Solimpeks Wunder CLS 2510 User manual

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com info@solimpeks.com

Solimpeks Solar Energy Systems Co.

Solarkeymark Registration No:

Wunder CLS models: 011-7S292-F

Wunder CNP models : 011-7S480-F

ITW Test Report No:

Wunder CLS models: 07COL593

Wunder CNP models : 08COL696/1

COLLECTOR INSTRUCTIONS MANUAL

1.1 Solar Energy

Benefits of Solar Energy

The Sun has been providing the Earth with its light and heat for billions of years and has facilitated life on

Earth. We have been utilising its energy and heat for many centuries. It heats up our living areas efficiently

during the summer. But in the winter alternatives for heat and energy production are used such as wood, coal,

liquid and solid fuel. Utilising the Sun’s energy will mean that the Earth has a huge stock of potential energy.

To use this resource effectively, the thermal energy sector has been developing solutions such as solar

thermal technology. One of the most important applications of solar energy is heating by the use of solar

thermal flat-collectors. The economic benefits that arise from these kinds of collectors, such as cost-saving,

are not just dreams. Indeed, it is a proven fact that heating using solar thermal systems have economic

benefits when using the correct solar thermal collectors. We at Solimpeks believe that investing in solar

energy is the most useful investment both for today and for our future generations.

Benefitting from Solar Energy by Using Solar Collectors

Different variables determine whether the solar collectors can maximise useful energy from the Sun. Here the

most important factor is the abundant supply of solar energy, and the other variables include the collector

types, installation directions and slopes.

The solar collector, Wunder, is one of the most efficient products in its class, it is based on Sol –Titanium

coated copper absorbers. This absorber gets the best possible absorption of solar rays and also has a very

low level of thermal radiation emittance. The heat carrier fluid flows in the copper pipes which are welded to

the absorber sheet by ultrasonic welding. The Absorber’s heat is reflected to the heat carrier fluid by copper

pipes. The Absorber is covered by the collector body which is well insulated to withstand high temperatures.

The Collector’s heat losses are decreased to minimal levels by using high quality insulation materials. This

rock wool mineral insulation material can endure high level temperatures. The collector’s face is covered by a

solar safety glass which is low iron tempered in order to lower the emittance (reflection losses). The glass and

collector face is covered by EPDM material and it is also fixed to the collector case by another aluminium

frame. The flexible connection pipes (supplied with Wunder collectors) have a real advantage as it is easy to

install up to seven collectors to a battery. The sensor stick is mounted on the outlet of the solar system to

control the systems temperature. The collector case has ventilation holes to prevent condensation that can

occur within the collector. The purpose of these ventilation holes is to allow excess water and steam to

escape, thus condensation is avioded.

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

3

COLLECTOR CASE

The collector case is produced from aluminium by Solimpeks solar energy systems. The aluminium used as raw

material is 6603-60 (AlMgSi05) (AA-USA) . The collector case is produced with a frame which is a user friendly both in

terms of mounting and dismounting the system. Wall thicknesses both for the case and frame are all according to DIN

EN 12975 -1 and 2. Collector case is made of aluminium which is electrostaticly painted with Ral 9005 matt black

powder paint and then oven baked. The use of this tecnique ensures the system is highly protected against all natural

conditions. Also taken into consideration is the possible thermal expansions that could occur on the glass, hence the

glass is set up with an optional space during casing and the collectors are produced to be able to work properly in all

regions of the world.

CASE - TECHNICAL SPECTS.

Specific gravity : 2,70 gr/cm3

Gravitation endurance : 15,5 (at 24C0Kg/mm2)

Flow endurance : 12 (Kg/mm2)

Hardness : 60-65 Brinell (HB) Kg/mm2)

Expansion coefficent : 23*10(200-100C0)/C0

Profiles : DIN 1748 Tolerance

Elasticity particle : 6900 Kg/mm2

Extension : %8 Delta L/L*100 (50 mm Length)

Cutting Endurance : 11,5 Kg/mm2

Paint thickness : 60-80 Microns

COLLECTOR INSULATION

Heat loss can occur on the bottom and the sides and this can be decreased by using insulation material.

Insulation material is designed to be resistant against high temperatures of up to 650 C within the collector.

The insulation material must be of a high quality in order to withstand these high temperatures. In addition,

this insulation material with its high density does not produce gas, thus the transparent cover’s solar

conductivity is not affected.

Mineral rock wool, a high quality insulation material, is used inside the collector which touches the absorber

sheet and also has an endurance against high temperatures. The insulation material rock wool is also water-

resistant against water which could accumulate in the collector.

TRANSPARENT COVER –THE GLASS

The glass used in Solimpeks collectors has the thickness of 4mm and has the tolerance of 0,2mm. The

density of the glass is 2,5 gr/cm2 . To increase the solar conductivity of the glass, the iron oxide level is

lowered.The prismatic shape of the glass brakes the solar rays which come inclined in the morning and

evening, and makes the solar rays vertical with this prismatic design, this ensures maximum efficiency. The

other important characteristic of the glass is has high endurance. During the transportation and mounting

process, to prevent the highly risk of breakage, Solimpeks uses tempered glass which can also be described

as safety glass. This type of tempered glass is very strong and brakes very rarely. Should the tempered glass

brake, it brakes into small pieces thus reducing the risk of harm.

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

Assembly of Glass and Case

The sides of the glass are wrapped with EPDM before being assembled onto the frame. EPDM is used for

leakproofing and it is resistant to 150 degrees and to the aging effect of the sun. Silicone is applied between

the EPDM and glass. Before assembling, the expansion of the glass must be taken into consideration.

Therefore, all the possible negative effects of expansion are neutralized by leaving enough room between the

glass and the case for expansion. Regular rain cleans the glass. In conditions where there is a of lack of rain,

the glass must be cleaned. It can be cleaned by ordinary cleaners and water. It should be remembered that

the cleaner the glass the more efficient the collector is.

WUNDER CNP COLLECTOR Cross-section (CLASSIC)

WUNDER CLS COLLECTOR Cross-section (PREMIUM)

5

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

WUNDER Case Dimensions

COLLECTOR Type

A

B

1808

1927

927

2008

2000

1000

2108

1988

1041

2510

1988

1218

Terms & Conditions related to the attention of the consumer:

The product guarantee granted by Solimpeks Solar Energy Systems Co. does not cover the damage

caused by usage of the collector in inappropriate conditions.

1. Get the guarantee certificate approved by the seller.

2. Guarantee Certificate is invalid if:

(i) Guarantee certificate is not stamped and approved by an authorised person.

(ii) The certificate is damaged, defaced, deformed and the serial number is erased.

3. Product must be used exactly as instructed in the manual. In case of an incomplient usage the guarantee

terms will be invalid.

4. Any damages sustained before the the product arrives is not covered by the guarentee.

5. Guarantee is invalid when damage caused is by freezing, which is due to lack of appropriate anti-freeze

use by the consumer when it is necessary to do so.

6. The breakage of glass because of the external factors invalidates the guarantee.

7. Any service by other than authorized personnel will invalidate the guarantee.

8. The lack of regular maintenance and controls invalidates the guarantee.

9. Possible damage caused while the liquid in the system is being evacuated with high pressure systems is

not covered by the guarantee.

10. The damage caused by the incorrect connection of pipes invalidates the guarantee.

11.The damage caused by the incorrect installation of the tank, collector and mounting kits invalidates the

guarantee.

12. The delivery of the guarantee certificate is under the responsibility of the technical service, seller or

branch.

.

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

7

TERMS OF WARRANTY

1. Warrantytime begins with the invoice date and contains different time periods for different types of

products.

2. All the defects and errors occured by Solimpeks during manufacturing process are under guarantee terms.

3. The products manufactured by Solimpeks have a limited time of repair under warranty terms, this limited

repair time is 30 working days.

4. The products imported or traded by Solimpeks are not under these warranty terms, Solimpeks just reflects

the same warranty terms and conditions of the original supplier.

5. If the defects are not possible to repair, Solimpeks replaces the product with a new one.

6. The defects and errors occured during the project process, installation, transportation and poor finishing are

not under these warranty terms.

7. Solimpeks guarantess the collectors for a period of 10 years and guarantees the boilers for 5 years.

INVALIDATES WARRANTY TERMS

1. The defects and errors during project, installation and poor finishing.

2. The defects and errors during transportation.

3. The defects and errors occured by and during open loop installation of the system, such as corrosion and

freezing of the system.

4. The defects and errors occured by not protecting the system against freezing on the closed loop

applicatons.

5. The defects and errors occured by mounting or repairing the system without the authorized dealer or

service.

6. Breakage of the glass.

7. Natural disasters like fire, calamity, earthquakes,hail etc..

8. The defects and errors occured by incorrect usage from the consumer.

9. The defects and errors occured by antifreeze liquid leakages such as corrosion and sedimentation.

10. Chemical and physical damage caused by other equipment while installing the system.

11. Any defects and errors on the warranty letter such as an unconfirmed warranty letter or any ammendments

and changes on it.

MANUFACTURER COMPANY

Solimpeks Enerji San. ve Tic. A.Ş.

Konsan Organize Sannayi Hilal Sk. No: 20

42300 - Karatay/KONYA / TURKEY

Tel: 0332-444 06 02 / Fax: 0332-444 06 08

SELLER COMPANY

Date / Signature / Stamp

WARRANTY LETTER WILL BE SENT TO THE MANUFACTURER COMPANY

I have read and accepted all the warranty terms and conditions.

PRODUCT

Brand:

Model:

Serial No :

Delivery date:

CUSTOMER

Name / Surname:

Tel :

Address:

………………………………………………….………………..

……………………………………………………….………..

………………………………………………………………...

………………………………………………………………….

Must be paid attention to:

The warehouse must protect the collectors from external conditions, such as the weather.

The collector must not be stocked in humid places.

Must be paid attention to during installation:

- All precautions must be taken before the installation since the area is high or sloped.

- Check the installation surface before installing.

- During the installation construction conditions, technical situations and local regulations must be obeyed.

- If the collector will be installed on the roof, it is crucial to installation that the collectors are installed as far

away as possible from the chimney so that smoke emitted from the chimney can be avoided.

-Trees, high buildings, chimneys etc. mustn’t shade the collectors.

- All the screws and bolts must be tightened firmly.

• Transportation of the collectors, boilers and mounting kits to the installation area.

-The goods mustn’t be unpacked before the installation under any circumstances.

-Collectors mustn’t be transported leaning vertically.

- Collector must be stacked parallel to the floor (max. 7 pieces).

- Collectors must be fixed securely during transportation and nothing must be loaded on top of them.

- Collectors must not be dragged.

- The boilers must be in the packaging until ready for installation.

- All accessories must not be unpacked until installation.

• Carrying the collectors and other equipment to the installation point.

- If the collectors are being pulled up by a rope, collectors must be pulled up one by one.

- Collectors must be pulled up in a fixed position.

-If the boiler is being pulled up with a rope, it mustn’t be unpacked and must be fixed by two points.

- If the mounting kits are being pulled up, profiles must not be unpacked.

- Anyone who pulls the materials up, must secure themselves.

- Anyone who hasn’t secured themselves mustn’t attend the installation.

- The systems must not be installed in adverse weather conditions such as snowy, rainy and windy weather.

• Preparing the surface for mounting kits

The direction and angle must be specified. Collectors must be faced towards the South.

The verification of the direction must be done by a compass.

The angle of the collector must be at the average latitude of the city for all year usage. If the system is going

to be used only in the summer, the angle must be 15 degrees lower than the latitude, in winter 15 degrees

higher.

It has be observed that the collectors are most productive at the the angles between 30º and 40º.

There must be at least a 10 cm gap between the bottom of the collector and the surface to minimize the

impact of the wind.

The installation area must not be shaded in winter between 09.30 and 16.00.

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

9

Specification / Type

Wunder CLS 2510

Wunder CLS 2108

Wunder CLS 2008

Wunder CLS 1808

Dimensions

1988 x 1218 x 90 mm

1988 x 1041 x 90 mm

2000 x 1000 x 90 mm

1927 x 927 x 90 mm

Casing Material

Electrostatic Painted Aluminium

Case

Electrostatic Painted

Aluminium Case

Electrostatic Painted Aluminium

Case

Electrostatic Painted Aluminium

Case

Weight

44 kg

37,2 kg

36,5 kg

34 kg

Sealing Material

EPDM & Silicone & ALUMINUM

FRAME

EPDM & Silicone & ALUMINUM

FRAME

EPDM & Silicone & ALUMINUM

FRAME

EPDM & Silicone & ALUMINUM

FRAME

Gross Area

2.42 m2

2.07 m2

2.0 m2

1,79 m2

Aperture Area

2.25 m2

1.92 m2

1.86 m2

1.65 m2

Absorber Area

2.23 m2

1.90 m2

1.84 m2

1.63 m2

Absorber Material

Selective Coated Copper

Selective Coated Copper

Selective Coated Copper

Selective Coated Copper

Thickness

0,12mm

0,12mm

0,12mm

0,12mm

Absorptance

%95

%95

%95

%95

Emittance

%3

%3

%3

%3

Welding Method

Ultrasonic welding

Ultrasonic welding

Ultrasonic welding

Ultrasonic welding

Heat Carrier Volume

1.27 liter

1.07 liter

1.41 liter

2.36 liter

Diameter of Absorber Tube

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

Absorber Tube Wall

Thickness

0,45 mm

0,45 mm

0,45 mm

0,45 mm

Diameter of Header Tube

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

Header Tube Wall Thickness

0,70 mm

0,70 mm

0,70 mm

0,70 mm

Number of Tubes

10

9

8

8

Tube pitch (mm)

110 mm

110 mm

110 mm

110 mm

Glass Material

Low Iron Tempered Glass

Low Iron Tempered Glass

Low Iron Tempered Glass

Low Iron Tempered Glass

Transmittance of Glass

%91

%91

%91

%91

Thickness of Glass

4 mm

4 mm

4 mm

4 mm

Insulation Material

Rock wool

Rock wool

Rock wool

Rock wool

Thermal Conductivity

0.037 W/(mK)

0.037 W/(mK)

0.037 W/(mK)

0.037 W/(mK)

Heat Capacity of wool

0.84 kJ/(kgK)

0.84 kJ/(kgK)

0.84 kJ/(kgK)

0.84 kJ/(kgK)

Density of wool

40 density

40 density

40 density

40 density

Thickness of wool

40 mm

40 mm

40 mm

40 mm

Stagnation Temperature at

1000 W/m_and 30 0C

203 0C

203 0C

203 0C

203 0C

Max. Operation Pressure

10 bar

10 bar

10 bar

10 bar

Test Pressure

20 bar

20 bar

20 bar

20 bar

Pressure Loss

1.8 mbar

1.6 mbar

1.5 mbar

1 mbar

Nominal Flow Rate

120 liter/h

105 liter/h

105 liter/h

100 liter/h

Base Sheatting

Embossed - finished Aluminium

Embossed - finished Aluminium

Embossed - finished Aluminium

Embossed - finished Aluminium

Mounting Mode

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

WUNDER CLS Technical Specifications

10

Specification / Type

Wunder CLSF 2510

Wunder CLSF 2108

Wunder CLSF 2008

Wunder CLSF 1808

Dimensions

1988 x 1218 x 90 mm

1988 x 1041 x 90 mm

2000 x 1000 x 90 mm

1927 x 927 x 90 mm

Casing Material

Electrostatic Painted

Aluminium Case

Electrostatic Painted

Aluminium Case

Electrostatic Painted

Aluminium Case

Electrostatic Painted

Aluminium Case

Weight

44 kg

37,2 kg

36,5 kg

34 kg

Sealing Material

EPDM & Silicone &

ALUMINUM FRAME

EPDM & Silicone &

ALUMINUM FRAME

EPDM & Silicone &

ALUMINUM FRAME

EPDM & Silicone & ALUMINUM

FRAME

Gross Area

2.42 m2

2.07 m2

2.0 m2

1,79 m2

Aperture Area

2.25 m2

1.92 m2

1.86 m2

1.65 m2

Absorber Area

2.23 m2

1.90 m2

1.84 m2

1.63 m2

Absorber Material

Full - face Selective Coated

Copper

Full - face Selective Coated

Copper

Full - face Selective Coated

Copper

Full - face Selective Coated

Copper

Thickness

0,20 mm

0,20 mm

0,20 mm

0,20 mm

Absorptance

%95

%95

%95

%95

Emittance

%3

%3

%3

%3

Welding Method

Ultrasonic welding

Ultrasonic welding

Ultrasonic welding

Ultrasonic welding

Heat Carrier Volume

1.27 liter

1.07 liter

1.41 liter

2.36 liter

Diameter of Absorber

Tube

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

Absorber Tube Wall

Thickness

0,45 mm

0,45 mm

0,45 mm

0,45 mm

Diameter of Header

Tube

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

Header Tube Wall

Thickness

0,70 mm

0,70 mm

0,70 mm

0,70 mm

Number of Tubes

10

9

8

8

Tube pitch (mm)

110 mm

110 mm

110 mm

110 mm

Glass Material

Low Iron Tempered Glass

Low Iron Tempered Glass

Low Iron Tempered Glass

Low Iron Tempered Glass

Transmittance of Glass

%91

%91

%91

%91

Thickness of Glass

4 mm

4 mm

4 mm

4 mm

Insulation Material

Rock wool

Rock wool

Rock wool

Rock wool

Thermall Conductivity

0.037 W/(mK)

0.037 W/(mK)

0.037 W/(mK)

0.037 W/(mK)

Heat Capacity of wool

0.84 kJ/(kgK)

0.84 kJ/(kgK)

0.84 kJ/(kgK)

0.84 kJ/(kgK)

Density of wool

40 density

40 density

40 density

40 density

Thickness of wool

40 mm

40 mm

40 mm

40 mm

Stagnation

Temperature at

1000 W/m_and 30 0C

203 0C

203 0C

203 0C

203 0C

Max. Operation

Pressure

10 bar

10 bar

10 bar

10 bar

Test Pressure

20 bar

20 bar

20 bar

20 bar

Pressure Loss

1.8 mbar

1.6 mbar

1.5 mbar

1 mbar

Nominal Flow Rate

120 liter/h

105 liter/h

105 liter/h

100 liter/h

Base Sheatting

Embossed - finished

Aluminium

Embossed - finished

Aluminium

Embossed - finished

Aluminium

Embossed - finished

Aluminium

Mounting Mode

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

WUNDER CLSF Technical Specifications

11

Specification / Type

Wunder CNP 2510

Wunder CNP 2108

Wunder CNP 2008

Wunder CNP 1808

Dimensions

1988 x 1218 x 90 mm

1988 x 1041 x 90 mm

2000 x 1000 x 90 mm

1927 x 927 x 90 mm

Casing Material

Electrostatic Painted Aluminium

Case

Electrostatic Painted Aluminium

Case

Electrostatic Painted Aluminium

Case

Electrostatic Painted Aluminium

Case

Weight

41,5 kg

36,5 kg

35 kg

31,4 kg

Sealing Material

EPDM & Silicone & ALUMINUM

FRAME

EPDM & Silicone & ALUMINUM

FRAME

EPDM & Silicone & ALUMINUM

FRAME

EPDM & Silicone & ALUMINUM

FRAME

Gross Area

2.42 m2

2.07 m2

2.0 m2

1,79 m2

Aperture Area

2.27 m2

1.93 m2

1.86 m2

1.65 m2

Absorber Area

2.23 m2

1.87 m2

1.84 m2

1.61 m2

Absorber Material

Black Painted Copper

Black Painted Copper

Black Painted Copper

Black Painted Copper

Thickness

0,12mm

0,12mm

0,12mm

0,12mm

Absorptance

%95

%95

%95

%95

Emittance

%3

%3

%3

%3

Welding Method

Ultrasonic welding

Ultrasonic welding

Ultrasonic welding

Ultrasonic welding

Heat Carrier Volume

1.27 liter

1.07 liter

1.41 liter

2.36 liter

Diameter of Absorber

Tube

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

8,0 mm / 10 mm / 12.7 mm

Absorber Tube Wall

Thickness

0,45 mm

0,45 mm

0,45 mm

0,45 mm

Diameter of Header Tube

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

18 mm / 22 mm / 24 mm

Header Tube Wall

Thickness

0,70 mm

0,70 mm

0,70 mm

0,70 mm

Number of Tubes

10

9

8

8

Tube pitch (mm)

110 mm

110 mm

110 mm

110 mm

Glass Material

Normal Iron Tempered Glass

Normal Iron Tempered Glass

Normal Iron Tempered Glass

Normal Iron Tempered Glass

Transmittance of Glass

%87.5

%87.5

%87.5

%87.5

Thickness of Glass

4 mm

4 mm

4 mm

4 mm

Insulation Material

Glass wool

Glass wool

Glass wool

Glass wool

Thermal Conductivity

0.040 W/(mK)

0.040 W/(mK)

0.040 W/(mK)

0.040 W/(mK)

Heat Capacity of wool

0.84 kJ/(kgK)

0.84 kJ/(kgK)

0.84 kJ/(kgK)

0.84 kJ/(kgK)

Density of wool

40 density

40 density

40 density

40 density

Thickness of wool

50 mm

50 mm

50 mm

50 mm

Max. Operation Pressure

10 bar

10 bar

10 bar

10 bar

Test Pressure

20 bar

20 bar

20 bar

20 bar

Pressure Loss

1.8 mbar

1.6 mbar

1.5 mbar

1 mbar

Nominal Flow Rate

120 liter/h

105 liter/h

105 liter/h

100 liter/h

Base Sheatting

Embossed - finished Aluminium

Embossed - finished Aluminium

Embossed - finished Aluminium

Embossed - finished Aluminium

Mounting Mode

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Inroof, onto-roof, flat roof

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

WUNDER CNP Technical Specifications

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

13

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

Slope and direction of the collector on the roof

To get the best efficiency from the solar collector, it must be mounted at the right direction and slope. Both the slope angle

and azimut angle must be calcuated before and while mounting the collector on the roof.

Slope angle α

Slope angle α is the angle between the collector and horizontal (x) axis . The absorber used in the collector can get the

most efficient energy when it is mounted absolutely vertically to the Sun’s rays. The angle of the Sun’s rays varies subject

to hourly and seasonal changes. Hence the collectors must be directioned with the correct angle and slope. It is advised

that the angles between 30 and 45 degrees are the most ideal angles to mount the collector.

Azimut angle

Azimut angle means the deflection of the collector axis from south direction. So the angle of the collectors direction to the

south is zero ( 0 ). The axis of the collector should be positioned as close as possible to the south. This is because the

Sun’s rays are at their peak at noon. The deviation up to 45 degrees to the south can be accepted.

A- Collector deflection

B- Azimut Angle

14

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

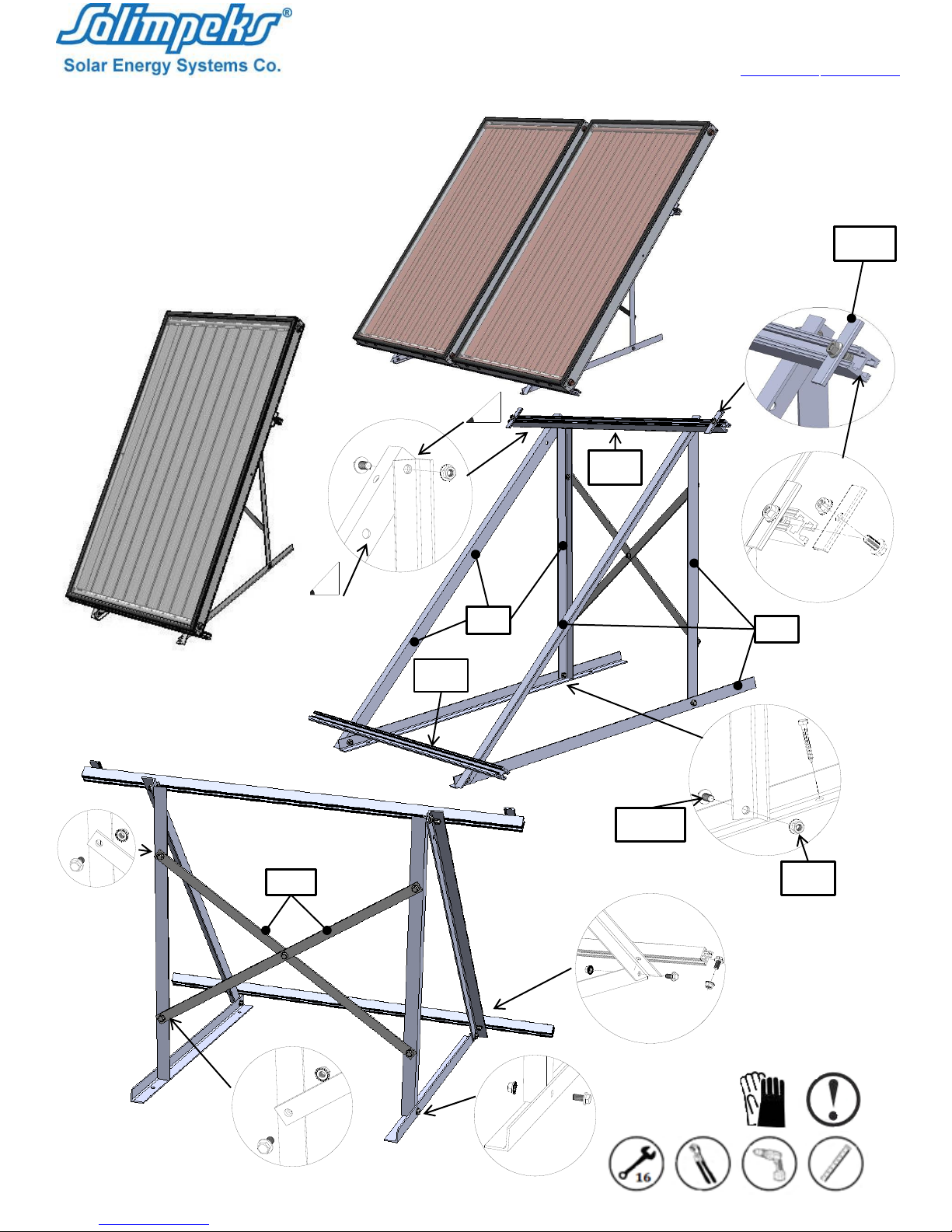

3R

45°

40°

5D

2L

1L

Clips

Nut

Screw

5U

FLAT ROOF

15

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

1 Collector 1808

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

3R

1

2 screwed pieces of 980 X 30 X 5 mm

5U

1

1050 X 30 X 30 mm

5D

1

1050 X 30 X 30 mm

Screw

17

M10 X 20

Nut

17

M10

Clips

2

90 X 30

2 Collector 1808

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

3R

1

2 screwed pieces of 1670 X 30 X 5 mm

5U

1

2100 X 30 X 30 mm

5D

1

2100 X 30 X 30 mm

Screw

19

M10 X 20

Nut

19

M10

Clips

4

90 X 30

1 Collector 2008

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

3R

1

2 screwed pieces of 980 X 30 X 5 mm

5U

1

1150 X 30 X 30 mm

5D

1

1150 X 30 X 30 mm

Screw

17

M10 X 20

Nut

17

M10

Clips

2

90 X 30

2 Collector 2008

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

3R

1

2 screwed pieces of 1670 X 30 X 5 mm

5U

1

2300 X 30 X 30 mm

5D

1

2300 X 30 X 30 mm

Screw

19

M10 X 20

Nut

19

M10

Clips

4

90 X 30

1 Collector 2510

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

3R

1

2 screwed pieces of 980 X 30 X 5 mm

5U

1

1335 X 30 X 30 mm

5D

1

1335 X 30 X 30 mm

Screw

17

M10 X 20

Nut

17

M10

Clips

2

90 X 30

2 Collector 2510

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

3R

1

2 screwed pieces of 1670 X 30 X 5 mm

5U

1

2670 X 30 X 30 mm

5D

1

2670 X 30 X 30 mm

Screw

19

M10 X 20

Nut

19

M10

Clips

4

90 X 30

1 Collector 2108

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 30 X 30 mm

3R

1

2 screwed pieces of 980 X 30 X 5 mm

5U

1

1150 X 30 X 30 mm

5D

1

1150 X 30 X 30 mm

Screw

17

M10 X 20

Nut

17

M10

Clips

2

90 X 30

2 Collector 2108

No

Unit

Dimensions

1L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

2L

1

3 screwed pieces of (1490 - 1190- 980) X 40 X 40 mm

3R

1

2 screwed pieces of 1670 X 30 X 5 mm

5U

1

2300 X 30 X 30 mm

5D

1

2300 X 30 X 30 mm

Screw

19

M10 X 20

Nut

19

M10

Clips

4

90 X 30

Flat - Roof Dimensions

16

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

Aluminum profile dimensions (mm)

Model

1 coll.

2 coll.

2510

1335 x 30 x 30

2670 x 30 x 30

2108

1150 x 30 x 30

2300 x 30 x 30

2008

1150 x 30 x 30

2300 x 30 x 30

1808

1050 x 30 x 30

2100 x 30 x 30

Part Name

Quantity

1 coll.

2 coll.

1

Straight Support

4

6

2

"Z" Support

4

6

3

8 x 60 Wood Screw

8

12

4

M8 x 12 Screw

8

12

5

M10 x 20 Screw

6

10

6

M10 Nut

6

10

7

Clips

2

4

8

Aluminum profile

1

1

9

Aluminum profile

1

1

ONTO ROOF

17

Aluminum profile dimensions (mm)

Model

1 coll.

2 coll.

2510

1335 x 30 x 30

2670 x 30 x 30

2108

1150 x 30 x 30

2300 x 30 x 30

1808

1050 x 30 x 30

2100 x 30 x 30

9

10

7

8

5

1

6

2

3

4

Part Name

Quantity

1 coll.

2 coll.

1

"Z" Support

4

4

2

8 x 60 Wood Screw

18

18

3

M10 x 25 Screw

12

14

4

M10 Nut

12

14

5

Clips

2

4

6

Tank holder

2

2

7

2450 X 40 X 40 mm

1

1

8

2450 X 40 X 40 mm

1

1

9

Aluminum profile

1

1

10

Aluminum profile

1

1

OR 1

2

3

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

18

Solimpeks Solar Enerji Sistemleri

Konsan Özel Organize San. Tic. Merkezi

Ankara Yolu 10. km. Hilal Sok. No: 20

42300 Karatay Konya / Türkiye

Tel: +903324440602 Fax: +903324440608

www.solimpeks.com [email protected]

This manual suits for next models

11

Table of contents