Solahart AtmosAir 180 User manual

Operation &Installation ManualOperation &Installation Manual

HEATPUMPHEATPUMP

Preface

This manual couldbe subject tochange without priornotice, if itis felt thatproduct

improvements are tobe carried out.

When Installing the hot water cylinder, please follow the Instructions as documented in this manual.

A maintenanceprogramme must becarried out asrecommended in thismanual.

Failure to complywith these recommendationswill invalidate the warranty.

It is importantthat the installationand operational instructionslaid out inthis manual are

strictly adhered to.

This manual includesall the necessaryinformation regarding theInstallation and

maintenance of thisproduct. Please takethe time toread it throughbefore operating.

Once the Installation is complete, check that all connections are secure before the power is turned

On.

The installer is to explain to the end user how to operate and maintain the unit in accordance to this

Instruction manual.

Content

Content

1. Safety Precautions

1

2. Specifications

3

2.1) appearance

3

2.2) characteristic

3

2.3) principle

4

2.4) dimensions

5

2.5) performance parameter

6

3. Function presentation

7

4. Installation

8

4.1) pipeline connection sketch

8

4.2) transportation

9

4.3) installation space

10

4.4) cable connection

12

4.5) trial running

12

5. Usage

13

5.1) function of wire controller

13

5.2) usage of wire controller

15

6. Maintenance and repair

25

7. Appendix

27

6.2) trouble shooting guide

25

6.1) maintenance

25

4.6) seismic restraints

12

27

28

7.1)caution

28

7.2)the method of grounding

29

7.3)use of the Pressure release valve

7.4)drain outthe waterin the storage tank

If the supplycord is damaged,it must bereplaced by themanufacturer, itsservice agentor

similarly qualified personsin order toavoid a hazard.

This appliance isnot intended foruse by persons(including children) withreduced physical,

sensory or mentalcapabilities, or lackof experience andknowledge, unless theyhave

been given supervisionor instruction concerninguse of theappliance by aperson

responsible for theirsafety.

Children should besupervised to ensurethat they donot play withthe appliance.

29

7.5)use of the overheating protector

Preface

This manual couldbe subject tochange without priornotice, if itis felt thatproduct

improvements are tobe carried out.

When Installing the hot water cylinder, please follow the Instructions as documented in this manual.

A maintenanceprogramme must becarried out asrecommended in thismanual.

Failure to complywith these recommendationswill invalidate the warranty.

It is importantthat the installationand operational instructionslaid out inthis manual are

strictly adhered to.

This manual includesall the necessaryinformation regarding theInstallation and

maintenance of thisproduct. Please takethe time toread it throughbefore operating.

Once the Installation is complete, check that all connections are secure before the power is turned

On.

The installer is to explain to the end user how to operate and maintain the unit in accordance to this

Instruction manual.

Content

Content

1. Safety Precautions

1

2. Specifications

3

2.1) appearance

3

2.2) characteristic

3

2.3) principle

4

2.4) dimensions

5

2.5) performance parameter

6

3. Function presentation

7

4. Installation

8

4.1) pipeline connection sketch

8

4.2) transportation

9

4.3) installation space

10

4.4) cable connection

12

4.5) trial running

12

5. Usage

13

5.1) function of wire controller

13

5.2) usage of wire controller

15

6. Maintenance and repair

25

7. Appendix

27

6.2) trouble shooting guide

25

6.1) maintenance

25

4.6) seismic restraints

12

27

28

7.1)caution

28

7.2)the method of grounding

29

7.3)use of the Pressure release valve

7.4)drain outthe waterin the storage tank

If the supplycord is damaged,it must bereplaced by themanufacturer, itsservice agentor

similarly qualified personsin order toavoid a hazard.

This appliance isnot intended foruse by persons(including children) withreduced physical,

sensory or mentalcapabilities, or lackof experience andknowledge, unless theyhave

been given supervisionor instruction concerninguse of theappliance by aperson

responsible for theirsafety.

Children should besupervised to ensurethat they donot play withthe appliance.

29

7.5)use of the overheating protector

1

1.Safety Precautions

Toprevent personal injuryand avoid causingdamage to theunit, please takethe time to

read the informationdocumented in thismanual.

Icon Meaning

Awrong operation maylead to seriousinjury or death.

A wrongoperation may leadto injury orloss of material.

WARNING

INSTALLATION WARNING

Icon Meaning

Compulsory -The listed actionmust be implemented.

Attention to whatis indicated.

Prohibited (Next tothis icon)

The heat pumpmust be installedby qualified persons.Improper

installation could resultin electrical shock/water leakage orfire.

Please ensure thatthe unit andpower connections havea good

earth. Failure todo this maycause an electricalshock.

Professional installer

required

Earthing is required

ATTENTION

Check drainage fittings Before installation, makesure there areno leakages onthe

drainage fittings.

1.Safety Precautions

2

Installation place

Fixing theunit

Circuit breaker required

The unit CANNOTbe installed nearflammable gas.

Ensure that thebase you arefixing to islevel and strongenough.

This unit requiresa circuit breaker. failure todo so couldresult in an

electrical shock orfire.

OPERATIONWARNING

Prohibited

Shut off thepower

Do not putfingers or anyother objects intothe fans. Childrenshould be

kept clear ofthis appliance.

In the eventof a unitmalfunction please shutthe power offand contact yourservice

engineer.

MOVE AND REPAIR

Important

If the heatpump needs tobe relocated orinstalled again, onlyuse an authorised

dealer or qualifiedpersons.

It is prohibitedfor the enduser to repairthe unit themselves,unless qualified. failure

to do somay lead toserious injury or, and damageto the unit.

Should the heatpump need tobe repaired, onlyuse an authoriseddealer or

qualified persons.

Prohibited

Important

OPERATIONATTENTION

Shut offthe power

Turn thepower offbefore cleaning theunit.

USAGE WARNING

Usage warning

Danger - High temperature.

Set a too high temperatu re of outlet water can cause scalding!

If the product need repair, please do not attempt to repair by yourself.

Inform the local vendors and send the barcode on the casing of the unit

order to reach professional repair.

1

1.Safety Precautions

Toprevent personal injuryand avoid causingdamage to theunit, please takethe time to

read the informationdocumented in thismanual.

Icon Meaning

Awrong operation maylead to seriousinjury or death.

A wrongoperation may leadto injury orloss of material.

WARNING

INSTALLATION WARNING

Icon Meaning

Compulsory -The listed actionmust be implemented.

Attention to whatis indicated.

Prohibited (Next tothis icon)

The heat pumpmust be installedby qualified persons.Improper

installation could resultin electrical shock/water leakage orfire.

Please ensure thatthe unit andpower connections havea good

earth. Failure todo this maycause an electricalshock.

Professional installer

required

Earthing is required

ATTENTION

Check drainage fittings Before installation, makesure there areno leakages onthe

drainage fittings.

1.Safety Precautions

2

Installation place

Fixing theunit

Circuit breaker required

The unit CANNOTbe installed nearflammable gas.

Ensure that thebase you arefixing to islevel and strongenough.

This unit requiresa circuit breaker. failure todo so couldresult in an

electrical shock orfire.

OPERATIONWARNING

Prohibited

Shut off thepower

Do not putfingers or anyother objects intothe fans. Childrenshould be

kept clear ofthis appliance.

In the eventof a unitmalfunction please shutthe power offand contact yourservice

engineer.

MOVE AND REPAIR

Important

If the heatpump needs tobe relocated orinstalled again, onlyuse an authorised

dealer or qualifiedpersons.

It is prohibitedfor the enduser to repairthe unit themselves,unless qualified. failure

to do somay lead toserious injury or, and damageto the unit.

Should the heatpump need tobe repaired, onlyuse an authoriseddealer or

qualified persons.

Prohibited

Important

OPERATIONATTENTION

Shut offthe power

Turn thepower offbefore cleaning theunit.

USAGE WARNING

Usage warning

Danger - High temperature.

Set a too high temperatu re of outlet water can cause scalding!

If the product need repair, please do not attempt to repair by yourself.

Inform the local vendors and send the barcode on the casing of the unit

order to reach professional repair.

2.Specifications

3

2.1 Appearance

Smart and efficient unit

The operational costs can be up to 75% less than that of an electric water heater, and can

be installed in locations which are unsuitable for solar hot water heating.

2.2 Characteristics

Easy to operate

Featuring an easy to use timer for both start and stop operations, with a controller to set the

desired water temperature.

Safe and environmentally friendly

Produces no harmful gases along with no open flame, making the unit safe to work with

when installing.

2. Specifications

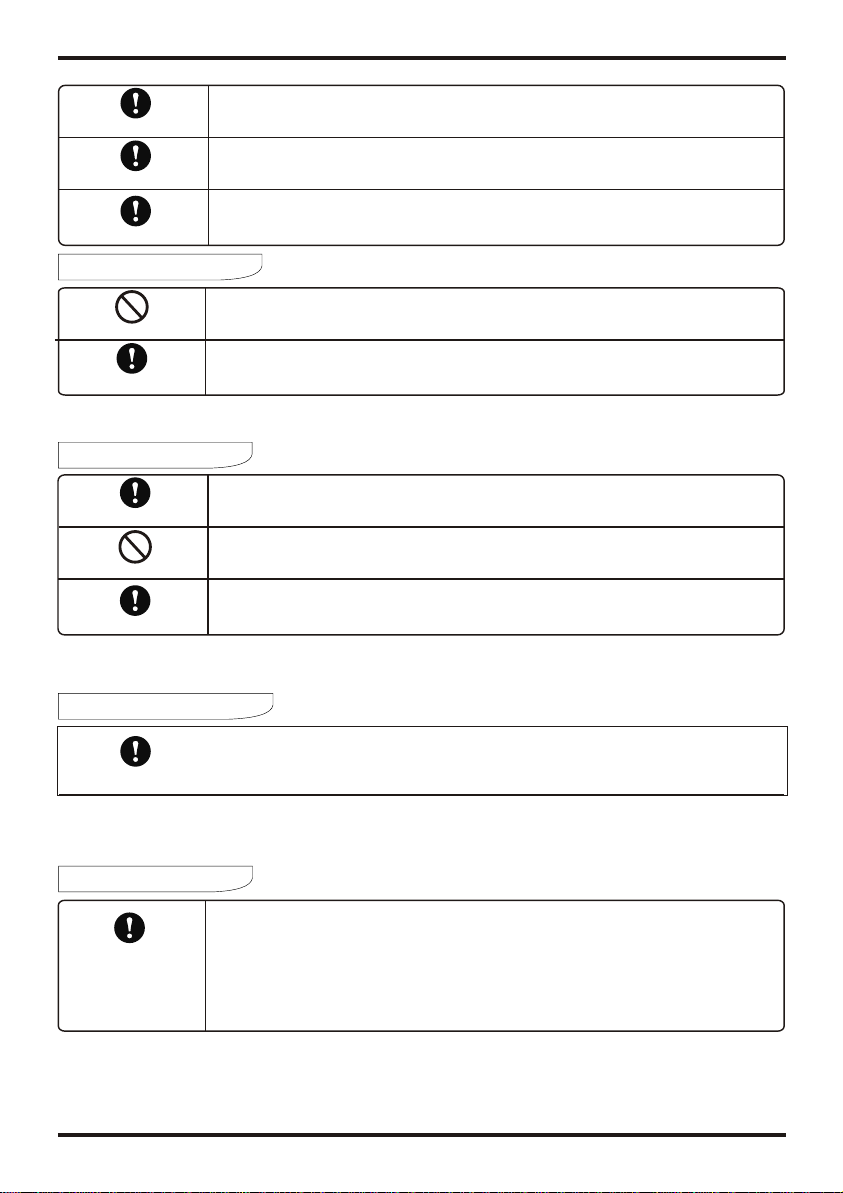

2.3 Principal

4

Air from

outside

Hot water

Low temp.

Compressor

Compressor

Water supply

Tank

Air

exchanger Water

exchanger

1Refrigerant is compressed into vapor with high temperature and high pressure when

it goes through the compressor.

On the discharge side of the compressor, the now hot and highly pressurized vapor

is cooled down through the heat exchange with the water in the tank until it

condenses into a high pressure, moderate temperature liquid.

Then the pressure of the liqiud refrigerant drops as it passes throttling device.

Finally, refrigerant absorbs heat from the surrounding air and evaporates into

vapor with low temperature and low pressure and then it goes into compressor

again.

The cooled surrounding air could be blew to the rooms which needs fresh cooled air.

2

3

4

5

System Principle:

Air inlet

Air outlet

controller

tank

Throttling

device

High temp.

2.Specifications

3

2.1 Appearance

Smart and efficient unit

The operational costs can be up to 75% less than that of an electric water heater, and can

be installed in locations which are unsuitable for solar hot water heating.

2.2 Characteristics

Easy to operate

Featuring an easy to use timer for both start and stop operations, with a controller to set the

desired water temperature.

Safe and environmentally friendly

Produces no harmful gases along with no open flame, making the unit safe to work with

when installing.

2. Specifications

2.3 Principal

4

Air from

outside

Hot water

Low temp.

Compressor

Compressor

Water supply

Tank

Air

exchanger Water

exchanger

1Refrigerant is compressed into vapor with high temperature and high pressure when

it goes through the compressor.

On the discharge side of the compressor, the now hot and highly pressurized vapor

is cooled down through the heat exchange with the water in the tank until it

condenses into a high pressure, moderate temperature liquid.

Then the pressure of the liqiud refrigerant drops as it passes throttling device.

Finally, refrigerant absorbs heat from the surrounding air and evaporates into

vapor with low temperature and low pressure and then it goes into compressor

again.

The cooled surrounding air could be blew to the rooms which needs fresh cooled air.

2

3

4

5

System Principle:

Air inlet

Air outlet

controller

tank

Throttling

device

High temp.

Model

Heating capacity

Water tankcapacity

Power input

Running current

Power supply

Compressor Number

Compressor

Rated outlet waterTemp.

Nosie

Water inlet/outletsize

*Auxiliary E-heater

Net dimensions

Shipping dimensions

Net weight

Shipping weight

kW

kW

A

dB(A)

inch

kW

mm

mm

kg

kg

ATMOSAIR 180

1.7

180

0.43

1.8

240V~/50Hz

1

rotary

55

See nameplate

3/4

1.5

See the drawingof the units

See package label

See nameplate

See package label

2. Specifications

5

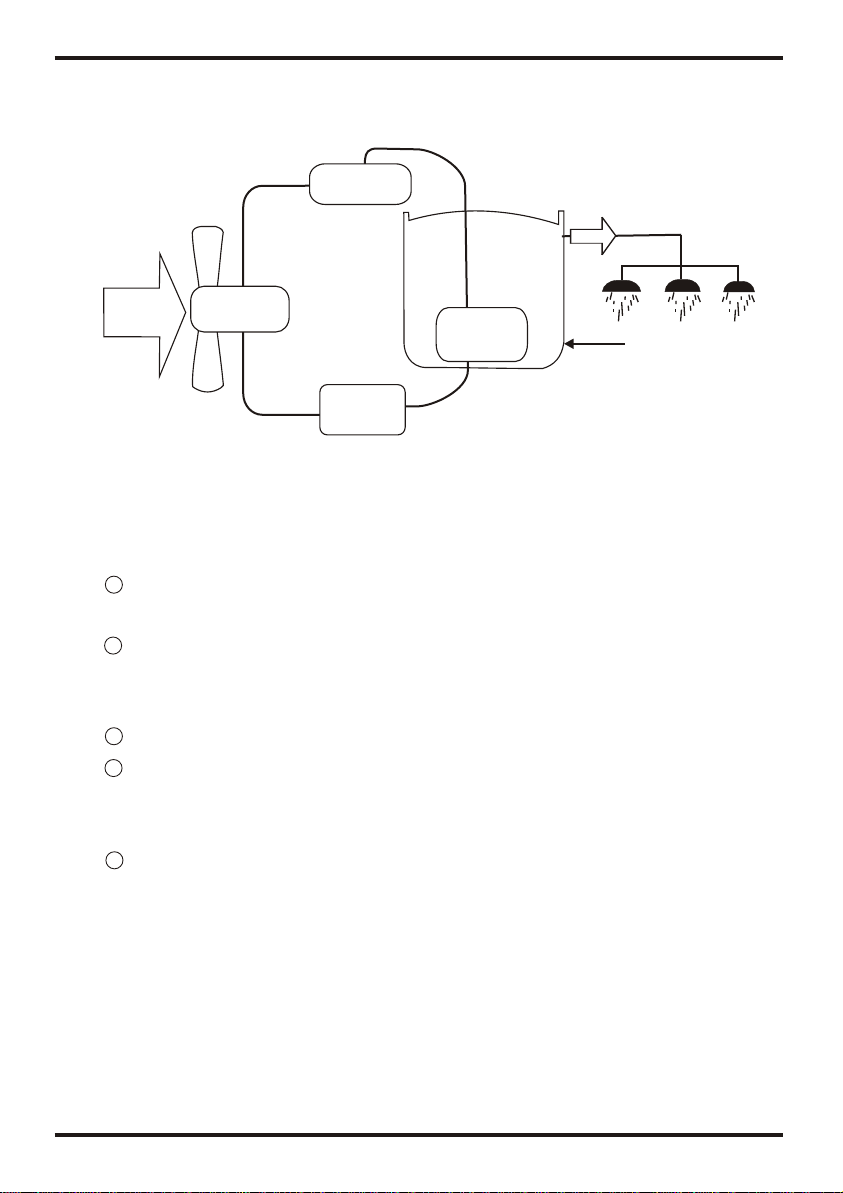

2.4 dimensions

2. Specifications

2.5 performance parameters

6

Work range

(1).Ambient temperatureis 0 ~40 (Heat Pump)

Measurement conditions:

Instant heating:Ambienttemperature20 /15 ,Water inlet15 , Wateroutlet 55

Operating parameters

The range ofthe operating waterpressures: 0.15~0.7MPa

Unit mm

MODEL: ATMOS AIR 180

FREEZE PROTECTION

The waterheater hasa freezeprotection system.The freezeprotection

system will protectthewater heater fromdamage, by preventingice

forming inthe waterwaysof thewater heater, inthe eventof freezing

conditions occurring.

16.5

1944.5

1277

Cold water

inlet

Hot water

outlet

Condensation

water outlet

Magnesium

Over heating

protector

Electric heater

Drainpipe

99 1177

1464.5

L

Pressure release

valve

540

Model

Heating capacity

Water tankcapacity

Power input

Running current

Power supply

Compressor Number

Compressor

Rated outlet waterTemp.

Nosie

Water inlet/outletsize

*Auxiliary E-heater

Net dimensions

Shipping dimensions

Net weight

Shipping weight

kW

kW

A

dB(A)

inch

kW

mm

mm

kg

kg

ATMOSAIR 180

1.7

180

0.43

1.8

240V~/50Hz

1

rotary

55

See nameplate

3/4

1.5

See the drawingof the units

See package label

See nameplate

See package label

2. Specifications

5

2.4 dimensions

2. Specifications

2.5 performance parameters

6

Work range

(1).Ambient temperatureis 0 ~40 (Heat Pump)

Measurement conditions:

Instant heating:Ambienttemperature20 /15 ,Water inlet15 , Wateroutlet 55

Operating parameters

The range ofthe operating waterpressures: 0.15~0.7MPa

Unit mm

MODEL: ATMOS AIR 180

FREEZE PROTECTION

The waterheater hasa freezeprotection system.The freezeprotection

system will protectthewater heater fromdamage, by preventingice

forming inthe waterwaysof thewater heater, inthe eventof freezing

conditions occurring.

16.5

1944.5

1277

Cold water

inlet

Hot water

outlet

Condensation

water outlet

Magnesium

Over heating

protector

Electric heater

Drainpipe

99 1177

1464.5

L

Pressure release

valve

540

3.Function presentation

3 minutes protection

If the unitstops and youre start theunit or turnit on bythe manual switch,the unit willnot

start to runagain for approx3 minutes.This is aprotection feature tosafe guard the

compressor.

In low ambientconditions the heatingoutput decreases.

Heating capacity

Working conditions

Defrosting

In the heatingmode the unitwill defrost automatically, maximizing theheating efficiency

(Lasting 2 -10 minutes).

The fan motorwill stop runningwhilst the unitis defrosting.

Water pressure protectiontemperature or

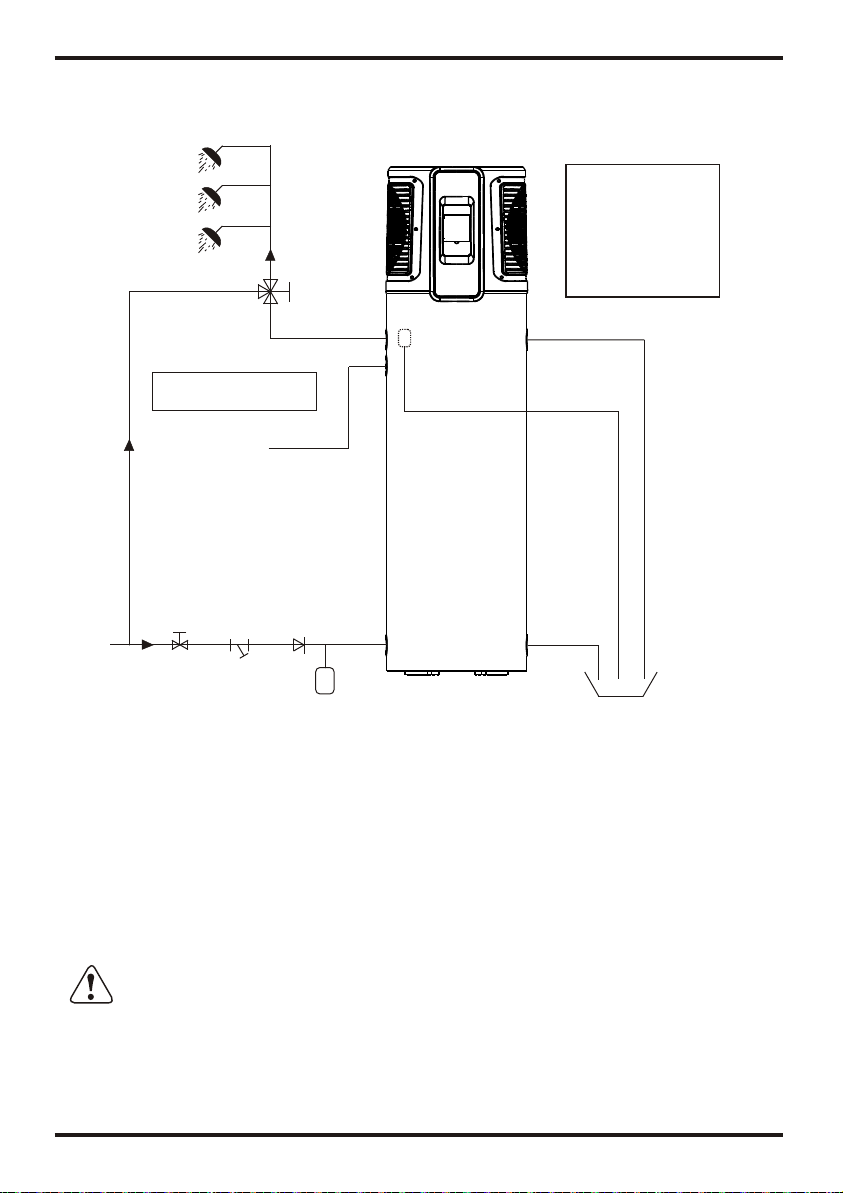

8

4.1 Pipeline connectionsketch

4. Installation

Y-shaped Filter

7

In order touse the unitcorrectly,please run theunit at environmenttemperature

0 ~40 . Theunit includes sophisticatedelectronic devices, prohibitedto use water

from lake, untreatedriver water andgroundwater!

Setup cannotaffect thebuilding structureand safety.

Notice:

A pressurerealeasing

valve isto befitted in

the installation.

Spec of Pressure

release valve:

Pressure: 0.7MPa

Notice:

Tempering valve required

Water Outlet

Water Inlet

Tap Water

Thermal expansion tank

(if required)

Magnesium

Condensate Outlet

Drainpipe

Barrel-drain

Pressure release valve

When the tankpressure reaches 0.7MPa,the Pressure release valve will open

automatically so asto decrease thepressure .

ATTENTION

Pipeline connection explanation

Installation of thewater inlet oroutlet pipes:The specification ofthe water inletand

outlet thread isBSP3/4(internal thread).pipesmust be heat-resistantand durable.

Installation of thepipe for Pressurerelease valve:The spec ofthe valve connecting

thread is BSP3/4(internal thread).After installation,it must beconfirmed that the

drainpipe outlet isexposed in theair. drainpipe is joinedto the

pressure relief orificeof this valve,you must ensure that the flexbledrainpipe

and exposed inthe air.

When the flexible is

pointing downwards

ATTENTION:The Pressurerelease valve attachedwith the unitmust be installed,

will cause damageto the unit, .failure to doso and possible personalinjury

Do not usestainless steel fittingsto connect directlywith other metalsto prevent

galvanic corrosion.

Drain the watertankthrough thedrain valveatthe bottom partofthe unit.

3.Function presentation

3 minutes protection

If the unitstops and youre start theunit or turnit on bythe manual switch,the unit willnot

start to runagain for approx3 minutes.This is aprotection feature tosafe guard the

compressor.

In low ambientconditions the heatingoutput decreases.

Heating capacity

Working conditions

Defrosting

In the heatingmode the unitwill defrost automatically, maximizing theheating efficiency

(Lasting 2 -10 minutes).

The fan motorwill stop runningwhilst the unitis defrosting.

Water pressure protectiontemperature or

8

4.1 Pipeline connectionsketch

4. Installation

Y-shaped Filter

7

In order touse the unitcorrectly,please run theunit at environmenttemperature

0 ~40 . Theunit includes sophisticatedelectronic devices, prohibitedto use water

from lake, untreatedriver water andgroundwater!

Setup cannotaffect thebuilding structureand safety.

Notice:

A pressurerealeasing

valve isto befitted in

the installation.

Spec of Pressure

release valve:

Pressure: 0.7MPa

Notice:

Tempering valve required

Water Outlet

Water Inlet

Tap Water

Thermal expansion tank

(if required)

Magnesium

Condensate Outlet

Drainpipe

Barrel-drain

Pressure release valve

When the tankpressure reaches 0.7MPa,the Pressure release valve will open

automatically so asto decrease thepressure .

ATTENTION

Pipeline connection explanation

Installation of thewater inlet oroutlet pipes:The specification ofthe water inletand

outlet thread isBSP3/4(internal thread).pipesmust be heat-resistantand durable.

Installation of thepipe for Pressurerelease valve:The spec ofthe valve connecting

thread is BSP3/4(internal thread).After installation,it must beconfirmed that the

drainpipe outlet isexposed in theair. drainpipe is joinedto the

pressure relief orificeof this valve,you must ensure that the flexbledrainpipe

and exposed inthe air.

When the flexible is

pointing downwards

ATTENTION:The Pressurerelease valve attachedwith the unitmust be installed,

will cause damageto the unit, .failure to doso and possible personalinjury

Do not usestainless steel fittingsto connect directlywith other metalsto prevent

galvanic corrosion.

Drain the watertankthrough thedrain valveatthe bottom partofthe unit.

9

4. Installation

4.2

As arule, the unitis to bestored and/or transportedin its shippingcontainer in the upright

position and withoutwater charge. Fortransport over shortdistance, and provideddue care is

exercised, an inclinationangle of upto 30 degreeis permitted. Bothduring transport and

storage, ambient temperaturesof 0 to 40 are permissible.

4.2.1 Transportusing a forklift

When transported bya fork lift,the unit mustremain mounted onthe pallet.The lifting rate

should be keptto a minimum.Due to itstop-heaviness, the unitmust be securedagainst

tipping over.To prevent anydamage, the unitmust be placedon a levelsurface!

4.2.2 Manual transport

For the manualtransport, the woodenpallet can beused for bottompart.

Using ropes orcarrying straps, asecond or thirdhandling configuration ispossible. With this

type of handling,care must betaken that themax.

Permissible inclination angleof 60 degreeis not exceeded.If transport inan inclined

position cannot beavoided, the unitshould be placedinto operation onehour after ithas been

moved into finalposition.

Transportation

CAUTION High center of gravity!

4. Installation

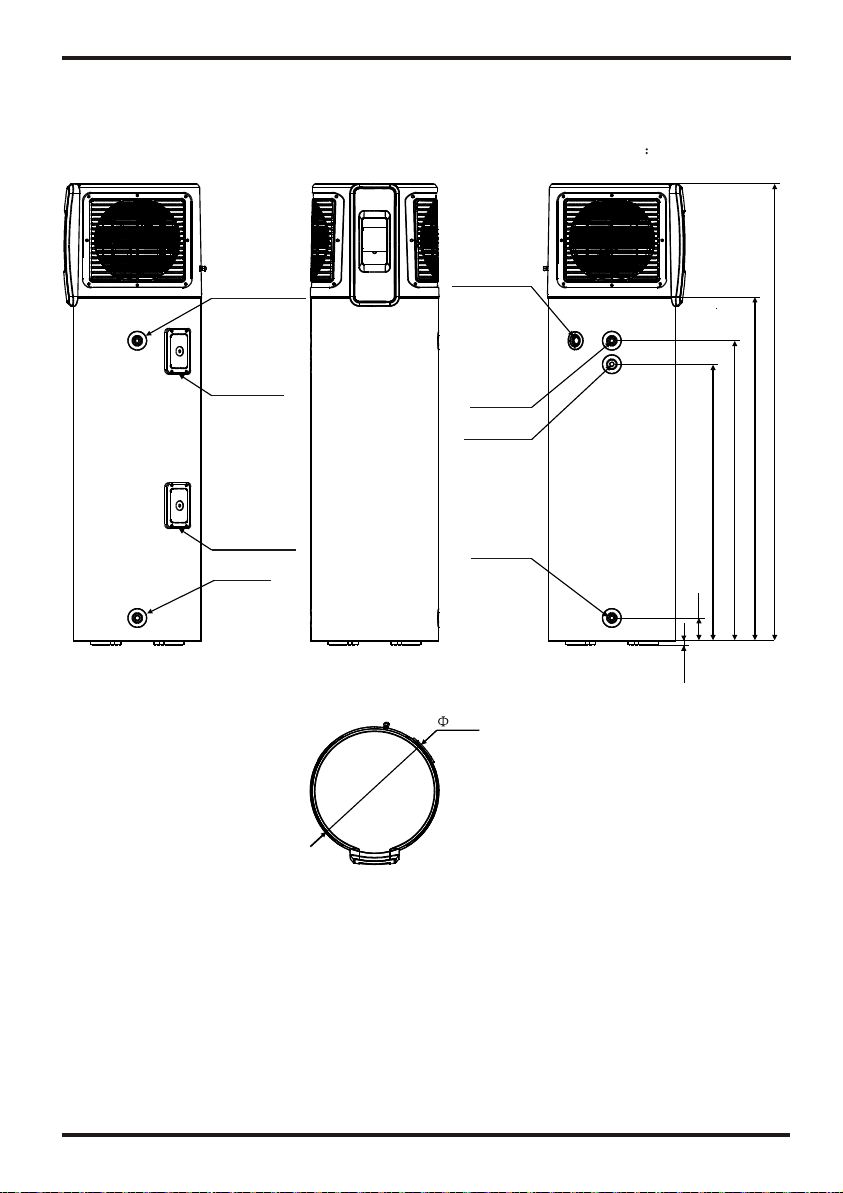

4.3 Installation space

Before installation, pleaseensure that youleave the spaceas shown belowfor maintenance.

Unit:mm

WARNING

For continuedsafety ofthis applianceit mstbe installed,operated and

maintained in accordancewith the manufacturer'sinstructions.

If thewater supplypressure exceedsthe ratedpressure, apressure reducing

valve is tubefitted when installingthe unit.

The watermay dripfrom thedischarge pipeof thepressure reliefdevice andthat

this pipemust beleft opento theatmosphere.

The pressurerelief device shouldbe operated regularlyto remove limedeposits

and verifythat itis notblocked.

Adischarge pipeconnected tothe pressurerelief deviceis tobe installedin a

continuously downward directionand in afrost-free environment.

Facilities ford rainingand filling ofsystems shall beprovided where thesea

required forservicing purposes.The drainagefacilities, wherefitted, shallbeat the

lowest point inthe closed circuit.

CAUTION :The minimum space of installation is 10 cubic meter.

10

Air inlet

Air outlet Display

Barrier

500 1000

300

9

4. Installation

4.2

As arule, the unitis to bestored and/or transportedin its shippingcontainer in the upright

position and withoutwater charge. Fortransport over shortdistance, and provideddue care is

exercised, an inclinationangle of upto 30 degreeis permitted. Bothduring transport and

storage, ambient temperaturesof 0 to 40 are permissible.

4.2.1 Transportusing a forklift

When transported bya fork lift,the unit mustremain mounted onthe pallet.The lifting rate

should be keptto a minimum.Due to itstop-heaviness, the unitmust be securedagainst

tipping over.To prevent anydamage, the unitmust be placedon a levelsurface!

4.2.2 Manual transport

For the manualtransport, the woodenpallet can beused for bottompart.

Using ropes orcarrying straps, asecond or thirdhandling configuration ispossible. With this

type of handling,care must betaken that themax.

Permissible inclination angleof 60 degreeis not exceeded.If transport inan inclined

position cannot beavoided, the unitshould be placedinto operation onehour after ithas been

moved into finalposition.

Transportation

CAUTION High center of gravity!

4. Installation

4.3 Installation space

Before installation, pleaseensure that youleave the spaceas shown belowfor maintenance.

Unit:mm

WARNING

For continuedsafety ofthis applianceit mstbe installed,operated and

maintained in accordancewith the manufacturer'sinstructions.

If thewater supplypressure exceedsthe ratedpressure, apressure reducing

valve is tubefitted when installingthe unit.

The watermay dripfrom thedischarge pipeof thepressure reliefdevice andthat

this pipemust beleft opento theatmosphere.

The pressurerelief device shouldbe operated regularlyto remove limedeposits

and verifythat itis notblocked.

Adischarge pipeconnected tothe pressurerelief deviceis tobe installedin a

continuously downward directionand in afrost-free environment.

Facilities ford rainingand filling ofsystems shall beprovided where thesea

required forservicing purposes.The drainagefacilities, wherefitted, shallbeat the

lowest point inthe closed circuit.

CAUTION :The minimum space of installation is 10 cubic meter.

10

Air inlet

Air outlet Display

Barrier

500 1000

300

11

4. Installation 4.Installation

12

4.4 Cable connection

4.5 Trial running

This unit requires an isolating switch as required by local by laws.

4.5.1 Inspection before trial running

Check the watersupply to thetank and pipeconnections for possibleleaks.

Check that allpower connections aresecure before switchingon.

4.5.2Trialrunning

Switch on the unit using the controller

In the caseof any unusualnoise, switch thepower offand consult yourprovider;

If the powercord is damaged,It must bereplaced by aqualified electrician.

The parameters havebeen pre setto a temperatureof 60 degrees.

Unit:mm

4.6 Seismic restraints

The unit must be braced with with seismic restraints according to local by laws.

1000

500

600

11

4. Installation 4.Installation

12

4.4 Cable connection

4.5 Trial running

This unit requires an isolating switch as required by local by laws.

4.5.1 Inspection before trial running

Check the watersupply to thetank and pipeconnections for possibleleaks.

Check that allpower connections aresecure before switchingon.

4.5.2Trialrunning

Switch on the unit using the controller

In the caseof any unusualnoise, switch thepower offand consult yourprovider;

If the powercord is damaged,It must bereplaced by aqualified electrician.

The parameters havebeen pre setto a temperatureof 60 degrees.

Unit:mm

4.6 Seismic restraints

The unit must be braced with with seismic restraints according to local by laws.

1000

500

600

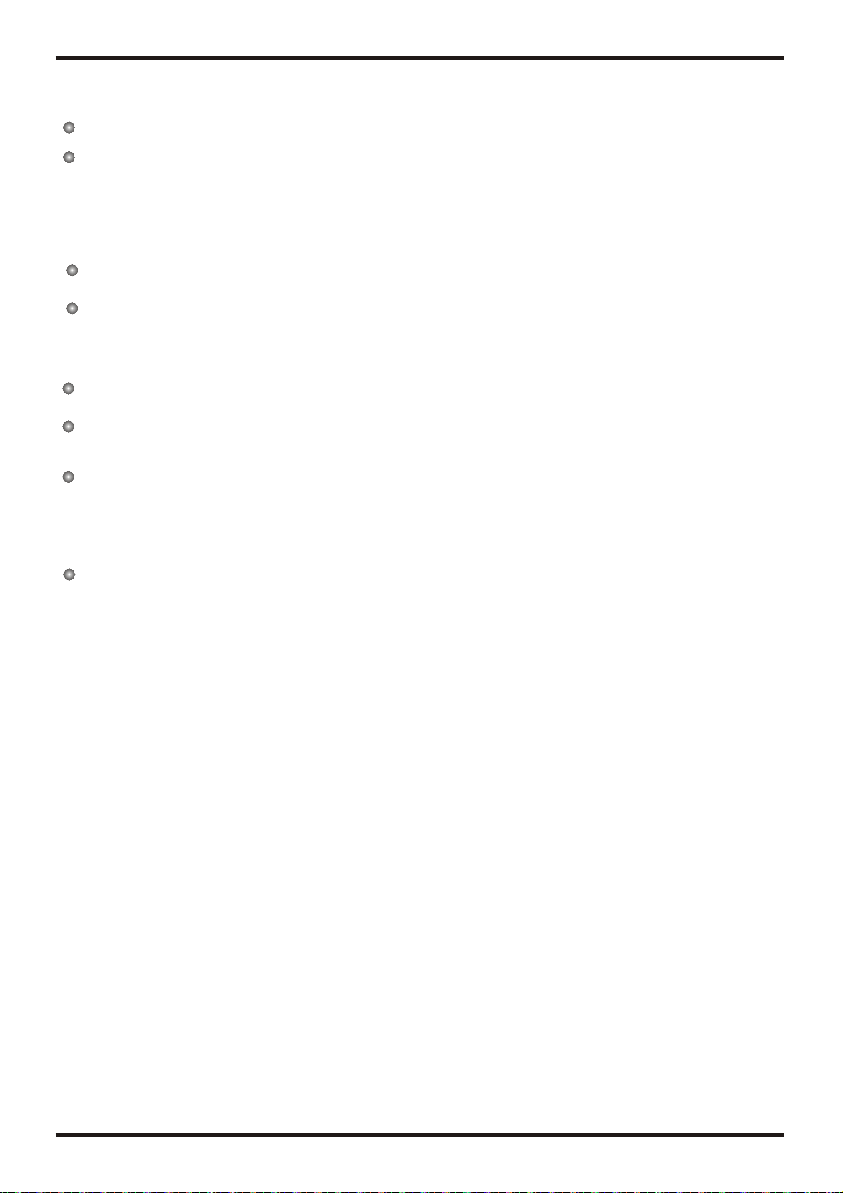

13 14

5.Usage Usage

5.1 Thefunction diagram ofthe wire controller

1.Function ofwire controller

1 Function of key

NO. Button Name Function

1

2

3

4

5

6

ON/OFF

Mode

Electric

Heater

Up

Down

Turn on/offthe unit.

Switch unit runningmodes or savesetting parameters.

Set the clockor the timer.

Turn on/offthe electric heateror switch fanmodes.

Move up orincrease parameter values.

Move down ordecrease parameter values.

Clock

Main display

area

Auxiliary display

area

123456

Electric

heater

Fan

Shows that theelectric heater ison.

Shows that thefan is onand the speedof the fan.

Set temperature

achieved Shows that thewater temperature hasreached the target

point and theunit shut off automatically.

Timer &ON

Timer &OFF Shows that theunit will beturned offby the timer

automatically.

Shows that theunit will beturned on bythe timer

automatically.

Minute Shows that themain display areadisplays the minute.

Second Shows that themain display areadisplays the second.

Centigrade

Fahrenheit

Parameter

setting Shows that theparameter is adjustable.

Lock Shows that thekeyboard is locked.

Status

icon What it means

Heating

Vacation

Shows that theunit is inheating mode.

Shows that theunit is invacation mode.

Eco.heating

Temperature Shows that thetemperature is non-adjustable

(measured value).

Name

Shows that theunit is ine mode.co.heating

Shows that thetemperature in Maindisplay area orAuxiliary

display area isin .

Shows that thetemperature in Maindisplay area orAuxiliary

display area isin .

13 14

5.Usage Usage

5.1 Thefunction diagram ofthe wire controller

1.Function ofwire controller

1 Function of key

NO. Button Name Function

1

2

3

4

5

6

ON/OFF

Mode

Electric

Heater

Up

Down

Turn on/offthe unit.

Switch unit runningmodes or savesetting parameters.

Set the clockor the timer.

Turn on/offthe electric heateror switch fanmodes.

Move up orincrease parameter values.

Move down ordecrease parameter values.

Clock

Main display

area

Auxiliary display

area

123456

Electric

heater

Fan

Shows that theelectric heater ison.

Shows that thefan is onand the speedof the fan.

Set temperature

achieved Shows that thewater temperature hasreached the target

point and theunit shut off automatically.

Timer &ON

Timer &OFF Shows that theunit will beturned offby the timer

automatically.

Shows that theunit will beturned on bythe timer

automatically.

Minute Shows that themain display areadisplays the minute.

Second Shows that themain display areadisplays the second.

Centigrade

Fahrenheit

Parameter

setting Shows that theparameter is adjustable.

Lock Shows that thekeyboard is locked.

Status

icon What it means

Heating

Vacation

Shows that theunit is inheating mode.

Shows that theunit is invacation mode.

Eco.heating

Temperature Shows that thetemperature is non-adjustable

(measured value).

Name

Shows that theunit is ine mode.co.heating

Shows that thetemperature in Maindisplay area orAuxiliary

display area isin .

Shows that thetemperature in Maindisplay area orAuxiliary

display area isin .

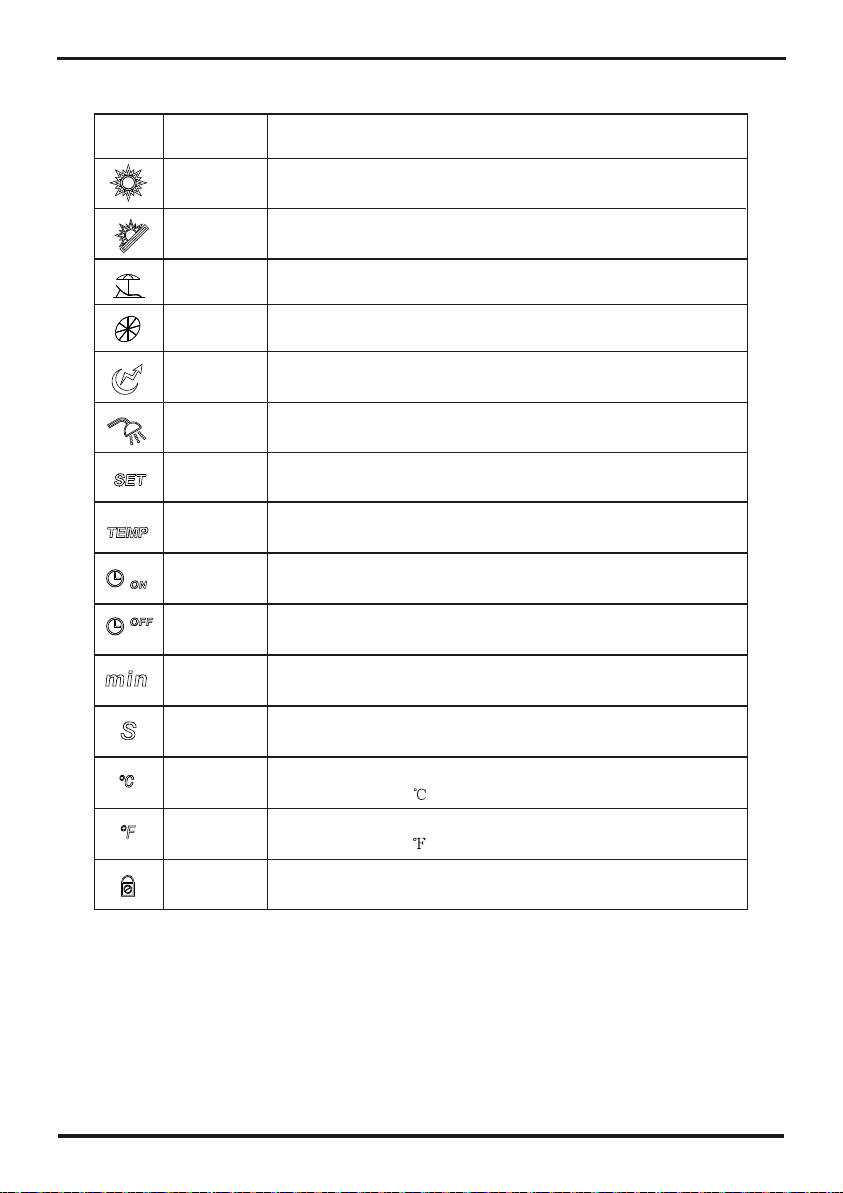

15

5.Usage

16

5.Usage

5.2 Usageof wirecontroller

Outlet water temperature

Press " " and hold for0.5s.

Inlet water

temperature

Heating mode

Standby interface

5.2.2 Modeselection

Press " " to select themode from Heating,Eco.heating , , Vacation, High

requirement in thestandby or runninginterface.

For example:

Intelligent

Running interface

5.2.1 TurnON/OFF the unit

Press " " and hold for0.5s in thestandby interface ofthe wire controllerto turn onthe

unit and atthis time themain display areashows the wateroutlet temperature.

Press " "and hold for 0.5s in therunning interface ofthe wire controllerto turn off the

unit and atthis time themain display areashows OFF.

Note: TheON/OFF button canonly be usedto turn on/off the unitin standby orrunning

interface of thewire controller.

5.2.3 Target temperature checkingand setting

In the standbyor running interface,press " "or " "once to checkthe target temperature

of the outletwater. Press " " or " " againto change thetarget temperature.After making

the changes tothe parameter,press " "to confirm or" " tocancel the changes,then

return to theprevious interface. Ifno operations areperformed on thekeypad for 5s,the

controller exits theparameter modification menuby timeout andthe changes areconfirmed.

Setting 75 " "

" "

C When the targettemperature is adjustedto 60 C, press andhold the for

5s. Atthis time, thetarget temperature isdisplayed as 61 C and thetemperature range

changed to 38-75C. Press the to set thetarget temperature to75 C.

Example: Change thetarget temperature from55 C to 70C when the actualoutlet water

temper is 18.

Press

Press

Press

Heating mode

Outlet water

temperature

Time Eco.heating mode

Vacation mode

Date

modeIntelligent

Press High requirement mode

15

5.Usage

16

5.Usage

5.2 Usageof wirecontroller

Outlet water temperature

Press " " and hold for0.5s.

Inlet water

temperature

Heating mode

Standby interface

5.2.2 Modeselection

Press " " to select themode from Heating,Eco.heating , , Vacation, High

requirement in thestandby or runninginterface.

For example:

Intelligent

Running interface

5.2.1 TurnON/OFF the unit

Press " " and hold for0.5s in thestandby interface ofthe wire controllerto turn onthe

unit and atthis time themain display areashows the wateroutlet temperature.

Press " "and hold for 0.5s in therunning interface ofthe wire controllerto turn off the

unit and atthis time themain display areashows OFF.

Note: TheON/OFF button canonly be usedto turn on/off the unitin standby orrunning

interface of thewire controller.

5.2.3 Target temperature checkingand setting

In the standbyor running interface,press " "or " "once to checkthe target temperature

of the outletwater. Press " " or " " againto change thetarget temperature.After making

the changes tothe parameter,press " "to confirm or" " tocancel the changes,then

return to theprevious interface. Ifno operations areperformed on thekeypad for 5s,the

controller exits theparameter modification menuby timeout andthe changes areconfirmed.

Setting 75 " "

" "

C When the targettemperature is adjustedto 60 C, press andhold the for

5s. Atthis time, thetarget temperature isdisplayed as 61 C and thetemperature range

changed to 38-75C. Press the to set thetarget temperature to75 C.

Example: Change thetarget temperature from55 C to 70C when the actualoutlet water

temper is 18.

Press

Press

Press

Heating mode

Outlet water

temperature

Time Eco.heating mode

Vacation mode

Date

modeIntelligent

Press High requirement mode

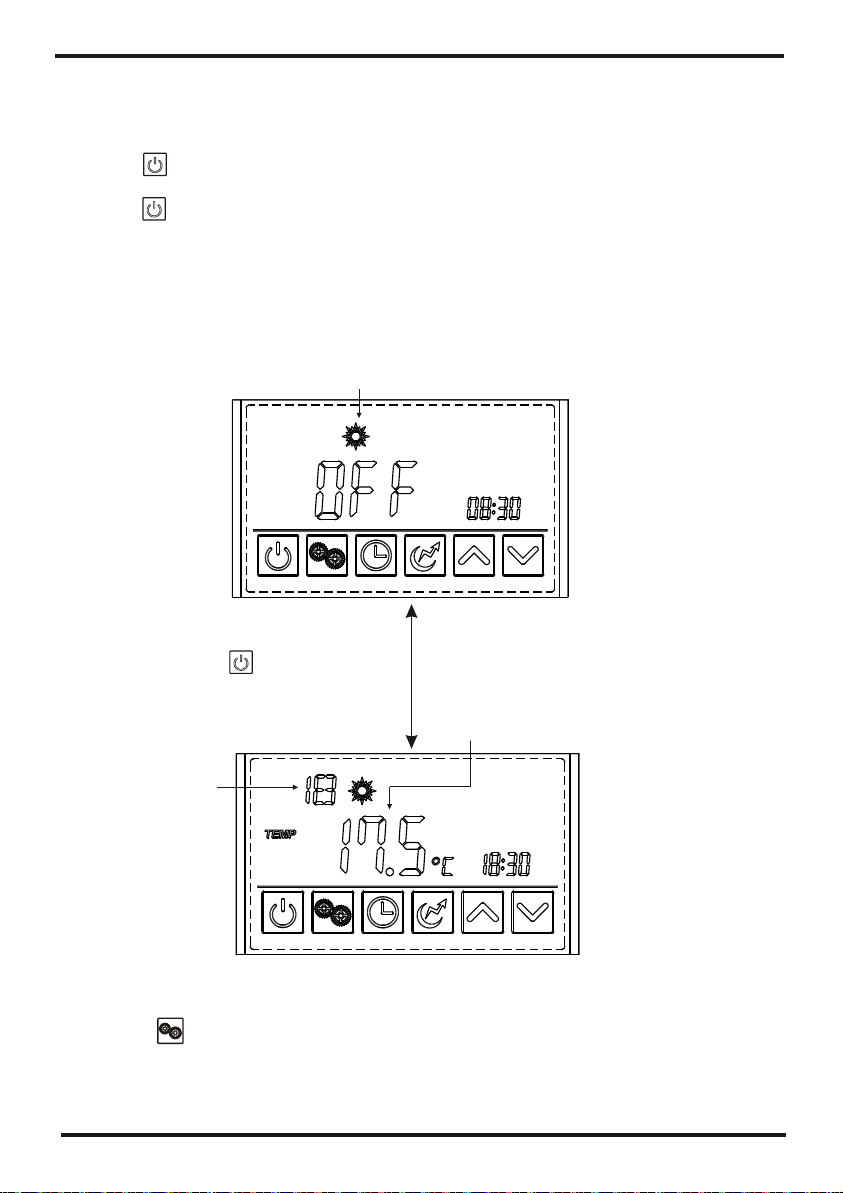

5.Usage

17

Outlet water temperature

Time Target temperature

Press and hold the for 5s ,then press

or again to change the target

temperature.

Press

to confirm

or to

cancel, then

return to the

previous

interface.

Press

to change the

target

temperature

from 55 to

60 .

5.2.4 Timesetting

In the standbyor running interface, do as followsto set thetime when inheating mode. When

press " "once, the timeparameter will flash.When press " " again, thehour parameter

will flash thenpress " "or " "to change it.After makingthe changes tothe parameter,

press" " toconfirm, then changethe minute parameteras well asthe date parameterin the

same way.

If no operationsare performed onthe keypad for10s, the controllerexits the parameter

modification menu bytimeout and thechanges are confirmed.

Note: Set the datein the sameway when in vacation mode.

Example: Change thetime and datefrom 18:30 onAugust 4thto 17:40 onSeptember 8th.

Time

Press

twice then

press or

to change

the hour

parameter

and press

to confirm.

Press " " or " " to change the minute

parameter.

5. Usage

18

The new set time

Press " " to confirm.

Press " " or " " to change the minute

parameter.

The date is flashing

Press once then press or to change

the month parameter and press to confirm.

Press " " or

" " to change

the day parameter.

Press" "

to confirm.

5.2.5 Timersetting

5.2.5.1 Under thestandard mode, economicmode, intelligent mode,you can enterthe timer

setting.

Press " "and hold for2s, the "ON"and " 1 " will flash,and then youcan set theturn on

time of timer1as the 24clock setting show. Afterfinishing, " OFF" and " 1 " willflash, that

means you canset the turnoff timeof timer1.The "ON "and " 2 " will flashafter finishing the

timer1 setting, youcan set theturn on timeof timer2.After finishing, the" OFF "and " 2" will

flash, and thenyou can setthe turn off time oftimer2. Press " " again tosave and backto

the interface. Ifyou don't needto set thetimer2, you canpress the " " to saveafter finishing

the timer1 setting.Youwill find the" ON "and " 2 " flash. Nooperation for 5s,the program will

back to theinterface automatically.

Note: When press" " andhold for 2s,the " ON " and "1 " willflash. It isnot necessary for

you to setthe turn ontime of thetimer1. You can sequentiallyto press " " for 2sto enter to

the turn off time oftimer1. So doesthe timer2. Orpress " "or " " to circularly display.

Timer Cancel:Press " " and hold for2s to enterinto the interface,and then press" "

to cancel allthe operation. Pleasesee the followingpicture for moredetails.

Table of contents

Other Solahart Heat Pump manuals

Popular Heat Pump manuals by other brands

alphainnoTec

alphainnoTec LW 161H-A/V operating manual

Glowworm

Glowworm Envirosorb 8 Instructions for use

alphainnoTec

alphainnoTec PWZS H1 Series operating manual

Aqua PRO

Aqua PRO ECO550 Installation and user manual

Pro-Team

Pro-Team P5 Installation and instruction manual

Seabreeze

Seabreeze SMZC9H4ZIGX user manual

Mark

Mark HKEU 353 Technical manual

Water Furnace

Water Furnace E Series installation manual

Trane

Trane Precedent PKGP-PRC003-EN user manual

Dimplex

Dimplex LA 17PS Installation and operating instructions

Dimplex

Dimplex WIH 120TU Installation and operating instruction

Galletti

Galletti EXCELIA MXE 009M manual