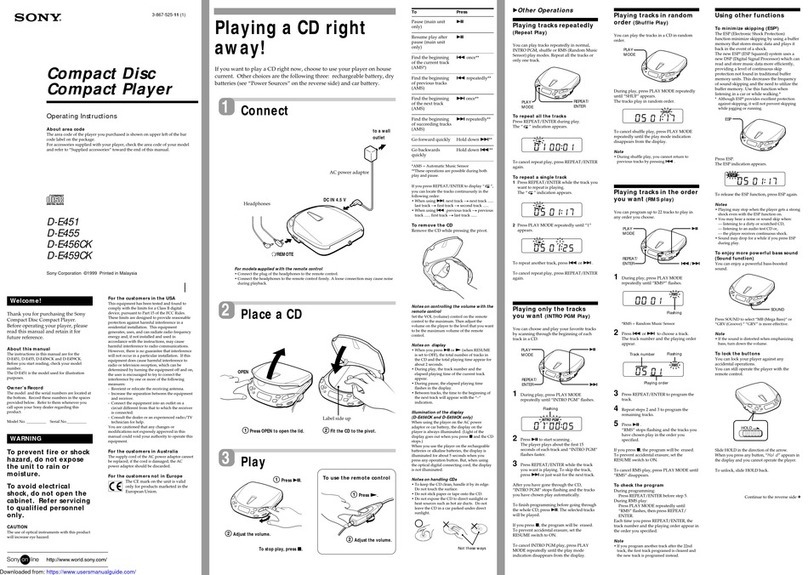

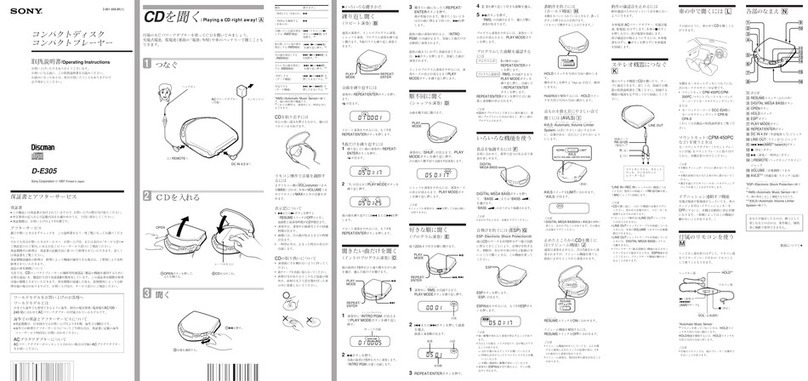

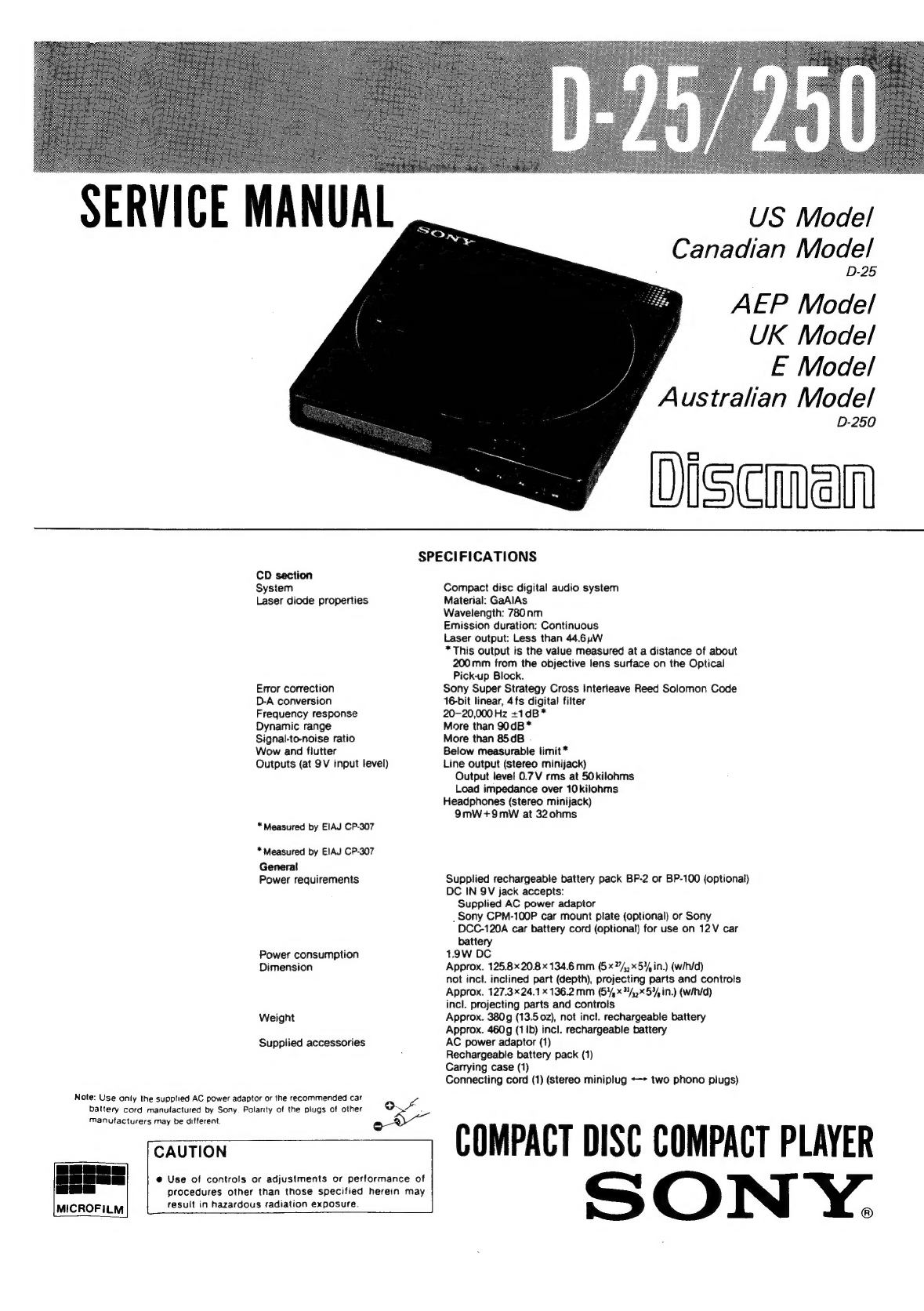

Sony Disman D-25 User manual

Other Sony CD Player manuals

Sony

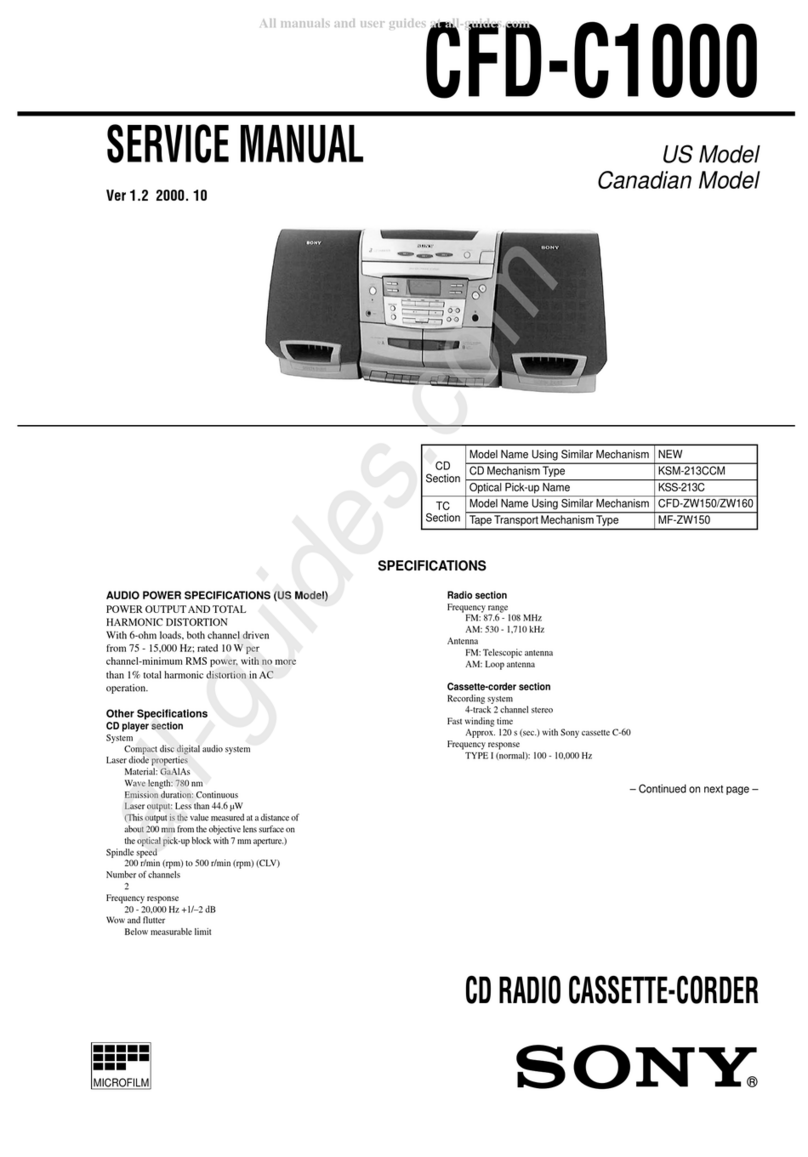

Sony CFD-C1000 - Boombox With Cd User manual

Sony

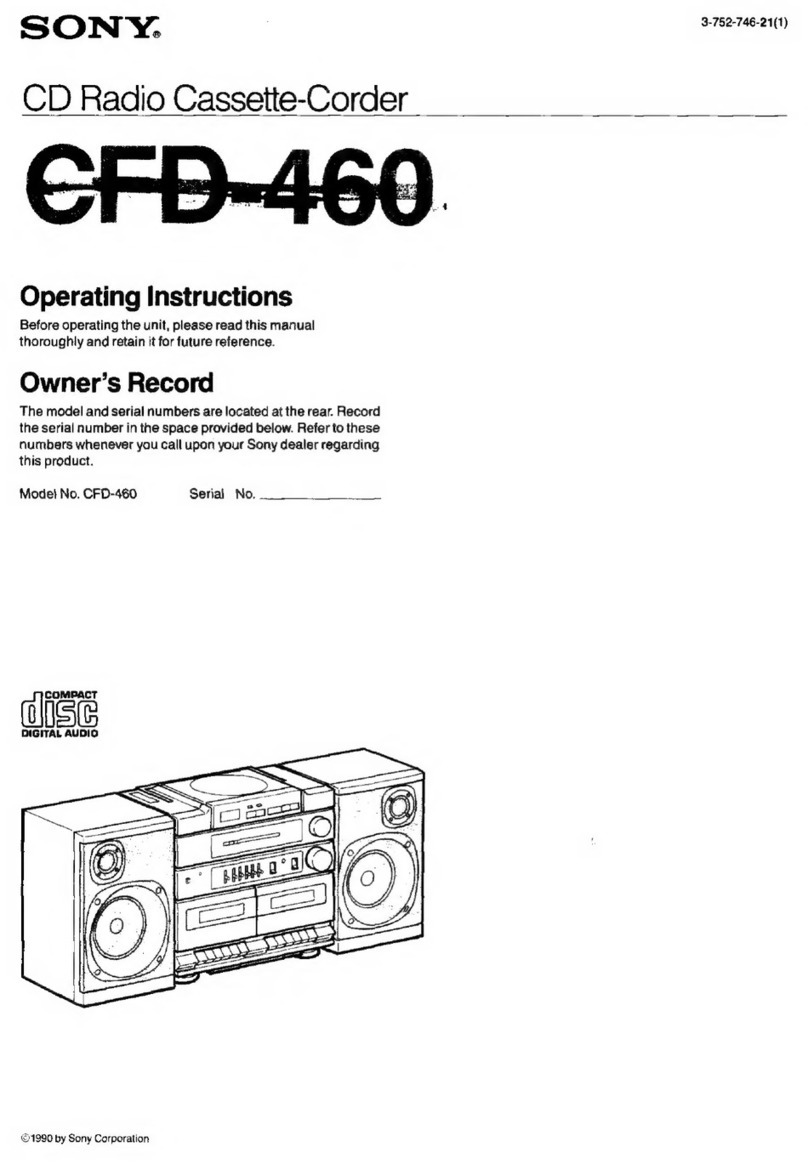

Sony CFD-460 User manual

Sony

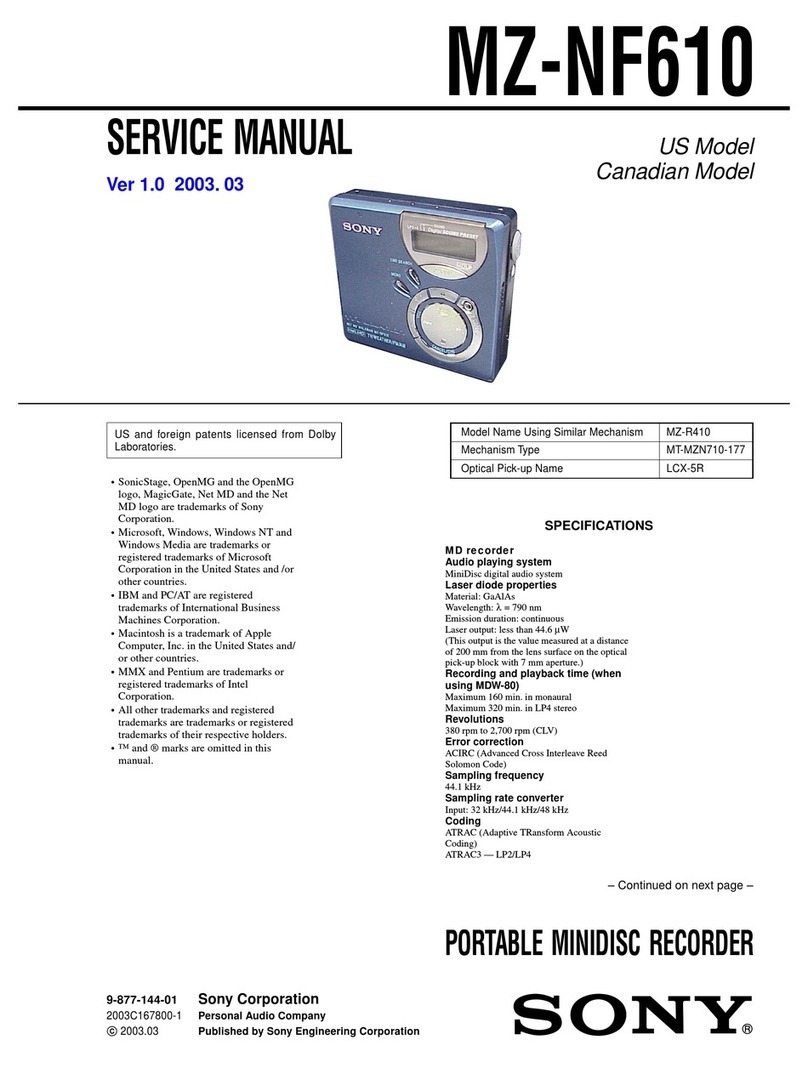

Sony Walkman MZ-NF610 User manual

Sony

Sony CFD-S22L User manual

Sony

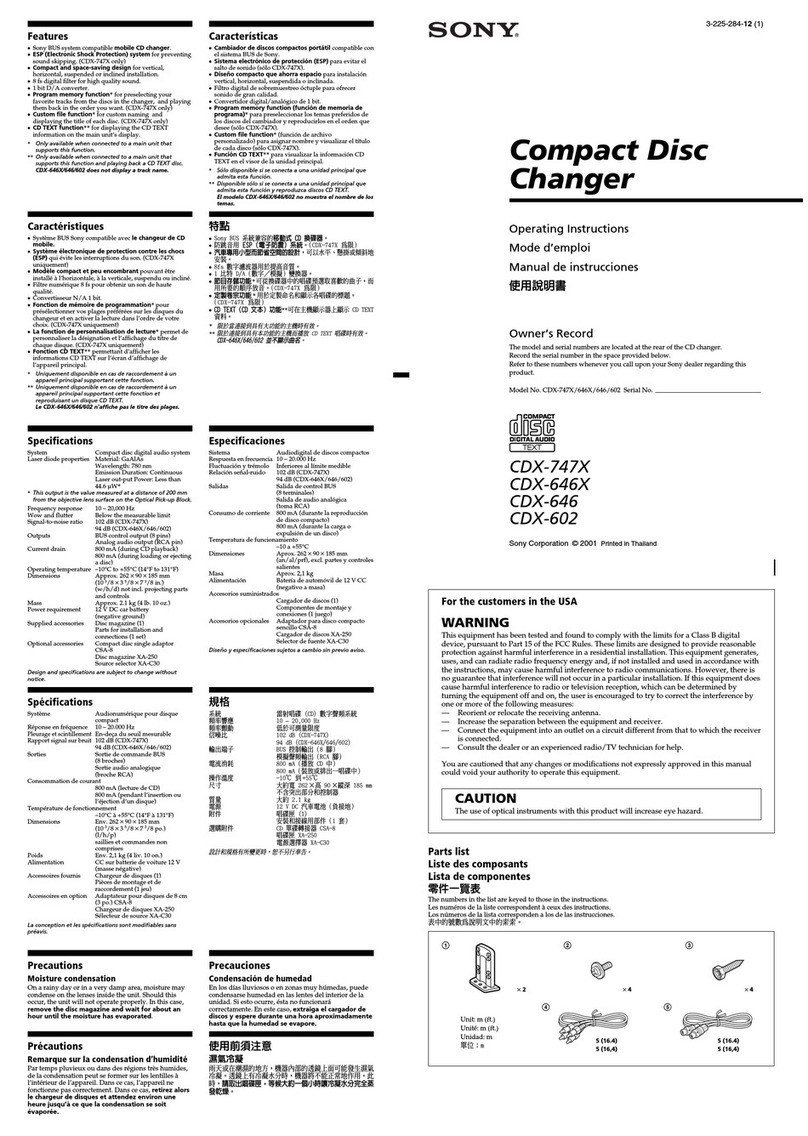

Sony CDX-602 - Compact Disc Changer User manual

Sony

Sony CDP-XE800 User manual

Sony

Sony XDCAM PDW-HD1200 User manual

Sony

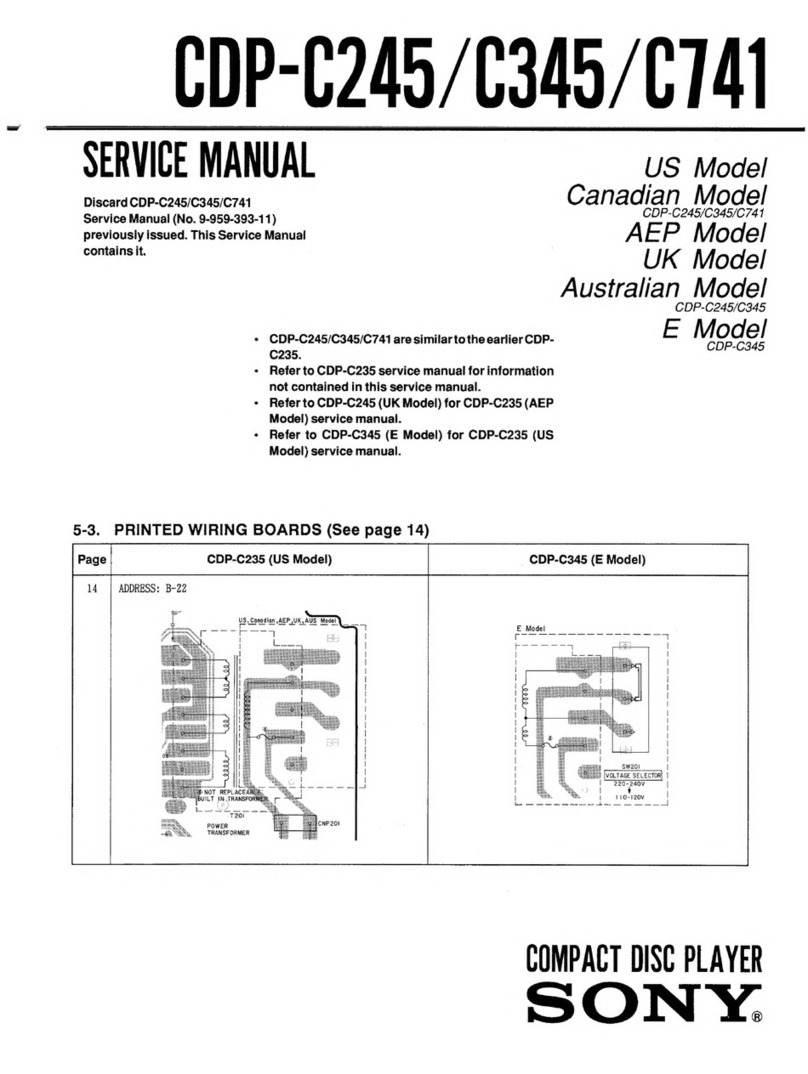

Sony CDP-C245 User manual

Sony

Sony CDP-XE900 User manual

Sony

Sony D-NE710 - ATRAC3/MP3 CD Walkman Portable Disc... User manual

Sony

Sony MZ-N707 OpenMG Jukebox NOTES on installing &... User manual

Sony

Sony CFD-S47 - Cd Radio Cassette-corder User manual

Sony

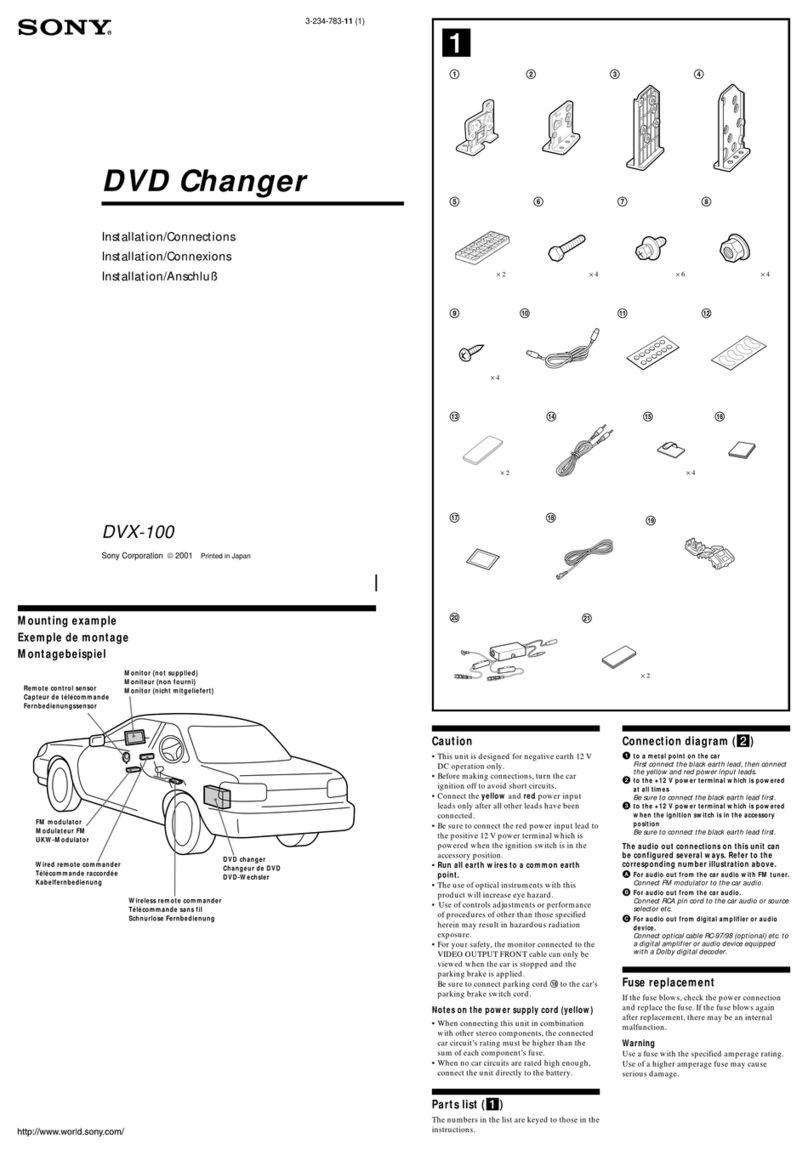

Sony DVX-100 - 10 Disc Dvd Changer Product guide

Sony

Sony MD Walkman MZ-R5ST User manual

Sony

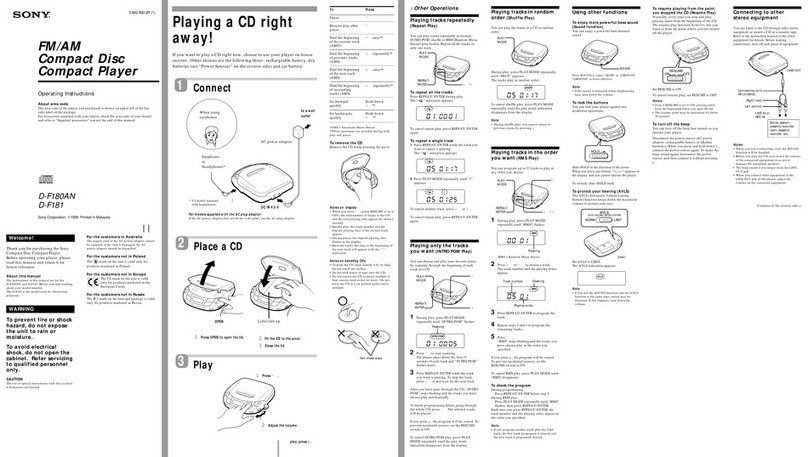

Sony D-F180AN User manual

Sony

Sony CDP-CE545 - Compact Disc Player User manual

Sony

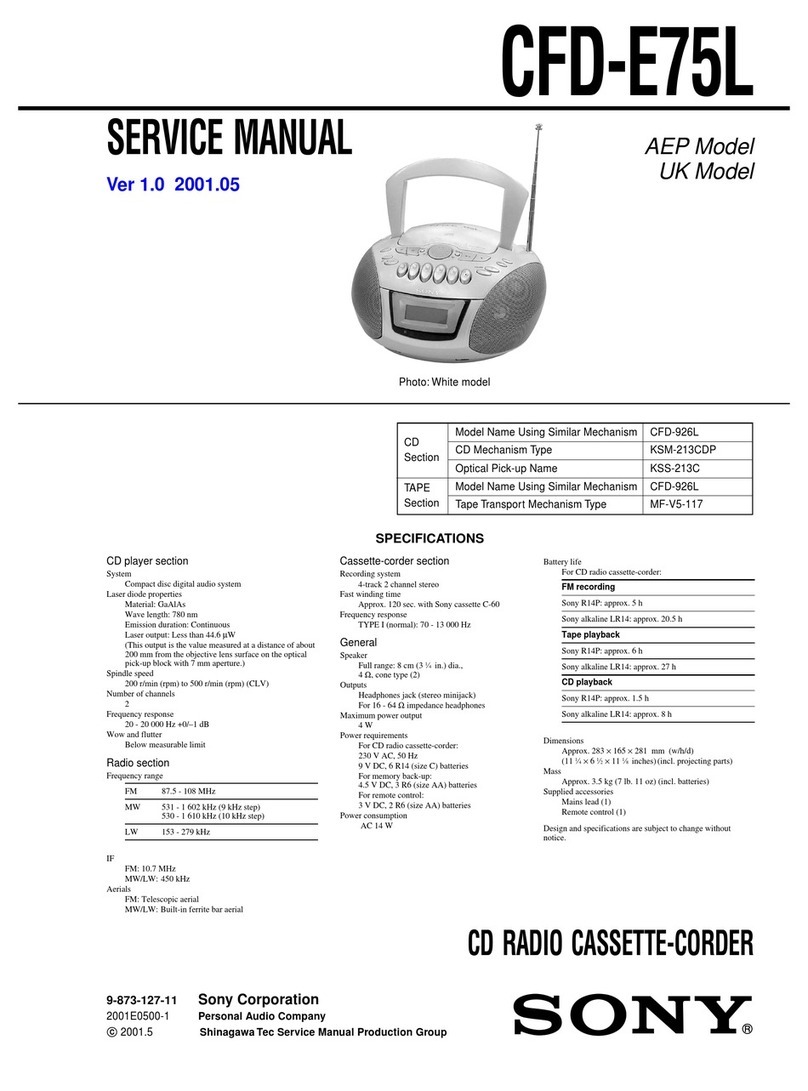

Sony CFD-E75L User manual

Sony

Sony Walkman D-CJ501 User manual

Sony

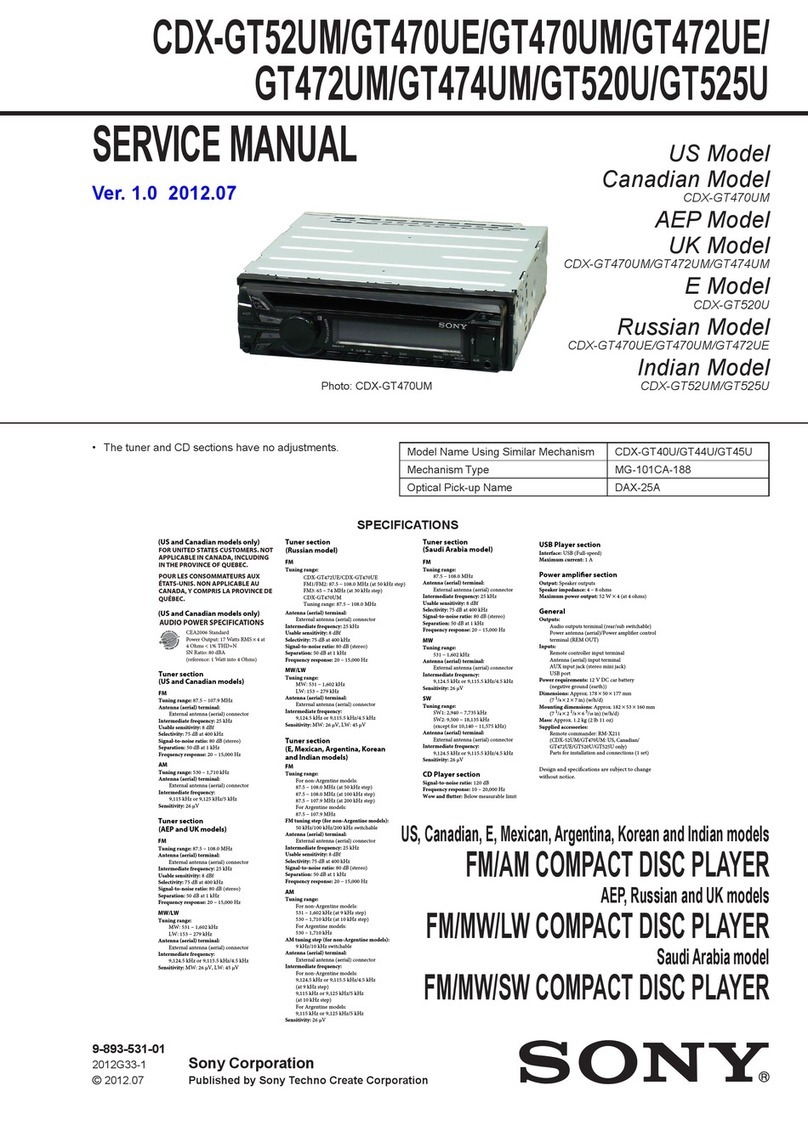

Sony CDX-GT52UM User manual

Sony

Sony CFD G505 - Xplod Boombox User manual