Solaris Vertical Fan Coil Manual

Vertical Fan CoilVertical Fan Coil

Installation and Maintenance ManualInstallation and Maintenance Manual

Code:20110615-0001

CONTENT

1.Preface

2.Safety precautions

Warning

Attention

Specifications

Parameter table

Contour map

Unit work principle

Unit characteristics

Installation

Installation precautions

Installation note places

Install note schemes

Conduit connections

Use

Wire control device functional specification

Wire control device usage

Wire control device functional specification

Wire control device instructions

Parameter table

Maintenance and Overhaul

Preventive and Maintenance

Common fault and the solving methods

Appendix

Controller of motherboard interface diagram

2.1 Mark Notes

2.2 Icon Notes

2.3

2.4

3

3.1

3.2

3.3

3.4

4

4.1

4.2

4.3

4.4

5

5.1

5.2

5.3

5.4

5.5

6

6.1

6.2

7

7.1

1

2

2

2

2

3

4

4

4

5

5

6

6

6

8

10

11

11

13

14

15

15

17

17

16

16

16

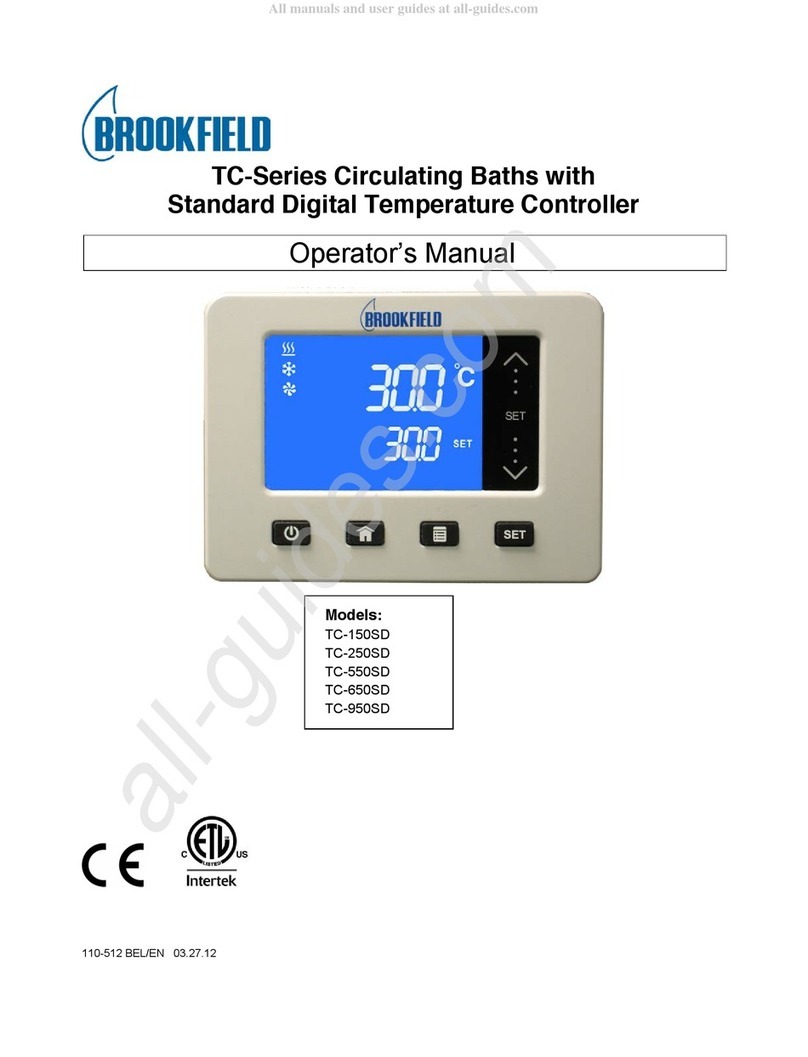

NO.

1

2

3

4

5

6

7

8

9

Signal

CN4

CN5

CN7

FAN

TEMP

N OUT

L

N

PE

meaning

Fan output

Programming port

Towire controller

Fan input

Toambient and coil temperature

Tovalve

Live wire

Neutral wire

Earth wire

7.Appendix

17

FAN

TEMP

CN7CN4

N

OUT

CN5

PE

PENL

MD1000

14

7.1PCB I/O port

1

Thank you for choosing PHNIX vertical water fan coil for controlling the climate in you home.

PHNIX products strictlycomply with designand production standardsto provide highquality

operation, perfect performance,high reliability andgood adaptability.

All repair ormaintenance interventions mustbe performed by

the technical servicedepartment or byprofessionally qualified personnel.Do notmodify or

intervene on theappliance as thiscould create dangeroussituations and themanufacturer will

not be responsiblefor any damagecaused.

al PHNIX technical

1.1Failure to complywith these recommendationswill invalidate thewarranty.

PHNIX appliances mustbe installed byan authorized installer.

All repair ormaintenance interventions mustbe performed bythe technical service

department or byprofessionally qualified personnel.

All repair ormaintenance interventions mustbe performed inthe specified periodand

times.

Use the spareparts ONLY provided by PHNIX.

1.2 In caseof water leaks,turn the masterswitch of thesystem to "OFF"and close thewater

taps. Assoon as possible,call the PHNIXtechnical service departmentor else professionally

qualified personnel anddo not intervenepersonally on theappliance.

If the unitis not usedfor a longtime, you should:

Power off the unit.

If there isno anti-freeze protection,please drain outthe water.

1.3 Note:

If the roomtemperature is toolow it isdamaging for thehealth and isalso a useless

waste of energy.

Avoid prolonged contact with the direct air flow.

Do not leavethe room closedfor long periods.Periodically open thewindows to ensurea

correct change ofair.

1.4 Packing list

Please read thisinstallation and maintenancemanual carefully beforeinstalling

and starting upthe appliance.

This instruction must be kept carefully and must always accompany the appliance. If it is

lost or damaged,please contact theloc service centre.

1.Preface

PFP:

PFP:

90

9090

90

2-8

2-8

165mm165mm

165mm

165mm

025~100025~100

90

90

165mm

165mm

165mm

165mm

025~100025~100

025

040

060

080

100

025

040

060

080

100

mm

0

200

400

600

800

mm

0

200

400

600

800

90

90

025

040

060

080

100

025

040

060

080

100

mm

0

200

400

600

800

mm

0

200

400

600

800

2-82-8

TEMP

MODE FAN

ON/OFF

PM10:50 000

UNIVERSALA/CREMOTE

Screw cap

Vertical WaterFan Coil

INSTALLATIONANDMAINTENANCE

MANUAL

electrothermal

3-way valve

Feet

optional

Screw

Toggle bolts

Brackets

Remote controller

optional

Installation Template

Vertical WaterFan Coil Manual Drain Pipe

Bellows

optional

Fig.1

Fig.18 Fig.19

Fig.20 Fig.21

A

Malfunction Code Cause

Ambient temperature

sensor is inopen circuit

or short circuit

Coil temperature sensor

is in opencircuit or short

circuit

Fan motor failureor fee

dback wire isnot

inserted well

P4

P5

E0

Indoor ambient

temperature sensor

Coil temperature sensor

Motor feedback signal

Measures

Check and replacethe

ambient temperature sensor

Check and replacethe

Coil temperature sensor

Check and replacethe motor

16

6.1 Maintenance andoverhaul

Routine maintenance isindispensable to keepthe VerticalWater Fan Coil in perfect working

condition, safe andreliable over theyears. This can be done every six months for some

interventions and annuallyfor others, bythe Technical Service Assistance.

Before every cleaningand maintenance intervention,disconnect the appliancefrom the

mains by switchingoff the master switch. Wait until theparts have cooled down to avoid the

risk of burns.

When necessary,clean the outer surfaces of the Vertical Water Fan Coilwith a soft cloth

damp cloth (fig.18).Donot use abrasivesponges or abrasiveor corrosive detergentsto avoid

damaging the paintedsurfaces.

Toensure normal operationand perfect performance,routine maintenance shouldbe made

as followed: Liftand extract themobile aspiration panel(fig.19ref. A).Extract the filter(fig.20

ref. D), washthe filter withrunning water withoutusing detergents orsolvents, and leaveto

dry.

6.2 Common faultand the solvingmethods

You can according towire control device, or remote fault display to judgment and trouble-

shooting

6.Maintenance

2

2. Installation precautions

Toprevent the usersand others fromthe harm ofthis unit, andavoid damage onthe unit or

other property, please use the heat pump properly, please read thismanual carefully and

understand the followinginformation correctly.

Mark Meaning

A wrongoperation may leadto death orheavy injury onpeople.

A wrongoperation may leadto harm onpeople or lossof material.

WARING

ATTENTION

Entrust a specializedpersonnel installation, Otherresearchers

installation may causeinstallation does notperfect, causing

irrigation, personnel electricshock or fires.

Confirm whether correct grounding, if is not perfect, may cause ground

personnel shock

INSTALLATION

PROFESSIONAL

INSTALLER IS REQUIRED.

EARTHING

IS REQUIRED.

Icon Meaning

Prohibition. What isprohibited will benearby this icon.

Compulsory implement. The listed action need to be taken.

Attention(include warning)

Please pay attentionto what isindicated.

Do not putfingers or othersinto the fansand evaporator ofthe unit,

otherwise harm maybe occurred.

OPERATION

PROHIBITION

SHUT OFF

THE POWER

When the heat pump need to be moved or installed again, please entrust

dealer or qualified person to carry it out. Improper installation will lead to

water leakage, electrical shock, injury or fire.

It is prohibited to repair the unit by the user himself, otherwise electrical

shock or fire may be occur.

When the heat pump need to be repaired, please entrust dealer or qualified

person to carry it out. Improper movement or repair on the unit will lead to

water leakage, electrical shock, injury or fire.

MOVE AND REPAIR

ENTRUST

ENTRUST

PROHIBIT

2.1 Mark Notes

(1) The injury means no need to be in hospital and cure for a long time.

(2) The material lost means property and datum lost.

2.2 Icon Notes

2.3 Waring

When there is something wrong or strange smell, the power supply need

to be shut off to stop the unit. Continue to run may cause electrical

shock or fire.

Press the key CLOCK and hold tillthe relative lightflashes, then youcould start toset the

time. Press thekey + or - to increase ordecrease the settingtemperature. Press the

key CLOCK again to savesetting and returnto main interface.

5.4.1 Function of F.Cool and F.Heat

5.4. Usage of remote controller

Pressing the key F.Cool , the systemwill be automatically set to cooling mode with

temperature of 69.8 , high wind speed and automatic wind direction.

5.4.2 Setting ofclock

Pressing the key F.Heat , the systemwill be automaticallyset to heatingmode with

temperature of 80.6 , high windspeed and automaticwind direction.

5.4.3 Setting oftiming startup orshutdown

TIME OFF The key is available when the unit is on.

01 The number 01 means the unit will turn on automatically after 1 hour and so

forth.

TIME ON The key isavailable when theunit is on.

01 The number 01 means the unit will shut down automatically after 1 hour and

so forth.

5.5 Parameter table

Meaning

Cooling temperature

Heating temperature

Automatic setting temperature

Default

75.2

82.4

71.6

Remark

adjustable

adjustable

adjustable

15

5.Usage

3

2.Safety precaution

INSTALLATION

Fix the unit

Need circuit breaker

Make sure thatthere is circuitbreaker for theunit, lack of

circuit breaker can lead to electrical shock or fire.

Prohibit

Please use thesuitable fuse.

If use copperor icon, itwill cause failure,even the fire.

OPERATION

Check the installation

basement

Switch off the unit

Please check theinstallation basement regularlyto avoid

any decline ordamage on thebasement, which mayhurt

people or damagethe unit.

Please switch off the power for clean or maintenance.

Make sure thatthe basement ofthe heat pumpis strong

enough to avoidany decline orfall down ofthe unit.

Meaning

Meaning

2.4 Attention

Waring:

Remember that somefundamental safety rulesshould be followedwhen using aproduct that

uses electricity andwater, suchas:

It is forbiddenfor the applianceto be usedby children orunassisted disabled persons.

It is forbiddento touch theappliance with wethands or bodywhen barefoot.

It is forbiddento carry outany cleaning beforehaving disconnected theappliances from the

electricity mains supplyby turning thesystem master switchto OFF.

It is forbiddento modify thesafety or adjustmentdevices or adjustwithout authorization and

indication of themanufacturer.

It is forbiddento pull, cutor knot theelectrical cables comingout of theappliance, even ifit is

disconnected from themains supply.

It is forbiddento poke objectsor anything elsethrough the inletor outlet grills.

It is forbiddento dispose ofor leave inthe reach ofchildren the packagingmaterials which

could become asource of danger.

It is forbiddento climb ontothe appliance orrest any objecton it.

It is forbiddento touch theunit with handsdirectly as theexternal parts ofthe appliance can

reach temperatures ofmore than 158 .

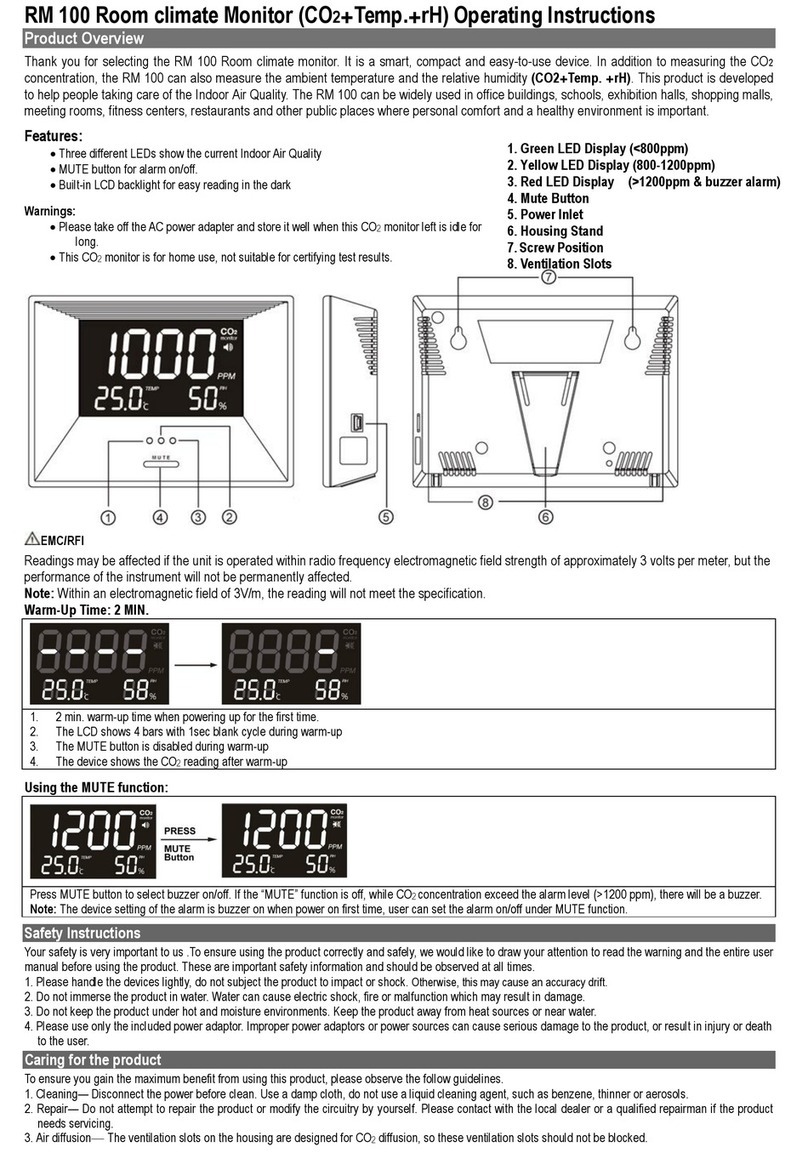

5.3 Functional description of remote controller

TEMP

MODE FAN

ON/OFF

PM10:50 0 00

UNIVERSAL A/C REMOTE

ON/OFF

Press this keyto start upor shut downthe unit.

Mode switch

You can select the mode of heating, cooling, automatic, dehumidifying and

ventilating by pressingthis key.

Wind speed

Press this keyand select thewind speed you want to set. High wind speed, medium

wind speed, lowwind speed and automatic air supply are available.

+

Increase the settingtemperature by pressing this key.

-

Decrease the settingtemperature by pressing this key.

Note: The key SET and OK are designed only for the professionals.

Kindly reminder 1 Takeout the batteriesif you donot use the remote controller

for a longtime.

Takeout the batteriesfor 35 minutes if there is failure in program in the remote

controller which iscaused by wrong operation. Put the batteries in again then you

will find remotecontroller return to normal.

ON/OFF

MODE

FAN

TEMP

MODE FAN

ON/OFF

UNIVERSAL A/C REMOTE

M.SWING

A.SWING

SET OK

CLOCK TIME ON

TIME OFF

F.Cool

F.Heat

AUTO

AM

PM

TIME OFFTIME ON

Signal radiation

Air flow rate

Wind direction

-

ON/OFF

Time regulation

Wind direction regulationmanully

Mode switch

Automatic mode

Cooling mode

Heating mode

Temperature

Clock

Timing shutdown

+

Air flow regulation

Timing startup

Fast cool

Fast heat

Timing shutdown

Low wind speed

Medium wind speed

High wind speed

Wind direction regulation

automutically

Ventilation mode

Dehumidification mode

5.Usage

14

A

29.25

26.38

3.43

7.32

3.27

12.48

5.12

1.77 1.77B

22.72

Mounting hole

4-

1.57

9.49

3.15

HEATCOOL

HIGH LOWMID

MM

HEATCOOL

HIGH LOWMID

MM

HEATCOOL

HIGH LOWMID

MM

HEATCOOL

HIGH LOWMID

MM

HEATCOOL

HIGH LOWMID

MM

Press to save settings

and change modesof the unit.

Press to

save settings and

change wind speed.

Press switch buttonto

save settings andshut

down the unit.

MM

Set temperature inheating mode

5.Usage

5.2 Usage of wire controlle

System will saveuser's

setting and returnback

to main interfaceif there

is no operationon buttons in5s.

13

3.Specification

4

3.1 Parameter list

Test conditions:

(1) Heating test conditions:

Based on entering water temp. at 158 ,difference in temp. Have 50 and entering air temp. at68 DB .

(2) Heating test conditions:

Based on entering water temp. at122 ,difference in temp. Have41 and entering air temp. at 68 DB .

(3) Cooling test conditions:

Based on entering water temp.at44.6 ,difference in temp.Have41 and entering air temp.at 80.6 DB/ 66.2 DB.

(4) Above data is subject to our change without prior notification.

3.2 Overall dimensions

Unit Model

PFP-100(V)

PFP-025(V)

PFP-040(V)

PFP-060(V)

PFP-080(V)

35.43

27.56

A(inch) 43.31 51.18 59.06

B(inch) 14.41

22.28

30.16 38.03 45.91

fig.2

W

Btu/h

gallon/min

psig

W

Btu/h

gallon/min

psig

W

Btu/h

gallon/min

psig

3

m/h

dB(A)

/

W

NPT

inch

inch

inch

lb

lb

PFP-025(V)

2550

8700

0.97

1.54

1350

4600

1.01

1.57

1000

3400

0.75

1.61

160

30

110-120V~/60Hz

12

3/4

0.63

PFP-040(V)

3950

13500

1.50

1.77

2500

8500

1.89

1.90

1900

6500

1.45

1.93

320

32

16

3/4

0.63

PFP-060(V)

5750

19600

2.16

3.80

3350

11400

2.55

3.99

2500

8500

1.89

4.02

460

37

20

3/4

0.63

Water flow rate

Net weight

Unit Model

Heating capacity

Water flow rate

Pressure drop

Heating capacity

Pressure drop

cooling capacity

Water flow rate

Pressure drop

Air volume

Noise

Power Supply

Power Input

Water In/Out

Drain

Net Dimensions(L/W/H)

Shipping Dimensions(L/W/H)

Gross weight

PFP-080(V)

7200

24600

2.73

3.99

4300

14600

3.26

4.05

3500

12000

2.64

4.10

580

39

24

3/4

0.63

PFP-100(V)

9400

32000

3.56

4.09

5200

17800

3.92

4.13

4350

14800

3.30

4.44

650

41

30

3/4

0.63

See below

See package label

See nameplate

See package label

5

3.3 The working principle of units

PHNIX moonlight treasurebox series--Ultra-thin fan-coilunit in whichwater and cooling,

heating medium ofa new generationof air terminalproduct, ultra-thin withcooling and heating

function, can applyto the roomrefrigeration, desiccant andheating fig.3 .

And the traditional fan-coil PHNIX compared ultra-thin fan coil, thinner, is more static, the

more beautiful; The ultra-thin design meticulously PHNIX fan-coil every broke traditional fan

coil installation modes,may realize thevertical, horizontal, hangwall and soon many kinds

of installation, sharplyreduced installation cost.

3.4 Unit characteristics

(1) Ultra-low mute

Using low noisetubular fan, combining advanced ventilation technology on internal exquisite

layout, let themachine low dboperation, let you sleep more comfortable

(2)Ultra-thin design

Internal parts ultra-thinprecision contact, thickness, compared to the normal vertical

9.84inch thickness ofthe disk, PHNIX5.12inch ultra-thin fan coil only the width, and palm, vie

for you leavemore valuable space.

(3)Appearance fashion

The appearance ofthe radian ofnoble fashion,white colour elegant and easy, no matterin any

one place, willindoor become beautiful scenery.

(4)Using a newdesign of vertical wind disk controller, appearance vogue, interface

contracted,operating more simple, more human nature.

Fig.3

Water inlet

cooling (or heating)

Water outlet

Air flow

3.Specification

5.2 Usage of wire controlle

2.1 Temperature setting

When on themain interface ofheating, cooling andautomatic mode, youcan press or

once to checkthe setting temperature.Press or again to increaseor

decrease the settingtemperature. Press , or ON/OFF buttonto change mode,

wind speed orshutdown the unitand save settings.

Note: System willsave user's settingand return backto main interfaceif there isno operation

on buttons in5 seconds.

or is invalid when the unit is in ventilating mode or dehumidifying mode.

MM

HEATCOOL

HIGH LOWMID

MM

Indoor ambient temperature

HEATCOOL

HIGH LOWMID

MM

Press or

to check thesetting

temperature of

current mode.

Set temperature inheating mode

Press or

to set thesetting

temperature of

current mode.

12

5.Usage

6

4.1 Installation precautions

4.1.1 To ensures that the installation is performed correctly and that the appliance will

perform perfectly carefully follow the instructions indicated in this manual. Failure to respect

the rules indicated not only can cause malfunctions of the appliance but also invalidate the

warranty and hence PHNIX shall not respond for any damage to persons, animals or property.

4.1.2 It is important that the electrical installation is made according to the laws in force,

respects the data indicated in the technical sheet and is correctly earthed.

4.1.3 The appliance must be installed in a position that allows the routine maintenance, such

as filter cleaning.

4.2 Positioning the unit

4.2.1 Avoid installing the unit in proximity to:

-positions subject to exposure to direct sunlight;

-in proximity to sources of heat;

-in damp areas or places with probable contact with water;

-in places with oil fumes

-places subject to high frequencies.

4.2.1 Make sure that:

-the wall on which the unit is to be installed is strong enough to support the weight;

-the part of the wall interested does not have pipes or electric wires passing through;

-the interested wall is perfectly flat;

-there is an area free of obstacles which could interfere with the inlet and outlet air flow;

-the installation wall is preferably an outside perimeter wall to allow the discharge of

condensation outside;

4.3 Minimum installation distances

4.3.1 Figure indicates the minimum mounting distances between the wall-mounted

cooler-convector and furniture present in the room.

Fig.4

4. Installation 5.Usage

11

5.1 Function description of wire controller

HEATCOOL

HIGH LOWMID

MM

About buttons:

ON/OFF BUTTON

Pressing this button would start up or shut down the unit

Press this button and select the mode you want to set.

Cooling mode: cooling indicator light keeps on green

Heating mode: heating indicator light keeps on red

Automatic mode: cooling indicator light and heating indicator light flashes in turn.

Ventilating mode: cooling and heating indicator lights are off, the fan indicator light keeps on

according to the chosen wind speed;

Dehumidifying mode: cooling indicator light keeps on for 2 seconds and off for 1second, and over

and over again.

Note: Changes of mode could only be done on main interface.

Press this button and select the wind speed you want to set.

High wind speed: High wind speed indicator light keeps on blue

Medium wind speed: Medium wind speed indicator light keeps on yellow

Low wind speed: Low wind speed indicator light keeps on orange

Automatic: high wind speed indicator light, medium wind speed indicator light and low wind speed

indicator light flashes in turn;

Note: Changes of wind speed could only be done on main interface. You could not choose the

automatic wind speed when in ventilating mode. When in dehumidifying mode, the wind speed is

fixed in low speed.

Changes of wind speed could only be done on main interface.

You could check the setting temperature of unit by pressing this button once.

You could increase the setting temperature by pressing this button again.

You could check the setting temperature of unit by pressing this button once.

You could decrease the setting temperature by pressing this button again.

MM

(Blue)high wind

speed indicator light

(Yellow)medium wind

speed indicator light

(Orange)low wind

speed indicator light

Heating indicator

light red

Cooling indicator

light green

0.79inch 0.79inch

3.54inch

15.75inch

5.51inch

4.Installation

7

4.3.2 Side opening (fig.5)

Dismount the upper grill (fig. ref.A) by unscrewing the fixing screws.

Lift the cover (fig. ref. B) that protects the screw (fig. ref. C) and unscrew et. Move the side

panel slightly and lift it out (fig. ref. E).

A

B

C

E

4.3.3 Vertical floor or wall installation

When mounting onthe floor withsupport feet, referto the relativemanual for themounting

of the feet(optional).

Using the papertemplate, trace theposition of thewall (fig.6). Usea suitable drillto make

the holes withand insert thetoggle bolts (2for each bracket)(fig.7 ref.A); fix thetwo

brackets (fig.7 ref.B).

fig.7

A

B

fig.5

4.4.4 Evacuating air whilefilling the system

If there isno electric powerand the thermo-valvehas already beenpowered use thespecial

cap to pressthe valve stopperto open it.

Start the fillingby slowly openingthe system waterfilling tap. Usea screwdriver to

unscrew the sidebattery breather (fig.17 ref.A). When waterstarts coming outof the breather

valves of theappliance, close themand continue fillinguntil reaching thenominal value forthe

system. Check thehydraulic seal ofthe gaskets.

It is advisableto repeat theseoperations after theappliance has beenrunning for afew hours

and periodically checkthe pressure ofthe system.

4.4.3 Condensation discharge

When mounting thecondensation discharge devicein the verticalversion, connect tothe

condensation collection traydischarge union (fig.16ref. C) apipe for theoutflow of theliquid

(fig. 16 ref.B) blocking itadequately. The condensation discharge network mustbe suitably

sized (minimum insidepipe diameter 0.63inch).

4.Installation

Fig.16

A

B

C

Attention :

-When discharging directlyinto the main

drains, it isadvisable to makea siphon to

prevent bad smellsreturning up thepipe

towards the room.The pipe towards the

room. The curve of the siphon must be

lower than thecondensation collection

bowl.

-If the condensationneeds to be

discharged into acontainer, itmust be

open to theatmosphere and thetube

must not beimmerged in waterto avoid

problems of adhesivenessand

counter-pressure that wouldinterfere

with the normaloutflow.

13

A

10

A

Fig. 17

PFPtemplatecode:20000-230309

Paralleltothefloor

Levelcheckline

165mm

165mm

90

90

Levelcheckline

165mm

165mm

025

025

040

040

060

060

080

080

100

100

0

0

200

200

400

400

600

600

800

800

90

90

025

025

040

040

060

060

080

080

100

100

0

0

200

200

400

400

600

600

800

800

2-8Locatehole

Reservedplace

forpowersupply

fig.6

Makesure that the space betweentwo templates

isaccording to

the table requirement when

installingPFP

025 to 100.

Thedistance from the center of

locate hole to the top edge of

machine is 165mm

Thedistance from the center of

locate hole to the top edge of

machine is 165mm

2-8Locatehole

Makesure that the space be

tweentwo tem

plates

isaccording to

the table requ

irement when

installingPFP

025 to 100.

Waterinlet hole

withoutelectrothermal 3-way valve

Water inlet hole

Water outlet hole

Condensationdrain hole

Thedistance between

twotemplates(mm)

Thedistance between

twotemplates(mm)

Model

Model

Thebottom of machine Thebottom of machine

Fold90 degree along this line Fold90 degree along this line

Reservedareaforwaterpipehole

PFPtemplate code:20000-230309

Paralleltothefloor

8

4.Installation

fig.8 fig.9

Do not over-tightenthe screws sothat the brackets can be adjusted with a spirit level (fig. 8).

Then fully tightenthe four screwsto block the two brackets.

Mount the unit,checking that itfits correctly onto the brackets and checking that it is stable

(fig. 9).

4.4 Hydraulic connections

4.4.1 Refer tofig.10 and fig.11 to connectthe inlet and outlet lines. The hydraulic linesand

joints must bethermally insulated.

Attention;

The hydraulic lines should be with the least resistance.

Piping system should be clean, no rust slag and jam in the pipeline. There will be no

leakage in the hydraulic lines and insult the lines after finish the connection.

The hydraulic lines should be connect to the water tank and the height of the water

should be 19.69inch higher.

Y type filter should be installed in the water inlet of the unit.

Air release valve should be arranged on top of the hydraulic lines to avoid air

retention.

Waterway system should be conducted the pressure test separately and not together

with the Vertical Water Fan Coil.

Water inlet

Water outlet

Water outlet

with 3-way valve

Water inlet

with 3-way valve

fig. 10

fig.11

4.4.2

Connection types for bellows

Connection types 1 with valve

Bellows of water inlet

Bellows of water outlet

Fig. 12 Bellows connect downward to inlet/outlet Fig. 13 Bellows connect backward to inlet/outlet

Bellows of water outlet

Bellows of water inlet

Connection types 2 with valve

Connection types 1 without valve

Bellows of water inlet

Bellows of water outlet

Fig. 14 Bellows connect downward to inlet/outlet

Connection types 2 without valve

Bellows of water inlet

Bellows of water outlet

Fig. 15 Bellows connect backward to inlet/outlet

9

4.Installation

Table of contents

Popular Temperature Controllers manuals by other brands

CARLO GAVAZZI

CARLO GAVAZZI T2000P Series manual

Viessmann

Viessmann VITOTROL 100 OT Installation and service instructions

aci

aci WH2630A Installation & operation instructions

Produal

Produal HLS 44 user guide

nvent

nvent Raychem RTD4AL installation instructions

Glas-Col

Glas-Col Minitrol Series User instructions

General

General DTH03A user manual

Viessmann

Viessmann VITOTROL 100 Operating Instructions for the System User

Brookfield

Brookfield TC Series Operator's manual

West Control Solutions

West Control Solutions KS 45 Operation Notes

Carbolite

Carbolite R38 operating instructions

Brookfield

Brookfield TC Series Operator's manual