “Danger”

indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Warning! “Warning!”

indicates a possible hazardous situation which, if not

avoided, could result in death or serious injury. The possible

hazards are explained in the text.

Caution! “Caution”

indicates a possible hazardous situation which, if not

avoided, may result in slight or moderate injury.

Note! “Note!”

indicates a situation which implies a risk of impaired

welding result and damage to the equipment.

Important! “Important!”

indicates practical tips and other useful

special-message. It is no signal word for a harmful or dangerous

situation.

Utilization for

intended

purpose only

•

The machine may only be used for jobs as defined by the

―Intended purpose‖.

•

Utilisation for any other purpose, or in any other manner, shall be

deemed to be ―not in accordance with the intended purpose‖. The

manufacturer shall not be liable for any damage resulting from

such improper use.

Safety signs

•

All the safety instructions and danger warnings on the machine

must be kept in legible condition, not removed, not be covered,

pasted or painted cover.

Safety

inspection

•

The owner/operator is obliged to perform safety inspection at

regular intervals.

•

The manufacturer also recommends every 3-6 months for regular

maintenance of power sources.

Electric

shock cankill

•

Touching live electrical parts can cause fatal shocks or severe

burns. The electrode and work circuit is electrically live whenever

the output is on. The input power circuit and machine internal

circuits are also live when power is on. In MIG/MAG welding, the

wire, drive rollers, wire feed housing and all metal parts touching

the welding wire are electrically live. Incorrectly installed or

improperly grounded equipment is a hazard.

•

Do not touch live electrical parts of the welding circuit, electrodes

and wires with your bare skin or wet clothing.

2. Safety Instructions

[4]

and body protection while performs the welding.

•

Insulate yourself from work and ground using dry insulating

protection which is large enough to prevent you full area of

physical contact with the work or ground.

•

Connect the primary input cable according to rules. Disconnect

input power or stop machine before installing or maintenance.

•

If welding must be performed under electrically hazardous

conditions as follow: indamp locations or wearing wet clothing; on

metal structures such as floors, gratings, or scaffolds; when in

cramped positions such as sitting, kneeling, or lying; or in

occasion when there is a high risk of unavoidable or accidental

contact with the work piece or ground. Must use additional safety

precautions: semiautomatic DC constant voltage (wire) welder,

DCmanual (Stick) welder and AC welder with reduced open-load

voltage.

•

Maintain the electrode holder, ground clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged part immediately.

Electric and

magnetic

fields (EMF)

may be

dangerous

•

If electromagnetic interference is found to be occurring, the

operator is obliged to examine any possible electromagnetic

problems that may occur on equipment as follow:

-

minas, signal and data-transmission leads

-

IT and telecoms equipment

-

measurement and calibration devices

-

Wearers of pacemakers

•

Measures for minimizing or preventing EMC problems:

-

Mains supply

If electromagnetic interference still occurs, despite the fact that

the mains connection in accordance with the regulations,

take additional measures

-

Welding cables

Keep these as short as possible

Connect the work cable to the work piece as close as possible to the

area being welded.

Lay tem well away from other cables.

Do not place your body between your electrode and work cables.

-

Equipotential bonding

-

Work piece grounding (earthing)

-

Shielding

Shield the entire welding equipment and other equipment nearby.

ARC rays can

burn.

•

Visible and invisible rays can burn eyes and skin.

•

Wear an approved welding helmet or suitable clothing made from

durable flame-resistant material (leather, heavy cotton, or wool) to

[5]

protect your eyes and skin from arc rays and sparks when welding

or watching.

•

Use protective screens or barriers to protect other nearby

personnel with suitable, non-flammable screening and/or warn

them not to watch the arc nor expose themselves to the arc rays

or to hot spatter or material.

Fumes and

gases can be

dangerous

•

Welding may produce fumes and gases, breathing these fumes

and gases can be hazardous to your health.

•

When welding, keep your head out of the fume. If inside, ventilate

the area at the arc to keep fumes and gases away from the

breathing zone. If ventilation is not good, wear an approved

air-supplied respirator.

•

Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator.

•

Welding fumes and gases can displace air and lower the oxygen

level causing injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

Welding and

cutting

sparks can

cause fire or

explosion

.

•

When not welding, make sure the electrode circuit is not touching

the work or ground. Accidental contact can cause sparks,

explosion, overheating, or fire. Make sure the area is safe before

doing any welding.

•

Welding and cutting on closed containers, such as tanks, drums,

or containers, can cause them to blow up. Make sure proper steps

have been taken.

•

When pressure gas is used at the work site, special precautions

are required to prevent hazardous situations.

•

Connect work cable to the work as close to the welding zone as

practical to prevent welding current from passing too long and

creating fire hazards or overheat.

•

Wear oil-free protective garments such as leather gloves, heavy

shirt, cuffless trousers, high shoes, and a cap. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

•

Be attention that welding sparks and hot materials from welding

can easily go through small cracks and openings to adjacent

areas and start a fire. Remove fire hazardous from the welding

area, if not possible, cover them thoroughly. Do not weld where

flying sparks can strike flammable material and where the

atmosphere may contain flammable dust, gas, or liquid vapors

(such as gasoline).

•

Protect yourself and others from flying sparks and hot metal.

Remove any combustibles from operator before perform any

welding.

[6]

•

Keep a fire extinguisher readily available.

•

Empty containers, tanks, drums, or pipes which have

combustibles before perform welding.

•

Apply correct fuses or circuit breakers. Do not Remove stick

electrode from electrode holder or cut off welding wire at contact

tip when not in use.

•

Oversize or bypass them.

Cylinder can

explode if

damaged.

•

Pressure gas cylinders contain gas under high pressure. If

damaged, a cylinder can explode. Since gas cylinders are

normally part of the welding process, be sure to treat them

carefully.

•

Cylinders should be located away from areas where they may be

struck or subjected to physical damage. Use proper equipment,

procedures, and sufficient number of persons to lift and move

cylinders.

•

Always install cylinders in an upright position by securing to a

stationary support or cylinder rack to prevent falling over or

tipping.

•

Keep a safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

•

No touching cylinder by welding electrode, electrode holder or

any other electrically ―hot‖ parts. Do not drape welding cables or

welding torches over a gas cylinder.

•

Use only correct compressed gas cylinders, regulators, hoses,

and fittings designed for the process used; maintain them and

associated parts in good condition.

•

Use only compressed gas cylinders containing the correct

shielding gas for the and properly operating regulators designed

for the gas and pressure used. All hoses, fittings, etc. should be

suitable for the application and maintained in good condition.

•

Open the cylinder valve slowly and keep your head and face

away from the cylinder valve outlet.

•

Valve protection caps should be kept in place over valve expect

when the cylinder is in use or connected foruse.

Hot parts can

burn

•

Do not touch hot parts with bare hand or skin.

•

Ensure equipment is cooled down before perform anywork.

•

If touching hot parts is needed, use proper tools and/or wear

heavy, insulated welding gloves and clothing to prevent burns.

Flying metal

or dirt can

injure eyes

•

When welding, chipping, wire brushing, and grinding can cause

sparks and flying metal. It can hurt your eyes.

•

Remember wear appropriate safety glasses with sideshields

when in welding zone, even under your welding helmet.

[7]

Noise can

damage

hearing

Moving parts

can injure

•

Noise from someprocesses or equipment can damage hearing.

•

Remember wear approved ear protection to protect ears if noise

level is high.

•

Stay away from moving parts such as fans.

•

Stay away from pinch points such as drive rolls.

•

Keep all doors, panels, covers, and guards closed and securely in

place.

•

Have only qualified persons remove doors, panels, covers, or

guards for servicing and maintenance.

•

Reinstall doors, panels, covers, or guards when servicing and

maintenance is finished and before reconnecting input power.

Overuse can

cause

overheating

Safety

markings

•

Use machine follow duty cycle. Reduce current or reduce duty

cycle before starting to weld again.

•

Allow cooling period.

•

Do not block or filter airflow to unit.

Equipment with CE-markings fulfils the basic requirements of the

Low-Voltage and Electromagnetic Compatibility Guideline (e.g.

relevant product standards according to EN 60 974).

[8]

Warning!

Operating the equipment incorrectly can cause serious injury and damage. Do not

use the functions described here until you have read and completely understood ―safety

rules‖.

Warning!

Amachine that topples over or falls from its stand can cause injury. Place

equipment on an even, firm floor in such a way that it stands firmly.

Note!

Inadequately dimensioned electrical installations can lead to serious damage. The mains

lead, and its fuse protection, must be dimensioned in accordance with the local power supply.

The technical data shown on the nameplate shall apply.

Utilization for intended purpose only

The power source may only be used for DC TIG , AC TIG , MMA , PULSE DC TIG , PULSE AC TIG

welding . Utilization for other purposes, or in any other manner, shall be deemed to be "not in

accordance with the intended purpose". The manufacturer shall not be liable for anydamage resulting

from such improper use. Operate, inspect and maintain should follow all the instructions given in this

manual.

Machine installation rules

Protection degree of this power source is IP23. However, the internal key components must be

protected from direct soaking.

The venting duct is very important for safety protections. When choosing the machine location, make

sure it is possible for the cooling air to freely enter and exit through the louvers on the front and back of

machine. Any electro conductive metallic dust like drillings must not be allowed to get sucked into the

machine.

Power source connection

- The power source is designed to run on the voltage given on thenameplate.

- The mains cables and plugs must be mounted in accordance with the relevant technical standards.

- The power supply sockets that come with power source are designed to use strictly according to the

marked voltages.

3. INSTALLATION AND COMMISSIONING OF AC/DC GTAW WELDINGMACHINE

[9]

Welding cables instruction

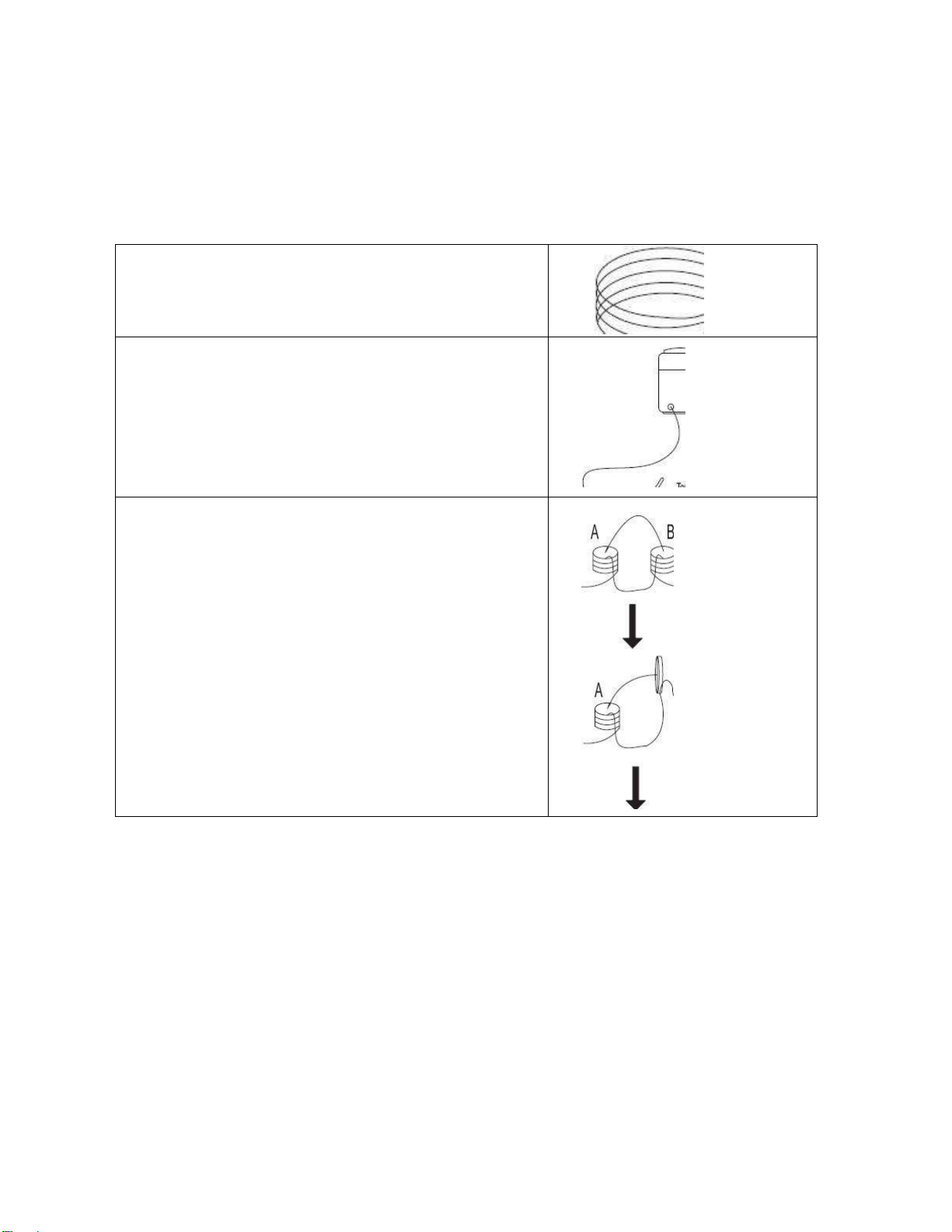

When welding, please pay attention to the followings:

a. The welding cables should be kept as short as possible;

b. If extended cable is used, please do as shown in Fig. 3-4-1.

Wrong

Coil the excess ground cable and welding cable in same

direction respectively.

Correct

Straighten the ground cable and welding cable and make

them close to each other.

Bundle the ground cable and welding cable together,

running the wires close to the ground.

Correct

When the excess cables are only be used by rolling up,

coil the cables to two windings in reverse direction and

overlap them.

The number of turns for A is same as the number for B.

Handle the welding cable and ground cable according to

above-mentioned method.

Welding cables instruction

Connecting to a mains electrical supply

THIS MACHINE IS OF AN INDUSTRIAL SPECIFICATION AND MUST BE FITTED TO A MINIMUM of

16AMP 415V MAINS INPUT

Connecting to an Engine Driven Generator

If connecting this machine to an engine driven generator please ensure the following

Minimum Generator KVA Output –20 KVAcontinuous

Generator to be fitted with AVR (automatic voltage regulation)

DO NOT USE ON A GENERATOR WITHOUTAVR

Connecting to a generator without the above minimum requirements will in-validate your

warranty.

[10]

Commissioning of AC/DC GTAW machine

Back panel machine connections

POWER SOURCE

1.

On/Off Switch

2.

Mains input cable :

Fit required plug as per your electrical installation

3.

Gas Inlet : Input connector

Connect input gas hose ensuring connection is tight . Gas hose

from Flow meter is connected here.

4.

Main chassis earth bolt :

If you experience interference you can fit extra earth to this point

(Not normally used)

[11]

Front panel machine connections

A:- Connections for TIG (GTAW) Welding

1.

Negative power connector -

Connect Tig Torch connector to power connector by inserting and

twisting until tight

ENSURE TIG TORCHIS FITTED TO NEGATIVE CONNECTOR OTHERWISE YOU WILL

EXPERIENCE TUNGSTEN BURNBACK

2.

Positive power connector +

Connect the earth lead to by inserting and twisting until tight and

the earth clamp to work/bench

3.

Gas outlet - Quick release type

Connect the torch gas hose

4.

Torch control socket 7-Pin

Connect torch control plug

5.

FRONT PANEL :

All welding Process and Parameter are SET and Operate operated from

this panel . Its Display will show all values. Details of each buttons and is use is elaborated

in chapter 6

6.

Water Inlet:

Connect water hose from TIG torch : Water input to cool the TIG torch

7.

Water outlet:

Connect water hose from TIG torch : Water Output from the TIG torch

8.

Water Circulating Tank:

Tank with Water Inlet and Wateroutlet

9.

Input Supply cable for water tank:

To make Water Cooling unitON

[12]

B:- Connections for STICK MMA (SMAW) Welding

1.

Negative power connector -

Connect the earth lead to by inserting and twisting until tight and the

earth clamp to work/bench

2.

Positive power connector +

Connect the electrode holder by inserting and twisting until tight

All other front panel connectors are not used for MMA welding

●

Gas cylinder installation

Gas cylinder installation

1. Stand the gas cylinder on the trolley and secure it by fixing the cylinder

strap around a point in the top third of the cylinder-but never around the

neck of the cylinder.

2. Take the protective cap off the gas cylinder.

3. Gently turn the gas-cylinder value anticlockwise, and blow off any dust

and dirt.

4. Screw the pressure regulator onto the gas cylinder and tighten it.

5. Connect the shielding-gas connector to the pressureregulator.

Note :-

To avoid a High Frequency shock keep the Tig torch in good condition and replace if any of

the insulation is damaged.

Connect the gas input hose to gas regulator and use ‗Gas Test ‗ Button to Set gas flow /

pressure to 8-12 LPM. Make sure gas bottle is secured and properly mounted in trolley to

avoid injury.

[13]

Welding in TIG mode –No Pulse –No remote footpedal

1. Connect the Tig Torch to machine, connect earth lead to machine & work piece.

2. Set to Tig mode pulse off

3. Select 2 or 4 way torch operation

4. Connect Argon gas and set flow to approx 8-12LPM

5. Adjust welding amps to desired welding current

6. Press the Tig torch switch to start welding and release to finish

Welding in TIG mode –with Pulse –No remote footpedal

1. Connect the Tig Torch to machine, connect earth lead to machine & work piece.

2. Set to Tig mode pulse on

3. Select 2 or 4 way torch operation

4. Connect Argon gas and set flow to approx 8-12LPM

5. Adjust Pulse freq. to desired setting (how often pulse happens)

6. Adjust base amperage %

7. Adjust pulse width to desired setting (how long pulse happens)

8. Adjust main current for maximum welding current

9. Press the Tig torch switch to start welding

The benefits of pulse welding is the ability to control the weld pool and amount of heat absorbed by

work resulting in a smaller heat affected zone which results in fewer deformations and reduced chance

of cracking. There are no set rules for pulse welding as this is down to personal choice by the welder.

Welding in TIG mode –with Remote amperage torch

1. Connect the Tig Torch to machine, connect earth lead to machine & work piece.

2. Set to Tig mode pulse OFF or Tig mode pulse ON In welding with pulse in remote torch, the foot

pedal controls peak main welding amperage.

3. Select 2T or 4T torch operation –Ensure the PEDAL (remote) LED is illuminated.

4. Connect Argon gas and set flow to approx 8-10LPM

5. Adjust welding amps knob on machine to desired maximum welding current that remote torch will go

to.

7. Press the torch switch to start welding. (on maximum it will go to maximum amps set on machine)

Welding in TIG mode –with Remote foot pedal

1. Connect the Tig Torch to machine, connect earth lead to machine & work piece.

2. Connect remote foot pedal to machine

3. Set to Tig mode pulse off or Tig mode pulse on In welding with pulse in foot pedal, the foot pedal

controls peak main welding amperage

4. Select 2 way torch operation - Foot pedal will not work in 4-WAY mode

5. Connect Argon gas and set flow to approx 8-12LPM

6. Adjust peak current knob on machine to desired maximum welding current that foot pedal will go to.

7. Press the foot pedal to start welding.

4. OPERATING INSTRUCTION

[14]

Note: When welding with remote foot pedal

Upon pressing of foot pedal welding arc will start, if you

find it hard to start arc push pedal down a bit further to aid starting. Press pedal fully to start weld, upon

weld pool formation you can release the pedal to decrease amperage to sustain perfect weld pool and

increase again as required to sustain weld characteristics. The foot pedal adjusts from Start (min)

current to maximum current as set on main current knob on front of machine.

Advantage of Remote current control on Torch switch : No need to vary current while starting as well

as operating TIG welding only if welder need variation then only you need to adjust. Foot switch is

needed always to press and foot pressing can not keep current at always the same level may vary as

foot shakes during welding.

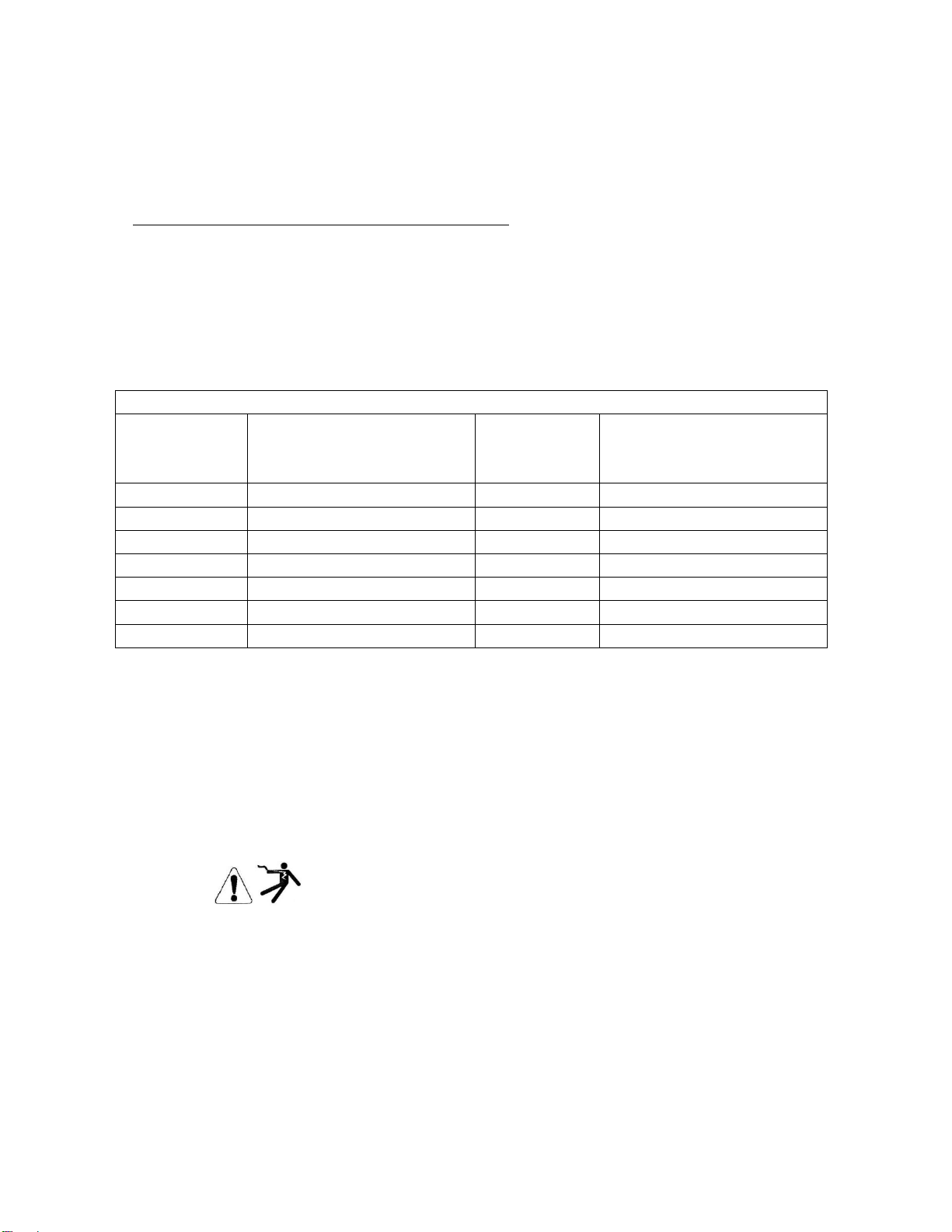

Tig tungsten size / amperage guide

All values below are based on using pure argon shielding gas. Other current values may be employed

depending on the shielding gas and application

ELECTRODE RATINGS

Electrode

Diameter (mm)

2% Thoriated on DC (amps)

Red Tip –Grind to point

Pure

Tungsten on

DC (amps)

Zirconiated 0.8% Tungsten

on AC (amps) White Tip –

No need to grind

1.0mm / 0.040‖

5 - 80

30

20 - 60

1.6mm / 1/16‖

40- 150

80

40 - 100

2.4 mm/ 3/32‖

140 - 250

130

80 - 180

3.2mm / 1/8‖

240 - 400

180

160 - 250

4.0mm / 5/32‖

380- 500

240

220 - 320

4.8mm / 3/16‖

500- 750

300

280 - 390

6.4mm / 1/4‖

750 - 1000

400

360 - 525

Welding in STICK MMA(SMAW) Mode

1. Fit MMA electrode holder to + terminal on machine

2. Fit earth lead to - terminal on machine and to workpiece

3. Select stick on front panel

4. Place electrode in holder

5. Select desired welding current with selector knob

6. Select desired MMA options, Arc Force, Hot start time and Amps

7. Strike arc and weld

WARNING!

ELECTRIC SHOCK CAN KILL

When machine is switched to MMA mode, output terminals are always live, take care and do not touch

electrode and earth by person at same time, otherwise electric shock will occur.

The foot pedal has no affect on welding current in MMA mode and the gas flow and high frequency

starting circuit is disabled.

NOTE:-

Please refer to

Chapter 6 Front Panel

for selecting and setting all parameters For TIG/MMA

welding.

[15]

Welding Plant components

AC/DC GTAW Welding Plant Includes

-

Power source with Inbuilt Water cooling unit

-

TIG Welding torch

-

Argon gas regulator with flow meter and gas hose

-

Welding cable with Electrode Holder

-

Ground Earthling cable with Clamp

-

Standard tool kit for operating plant

Scope of supply by Consignee:

-

Input Supply 3 PHASE , 340 to 460 VAC , 50 Hz

-

Argon gas cylinder (Provided by consignee)

-

Welding material (Electrode /wire)

5. COMPONENT DETAILS OF WELDING PLANT

[16]

1.

Memory store function :

There are memory store programs to enable you to select required parameters for job in hand and then

store to select channel. Press memory button until required program you wish to store is showing in

LED Then enter parameters as required, now press and hold save button for 3 seconds and release,

the green save LED will now light for about 2 seconds and then go out. The parameters have now

been stored. The red select LED will then come back on, if you make any more adjustments these will

not be save until you save again

2.

Save button: to save the parameters on controlpanel

3.

Select :

Parameter selector Button :

Press this button to scroll from left (A) to right (L) to select the

machine parameters an adjust the value of the same within 2 seconds or you have to repeat the

procedure again as LED will move to its initial (D)position.

4.

Parameter Sequence : From A to L as explained below :

A.

Pre-flow gas :

Adjustable from 0 - 25 seconds, this enables the backed up gas pressure to be

released from torch before actual arc is started. Common settings for most application is about .3 to.5

seconds - If welding stainless steel etc sometimes a longer pre-flow is required.

6. WELDING PARAMETER SELECTION AND SETTING [ FRONT PANEL]

[17]

B.

Start Amperage :

This allows you to set the initial start current from 5A DC and 10A AC. In 4T

mode when trigger is pressed and held you will remain at start amps, when you let go machine will then

go to main set amps. Do not set the start amperage too low for tungsten size otherwise you may

experience sluggish / non arc starting. I.E A 3.2mm tungsten is for high range 160+ amps welding, so

you would not need to set start amps at 5. The thicker the tungsten used the higher the start amperage

has to be. We recommend to achieve faster arc starting:-1.0mm Tungsten - 5 Amps minimum1.6mm

Tungsten - 15-20 Amps minimum2.4mm Tungsten - 40 Amps minimum3.2mm Tungsten - 60 Amps

minimum Note:

C.

Up-Slope :

Adjustable from 0 - 25 seconds, This allows you to gradually increase the amperage

from start amps to main amps when using torch trigger operation.

D.

Welding Amps : Main current control :

This adjusts the main welding current and is shown in

L.E.D when welding is in process. Welding range AC is 5A to 300AWelding range DC is 3A to 300A

E.

Pulse Time ON (%) : Pulse width

When pulse welding you have the main (peak) amperage and

base (background)amperage set. By adjusting the width you determine which will be more prominent,

the pulse or the base. This is adjustable from 5-95%. At a low % the base current will be on long so you

will reduce heat input. At a high % the pulse current will be more prominent so you will get increased

heat input..

F.

Pulse Amps (%) :

This sets the base amperage as a % of main amps set. I.E if mains amperage is

120A and you set to 50%, base amps will be 60A.

G.

Pulse Frequency (Hz) Adjustment :

This can be adjusted as follows: DC Mode 0.1 to 500HzAC

Advanced Squarewave 0.1 - 250HzAC Soft Square, Triangular and Sinewave 0.1 - 10HzAdvanced AC

Pulse 0.1 - 10Hz

H.

AC Balance

This sets the % of electrode positive used during AC welding to provide a cleaning

action as alloys have a oxide layer that has a higher melting temperature than the base metal and this

needs to be lifted off. Soyou can control the amount of cleaning or penetration. Too much cleaning will

cause the tungsten to wobble and split, Too little cleaning can result in a dirty dull weld. So as you

increase the % the more cleaning will happen however less penetration will be achieved. For most

situations a setting of 30 - 40% will give you a good clean weld finish, If you go above 50% you will find

the tungsten will overheat and the end can fall of into weld pool. If you find you are getting tungsten

wobble using 30-40% balance then you may need to go up a tungsten size.

I.

AC Frequency

Transformer based welders are normally fixed at 60Hz, due to the advanced inverter

technology you can adjust from 20 - 250Hz.The higher the AC frequency the narrower the arc

becomes allowing you to have a more precise weld bead and penetration. This can also quicken up

travel speed and ideal for production welding. You will hear the pitch of the weld noise get higher, this

is normal. Welding at lower frequency will give reduced control of arc and a wider weld pool.

J.

Down-Slope

Adjustable from 0 - 25 seconds, This allows you to gradually decrease the amperage

from main amps to end/final amps when using torch trigger operation.

Table of contents

Other Soham Impex Welding System manuals

Popular Welding System manuals by other brands

Murex

Murex Tradesmig 280?3 instruction manual

Northern Industrial

Northern Industrial Flux Core 125 Quick setup guide

Cloos

Cloos qineo PULSE MASTER-Plus operating instructions

Oerlikon

Oerlikon CITOLINE 3000T Safety instruction for use and maintenance

STAMOS

STAMOS S-MMA-250PI user manual

GYS

GYS GYSPOT ARCPULL 350 manual

Everlast

Everlast CT416 owner's manual

Lincoln Electric

Lincoln Electric POWER MIG SVM167-A Service manual

Klutch

Klutch MIG 140i owner's manual

Miller Electric

Miller Electric Spectrum 875 Auto-Line owner's manual

Rothenberger

Rothenberger ROWELD P 250 A Instructions for use

Tregaskiss

Tregaskiss TOUGH GUN Technical guide