Sony Trinitron KV-20EXR20 User manual

Other Sony TV manuals

Sony

Sony Trinitron WEGA KV-DA322 User manual

Sony

Sony KDL-40R478B User manual

Sony

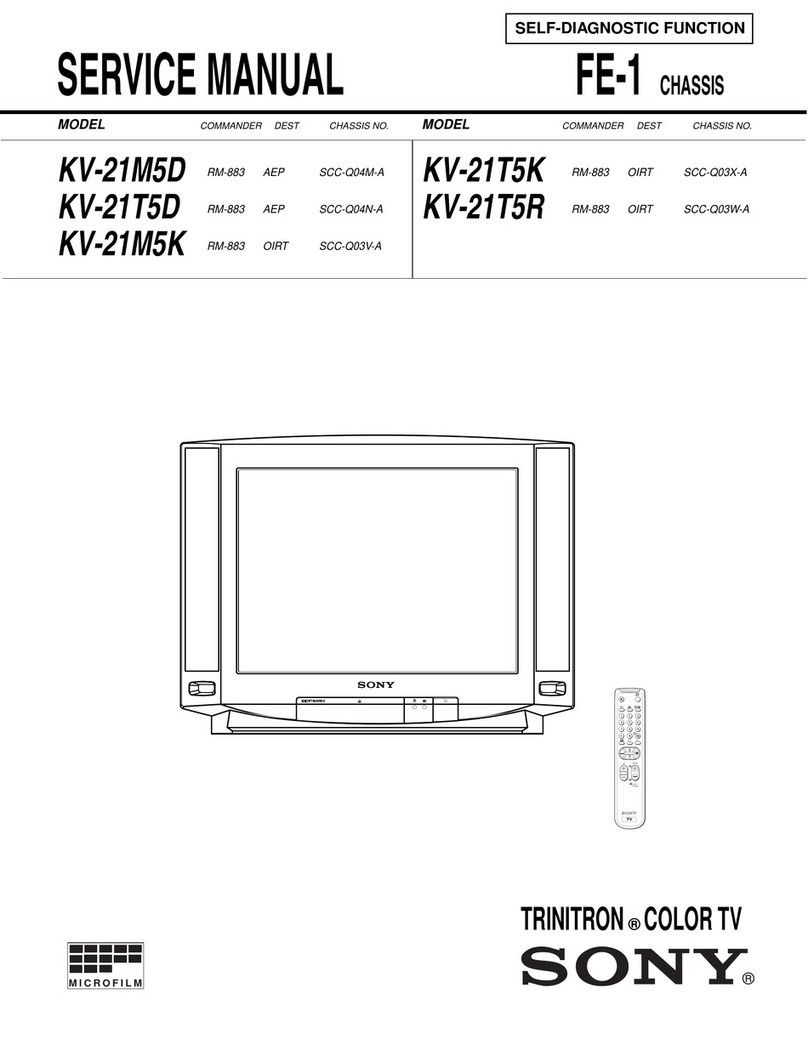

Sony TRINITRON KV-21M5D User manual

Sony

Sony BRAVIA XBR-65A8G User manual

Sony

Sony KV-13M10 User manual

Sony

Sony BRAVIA KDL-48W585B User manual

Sony

Sony KD-65X9500B User manual

Sony

Sony WEGA KV 27FS320 User manual

Sony

Sony BRAVIA KD-65XE70 Series User manual

Sony

Sony KV-32HQ100B User manual

Sony

Sony BRAVIA KD-75X9000E User manual

Sony

Sony BRAVIA KDL-60EX723 User manual

Sony

Sony BRAVIA KD-32W830K User manual

Sony

Sony FD Trinitron WEGA KV-20FV300 User manual

Sony

Sony TRINITRON KV-J51PF2S User manual

Sony

Sony Trinitron KV-27V22 User manual

Sony

Sony KDL-32EX421 User manual

Sony

Sony Bravia XBR-65X900F User manual

Sony

Sony KDE-P61MRX1D User manual

Sony

Sony KV-HR36 User manual