Solaria S6P2G User manual

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

Installation manual for Solaria photovoltaic

standard modules

S6M2G, S6P2G, S6M2G-3BB, S6P2G-3BB

2

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

Installation Manual

Tips for the Installer

Contents

-Safety Warnings

-Product Identification

-Fire Safety

-Unpacking And Transitory Use Of The Module

-Mechanical Installation

-Electrical Instructions

-Grounding

-Maintenance, Cleaning & Recycling

-Data Sheet (Electrical Performance)

3

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

Solaria Photovoltaic Modules

INSTALLATION, USE & MAINTENANCE

INSTRUCTIONS

This document contains information about the

installation and safety issues of the photovoltaic

modules manufactured by Solaria. Before handling

or connecting the modules it is very important to

read and understand all the instructions. The

module produces electricity as soon as the cells are

exposed to the sunlight. This manual is valid for the

following families of SOLARIA´s standard

photovoltaic modules: S6M2G and S6P2G.

DISCLAIMER

The manufacturer assumes NO liability for damage

incurred due to non-compliance of these

instructions. These instructions are only for

specialists who are familiar with the installation due

to their technical qualification.

PRODUCT CERTIFICATE & GUARANTEE

SOLARIA photovoltaic modules are manufactured

with high quality materials, according to the

international IEC 61215:2005 standards. The

modules are Class A rated according to the IEC

61730-1:2004 standards and they meet electrical

safety Class II requirements established in the IEC

61140 standard.

SAFETY WARNINGS

-Do not touch the electrical terminals when

the module is exposed to the light or while

the module is installed. The photovoltaic

modules produce electricity when they are

exposed to the light so the contact with the

conductor poles of the module can produce

sparks or burns.

-Cover the front side of the module with an

opaque element during the installation in

order to avoid the generation of electrical

current during the stages of mechanical and

electrical installation.

-Use only insulated tools that have the

necessary requirements to operate in

electrical installations

-DO NOT use modules near to

equipments or in places where inflammable

gases are accumulated.

-DO NOT handle the modules if they are

wet.

-Disconnect the module from other electrical

sources, as for example batteries during

installation or any other maintenance

activity. Read carefully manufacturer´s

instructions when using batteries.

-DO NOT touch the terminals with bare

hands.

-When working both in “rooftop and ground

mounted installations”, installers must wear

electrical safety boots.

-When assembling on the roof check existing

regulations and safety instructions to

prevent from falling objects and ensure you

follow accident prevention regulations and

use appropriate safety rails.

-Respect the polarity of the modules cables

at the interconnection with other modules

or another electric element.

-DO NOT disconnect the terminals while

the photovoltaic modules generate

electricity and are connected to the grid; in

this way you will avoid the risk of electrical

shock.

-Never dismantle the junction box, frame or

any other component of the module.

-When assembling and servicing photovoltaic

modules observe national grid regulations

and safety instructions for the installation of

electrical devices and any regulations from

4

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

the utility regarding the grid tie operation of

photovoltaic systems.

-When installing any product for lightning

and surge protection read carefully the

manufacturer´s specifications and national

grid regulations

Danger of Death!

-Before any operation of maintenance and

during installation, switch the modules off

with a disconnection switch. Working with

conductors which conduct direct current

can cause electric arcs.

-DO NOT exceed the maximum system

voltage specified in the label of the module

under any ambient temperatures.

Danger of Death!

-When connecting/disconnecting the

modules to the inverter take special care

and perform the operation under secure

conditions. Observe carefully the

instructions of the inverter. Even after

disconnection of the inverter there is a risk

of electric shock.

PRODUCT IDENTIFICATION

SOLARIA photovoltaic modules have a label at the

rear side that provides detailed information for the

identification of the product:

-The name of the module´s type is formed by

an “S”, followed by a number and a second

letter that determines the technology of the

cells. The word that identifies the family (for

example “2G”) is followed by a number that

shows the nominal power of the PV module

-The serial number, used to identify the

specific product. Every module has a unique

serial number.

-Electrical characteristics of the module.

-Maximum system voltage.

DO NOT remove the label.

If you remove the label, SOLARIA will not be responsible for the

warranty of the product.

FIRE SAFETY

-SOLARIA recommends checking local

authority guidelines and requirements for

building safety.

-DO NOT install modules near equipment or

locations where flammable gases can be

produced or located.

-When installing on a roof, modules must be

mounted on an approved fire resistant cover

for this type of installation.

-Operating temperature: All Solaria modules

must be mounted in environments that

ensure Solaria modules will operate within

the following maximum and minimum

operating temperature:

Maximum Operating

Temperature

+90º Celsius, +194º

Fahrenheit

Minimum Operating

Temperature

-40º Celsius-40

ºFahrenheit

UNPACKING & TRANSITORY USE OF THE MODULE

5

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

-Preserve the module in its package until it is

ready for installation.

-It´s recommendable to make all necessary

product inspection before installation.

-Do not use the junction box or external

connection wires to handle the module.

-Do not put the modules on the frame corners or

on top of each other. This could damage the

frames and shall lead the withdrawal of the

warranty of the module.

-It´s recommended opening the top and front

side of the packaging for the extraction of the

modules. Please do this operation carefully to do

not damage the glass or the backsheet.

-Do not store the modules on wet locations.

-Store modules with good ventilation and keep

contacts free of dust.

-Protect the glass and the backsheet of the

module against scratching or other damages.

MECHANICAL INSTALLATION

Site Selection

Select a suitable location to install the module. It

should be positioned avoiding any shadow from

other objects between 9.00 and 15.00h (during

the shortest day of the year). The photovoltaic

modules should typically face South in the

Northern Hemisphere and typically should face

North in the Southern Hemisphere. An ideal

installation should be with no shading effect at

any time during the year. Modules must be

correctly fixed in their place so they can resist

any load, including wind and the weight of the

snow.

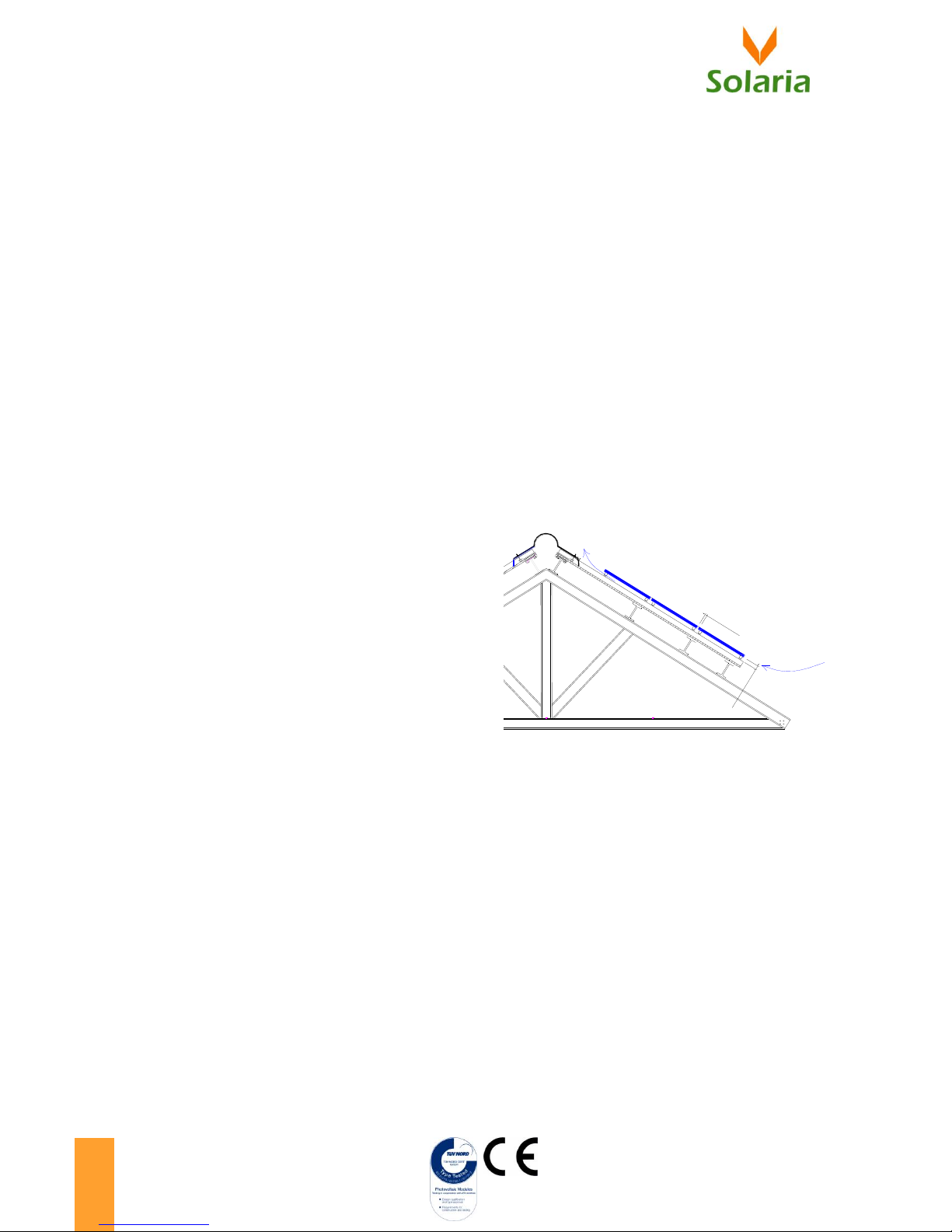

Ventilation

-It´s recommendable to install the modules

leaving a separation of 2 cm between them to

allow a correct thermal expansion.

-Assembling on roof allows good ventilation in

the back side of the modules assuring enough

distance between the back side and the

mounting structure. Minimum distance between

the wall or roof and the modules must be

approximately 10 centimetres to allow air

circulation behind the module and to dissipate

any condensation or moisture. Install the

modules in a way that air can flow between the

roof and the module.

Assembling

Manufacturer recommends attaching the modules

to the support structure using the proper fixing

systems according to the information provided in

this manual. The owner will be responsible of

damages caused by a wrong attachment.

Do not make drills in the frame or in the glass of

the module. Otherwise, SOLARIA will not be

responsible for the warranty of the product.

10cm

2cm

Linear Thermal Expansion

ventilation

6

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

Mechanical Load

-Modules must be properly fixed so they can

resist any load, including wind and snow load

specified in the product data sheet. The

attachments must be dimensioned to cope with

location´s load requirements.

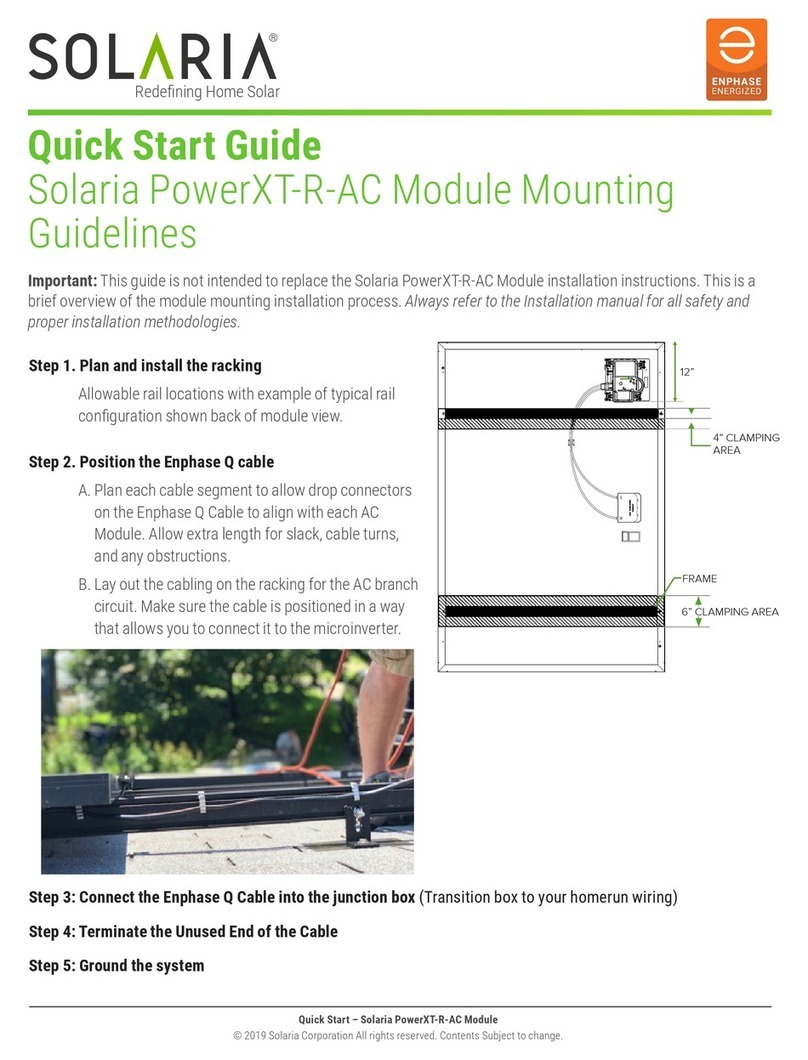

Clamping System & Assembly boreholes

-Solaria PV modules can either be installed in a

vertical or horizontal position by using stainless

steel screws on the existing assembly boreholes

factory carved on the module frame or by using

module clamps on the module frame.

-If the module is installed in a horizontal position,

it must be fixed with a screw fitting or clamp on

the long side of the frame. DO NOT fix the

module using the short side of the frame.

-The minimum number of attachment points will

be 4as the number of the mounting frame holes

(see the detail of the drawing below) or 4

module clamps located in the right area (see

attachment guidelines).

Detail of one attachment point (mm)

Clamping System

Modules can be fixed to the structure by using fixing

module clamps. Module clamps must not deform

the frame and must not come in contact with the

front glass.

Assembly boreholes (with screw fitting)

Frame Holes: Secure the module to the structure by

using the mounting holes with a screw fitting. Four

0.25” or M6 stainless steel bolts, with nuts, washers,

and lock washer are recommended per module.

For other types of mounting methods, please consult SOLARIA.

Any different mounting methodology not checked first with

Solaria, will cancel the warranty of the product and the module

certification

Assembly

Boreholes

M6x12mm

Assembly

Module

Clamps

AssemblyBoreholes

M6X12mm

Assembly

ModuleClamps

Assembly

Boreholes

Assembly

Boreholes

AssemblyModule

Clamps

AssemblyModule

Clamps

7

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

Attachments Guideline

Maximum load 5.400 Pa

MODULE TYPE

VERTICAL ASSEMBLY

HORIZONTAL ASSEMBLY

S6P(S6M)2G

Screw fitting on assembly boreholes

L = 1646 mm / B = 991 mm

L1 = 1098 mm

L2 = 274 mm

Assembly with Module Clamps

Module Clamp

F = Distance to the module´s clamp axis

Fmin = 1/4 L

Fmax = 1/8 L

L = 1646 mm / B = 991 mm

L1 = 1098 mm

L2 = 274 mm

Clamps must be fixed on the longer side of

the frame

Screw fitting on assembly boreholes

L = 1646 mm / B = 991 mm

L1 = 1098 mm

L2 = 274 mm

Assembly with Module Clamps

Module Clamp

F = Distance to the module´s clamp axis

Fmin = 1/4 L

Fmax = 1/8 L

L = 1646 mm / B = 991 mm

L1 = 1098 mm

L2 = 274 mm

Clamps must be fixed on the longer side of the

frame

Assembly

Boreholes

M6x12mm

Assembly

Module

Clamps

AssemblyBoreholes

M6X12mm

Assembly

ModuleClamps

Assembly

Boreholes

Assembly

Boreholes

AssemblyModule

Clamps

AssemblyModule

Clamps

Assembly

Boreholes

M6x12mm

Assembly

Module

Clamps

AssemblyBoreholes

M6X12mm

Assembly

ModuleClamps

Assembly

Boreholes

Assembly

Boreholes

AssemblyModule

Clamps

AssemblyModule

Clamps

Assembly

Boreholes

M6x12mm

Assembly

Module

Clamps

AssemblyBoreholes

M6X12mm

Assembly

ModuleClamps

Assembly

Boreholes

Assembly

Boreholes

AssemblyModule

Clamps

AssemblyModule

Clamps

Assembly

Boreholes

M6x12mm

Assembly

Module

Clamps

AssemblyBoreholes

M6X12mm

Assembly

ModuleClamps

Assembly

Boreholes

Assembly

Boreholes

AssemblyModule

Clamps

AssemblyModule

Clamps

8

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

ELECTRICAL INSTRUCTIONS

-Photovoltaic stuffs should be installed by qualified

personnel only.

-In order to protect the module against hot spots,

the photovoltaic modules have protection diodes

(by-pass diodes) integrated in the junction box,

installed in the back side of the module.

-In normal conditions, SOLARIA modules can produce

more current and voltage than the indicated in the

standard conditions that appear in the module

label. For this reason, the Isc and Voc values should

be multiplied by a 1,25 factor for the design of the

fuses, wiring and other elements of the installation.

-Equipments and wiring should be suitable for

electrical photovoltaic systems. Use only UV-

resistant and weather-resistant elements. For the

wire section calculations the directive “2006/95/EC”

were used.

-The fuses amperage used to protect the system

from overcurrents is 15A. These fuses should be

placed in series with the module/s.

-Observe that electrical continuity exists between

the frames of the module because corner key used

between frames is Aluminium 6060 Treatment T6.

SOLARIA photovoltaic modules should be ground

connected for safety reasons.

Connecting modules in series

-Note that if modules are connected in series, the

total voltage will be equal to the sum of the

individual voltages, so modules connected in

parallel don’t make the system voltage to be higher

than the maximum system voltage specified in the

module label. All modules connected in series must

be modules of the same model.

-SOLARIA photovoltaic modules guarantee an

electrical isolation up to 1000 V. Consequently,

modules can be connected in series up to the

voltage mentioned above.

Connecting modules in parallel

-If the modules are connected in parallel, total

current will be the sum of all the individual currents,

which must be considered for the selection of the

type of connectors and the wire section

calculations.

Wiring and Junction Box

-DO NOT open the junction box.

-The junction box has an IP65 protection degree,

with fast no- error connectors with IP67

protection degree.

-Modules incorporate a solar cable with the

following specifications:

Size and type characteristics of the wires: 2 solar black

cables of 100 cm and a section of 4mm2with Tyco

Solar-Lock connectors. Plugs are marked with the

respective polarity. The Minus pole is minus-coded and

the Plus pole is neutrally coded:

Minus Pole Plus Pole

(Female Cable Coupler) (Male Cable Coupler)

Thermal Characteristics: Solar black cables must work

in a range of temperature between: - 40 ⁰ C and + 90 ⁰

C.

9

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

GROUNDING

-SOLARIA photovoltaic modules should be ground

connected for safety reasons. Modules have several

holes in the frame for this purpose, and wiring to

ground will be done using any of them. Please

follow instructions of grounding section. This

connection should be done according to the

standards and local regulations.

-SOLARIA recommends the following method for

grounding the module frame:

-Modules frame have two 0.16‘’

grounding holes that should be ground

connected for safety and protection

reasons.

-A stainless steel bolt M4 of 2 cm length

(Torque grading 1.08 Nm) will be used.

A nut M4 stainless steel will be used.

-It is suggested to use a single ground

conductor 12 AWG (General Cable

H07V-U).

-A spring stainless steel M4, 3 flats

washer stainless steel M4, a cup washer

M4, and a star washer stainless steel

M4, will be used to assembly the

grounding.

-SOLARIA also recommend the following methods for

grounding connection:

-Tyco Electronics Solklamp, M4 bolt

-Tyco Electronics Solklip, M4 bolt

MAINTENANCE, CLEANING & RECYCLING

-It’s recommended to wear rubber gloves for

electrical insulation whilst maintaining, washing

or cleaning modules.

-Do not walk or rest on the surface of the

module and do not drop anything on top of the

the module.

-SOLARIA photovoltaic modules do not need a

high level of maintenance, but it is advisable to

check their electrical and mechanical

connections periodically.

-When necessary, you can clean the surface of

the glass with water, a soft window cleaner (not

abrasive) and a cloth to avoid damages on the

surface.

-Non aggressive and abrasive cleaners or

chemicals should ever be used on the treated

Groundingholes

Drainageholes Drainageholes

Drainageholes Drainageholes

Orificiospara

PuestaaTierra

Orificiosde

Drenaje Orificiosde

Drenaje

Orificiosde

Drenaje Orificiosde

Drenaje

10

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

front glass. No alkali based chemicals should be

used including ammonia based solutions.

-SOLARIA suggest checking electrical connections

for loose connections and corrosion.

-In case of covering the surface of the module by

snow, DO NOT use any type of scraper. Perform

the operation with any other object than cutting

or stabbing.

-Frame is factory carved with special drains to

prevent accumulation of snow and rain on the

back side of the frame. DO NOT block or modify

these drain holes:

-To recycle the modules observe current national

requirements and consult a qualified and authorized

specialist.

Groundingholes

Drainageholes Drainageholes

Drainageholes Drainageholes

Orificiospara

PuestaaTierra

Orificiosde

Drenaje Orificiosde

Drenaje

Orificiosde

Drenaje Orificiosde

Drenaje

11

www.solariaenergia.com

IEC Edition 3.0

v3-September-2012

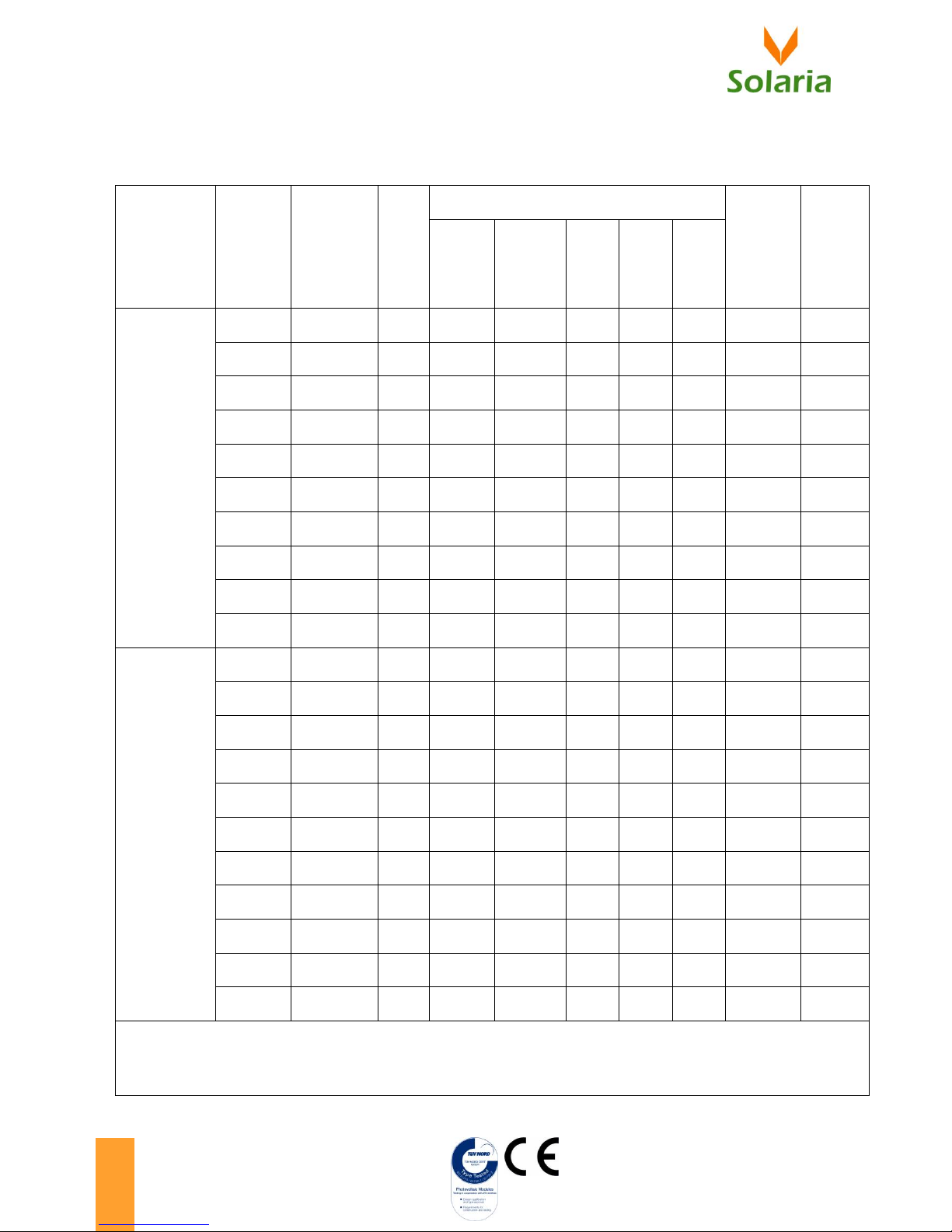

DATA SHEET

Module Series

Model

Dimensions

( ±3 mm )

Weight

(kg)

Electrical Performance @ STC (*)

Max.System

Voltage

[Vdc]

Max.Fuses

Series

[A]

Maximum

Power

Pmp [Wp]

Voltage at

Max.Power

Vmp [V]

Current

at

Max.

Power

Imp [A]

Open

Circuit

Voltage

Voc [V]

Short

Circuit

Current

Isc [A]

60 cells 156 x 156 mm

Monocrystalline Silicon

SPV Module

S6M2G195

1646x991x38

19

195

27,17

7,18

35,42

8,27

1000

15

S6M2G200

1646x991x38

19

200

27,52

7,27

35,66

8,29

1000

15

S6M2G205

1646x991x38

19

205

27,86

7,36

35,90

8,32

1000

15

S6M2G210

1646x991x38

19

210

28,20

7,45

36,14

8,34

1000

15

S6M2G215

1646x991x38

19

215

28,52

7,54

36,38

8,37

1000

15

S6M2G220

1646x991x38

19

220

28,84

7,63

36,62

8,39

1000

15

S6M2G225

1646x991x38

19

225

29,15

7,72

36,86

8,42

1000

15

S6M2G230

1646x991x38

19

230

29,46

7,81

37,10

8,44

1000

15

S6M2G235

1646x991x38

19

235

29,75

7,90

37,34

8,47

1000

15

S6M2G240

1646x991x38

19

240

30,05

7,99

37,58

8,49

1000

15

60 cells 156 x 156 mm

Polycrystalline Silicon

SPV Module

S6M2G245

1646x991x38

19

245

30,33

8,08

37,82

8,52

1000

15

S6P2G195

1646x991x38

19

195

27,90

6,99

35,14

7,80

1000

15

S6P2G200

1646x991x38

19

200

28,26

7,08

35,45

7,87

1000

15

S6P2G205

1646x991x38

19

205

28,60

7,17

35,76

7,95

1000

15

S6P2G210

1646x991x38

19

210

28,93

7,26

36,07

8,02

1000

15

S6P2G215

1646x991x38

19

215

29,26

7,35

36,38

8,10

1000

15

S6P2G220

1646x991x38

19

220

29,58

7,44

36,69

8,17

1000

15

S6P2G225

1646x991x38

19

225

29,89

7,53

37,00

8,25

1000

15

S6P2G230

1646x991x38

19

230

30,19

7,62

37,31

8,32

1000

15

S6P2G235

1646x991x38

19

235

30,49

7,71

37,62

8,40

1000

15

S6P2G240

1646x991x38

19

240

30,78

7,80

37,93

8,47

1000

15

(*) Electric values under Standard Test Conditions (STC) with an irradiation of 1000 W/m2, at an AM 1.5 solar spectrum and a

Temperature of 25⁰ C.

This manual suits for next models

3

Table of contents

Other Solaria Solar Panel manuals