– 9 –

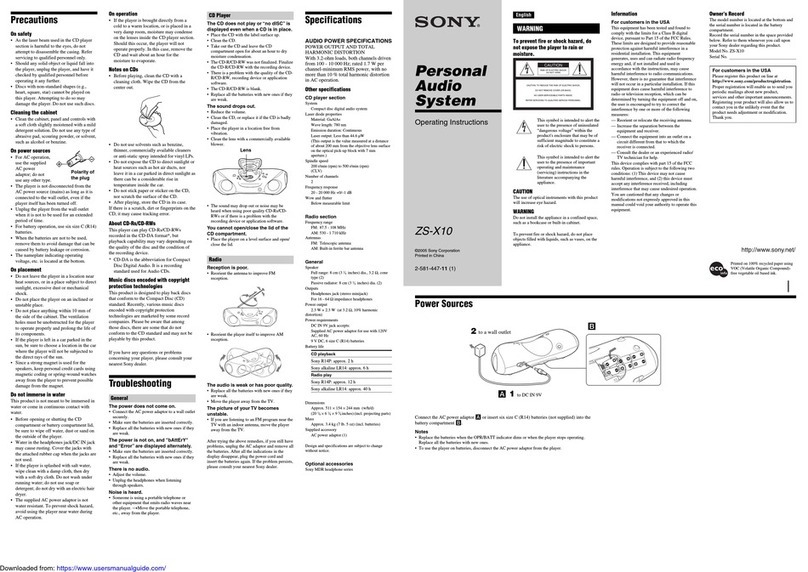

TAPE DECK SECTION 0 dB=0.775 V

1. The adjustments should be performed in the order given in the

service manual. (As a general rule. Playback circuit adjust-

ment should be completed before performing recording cir-

cuit adjustment.)

2. The adjustments should be performed for both L-ch and R-ch

unless otherwise indicated.

• Switch and control position

FUNCTION switch............................. TAPE (RADIO OFF)

BALANCE control ............................. center click

MEGA BASS control ......................... mechanical center

BALANCE control ............................. center click

PRESET MODE switch...................... MANUAL

VOLUME control ............................... maximum

Standard Output Level

TestTape

Tape Speed Adjustment

Procedure:

Mode: FWD/REV playback (DECKA)

FWD playback (DECK B)

1. Set playback mode (normal speed).

2. Make sure that the value indicated on the frequency counter

falls into the specification.

3. If out of specification, adjust RV303 so that the value on the

frequency counter becomes 3 kHz.

Specifications: 2,985 to 3,015 Hz

4. Adjust so that the frequency at the beginning and that at the

end of tape winding are between 2,970 and 3,030 Hz.

5. Set high speed dubbing mode.

6. Confirm so that the value on the frequency counter is between

5,300 and 6,300 Hz.

7. Confirm frequency difference the beginning and the end of

the tape should be within 1%.

Adjustment Location: MAIN board (See page 11)

SECTION 5

ELECTRICAL ADJUSTMENTS

SP Out Phones

Load impedance 6 Ω32 Ω

Output level 0.775 V (0 dB) 0.25 V (–10 dB)

Type Signal Used for

WS-48B 3 kHz, 0 dB Tape speed adjustment

+

–

set

32

Ω

frequency

counter

PHONES jack (J301)

test tape

WS-48B

(3kHz, 0 dB)

DECK-A DECK-B

SECTION 4

MECHANICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback head pinch rollers

playback head rubber belts

erase head idlers

capstan

2. Demagnetize the record/playback head with a head demagne-

tizer. (Do not bring the head demagnetizer close to the erase

head)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

TapeTension Measurement

DECK A DECK B

Mode Torque Meter Meter Reading

Playback CQ-102C 30 – 75 g•cm

(0.42 – 1.04 oz•inch)

Back tension CQ-102C 1.5 – 6.0 g•cm

(0.021 – 0.083 oz•inch)

Rewind Deck-A: More than 60 g•cm

CQ-201B (More than 0.84 oz•inch)

Fast forward Deck B: More than 50 g•cm

(More than 0.70 oz•inch)

Tension Meter Meter Reading

CQ-403A Deck-A: More than 90 g (3.18 oz)

Deck-B: More than 100 g (3.53 oz)

DECK A DECK B

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com