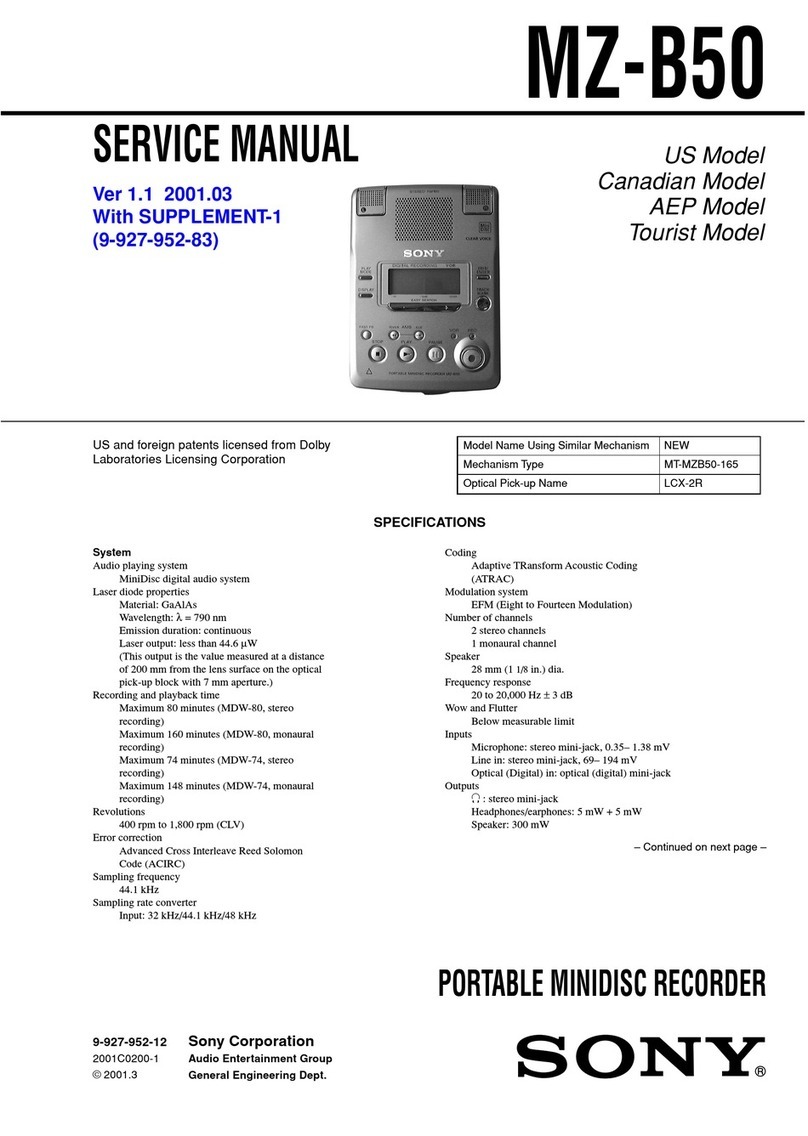

– 5 –

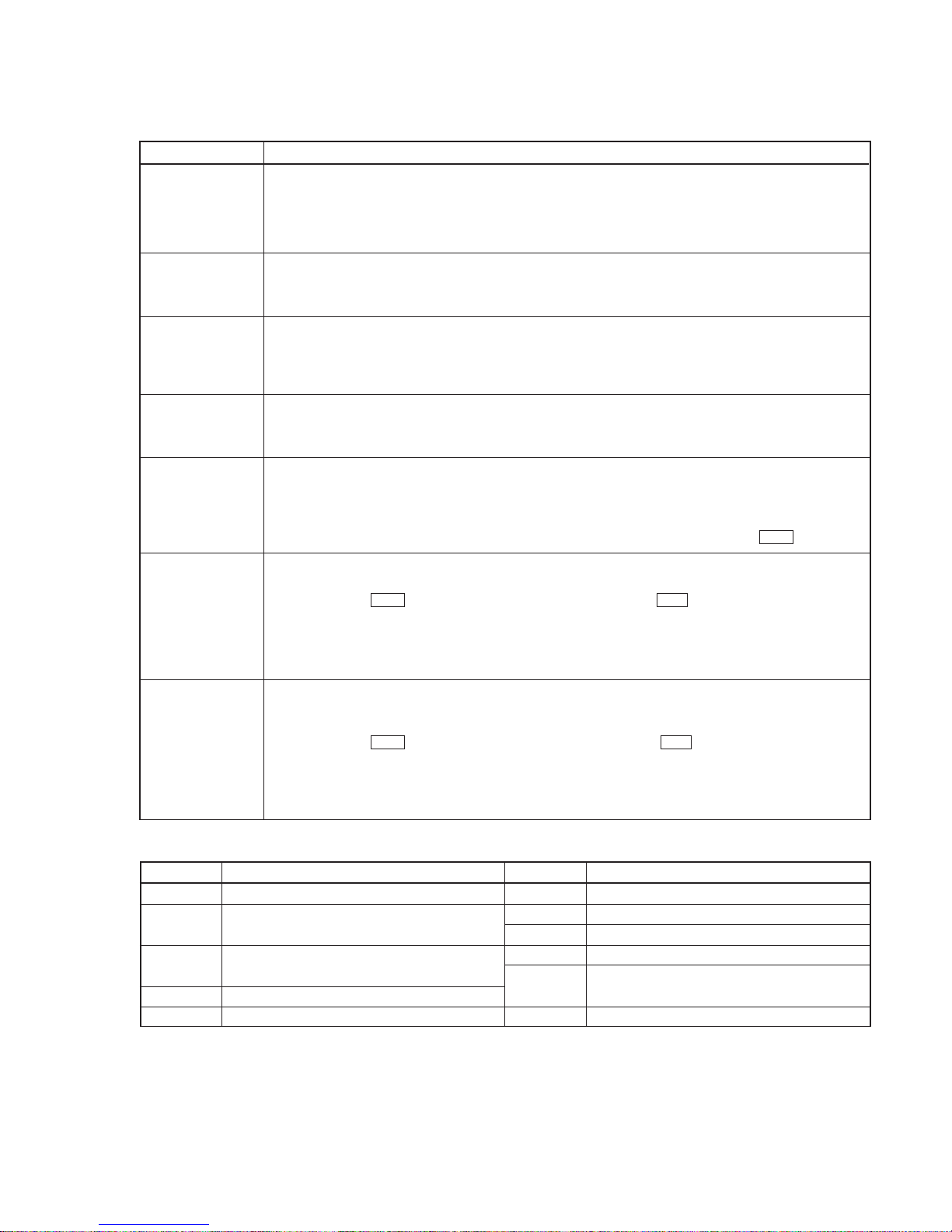

TABLE OF CONTENTS

1. SERVICING NOTE ..........................................................6

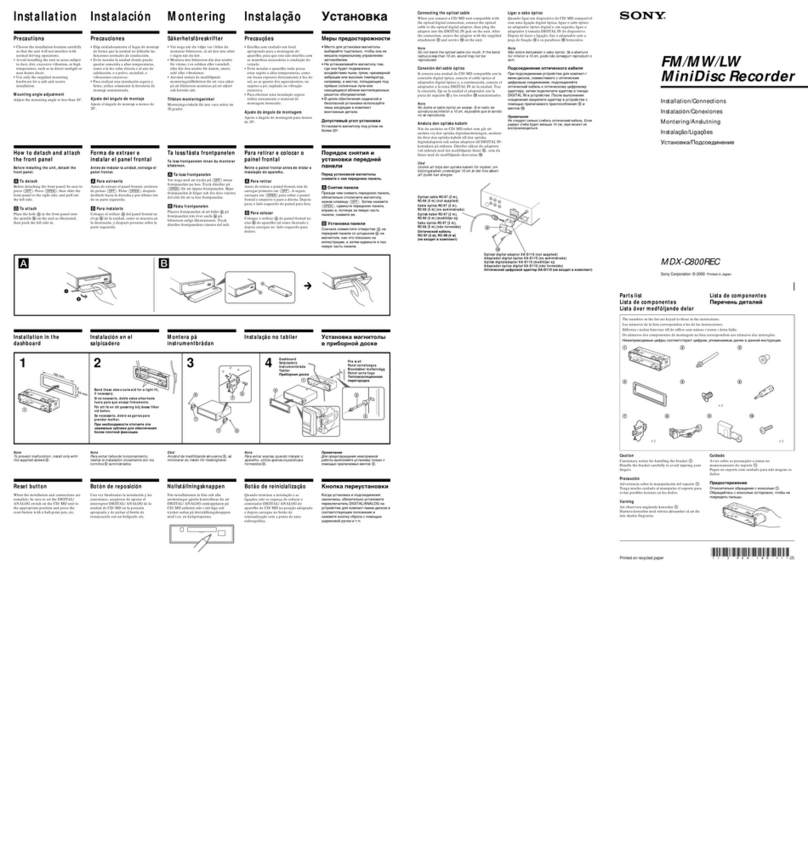

2. GENERAL ........................................................................11

3. DISASSEMBLY

3-1. Front Panel ......................................................................... 35

3-2. Slider (Cam) ........................................................................ 35

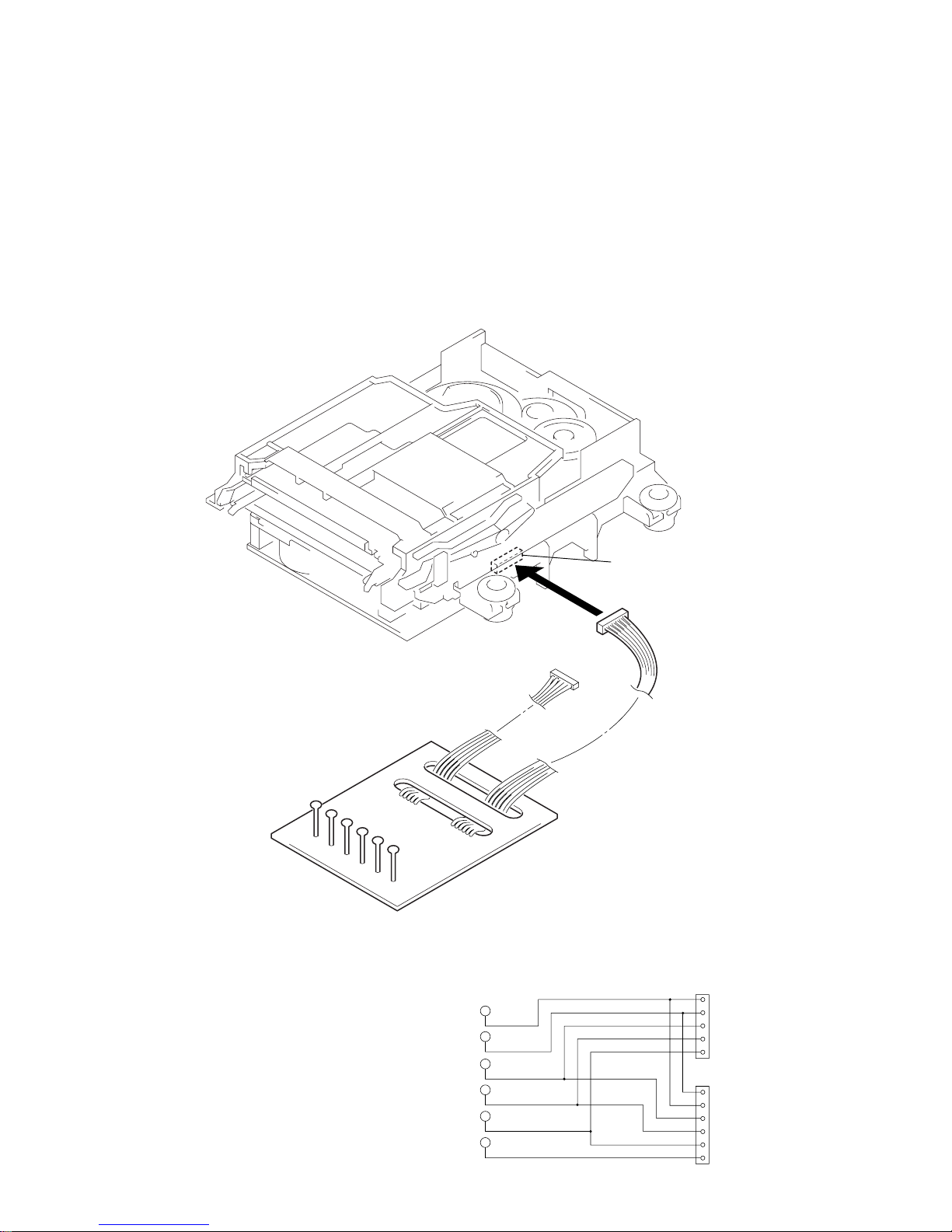

3-3. Base Unit (MBU-5B) and BD Board .................................. 36

3-4. SW Board and Loading Motor (M103) .............................. 36

4.TEST MODE ..................................................................... 37

5. ELECTRICAL ADJUSTMENTS ............................... 41

6. DIAGRAMS

6-1. Circuit Boards Location ......................................................50

6-2. Block Diagrams

• BD Section ....................................................................... 51

• Input/Output Section ........................................................ 53

• Control Section ................................................................55

• Power Section ..................................................................58

6-3. Printed Wiring Board – BD Section –................................. 61

6-4. Schematic Diagram – BD (1/2) Section –........................... 63

6-5. Schematic Diagram – BD (2/2) Section –........................... 65

6-6. Schematic Diagram – Jack (1/2) Section – ......................... 67

6-7. Schematic Diagram – Jack (2/2) Section – ......................... 69

6-8. Printed Wiring Board – Jack Section – ............................... 71

6-9. Printed Wiring Board – Main Section –..............................73

6-10. Schematic Diagram – Main (1/5) Section – ......................77

6-11. Schematic Diagram – Main (2/5) Section – ......................79

6-12. Schematic Diagram – Main (3/5) Section – ......................81

6-13. Schematic Diagram – Main (4/5) Section – ......................83

6-14. Schematic Diagram – Main (5/5) Section – ......................85

6-15. Schematic Diagram – BD Switch Section – ..................... 87

6-16. Printed Wiring Board – BD Switch Section –...................87

6-17. Printed Wiring Board – Panel Section –............................89

6-18. Schematic Diagram – Panel Section – .............................. 91

6-19. Printed Wiring Board – Power Section – ..........................93

6-20. Schematic Diagram – Power Section – ............................. 95

6-21. Printed Wiring Board – Trans Section – ........................... 97

6-22. Schematic Diagram – Trans Section – ..............................99

6-23. IC Block Diagrams......................................................... 101

6-24. IC Pin Functions............................................................. 105

7. EXPLODED VIEWS

7-1. Case Section ...................................................................... 115

7-2. Front Panel Section ........................................................... 116

7-3. Chassis Section ................................................................. 117

7-4. Mechanism Deck Section (MDM-5B) .............................. 118

7-5. Base Unit Section (MBU-5B) ........................................... 119

8. ELECTRICAL PARTS LIST ......................................120