Solahart atmos air 180 User manual

Operation & Installation Manual

HEAT PUMP

Preface

This manual could be subject to change without prior notice, if it is felt that product

improvements are to be carried out.

When installing the hot water cylinder, please follow the Instructions as documented in this manual.

A maintenance programme must be carried out as recommended in this manual.

Fail to comply with these recommendations will invalidate the warranty.

It is important that the installation and operational instructions laid out in this manual are

strictly adhered to.

This manual includes all the necessary information regarding the installation and

maintenance of this product. Please take the time to read it through before operating.

Once the installation is complete, check that all connections are secure before the power is turned

On.

The installer is to explain to the end user how to operate and maintain the unit in accordance to this

instruction manual.

Content

Content

1. Safety Precautions

1

2. Specifications

3

2.1) appearance

3

2.2) characteristic

3

2.3) principle

4

2.4) dimensions

5

2.5) performance parameter

6

3. Function presentation

7

4. Installation

8

4.1) pipeline connection sketch

8

4.2) transportation

9

4.3) installation space

10

4.4) cable connection

12

4.5) trial running

12

5. Usage

13

5.1) function of wire controller

13

5.2) usage of wire controller

15

6. Maintenance and repair

24

6.2) trouble shooting guide

25

6.1) maintenance

24

4.6) seismic restraints

12

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified personnel in order to avoid a hazard.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

7. Appendix

30

30

31

7.1)caution

31

7.2)the method of grounding

32

7.3)use of the P&T valve

7.4)drain out the water in the storage tank

32

7.5)use of the overheating protector

6.3) major service

6.4) water supplies, water chemistry and water quality

6.5) product warranty

26

27

28

Preface

This manual could be subject to change without prior notice, if it is felt that product

improvements are to be carried out.

When Installing the hot water cylinder, please follow the Instructions as documented in this

A maintenance programme must be carried out as recommended in this manual.

Failure to comply with these recommendations will invalidate the warranty.

It is important that the installation and operational instructions laid out in this manual are

strictly adhered to.

This manual includes all the necessary information regarding the Installation and

maintenance of this product. Please take the time to read it through before operating.

Once the Installation is complete, check that all connections are secure before the power is turned

On.

The installer is to explain to the end user how to operate and maintain the unit in accordance to this

Instruction manual.

Content

Content

1. Safety Precautions

1

2. Specifications

3

2.1) appearance

3

2.2) characteristic

3

2.3) principle

4

2.4) dimensions

5

2.5) performance parameter

6

3. Function presentation

7

4. Installation

8

4.1) pipeline connection sketch

8

4.2) transportation

9

4.3) installation space

10

4.4) cable connection

12

4.5) trial running

12

5. Usage

13

5.1) function of wire controller

13

5.2) usage of wire controller

15

6. Maintenance and repair

24

6.2) trouble shooting guide

25

6.1) maintenance

24

4.6) seismic restraints

12

If the supply cord is damaged, it must be replaced by the manufacturer, its service agentor

similarly qualified persons in order to avoid a hazard.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

7. Appendix

30

30

31

7.1)caution

31

7.2)the method of grounding

32

7.3)use of the P&T valve

7.4)drain out the water in the storage tank

32

7.5)use of the overheating protector

6.3) major service

6.4) water supplies, water chemistry and water quality

6.5) product warranty

26

27

28

1

1.Safety Precautions

To prevent personal injury and avoid causing damage to the unit, please take the time to

read the information documented in this manual.

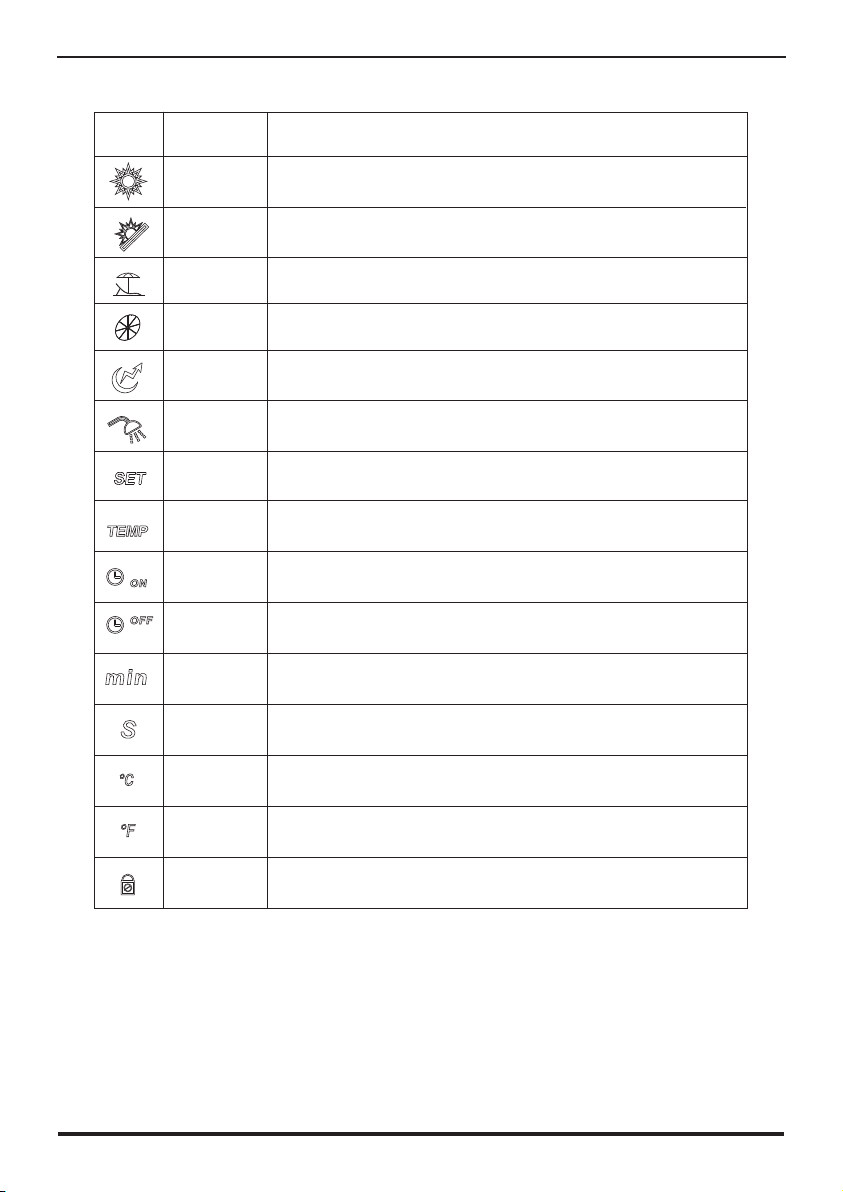

Icon Meaning

A wrong operation may lead to serious injury or death.

A wrong operation may lead to injury or loss of material.

WARNING

INSTALLATION WARNING

Icon Meaning

Compulsory - The listed action must be implemented.

Attention to what is indicated.

Prohibited (Next to this icon)

The heat pump must be installed by qualified personnel. Improper

installation could result in electrical shock /water leakage or fire.

Please ensure that the unit and power connections have a good

earth. Fail to do this may cause an electrical shock.

Professional installer

required

Earthing is required

ATTENTION

Check drainage fittings

Before installation, make sure there are no leakages on the

drainage fittings.

1.Safety Precautions

2

Installation place

Fixing the unit

Circuit breaker required

The unit CANNOT be installed near flammable gas.

Ensure that the base you are fixing to is level and strong enough.

This unit requires a circuit breaker. failure to do so could result in an

electrical shock or fire.

OPERATION WARNING

Prohibited

Shut off the power

Do not put fingers or any other objects into the fans. Children should be

kept clear of this appliance.

In the event of a unit malfunction please shut the power off and contact your service

engineer.

MOVE AND REPAIR

Important

If the heat pump needs to be relocated or installed again, only use an authorised

dealer or qualified persons.

It is prohibited for the end user to repair the unit themselves, unless qualified. failure

to do so may lead to serious injury or, and damage to the unit.

Should the heat pump need to be repaired, only use an authorised dealer or

qualified persons.

Prohibited

Important

OPERATION ATTENTION

Shut off the power

Turn the power off before cleaning the unit.

USAGE WARNING

Usage warning

Danger - High temperature.

Set a too high temperatu re of outlet water can cause scalding!

If the product need repair, please do not attempt to repair by yourself.

Inform the local vendors and send the barcode on the casing of the unit

order to reach professional repair.

1

1.Safety Precautions

To prevent personal injury and avoid causing damage to the unit, please take the time to

read the information documented in this manual.

Icon Meaning

A wrong operation may lead to serious injury or death.

A wrong operation may lead to injury or loss of material.

WARNING

INSTALLATION WARNING

Icon Meaning

Compulsory - The listed action must be implemented.

Attention to what is indicated.

Prohibited (Next to this icon)

The heat pump must be installed by qualified persons. Improper

installation could result in electrical shock /water leakage or fire.

Please ensure that the unit and power connections have a good

earth. Failure to do this may cause an electrical shock.

Professional installer

required

Earthing is required

ATTENTION

Check drainage fittings

Before installation, make sure there are no leakages on the

drainage fittings.

1.Safety Precautions

2

Installation place

Fixing the unit

Circuit breaker required

The unit CANNOT be installed near flammable gas.

Ensure that the base you are fixing to is level and strong enough.

This unit requires a circuit breaker. failure to do so could result in an

electrical shock or fire.

OPERATION WARNING

Prohibited

Shut off the power

Do not put fingers or any other objects into the fans. Children should be

kept clear of this appliance.

In the event of a unit malfunction please shut the power off and contact your

service engineer.

MOVE AND REPAIR

Important

If the heat pump needs to be relocated or installed again, only use an authorised

dealer or qualified personnel.

It is prohibited for the end user to repair the unit themselves, unless qualified. fail to do so

may lead to serious injury or/and damage to the unit.

Should the heat pump need to be repaired, only use an authorised dealer or

qualified persons.

Prohibited

Important

OPERATION ATTENTION

Shut off the power

Turn the power off before cleaning the unit.

USAGE WARNING

Usage warning

Danger - High temperature.

Setting a too high temperature of outlet water can cause scalding!

If the product need repair, please do not attempt to repair it by yourself.

Inform the local vendors and send the barcode on the casing of the unit

order to reach professional repair.

2.Specifications

3

2.1 Appearance

Smart and efficient unit

The operational costs can be up to 75% less than that of an electric water heater, and can

be installed in locations which are unsuitable for solar hot water heating.

2.2 Characteristics

Easy to operate

Featuring an easy-to-use timer for both start and stop operations, with a controller to set

the desired water temperature.

Safe and environmentally friendly

Produces no harmful gases along with no open flame, making the unit safe to work with

when installing.

2. Specifications

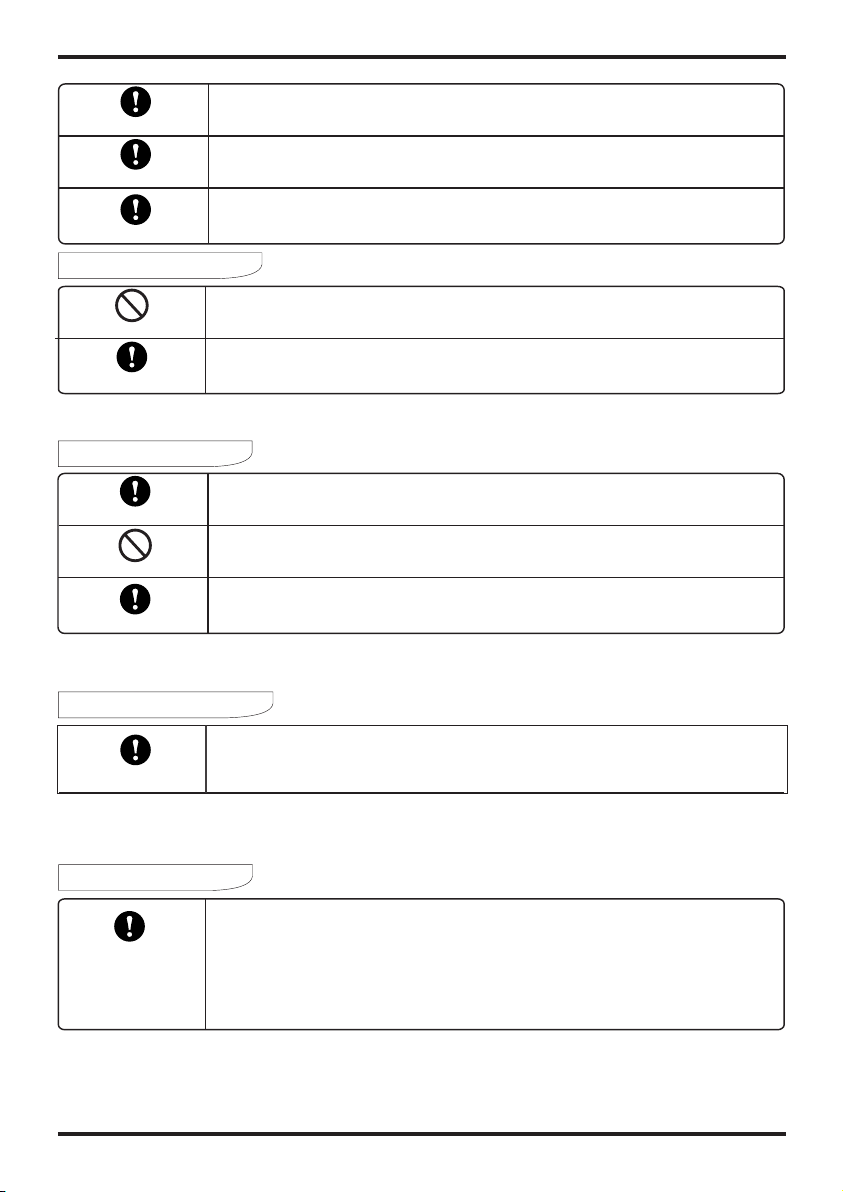

2.3 Principal

4

Air from

outside

Hot water

Low temp.

Compressor

Compressor

Water supply

Tank

Air

exchanger Water

exchanger

1Refrigerant is compressed into vapor with high temperature and high pressure when

it goes through the compressor.

On the discharge side of the compressor, the now hot and highly pressurized vapor

is cooled down through the heat exchange with the water in the tank until it

condenses into a high pressure, moderate temperature liquid.

Then the pressure of the liqiud refrigerant drops as it passes throttling device.

Finally, refrigerant absorbs heat from the surrounding air and evaporates into

vapor with low temperature and low pressure and then it goes into compressor

again.

The cooled surrounding air could be blew to the rooms which needs fresh cooled air.

2

3

4

5

System Principle:

Air inlet

Air outlet

Controller

Tank

Throttling

device

High temp.

2.Specifications

3

2.1 Appearance

Smart and efficient unit

The operational costs can be up to 75% less than that of an electric water heater, and can

be installed in locations which are unsuitable for solar hot water heating.

2.2 Characteristics

Easy to operate

Featuring an easy to use timer for both start and stop operations, with a controller to set the

desired water temperature.

Safe and environmentally friendly

Produces no harmful gases along with no open flame, making the unit safe to work with

when installing.

2. Specifications

2.3 Principal

4

Air from

outside

Hot water

Low temp.

Compressor

Compressor

Water supply

Water tank

Air

exchanger Heat

exchanger

1Refrigerant is compressed into vapor with high temperature and high pressure when

it goes through the compressor.

On the discharge side of the compressor, the now hot and highly pressurized vapor

is cooled down through the heat exchanger with the water in the tank until it

condenses into a high pressure, moderate temperature liquid.

Then the pressure of the liqiud refrigerant drops as it passes throttling device.

Finally, refrigerant absorbs heat from the surrounding air and evaporates into

vapor with low temperature and low pressure and then it goes into compressor

again.

The cooled surrounding air could be blew to the rooms which needs fresh cooled air.

2

3

4

5

System Principle:

Air inlet

Air outlet

controller

tank

Throttling

device

High temp.

Model

Heating capacity

Water tank capacity

Power input

Running current

Power supply

Compressor Number

Compressor

Rated outlet water Temp.

Nosie

Water inlet/outlet size

*Auxiliary E-heater

Net dimensions

Shipping dimensions

Net weight

kW

kW

A

dB(A)

inch

kW

mm

mm

kg

ATMOS AIR 180

1.7

180

0.43

1.8

240V~/50Hz

1

rotary

60

See nameplate

3/4

1.5

See the drawing of the units

See package label

See nameplate

2. Specifications

5

2.4 dimensions

2. Specifications

2.5 performance parameters

6

Work range

(1).Ambient temperature is -5℃~43℃(Heat Pump)

Measurement conditions:

Instant heating: Ambient temperature20℃/15℃,Water inlet 15℃, Water outlet 55

℃

Operating parameters

The range of the operating water pressures: 0.15~0.7MPa

Unit:mm

MODEL: ATMOS AIR 180

FREEZE PROTECTION

The water heater has a freeze protection system. The freeze protection

system will protect thewater heater from damage, by preventing ice

forming in the waterways of the water heater, in the event of freezing

conditions occurring.

16.5

1944.5

1277

Cold water

inlet

Hot water

outlet

Condensation

water outlet

Magnesium

Over heating

protector

Electric heater

Drainpipe

99 1177

1464.5

L

P&T valve

540Φ

Model

Heating capacity

Water tank capacity

Power input

Running current

Power supply

Compressor Number

Compressor

Rated outlet water Temp.

Nosie

Water inlet/outlet size

*Auxiliary E-heater

Net dimensions

Shipping dimensions

Net weight

kW

kW

A

dB(A)

inch

kW

mm

mm

kg

ATMOS AIR 180

1.7

180

0.43

1.8

240V~/50Hz

1

rotary

60

See nameplate

3/4

1.5

See the drawing of the units

See package label

See nameplate

2. Specifications

5

2.4 dimensions

2. Specifications

2.5 performance parameters

6

Work range

(1).Ambient temperature is -5℃~43℃(Heat Pump)

Measurement conditions:

Instant heating: Ambient temperature20℃/15℃,Water inlet 15℃, Water outlet 55

℃

Operating parameters

The range of the operating water pressures: 0.15~0.7MPa

Unit:mm

MODEL: ATMOS AIR 180

FREEZE PROTECTION

The water heater has a freeze protection system. The freeze protection

system will protect thewater heater from damage, by preventing ice

forming in the waterways of the water heater, in the event of freezing

conditions occurring.

16.5

1944.5

1277

Cold water

inlet

Hot water

outlet

Condensation

water outlet

Magnesium

Over heating

protector

Electric heater

Drainpipe

99 1177

1464.5

L

P&T valve

540Φ

3.Function presentation

3 minutes protection

If the unit stops and you restart the unit or turn it on by the manual switch, the unit will not start

to run again for approx 3 minutes. This is a protection feature to safe guard the compressor.

In low ambient conditions the heating output decreases.

Heating capacity

Working conditions

Defrosting

In the heating mode the unit will defrost automatically, maximizing the heating efficiency

(Lasting 2 - 10 minutes).

The fan motor will stop running whilst the unit is defrosting.

Water pressure protectiontemperature or

8

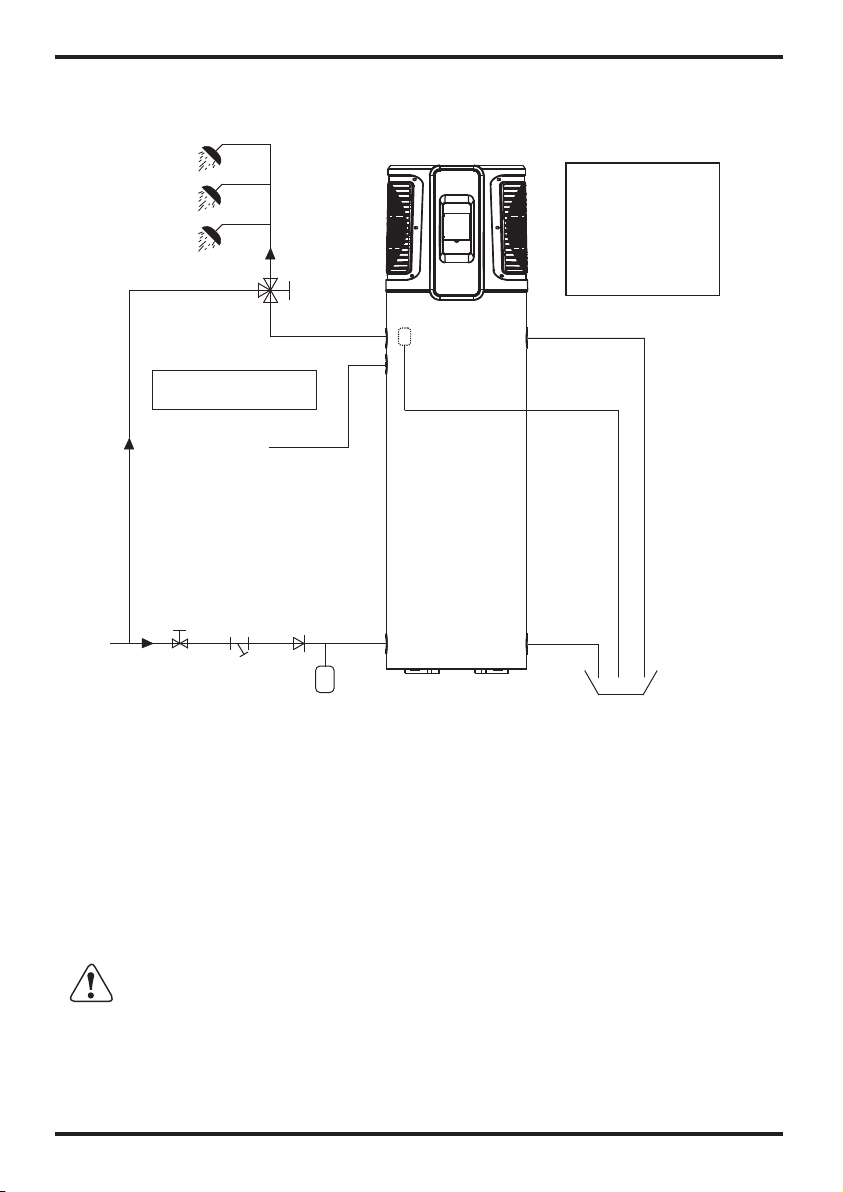

4.1 Pipeline connection sketch

4. Installation

Y-shaped Filter

7

In order to use the unit correctly, please run the unit at environment temperature

-5℃~43℃. The unit includes sophisticated electronic devices, prohibited to use water

from lake, untreated river water and groundwater!

Setup cannot affect the building structure and safety.

Notice:

A pressure realeasing

valve isto be fitted in

the installation.

Spec of P&T valve.

Pressure: 0.85MPa

Temperature: 99℃

Notice:

Tempering valve required

Water Outlet

Water Inlet

Tap Water

Thermal expansion tank

(if required)

Magnesium

Condensate Outlet

Drainpipe

Barrel-drain

P&T valve

When the tank pressure reaches 0.85MPa or when the tank temperature reach 99

℃, the P&T valve will open automatically so as to release the pressure or decrease

the temperature.

ATTENTION

Pipeline connection explanation

Installation of the water inlet or outlet pipes: The specification of the water inlet and

outlet thread is BSP3/4(internal thread).pipes must be heat-resistant and durable.

Installation of the pipe for P&T valve: The spec of the valve connecting thread is

BSP3/4(internal thread).After installation, it must be confirmed that the drainpipe

outlet is exposed in the air. drainpipe is joined to the pressure

relief orifice of this valve, you must ensure that the flexble drainpipe

and exposed in the air.

When the flexible

is pointing

downwards

ATTENTION: The Pressure release valve attached with the unit must be installed,

will cause damage to the unit, .failure to do so and possible personal injury

Do not use stainless steel fittings to connect directly with other metals to prevent

galvanic corrosion.

Drain the watertank through thedrain valve atthe bottom partof the unit.

3.Function presentation

3 minutes protection

If the unit stops and you re start the unit or turn it on by the manual switch, the unit will not

start to run again for approx 3 minutes. This is a protection feature to safe guard the

compressor.

In low ambient conditions the heating output decreases.

Heating capacity

Working conditions

Defrosting

In the heating mode the unit will defrost automatically, maximizing the heating efficiency

(Lasting 2 - 10 minutes).

The fan motor will stop running whilst the unit is defrosting.

Water pressure protectiontemperature or

8

4.1 Pipeline connection sketch

4. Installation

Y-shaped Filter

7

In order to use the unit correctly, please run the unit at environment temperature

-5℃~43℃. The unit includes sophisticated electronic devices, prohibited to use water

from lake, untreated river water and groundwater!

Setup cannot affect the building structure and safety.

Notice:

A pressure realeasing

valve is to be fitted in

the installation.

Spec of P&T valve.

Pressure: 0.85MPa

Temperature: 99℃

Notice:

Tempering valve required

Water Outlet

Water Inlet

Tap Water

Thermal expansion tank

(if required)

Magnesium

Condensate Outlet

Drainpipe

Barrel-drain

P&T valve

When the tank pressure reaches 0.85MPa, the Pressure release valve will open

automatically so as to decrease the pressure .

ATTENTION

Pipeline connection explanation

Installation of the water inlet or outlet pipes: The specification of the water inlet and

outlet thread is BSP3/4(internal thread).pipes must be heat-resistant and durable.

Installation of the pipe for P&T valve: The spec of the valve connecting thread is

BSP3/4(internal thread). After installation, it must be confirmed that the drainpipe outlet

is exposed in the air. When the flexible drainpipe is joined to the pressure relief orifice

of this valve, you must ensure that the flexible drainpipe is pointing downwards and

exposed in the air.

ATTENTION: The Pressure release valve attached with the unit must be installed, fail to

do so will cause damage to the unit, and possible personal injury.

Do not use stainless steel fittings to connect directly with other metals to prevent

galvanic corrosion.

Drain the water tank through the drain valve at the bottom part of the unit.

9

4. Installation

4.2

As a rule, the unit is to be stored and/or transported in its shipping container in the upright

position and without water charge. For transport over short distance, and provided due care is

exercised, an inclination angle of up to 30 degree is permitted. Both during transport and

storage, ambient temperatures of -5 to 43 are permissible.

4.2.1 Transport using a fork lift

When transported by a fork lift, the unit must remain mounted on the pallet. The lifting rate

should be kept to a minimum. Due to its top-heaviness, the unit must be secured against

tipping over. To prevent any damage, the unit must be placed on a level surface!

4.2.2 Manual transport

For the manual transport, the wooden pallet can be used for bottom part.

Using ropes or carrying straps, a second or third handling configuration is possible. With this

type of handling, care must be taken.

Permissible inclination angle of 60 degree is not exceeded. If transport in an inclined

position cannot be avoided, the unit should be placed into operation one hour after it has been

moved into final position.

Transportation

℃ ℃

CAUTION High center of gravity!

4. Installation

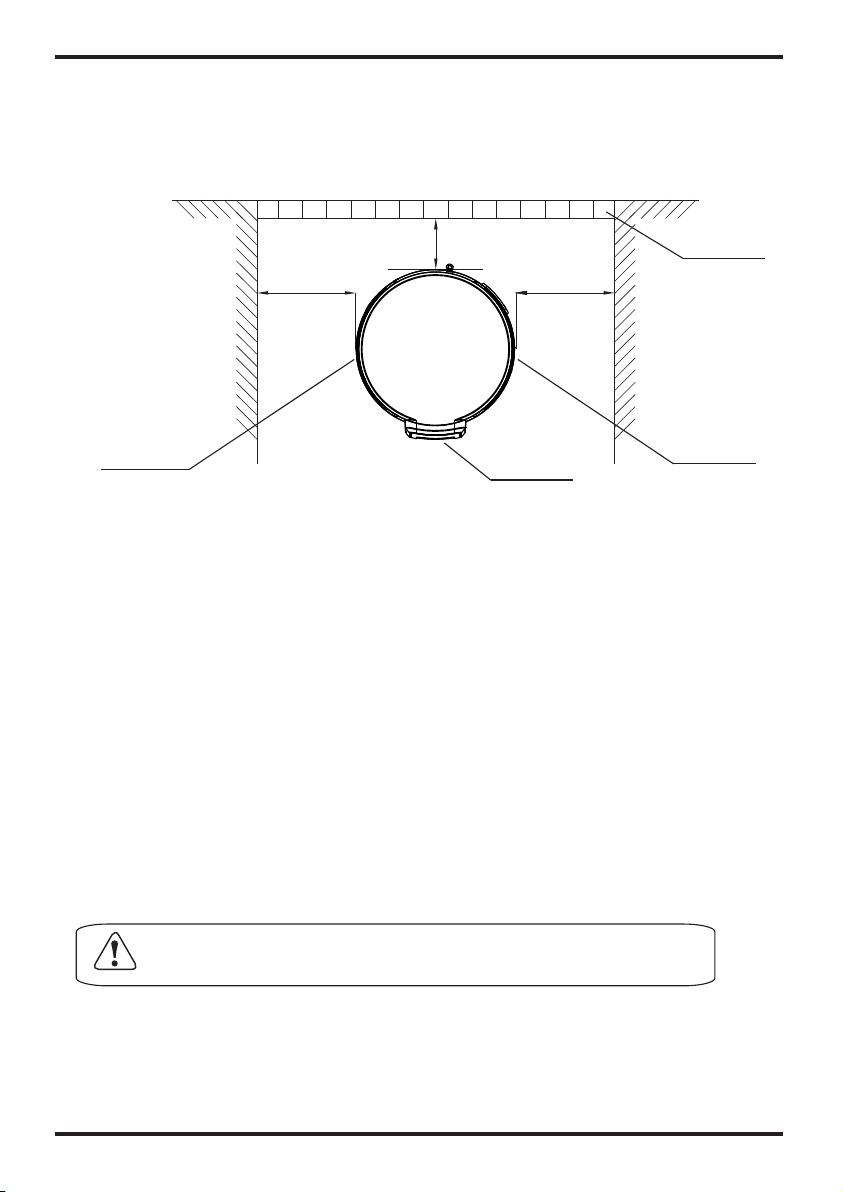

4.3 Installation space

Before installation, please ensure that you leave the space as shown below for maintenance.

Unit:mm

WARNING

For continued safety of this appliance it must be installed, operated and maintained in

accordance with the manufacturer's instructions.

If the water supply pressure exceeds the rated pressure, a pressure reducing valve is

tube fitted when installing the unit.

The water may drip from the discharge pipe of the pressure relief device and that

this pipe must be left open to the atmosphere.

The pressure relief device should be operated regularly to remove lime deposits

and verify that it is not blocked.

A discharge pipe connected to the pressure relief device is to be installed in a

continuously downward direction and in a frost-free environment.

Facilities ford raining and filling of systems shall be provided where these a

required for servicing purposes. The drainage facilities, where fitted, shall beat the

lowest point in the closed circuit.

CAUTION :The minimum space of installation is 10 cubic meter.

10

Air inlet

Air outlet Display

Barrier

500≥1000≥

≥300

9

4. Installation

4.2

As a rule, the unit is to be stored and/or transported in its shipping container in the upright

position and without water charge. For transport over short distance, and provided due care is

exercised, an inclination angle of up to 30 degree is permitted. Both during transport and

storage, ambient temperatures of -5 to 43 are permissible.

4.2.1 Transport using a forklift

When transported by a fork lift, the unit must remain mounted on the pallet. The lifting rate

should be kept to a minimum. Due to its top-heaviness, the unit must be secured against

tipping over. To prevent any damage, the unit must be placed on a level surface!

4.2.2 Manual transport

For the manual transport, the wooden pallet can be used for bottom part.

Using ropes or carrying straps, a second or third handling configuration is possible. With this

type of handling, care must be taken that the max.

Permissible inclination angle of 60 degree is not exceeded. If transport in an inclined

position cannot be avoided, the unit should be placed into operation one hour after it has been

moved into final position.

Transportation

℃ ℃

CAUTION High center of gravity!

4. Installation

4.3 Installation space

Before installation, please ensure that you leave the space as shown below for maintenance.

Unit:mm

WARNING

For continued safety of this appliance it mst be installed, operated and

maintained in accordance with the manufacturer's instructions.

If the water supply pressure exceeds the rated pressure, a pressure reducing

valve is tube fitted when installing the unit.

The water may drip from the discharge pipe of the pressure relief device and that

this pipe must be left open to the atmosphere.

The pressure relief device should be operated regularly to remove lime deposits

and verify that it is not blocked.

A discharge pipe connected to the pressure relief device is to be installed in a

continuously downward direction and in a frost-free environment.

Facilities ford raining and filling of systems shall be provided where these a

required for servicing purposes. The drainage facilities, where fitted, shall beat the

lowest point in the closed circuit.

CAUTION :The minimum space of installation is 10 cubic meter.

10

Air inlet

Air outlet Display

Barrier

500≥ 1000≥

≥300

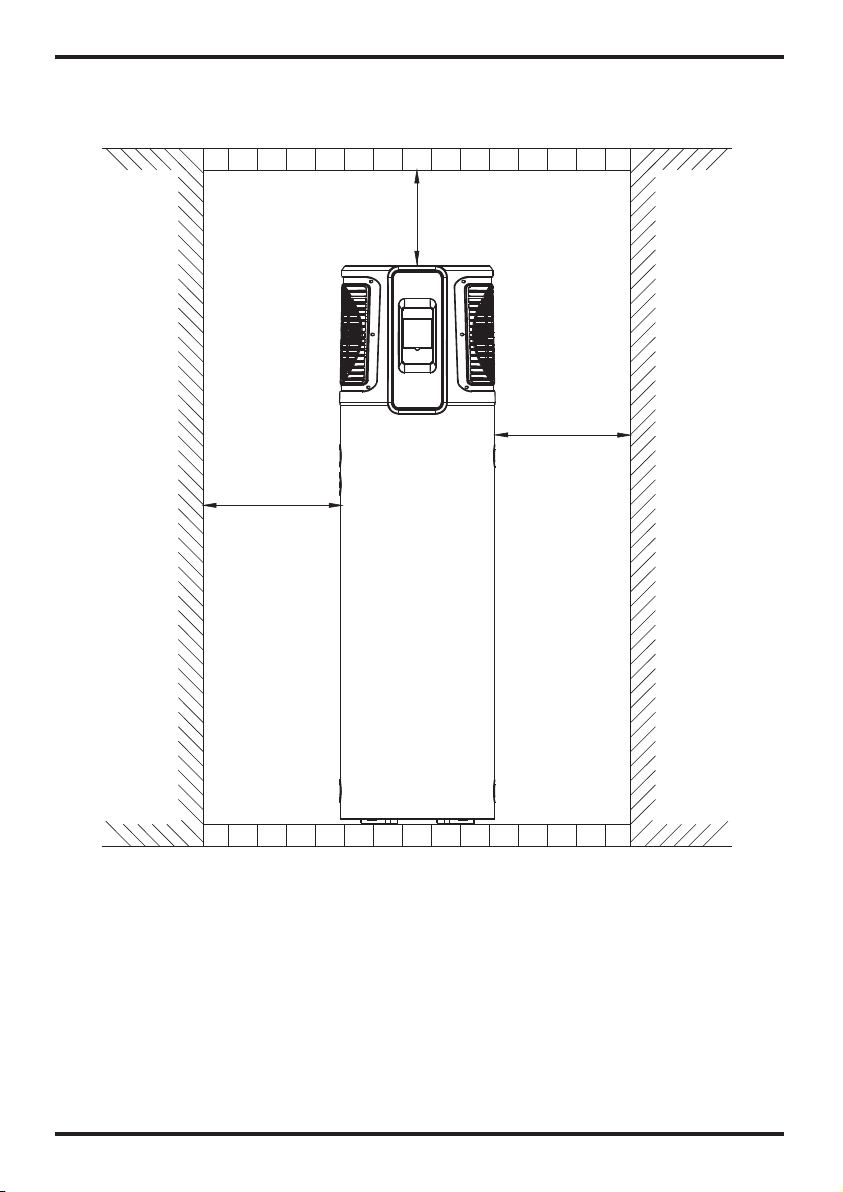

11

4. Installation 4.Installation

12

4.4 Cable connection

4.5 Trial running

This unit requires an isolating switch as required by local by laws.

4.5.1 Inspection before trial running

Check the water supply to the tank and pipe connections for possible leaks.

Check that all power connections are secure before switching on.

4.5.2 Trial running

Switch on the unit using the controller

In the case of any unusual noise, switch the power off and consult your provider;

If the power cord is damaged, It must be replaced by a qualified electrician.

The parameters have been pre set to a temperature of 60 degrees.

Unit:mm

4.6 Seismic restraints

The unit must be braced with with seismic restraints according to local by laws.

1000≥

500≥

600≥

11

4. Installation 4.Installation

12

4.4 Cable connection

4.5 Trial running

This unit requires an isolating switch as required by local by laws.

4.5.1 Inspection before trial running

Check the water supply to the tank and pipe connections for possible leaks.

Check that all power connections are secure before switching on.

4.5.2 Trial running

Switch on the unit using the controller

In the case of any unusual noise, switch the power off and consult your provider;

If the power cord is damaged, It must be replaced by a qualified electrician.

The parameters have been pre set to a temperature of 60 degrees.

Unit:mm

4.6 Seismic restraints

The unit must be braced with with seismic restraints according to local by laws.

1000≥

500≥

600≥

13 14

5.Usage

Electric

heater

Fan

Shows that the electric heater is on.

Shows that the fan is on and the speed of the fan.

Set temperature

achieved

Shows that the water temperature has reached the target

point and the unit shut off automatically.

Timer & ON

Timer & OFF Shows that the unit will be turned off by the timer

automatically.

Shows that the unit will be turned on by the timer

automatically.

Minute Shows that the main display area displays the minute.

Second Shows that the main display area displays the second.

Centigrade

Fahrenheit

Parameter

setting Shows that the parameter is adjustable.

Lock Shows that the keyboard is locked.

Status

icon What it means

Heating

Vacation

Shows that the unit is in heating mode.

Shows that the unit is in vacation mode.

Eco.heating

Temperature Shows that the temperature is non-adjustable

(measured value).

Name

Shows that the unit is in e mode.co.heating

5.Usage

5.1 The function diagram of the wire controller

1.Function of wire controller

NO. Button Name Function

1

2

3

4

5

6

ON/OFF

Mode

Electric

Heater

Up

Down

Turn on/off the unit.

Switch unit running modes or save setting parameters.

Set the clock or the timer.

Turn on/off the electric heater or switch fan modes.

Move up or increase parameter values.

Move down or decrease parameter values.

Clock

Main display

area

Auxiliary display

area

1 2 3 4 5 6

Shows that the temperature in Main display area or Auxiliary

display area is in ℉.

Shows that the temperature in Main display area or Auxiliary

display area is in ℃.

13 14

5.Usage

Electric

heater

Fan

Shows that the electric heater is on.

Shows that the fan is on and the speed of the fan.

Set temperature

achieved

Shows that the water temperature has reached the target

point and the unit shut off automatically.

Timer & ON

Timer & OFF Shows that the unit will be turned off by the timer

automatically.

Shows that the unit will be turned on by the timer

automatically.

Minute Shows that the main display area displays the minute.

Second Shows that the main display area displays the second.

Centigrade

Fahrenheit

Parameter

setting Shows that the parameter is adjustable.

Lock Shows that the keyboard is locked.

Status

icon What it means

Heating

Vacation

Shows that the unit is in heating mode.

Shows that the unit is in vacation mode.

Eco.heating

Temperature Shows that the temperature is non-adjustable

(measured value).

Name

Shows that the unit is in e mode.co.heating

5.Usage

5.1 The function diagram of the wire controller

1.Function of wire controller

NO. Button Name Function

1

2

3

4

5

6

ON/OFF

Mode

Electric

Heater

Up

Down

Turn on/off the unit.

Switch unit running modes or save setting parameters.

Set the clock or the timer.

Turn on/off the electric heater or switch fan modes.

Move up or increase parameter values.

Move down or decrease parameter values.

Clock

Main display

area

Auxiliary display

area

1 2 3 4 5 6

Shows that the temperature in Main display area or Auxiliary

display area is in ℉.

Shows that the temperature in Main display area or Auxiliary

display area is in ℃.

15

5.Usage

16

5.Usage

5.2 Usage of wire controller

Outlet water temperature

Press " " and hold for 0.5s.

Inlet water

temperature

Heating mode

Standby interface

5.2.2 Mode selection

Press " " to select the mode from Heating ,Eco.heating ,Vacation, , High

requirement in the standby or running interface.

For example:

Intelligent

Running interface

5.2.1 Turn ON/OFF the unit

Press " " and hold for 0.5s in the standby interface of the wire controller to turn on the

unit and at this time the main display area shows the water outlet temperature.

Press " " and hold for 0.5s in the running interface of the wire controller to turn off the

unit and at this time the main display area shows OFF.

Note: The ON/OFF button can only be used to turn on/off the unit in standby or running

interface of the wire controller.

5.2.3 Target temperature checking and setting

In the standby or running interface, press " " or " " once to check the target temperature

of the outlet water. Press " " or " " again to change the target temperature. After making

the changes to the parameter, press " " to confirm or " " to cancel the changes, then

return to the previous interface. If no operations are performed on the keypad for 5s, the

controller exits the parameter modification menu by timeout and the changes are confirmed.

Setting 75 : " "

°" "

°C When the target temperature is adjusted to 60 °C, press and hold the for

5s. At this time, the target temperature is displayed as 61 °C and the temperature range

changed to 38-75 C. Press the to set the target temperature to 75 °C.

Example: Change the target temperature from 55°C to 70°C when the actual outlet water

temper is 18°C.

Press“ ”

Press“ ”

Press“ ”

Heating mode

Outlet water

temperature

Time Eco.heating mode

Vacation mode

Date

modeIntelligent

Press“ ” High requirement mode

15

5.Usage

16

5.Usage

5.2 Usage of wire controller

Outlet water temperature

Press " " and hold for 0.5s.

Inlet water

temperature

Heating mode

Standby interface

5.2.2 Mode selection

Press " " to select the mode from Heating ,Eco.heating ,Vacation, , High

requirement in the standby or running interface.

For example:

Intelligent

Running interface

5.2.1 Turn ON/OFF the unit

Press " " and hold for 0.5s in the standby interface of the wire controller to turn on the

unit and at this time the main display area shows the water outlet temperature.

Press " " and hold for 0.5s in the running interface of the wire controller to turn off the

unit and at this time the main display area shows OFF.

Note: The ON/OFF button can only be used to turn on/off the unit in standby or running

interface of the wire controller.

5.2.3 Target temperature checking and setting

In the standby or running interface, press " " or " " once to check the target temperature

of the outlet water. Press " " or " " again to change the target temperature. After making

the changes to the parameter, press " " to confirm or " " to cancel the changes, then

return to the previous interface. If no operations are performed on the keypad for 5s, the

controller exits the parameter modification menu by timeout and the changes are confirmed.

Setting 75°C: When the target temperature is adjusted to 60 °C, press and hold the" " for

5s. At this time, the target temperature is displayed as 61 °C and the temperature range

changed to 38-75°C. Press the" " to set the target temperature to 75 °C.

Example: Change the target temperature from 55°C to 70°C when the actual outlet water temperature

is 18°C.

Press“ ”

Press“ ”

Press“ ”

Heating mode

Outlet water

temperature

Time Eco.heating mode

Vacation mode

Date

modeIntelligent

Press“ ”High requirement mode

5.Usage

17

Outlet water temperature

Time

Target temperature

Press and hold the for 5s ,then press

or again to change the target

temperature.

Press

to confirm

or to

cancel, then

return to the

previous

interface.

Press

to change the

target

temperature

from 55℃ to

60℃.

5.2.4 Time setting

In the standby or running interface, do as follows to set the time when in heating mode. When

press " " once, the time parameter will flash. When press " " again, the hour parameter

will flash then press " " or " " to change it. After making the changes to the parameter,

press" " to confirm, then change the minute parameter as well as the date parameter in the

same way.

If no operations are performed on the keypad for 15s, the controller exits the parameter

modification menu by timeout and the changes are confirmed.

Note: Set the date in the same way when in vacation mode.

Example: Change the time and date from 18:30 on August 4th to 17:40 on September 8th.

Time

Press

twice then

press or

to change

the hour

parameter

and press

to confirm.

Press " " or " " to change the minute

parameter.

5. Usage

18

The new set time

Press " " to confirm.

Press " " or " " to change the minute

parameter.

The date is flashing

Press once then press or to change

the month parameter and press to confirm.

Press " " or

" " to change

the day parameter.

Press" "

to confirm.

5.2.5 Timer setting

5.2.5.1 Under the standard mode, economic mode, intelligent mode, you can enter the timer

setting.

Press " " and hold for 2s, the "ON "and " 1 " will flash, and then you can set the turn on

time of timer1 as the 24 clock setting show. After finishing, " OFF " and " 1 " will flash, that

means you can set the turn off time of timer1. The "ON " and " 2 " will flash after finishing the

timer1 setting, you can set the turn on time of timer2. After finishing, the " OFF " and " 2 " will

flash, and then you can set the turn off time of timer2. Press " " again to save and back to

the interface. If you don't need to set the timer2, you can press the " " to save after finishing

the timer1 setting. You will find the " ON " and " 2 " flash. No operation for 5s, the program will

back to the interface automatically.

Note: When press " " and hold for 2s, the " ON " and " 1 " will flash. It is not necessary for

you to set the turn on time of the timer1. You can sequentially to press " " for 2s to enter to

the turn off time of timer1. So does the timer2. Or press " " or " " to circularly display.

Timer Cancel: Press " " and hold for 2s to enter into the interface, and then press " "

to cancel all the operation. Please see the following picture for more details.

Table of contents

Other Solahart Heat Pump manuals

Popular Heat Pump manuals by other brands

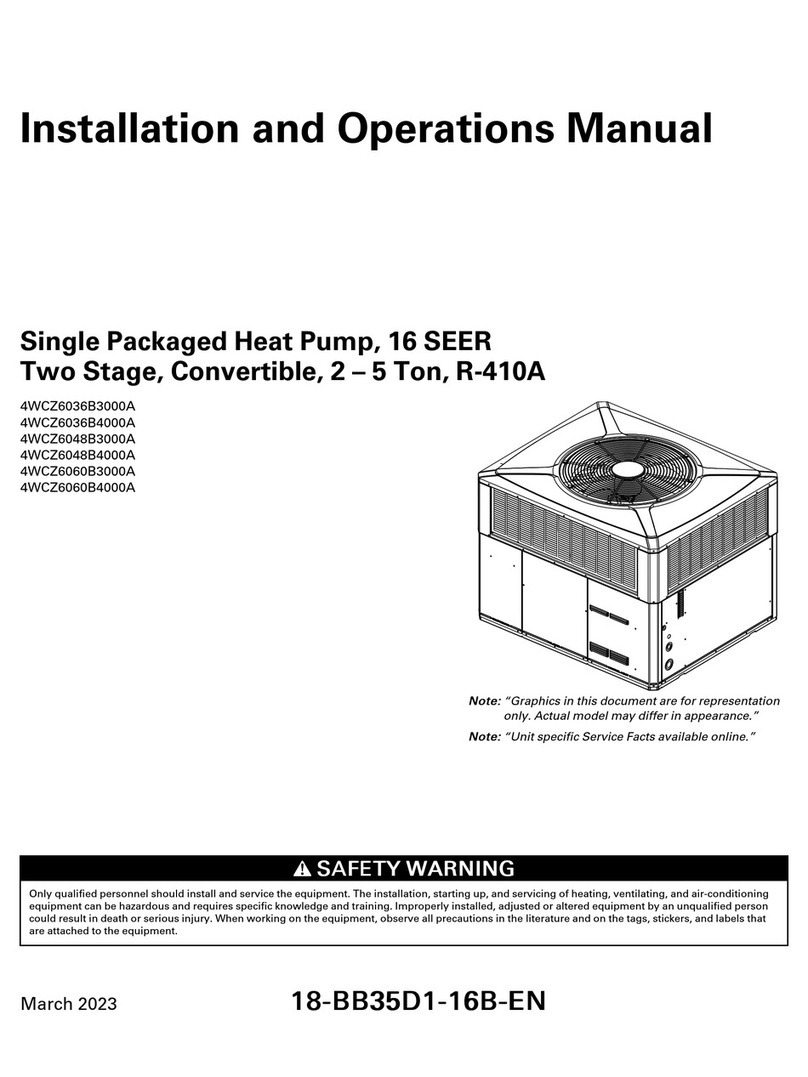

Trane

Trane 4WCZ6036B3000A Installation and operation manual

Viessmann

Viessmann VITOBLOC 200 Series operating instructions

Fedders

Fedders CH1042CBD1VF Specification sheet

Zodiac

Zodiac Z250 MD3 Instructions for installation and use

STIEBEL ELTRON

STIEBEL ELTRON SHP-A 220 Plus Operation and installation

DeLonghi

DeLonghi Bran 0011M H Installation, operating & service instructions

Nova Booster

Nova Booster Swimming Pool Heat Pump User & service manual

Electra

Electra PXD 25 DCI Service manual

Danfoss

Danfoss BW10 020-090 Operation instructions

TLV

TLV J10 instruction manual

Samsung

Samsung HHSM-G500005-1 installation manual

Nordyne

Nordyne Q5RD Series User's manual & installation instructions