Sorensen MML Series MML-4 Owner's manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Looking for more information?

Visit

us

on the

web

at http://www.artisan-scientific.com for more information:

•

Price

Quotations •

Drivers·

Technical

Specifications.

Manuals and Documentation

Artisan

Scientific

is

You~

Source

for:

Quality

New

and

Certified-Used/Pre:-awned ECJuiflment

•

Tens

of

Thousands

of

In-Stock

Items

•

Hundreds

of

Manufacturers

Supported

•

Fast

Shipping and

DelIve1y

•

Leasing

/Monthly

Rentals

•Equipment Demos

•

Consignment

Service Center Repairs

Experienced Engineers and Technicians

on

staff

in

our

State-of-the-art Full-Service In-House Service Center Facility

InstraView Remote Inspection

Remotely inspect equipment before purchasing with

our

Innovative InstraView-website at http://www.instraview.com

We

bUy

used

equipment!

We

also

offer

credit

for

Buy-Backs

and

Trade-Ins

Sell

your

excess.

underutilized. and idle used equipment. Contact one

of

our

Customer

Service

Representatives todayl

Talk to alive person: 88EM38-S0URCE fB88-887-68721 IContact

us

by

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

i

SORENSEN ONE-YEAR WARRANTY

Sorensen, a division of Elgar Electronics Corporation, warrants its products to be free from defects in

material and workmanship. This warranty is effective for one year from the date of shipment of the product to

the original purchaser. Liability of Sorensen under this warranty shall exist provided that:

• the Buyer exposes the product to normal use and service and provides normal maintenance on the

product;

• Sorensen is promptly notified of defects by the Buyer and that notification occurs within the warranty period;

• the Buyer receives a Return Material Authorization (RMA) number from Sorensen’s Repair Department

prior to the return of the product to Sorensen for repair, phone 800-733-5427;

• the Buyer returns the defective product in the original, or equivalent, shipping container;

• if, upon examination of such product by Sorensen it is disclosed that, in fact, a defect in materials and/or

workmanship does exist, that the defect in the product was not caused by improper conditions, misuse,

or negligence; and,

• that Sorensen QA seal and nameplates have not been altered or removed and the equipment has not been

repaired or modified by anyone other than Sorensen authorized personnel.

This warranty is exclusive and in lieu of all other warranties, expressed or implied, including, but not limited

to, implied warranties of merchantability and fitness of the product to a particular purpose. Sorensen, its

agents, or representatives shall in no circumstance be liable for any direct, indirect, special, penal, or

consequential loss or damage of any nature resulting from the malfunction of the product. Remedies under

this warranty are expressly limited to repair or replacement of the product.

CONDITIONS OF WARRANTY

• To return a defective product, contact a Sorensen representative or the Sorensen factory for an RMA

number. Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

• For Sorensen products found to be defective within thirty days of receipt by the original purchaser,

Sorensen will absorb all ground freight charges for the repair. Products found defective within the warranty

period, but beyond the initial thirty-day period, should be returned prepaid to Sorensen for repair. Sorensen

will repair the unit and return it by ground freight pre-paid.

• Normal warranty service is performed at Sorensen during the weekday hours of 7:30 am to 4:30 pm Pacific

time. Warranty repair work requested to be accomplished outside of normal working hours will be subject to

Sorensen non-warranty service rates.

• Warranty field service is available on an emergency basis. Travel expenses (travel time, per diem expense,

and related air fare) are the responsibility of the Buyer. A Buyer purchase order is required by Sorensen

prior to scheduling.

• A returned product found, upon inspection by Sorensen, to be in specification is subject to an inspection fee

and applicable freight charges.

• Equipment purchased in the United States carries only a United States warranty for which repair must be

accomplished at the Sorensen factory.

Committed to Quality...Striving for Excellence

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

SAFETY NOTICE

Before applying power to the system, verify that the MML Series unit is configured properly for the user’s

particular application.

WARNING!

HAZARDOUS VOLTAGES IN EXCESS OF 280 VRMS, 600V PEAK MAY BE

PRESENT WHEN COVERS ARE REMOVED. QUALIFIED PERSONNEL MUST

USE EXTREME CAUTION WHEN SERVICING THIS EQUIPMENT. CIRCUIT

BOARDS, TEST POINTS, AND OUTPUT VOLTAGES MAY BE FLOATING

ABOVE (BELOW) CHASSIS GROUND.

Installation and service must be performed by qualified personnel who are aware of dealing with attendant

hazards. This includes such simple tasks as fuse verification.

Ensure that the AC power line ground is connected properly to the MML Series unit input connector

or chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting the

input/output power cables.

During normal operation, the operator does not have access to hazardous voltages within

the chassis. However, depending on the user’s application configuration, HIGH VOLTAGES

HAZARDOUS TO HUMAN SAFETY may be generated normally on the output terminals.

Ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated. To guard against risk of electrical

shock during open cover checks, do not touch any portion of the electrical circuits. Even when the power

is off, capacitors can retain an electrical charge. Use safety glasses during open cover checks to avoid

personal injury by any sudden failure of a component.

Due to filtering, the unit has high leakage current to the chassis. Therefore, it is essential to operate this unit

with a safety ground.

Some circuits are live even with the front panel switch turned off. Service, fuse verification, and

connection of wiring to the chassis must be accomplished at least five minutes after power has been

removed via external means; all circuits and/or terminals to be touched must be safety grounded to

the chassis.

After the unit has been operating for some time, the metal near the rear of the unit may be hot enough to

cause injury. Let the unit cool before handling.

Qualified service personnel need to be aware that some heat sinks are not at ground, but at high potential.

These operating instructions form an integral part of the equipment and must be available to the operating

personnel at all times. All the safety instructions and advice notes are to be followed.

Neither Sorensen, San Diego, California, USA, nor any of the subsidiary sales organizations, can accept any

responsibility for personal, material or consequential injury, loss, or damage that results from improper use of

the equipment and accessories.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

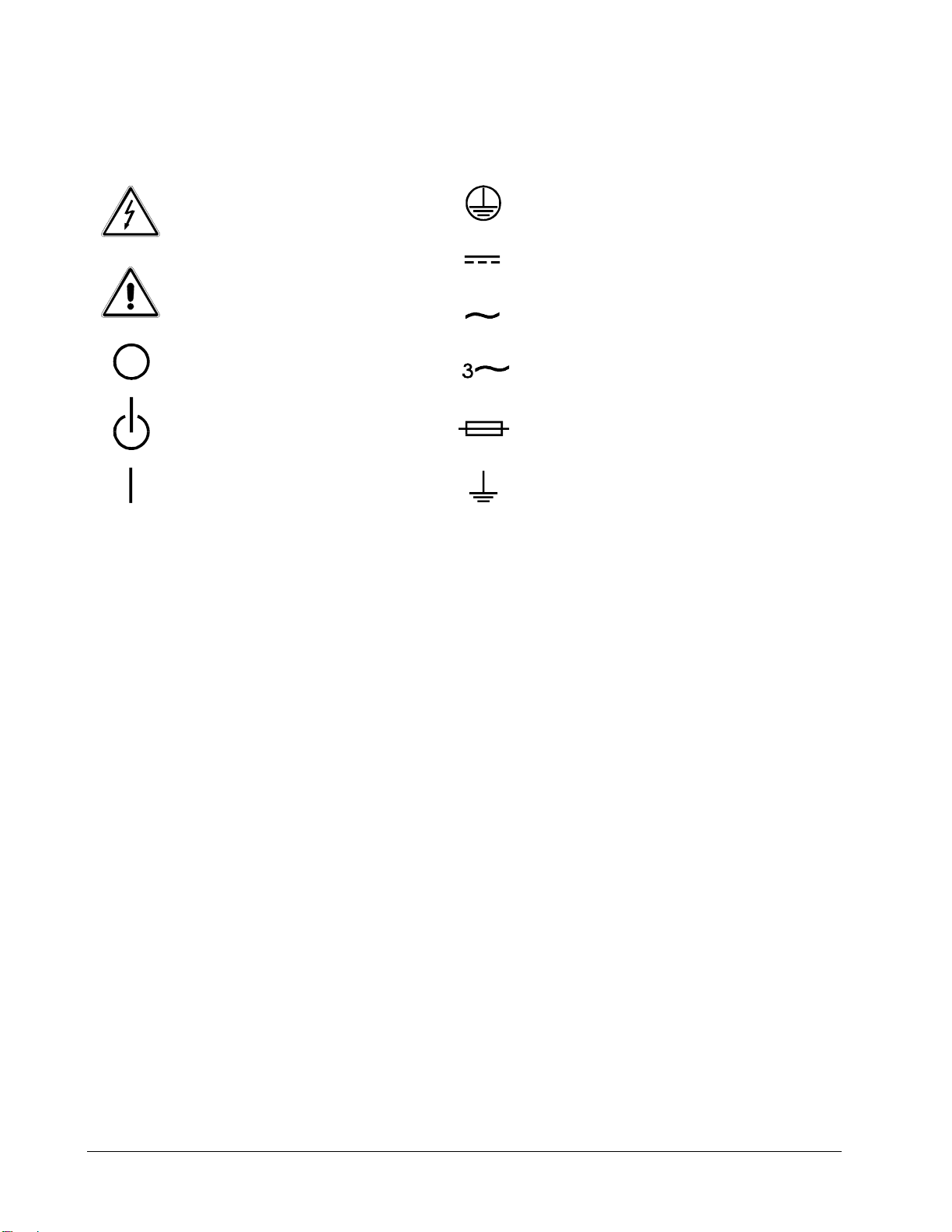

SAFETY SYMBOLS

CAUTION

Risk of Electrical Shock

CAUTION

Refer to Accompanying Documents

Off (Supply)

Standby (Supply)

On (Supply)

Direct Current (DC)

Alternating

Three–Phase

Fuse

Earth (Ground) Terminal

Protective Conductor Terminal

Current (AC)

Alternating Current

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

CONTENTS

1. GENERAL INFORMATION

1.1 Introduction .................................................................................................. 1-1

1.2 Description................................................................................................... 1-1

1.3 Overview of Key Features............................................................................ 1-1

1.4 Specifications............................................................................................... 1-2

2. INSTALLATION

2.1 Introduction .................................................................................................. 2-1

2.2 Inspection .................................................................................................... 2-1

2.3 Installing the Modules .................................................................................. 2-1

2.3.1 Channel Number.............................................................................. 2-2

2.4 Installing the Mainframe............................................................................... 2-3

2.4.1 Changing Line Voltage..................................................................... 2-3

2.4.2 Turn-On Self-Test ............................................................................ 2-4

2.5 Application Connection ................................................................................ 2-5

2.5.1 Load Connections ............................................................................ 2-5

2.5.2 Remote Sensing Connections.......................................................... 2-6

2.5.3 Parallel Connections ........................................................................ 2-7

2.6 Remote Control Connection......................................................................... 2-7

3. OPERATION OVERVIEW

3.1 Introduction .................................................................................................. 3-1

3.2 Front Panel Description ............................................................................... 3-1

3.3 Rear Panel Description ................................................................................ 3-2

3.4 Local/Remote Control .................................................................................. 3-2

3.5 Modes of Operation ..................................................................................... 3-3

3.5.1 Constant Current Mode.................................................................... 3-3

3.5.2 Constant Resistance Mode .............................................................. 3-6

3.5.3 Constant Voltage Mode.................................................................... 3-7

3.6 Load Synchronization .................................................................................. 3-8

3.7 Measurements ............................................................................................. 3-8

3.8 Slew Rate and Minimum Transient Time ..................................................... 3-8

3.9 Start/Stop Sink Current ................................................................................ 3-8

3.10 Short On/Off............................................................................................... 3-10

3.11 Load On/Off ............................................................................................... 3-10

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Sorensen MML Series Operation and Programming Manual

vi

3.12 Protection Features ....................................................................................3-10

3.13 Save/Recall Setting ....................................................................................3-12

3.14 Program......................................................................................................3-12

4. LOCAL OPERATION

4.1 Introduction...................................................................................................4-1

4.2 Local Operation of Load Mainframe .............................................................4-1

4.1.1 Selecting the Channel ....................................................................4-3

4.1.2 Setting the Operation Mode............................................................4-3

4.1.3 Setting the Program........................................................................4-7

4.1.4 Running the Program ...................................................................4-10

4.1.5 Setting the Specifications .............................................................4-10

4.1.6 Setting the Configuration ..............................................................4-11

4.1.7 Recalling Files ..............................................................................4-15

4.1.8 Saving Files ..................................................................................4-15

4.1.9 Saving Defaults ............................................................................4-16

4.1.10 Saving Programs ..........................................................................4-16

4.1.11 Going To Local .............................................................................4-16

4.1.12 Lock Operation .............................................................................4-16

4.1.13 Setting System and RS-232C Connection....................................4-16

4.1.14 Connecting the GO/NG Output Port .............................................4-17

4.1.15 Setting the GPIB Address.............................................................4-17

4.3 Local Operation of Load Module ................................................................4-18

4.3.1 Local Operation of Single Channel/Module (Panel A) ..................4-18

4.1.2 Local Operation of Double Channels/Module (Panel B) ...............4-21

4.1.3 Online Change Level ....................................................................4-24

5. REMOTE OPERATION

5.1 Introduction...................................................................................................5-1

5.2 DIP Switches on the GPIB Card...................................................................5-1

5.2.1 GPIB Address...................................................................................5-1

5.2.2 Other DIP Switches ..........................................................................5-2

5.3 GPIB Capability of the Electronic Load.........................................................5-3

5.4 RS232C in Remote Control ..........................................................................5-3

5.5 Basic Programming Definitions ....................................................................5-4

5.6 Numerical Data Formats...............................................................................5-5

5.7 Character Data Formats ...............................................................................5-6

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Contents

vii

5.8 Separators and Terminators ........................................................................ 5-6

5.9 Language Dictionary.................................................................................... 5-8

5.9.1 Common Commands ....................................................................... 5-8

5.10 Specific Commands ................................................................................... 5-13

5.10.1 ABORT Subsystem...................................................................... 5-13

5.10.2 CHANNEL Subsystem ................................................................. 5-13

5.10.3 CONFIGURE Subsystem............................................................. 5-16

5.10.4 CURRENT Subsystem................................................................. 5-21

5.10.5 FETCH Subsystem ...................................................................... 5-25

5.10.6 LOAD Subsystem ........................................................................ 5-27

5.10.7 MEASURE Subsystem ................................................................ 5-29

5.10.8 MODE Subsystem ....................................................................... 5-32

5.10.9 PROGRAM Subsystem................................................................ 5-33

5.10.10 RESISTANCE Subsystem ........................................................... 5-37

5.10.11 RUN Subsystem .......................................................................... 5-39

5.10.12 SHOW Subsystem ....................................................................... 5-39

5.10.13 SPECIFICATION Subsystem....................................................... 5-40

5.10.14 STATUS Subsystem .................................................................... 5-43

5.10.15 VOLTAGE Subsystem ................................................................. 5-48

5.11 Status Reporting ........................................................................................ 5-50

5.11.1 Introduction .................................................................................. 5-50

5.11.2 Register Information in Common ................................................. 5-50

5.11.3 Channel Status ............................................................................ 5-52

5.11.4 Channel Summary ....................................................................... 5-53

5.11.5 Questionable Status..................................................................... 5-53

5.11.6 Output Queue .............................................................................. 5-54

5.11.7 Standard Event Status ................................................................. 5-54

5.11.8 Status Byte Register .................................................................... 5-55

5.11.9 Service Request Enable Register ................................................ 5-55

6. PROGRAMMING EXAMPLE

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-1

1 GENERAL INFORMATION

1.1 Introduction

This manual contains specifications, installation, operation, and programming

instructions of MML-4, MML-2 electronic load mainframes as well as the

MML-80-20-102 and MML-80-60-301 electronic load modules. Here “Load” means the

electronic load modules of Sorensen MML series while “Mainframe” the MML-4, MML-2

electronic load mainframes.

1.2 Description

The functions of MML-4 and MML-2 mainframes are the same. The former has four

slots for Load modules while the latter two slots. The functions of MML-80-20-102,

MML-80-60-301, etc. are all the same. The differences are in input voltage, load

current, and power ratings. An individual module may have one or two channels.

Each channel has its own channel number, load and measurement connectors, and

operates independently in constant current (CC) mode, constant resistance (CR) mode,

or constant voltage (CV) mode.

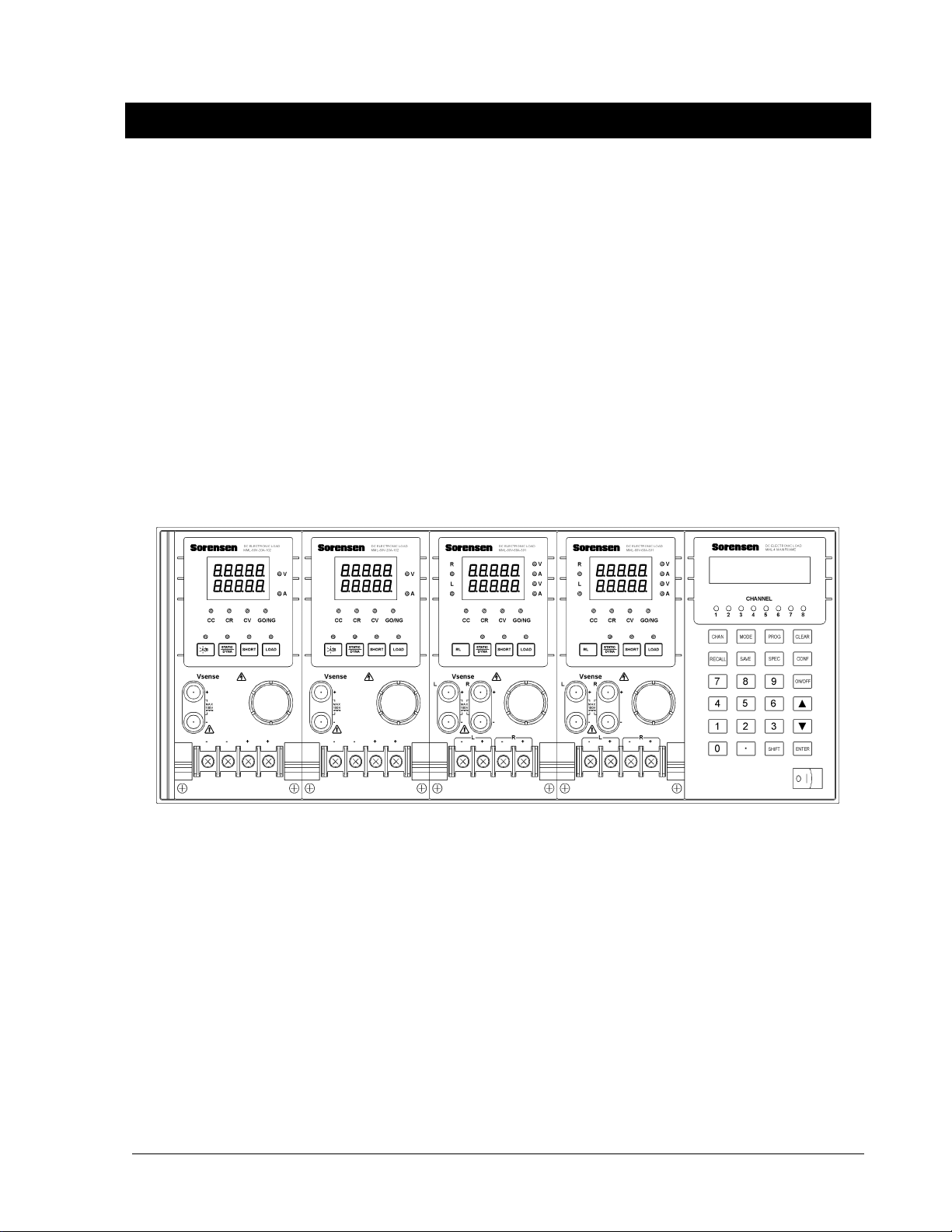

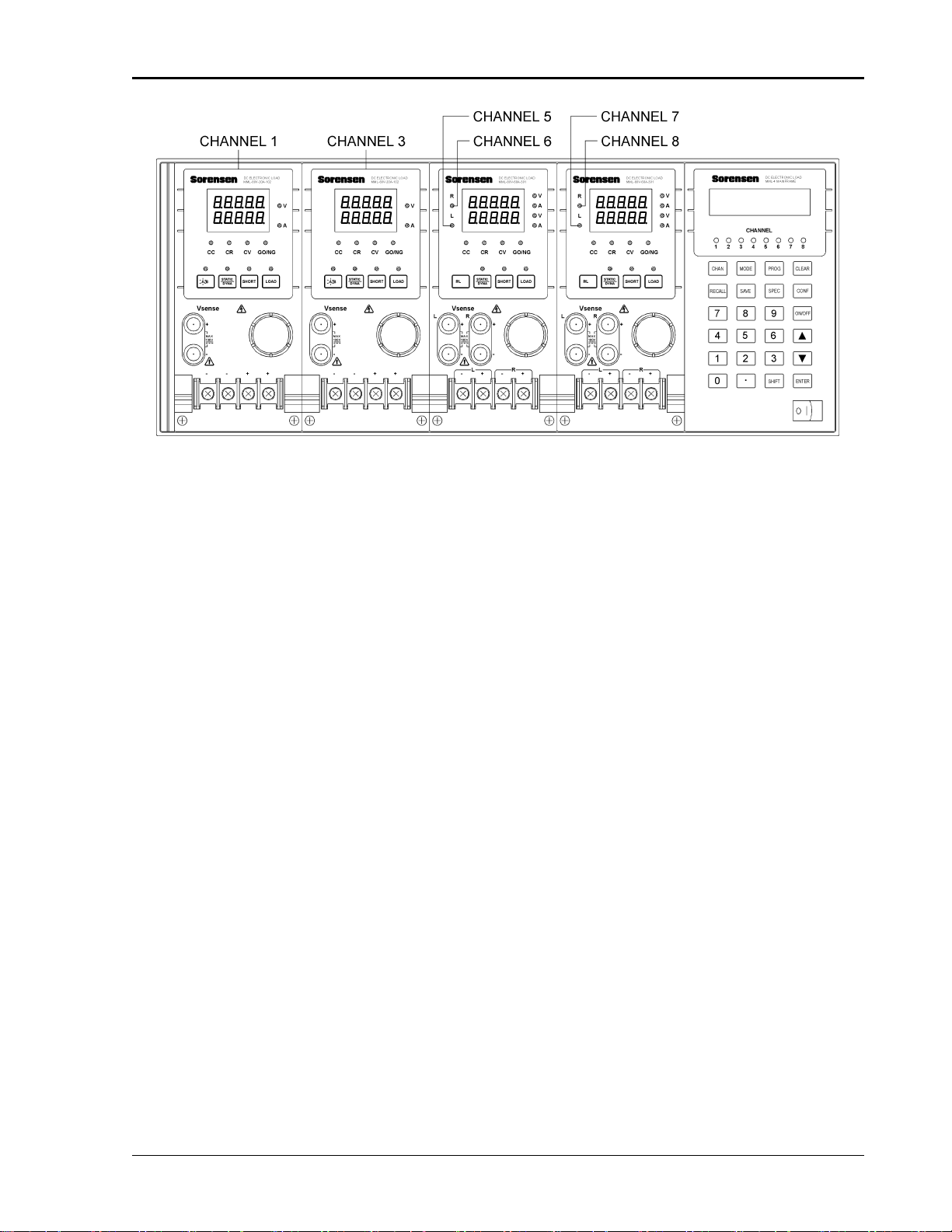

Figure 1-1 Front Panel of the Electronic Load

There are two groups of keypads on the front panel of the electronic load (see Figure

1-1). One is the Mainframe keypad; the other is the Load keypad. In this manual, the

Mainframe keypad is referred to as MODE; the Load keypad is referred to as SHORT.

1.3 Overview of Key Features

1.3.1 Configuration

• Flexible configuration using plug-in electronic load modules to mainframes.

• Local operation on front panel keypad.

• Remote control via GPIB or RS-232C interface.

• Photocoupler isolation to offer true floating Load.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Sorensen MML Series Operation and Programming Manual

1-2

• Automatic fan speed control to reduce noise.

• Up to 8 channels for one Mainframe.

1.3.2 Load

• Constant current (CC), constant resistance (CR), and constant voltage (CV)

operation modes.

• Programmable slew rate, load levels, load periods, and conduct voltage (Von).

• Programmable dynamic loading with speed up to 20KHz.

• Minimum input resistance allowing load to sink high current even with low input

voltage (1 V).

• Selective voltage and current ranges.

• Remote sensing capability.

• 100 sets of memories to save/recall user-definable setups.

• 10 sets of programs to link files for automatic test.

• 15-bit A/D converter with precision measurement.

• Short circuit simulation.

• Automatic GO/NG inspection to confirm UUT within spec.

• Independent GO/NG signals for each channel.

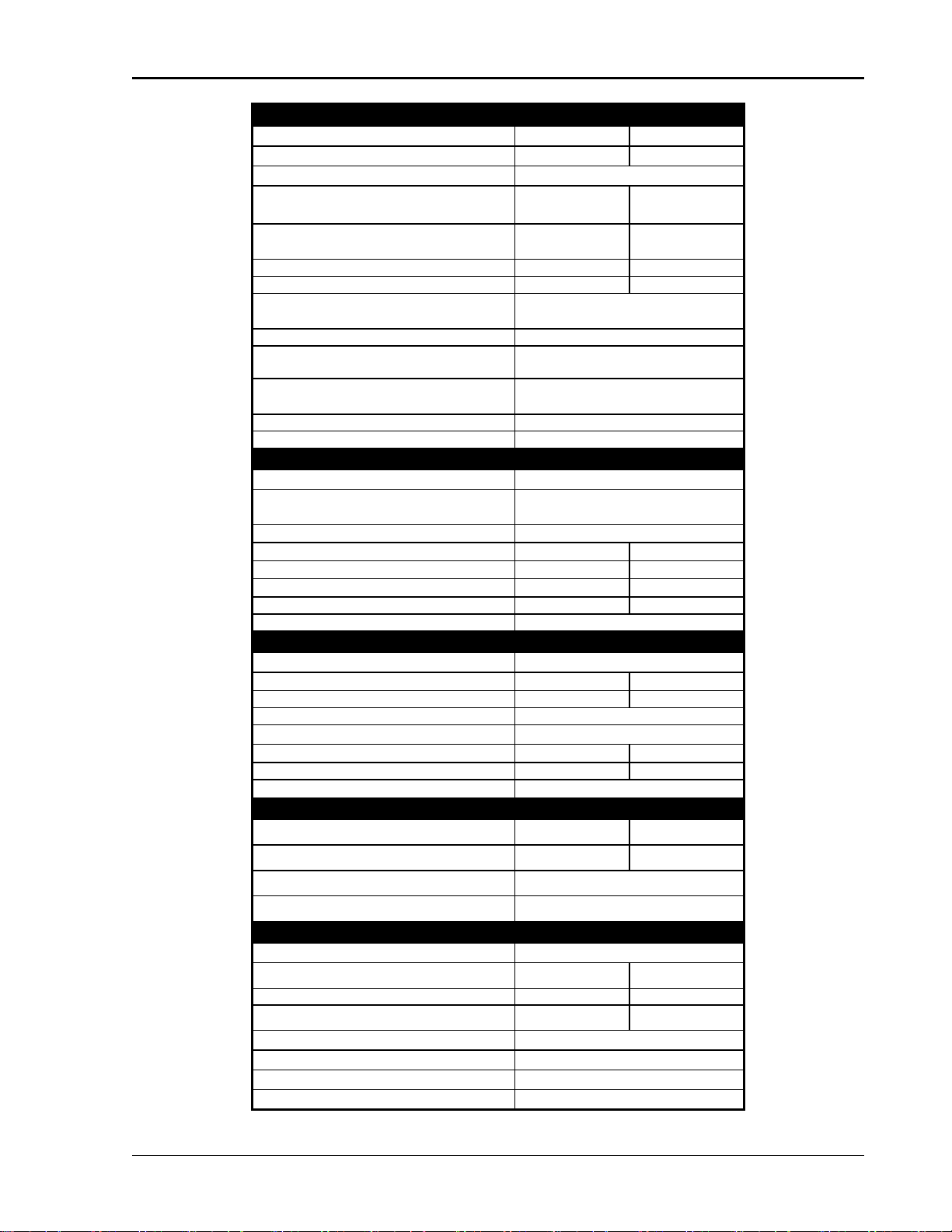

1.4 Specifications

Mainframe: MML-4

AC input: 115/230 switchable or 100/200 switchable Vac line

Fuse: 5A/250V

Amplitude: ±10%

Frequency: 47 to 63 Hz

Maximum VA: 180VA

Trigger output: Vlo = 0.8V maximum at Ilo = 1 mA

Vhi = 3.2V minimum at Ihi = −40µA

Weight: 24Kg

Dimensions: Width: 440mm

Height: 177.4 mm (excluding feet), 186mm (including feet)

Depth: 560mm (including Load module)

Load specifications are listed in the tables below.

NOTES

1. All specifications are tested at 20°C ∼30°C except otherwise stated.

2. The range of operation temperature is 0°C ∼40°C.

3. The specifications of DC current accuracy are tested after the input is applied for 30

seconds.

4. The power of the load module of MML series is supplied from MML-4/MML-2

mainframe.

5. The typical temperature coefficient is 100ppm.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

General Information

1-3

MODEL MML-80-20-102(100W*2)

POWER 20W 100W

CURRENT 0∼2A 0∼20A

VOLTAGE 1∼80V

MINIMUM OPERATING VOLTAGE

(DC)

1.0V at 2A 1.0V at 20A

CONSTANT CURRENT MODE

Range

0∼2A 0∼20A

Resolution 0.5mA 5mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE MODE

Range

CRL: (0.075Ω∼300Ω) (100W/16V)

CRH: (3.75Ω∼15KΩ) (100W/80V)

Resolution 12 bits

Accuracy CRL: 0.1mho+0.2%

CRH: 0.01mho+0.1%

CONSTANT VOLTAGE MODE

Range

1∼80V

Resolution 20mV

Accuracy 0.05%+0.1%F.S.

DYNAMIC MODE

DYNAMIC MODE C.C. MODE

T1 and T2 0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

Accuracy 1µS /1mS+100ppm

Slew Rate 0.32∼80mA/µS 3.2∼800mA/µS

Resolution 0.32mA/µS 3.2mA/µS

Current 0∼2A 0∼20A

Resolution 0.5mA 5mA

Current Accuracy 0.4% F.S.

MEASUREMENT SECTION

VOLTAGE READ BACK

Range 0∼16V 0∼80V

Resolution 0.5mV 2.5mV

Accuracy 0.05%+0.05% F.S.

CURRENT READ BACK

Range 0∼2A 0∼20A

Resolution 0.0625mA 0.625mA

Accuracy ±(0.1%+0.1% F.S.)

PROTECTIVE SECTION

Over Power Protection ≒20.8W ≒104W

Over Current Protection ≒2.04A ≒20.4A

Over Temperature Protection ≒85°C

Over Voltage Protection ≒81.6V/16.3V

GENERAL

SHORT CIRCUIT

Current (CC) ≒2.2/2A ≒22/20A

Voltage (CV) 0V 0V

Resistance (CR) ≒3.75Ω≒0.075Ω

INPUT RESISTANCE (LOAD OFF) 100KΩ(Typical)

SIZE 81(W)×172(H)×495(D)

WEIGHT (Approx.) 4.2Kg

EMC and SAFETY CE

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Sorensen MML Series Operation and Programming Manual

1-4

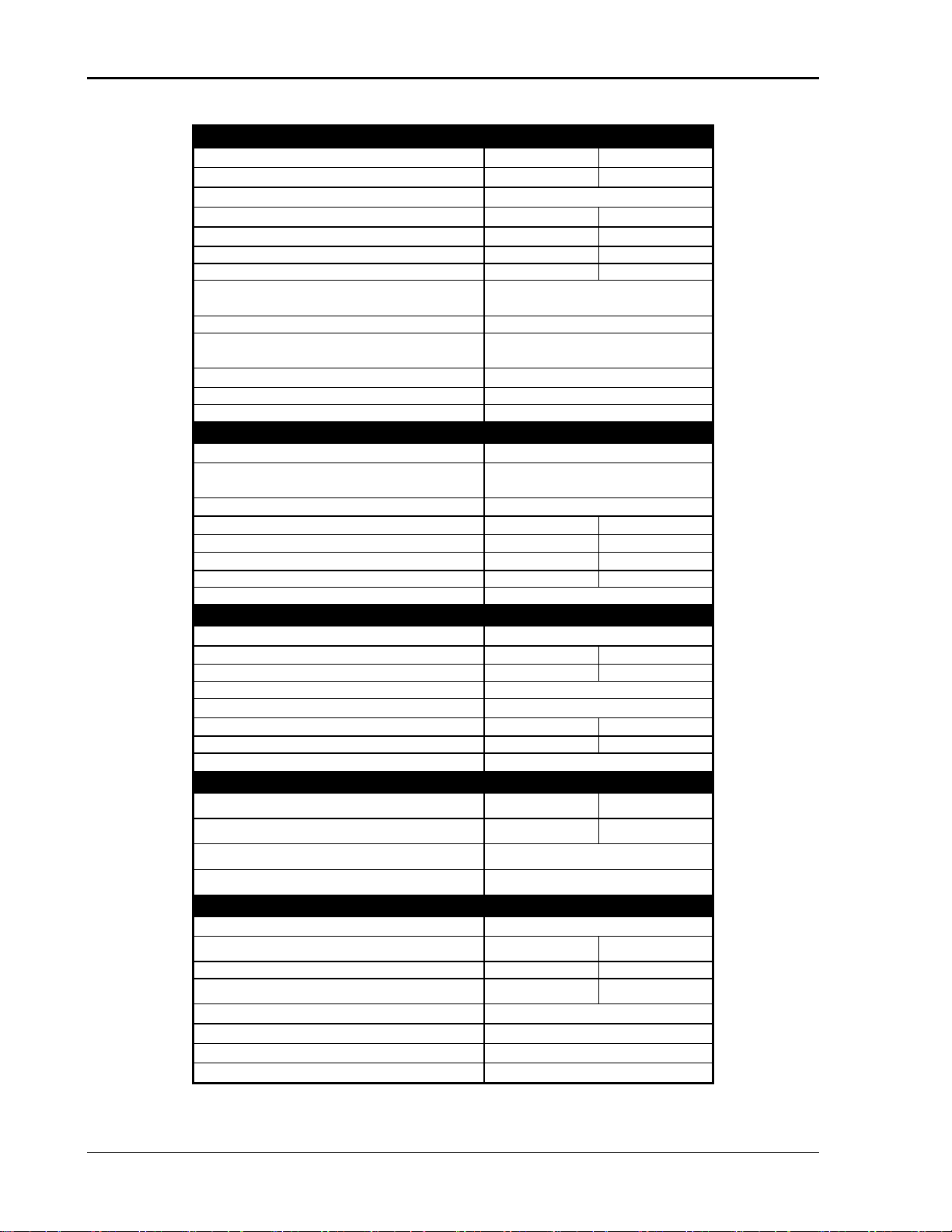

MODEL MML-80-60-301

POWER 30W 300W

CURRENT 0∼6A 0∼60A

VOLTAGE 1∼80V

MINIMUM OPERATING VOLTAGE (DC) 1.0V at 6A 1.0V at 60A

CONSTANT CURRENT MODE Range 0∼6A 0∼60A

Resolution 1.5mA 15mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE MODE

Range

0.025Ω∼100Ω(300W/16V)

1.25Ω∼5KΩ(300W/80V)

Resolution 12 bits

Accuracy CRL (100Ω): 0.1mho+0.2%

CRH (5KΩ): 0.01mho+0.1%

CONSTANT VOLTAGE MODE Range 2.5∼500V

Resolution 20mV

Accuracy 0.05%+0.1%F.S.

DYNAMIC MODE

DYNAMIC MODE C.C. MODE

T1 and T2 0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

Accuracy 1µS /1mS+100ppm

Slew Rate 0.001∼0.25A/µS 0.01∼2.5A/µS

Resolution 0.001A/µS 0.01A/µS

Current 0∼6A 0∼60A

Resolution 1.5mA 15mA

Current Accuracy 0.4% F.S.

MEASUREMENT SECTION

VOLTAGE READ BACK

Range 0∼16V 0∼80V

Resolution 0.5mV 2.5mV

Accuracy 0.05%+0.05% F.S.

CURRENT READ BACK

Range 0∼6A 0∼60A

Resolution 0.1875mA 1.875mA

Accuracy ±(0.1%+0.1% F.S.)

PROTECTIVE SECTION

Over Power Protection ≒31.2W ≒312W

Over Current Protection ≒6.12A ≒61.2A

Over Temperature Protection ≒85°C

Over Voltage Protection ≒81.6V/16.3V

GENERAL

SHORT CIRCUIT

Current (CC) ≒6.6/6A ≒66/60A

Voltage (CV) 0V 0V

Resistance (CR) ≒1.25Ω≒0.025Ω

INPUT RESISTANCE (LOAD OFF) 100KΩ(Typical)

SIZE 81(W)×172(H)×495(D)

WEIGHT (Approx.) 4.2Kg

EMC and SAFETY CE

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

General Information

1-5

MODEL MML-80-120-601

POWER 60W 600W

CURRENT 0∼12A 0∼120A

VOLTAGE 1∼80V

MINIMUM OPERATING VOLTAGE (DC) 1.0V at 12A 1.0V at 120A

CONSTANT CURRENT MODE Range

0∼12A

0∼120A

Resolution 3mA 30mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE MODE Range 0.0125Ω∼50Ω(600W/16V)

0.625Ω∼2.5KΩ(600W/80V)

Resolution 12 bits

Accuracy CRL (50Ω): 0.4mho+0.5% (top)

CRH (2.5KΩ): 0.04mho+0.2%

(bottom)

CONSTANT VOLTAGE MODE Range 1∼80V

Resolution 20mV

Accuracy ±(0.05%+0.1%F.S.)

DYNAMIC MODE

DYNAMIC MODE C.C. MODE

T1 and T2 0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

Accuracy 1µS /1mS+100ppm

Slew Rate 0.002∼0.5A/µS 0.02∼5A/µS

Resolution 0.002A/µS 0.02A/µS

Current 0∼12A 0∼120A

Resolution 3mA 30mA

Current Accuracy 0.4% F.S.

MEASUREMENT SECTION

VOLTAGE READ BACK

Range 0∼16V 0∼80V

Resolution 0.5mV 2.5mV

Accuracy 0.05%+0.05% F.S.

CURRENT READ BACK

Range 0∼12A 0∼120A

Resolution 0.375mA 3.75mA

Accuracy 0.1%+0.1% F.S.

PROTECTION SECTION

Over Power Protection ≒62.4W ≒624W

Over Current Protection ≒12.24A ≒122.4A

Over Temperature Protection ≒85°C

Over Voltage Protection ≒81.6V/16.3V

GENERAL

SHORT CIRCUIT

Current (CC) ≒13.2/12A ≒132/120A

Voltage (CV) 0V 0V

Resistance (CR) ≒0.625Ω≒0.0125Ω

INPUT RESISTANCE (LOAD OFF) 100KΩ(Typical)

SIZE 162(W)×172(H)×495(D)

WEIGHT (Approx.) 8.4Kg

EMC and SAFETY CE

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Sorensen MML Series Operation and Programming Manual

1-6

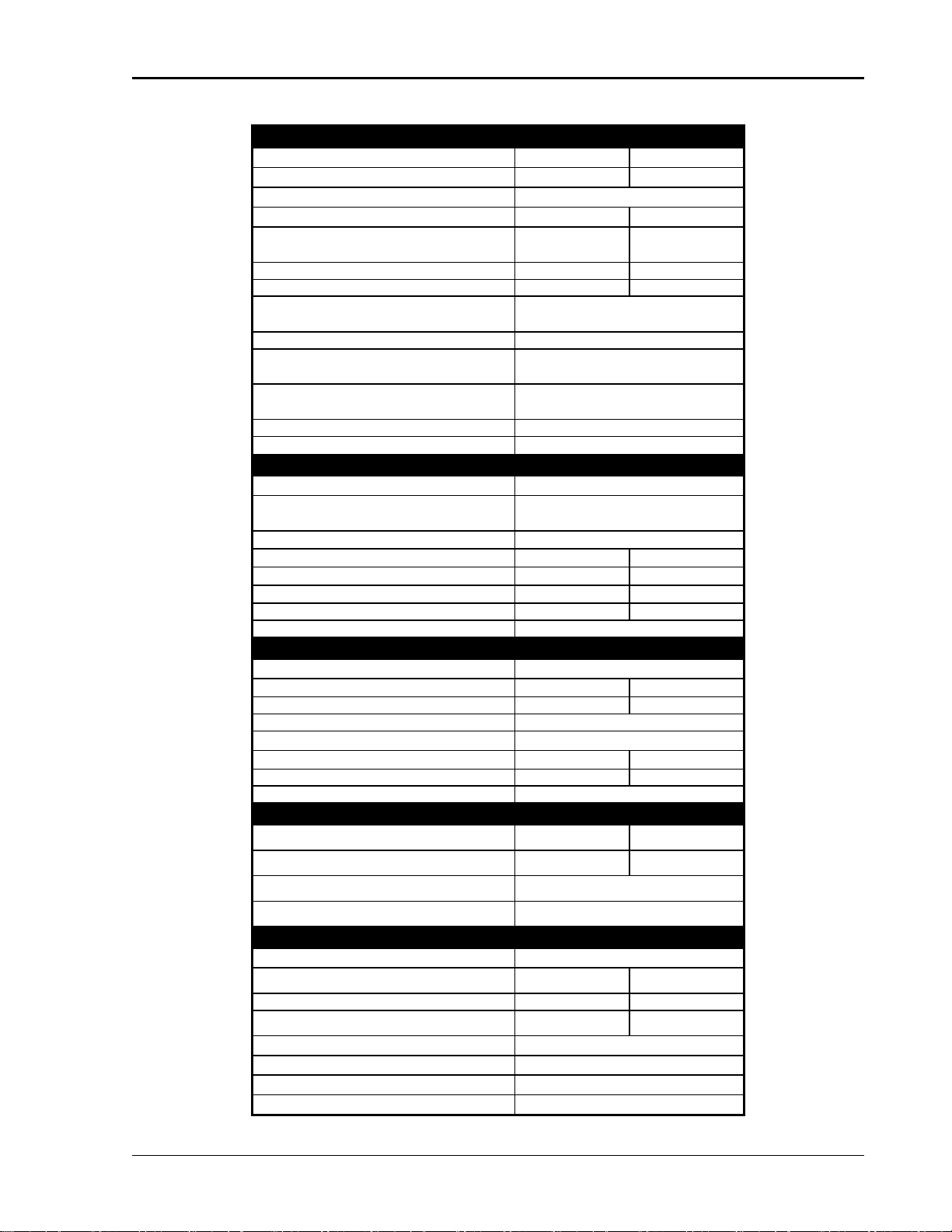

MODEL MML-500-10-301

POWER 30W 300W

CURRENT 0∼1A 0∼10A

VOLTAGE 2.5∼500V

MIN. OPERATING VOLTAGE (DC) 2.5V at 1A 2.5V at 10A

CONSTANT CURRENT MODE

Range

0∼1A 0∼10A

Resolution 0.25mA 2.5mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE MODE

Range

1.25Ω∼5KΩ(300W/125V)

50Ω∼200KΩ(300W/500V)

Resolution 12 bits

Accuracy 5KΩ: 0.02 mho+0.2%

200KΩ: 0.005 mho+0.1%

CONSTANT VOLTAGE MODE

Range

2.5∼500V

Resolution 125mV

Accuracy 0.05%±0.1%F.S.

DYNAMIC MODE

DYNAMIC MODE C.C. MODE

T1 & T2 0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

Accuracy 1µS /1mS+100ppm

Slew Rate 0.16∼40mA/µS 1.6∼400mA/µS

Resolution 0.16mA/µS 1.6mA/µS

Current 0∼1A 0∼10A

Resolution 0.25mA 2.5mA

Current Accuracy 0.4% F.S.

MEASUREMENT SECTION

VOLTAGE READ BACK

Range 0∼125V 0∼500V

Resolution 4mV 16mV

Accuracy 0.05%+0.05% F.S.

CURRENT READ BACK

Range 0∼1A 0∼10A

Resolution 0.032mA 0.32mA

Accuracy 0.1%+0.1% F.S.

PROTECTION SECTION

Over Power Protection ≒31.2W ≒312W

Over Current Protection ≒1.02A ≒10.2A

Over Temperature Protection ≒85°C

Over Voltage Protection ≒510V/127.5V

GENERAL

SHORT CIRCUIT

Current (CC) ≒1.1/1A ≒11/10A

Voltage (CV) 0V 0V

Resistance (CR) ≒50Ω≒1.25Ω

INPUT RESISTANCE (LOAD OFF) 100KΩ(Typical)

SIZE 81(W)×172(H)×495(D)

WEIGHT (Approx.) 4.2Kg

EMC & SAFETY CE

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

General Information

1-7

MODEL MML-500-20-601

POWER 60W 600W

CURRENT 0∼2A 0∼20A

VOLTAGE 2.5∼500V

MIN. OPERATING VOLTAGE (DC) 2.5V at 2A 2.5V at 20A

CONSTANT CURRENT MODE

Range

0∼2A 0∼20A

Resolution 0.5mA 5mA

Accuracy 0.1%+0.1%F.S. 0.1%+0.2%F.S.

CONSTANT RESISTANCE MODE

Range

0.625Ω∼2.5KΩ(600W/125V)

25Ω∼100KΩ(600W/500V)

Resolution 12 bits

Accuracy 2.5KΩ: 0.05mho+0.2%

100KΩ: 0.005mho+0.1%

CONSTANT VOLTAGE MODE

Range

2.5∼500V

Resolution 125mV

Accuracy 0.05%±0.1%F.S.

DYNAMIC MODE

DYNAMIC MODE C.C. MODE

T1 & T2 0.025mS∼10mS / Res: 1µS

1mS∼30S / Res: 1mS

Accuracy 1µS /1mS+100ppm

Slew Rate 0.32∼80mA/µS 3.2∼800mA/µS

Resolution 0.32mA/µS 3.2mA/µS

Current 0∼2A 0∼20A

Resolution 0.5mA 5mA

Current Accuracy 0.4% F.S.

MEASUREMENT SECTION

VOLTAGE READ BACK

Range 0∼125V 0∼500V

Resolution 4mV 16mV

Accuracy 0.05%+0.05% F.S.

CURRENT READ BACK

Range 0∼2A 0∼20A

Resolution 0.0625mA 0.625mA

Accuracy 0.1%+0.1% F.S.

PROTECTION SECTION

Over Power Protection ≒62.4W ≒624W

Over Current Protection ≒2.04A ≒20.4A

Over Temperature Protection ≒85°C

Over Voltage Protection ≒510V/127.5V

GENERAL

SHORT CIRCUIT

Current (CC) ≒2.2/2A ≒22/20A

Voltage (CV) 0V 0V

Resistance (CR) ≒25Ω≒0.625Ω

INPUT RESISTANCE (LOAD OFF) 100KΩ(Typical)

SIZE 162(W)×172(H)×495(D)

WEIGHT (Approx.) 8.4Kg

EMC & SAFETY CE

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-1

2 INSTALLATION

2.1 Introduction

This chapter discusses installation of the Load to the Mainframe, Load connections,

and unit self-tests, as well as application considerations.

2.2 Inspection

As soon as the instrument is unpacked, inspect any damage that might have occurred

in shipping. Keep all packing materials in case the Load or the Mainframe has to be

returned. If any damage is found, please file a claim with the carrier immediately. Do

not return the instrument to Sorensen without prior approval.

In additon to this manual, be sure that the following items have also been received with

your Mainframe and Load:

• Mainframe: Power Cord

• Load Module: Measurement and Load Cables

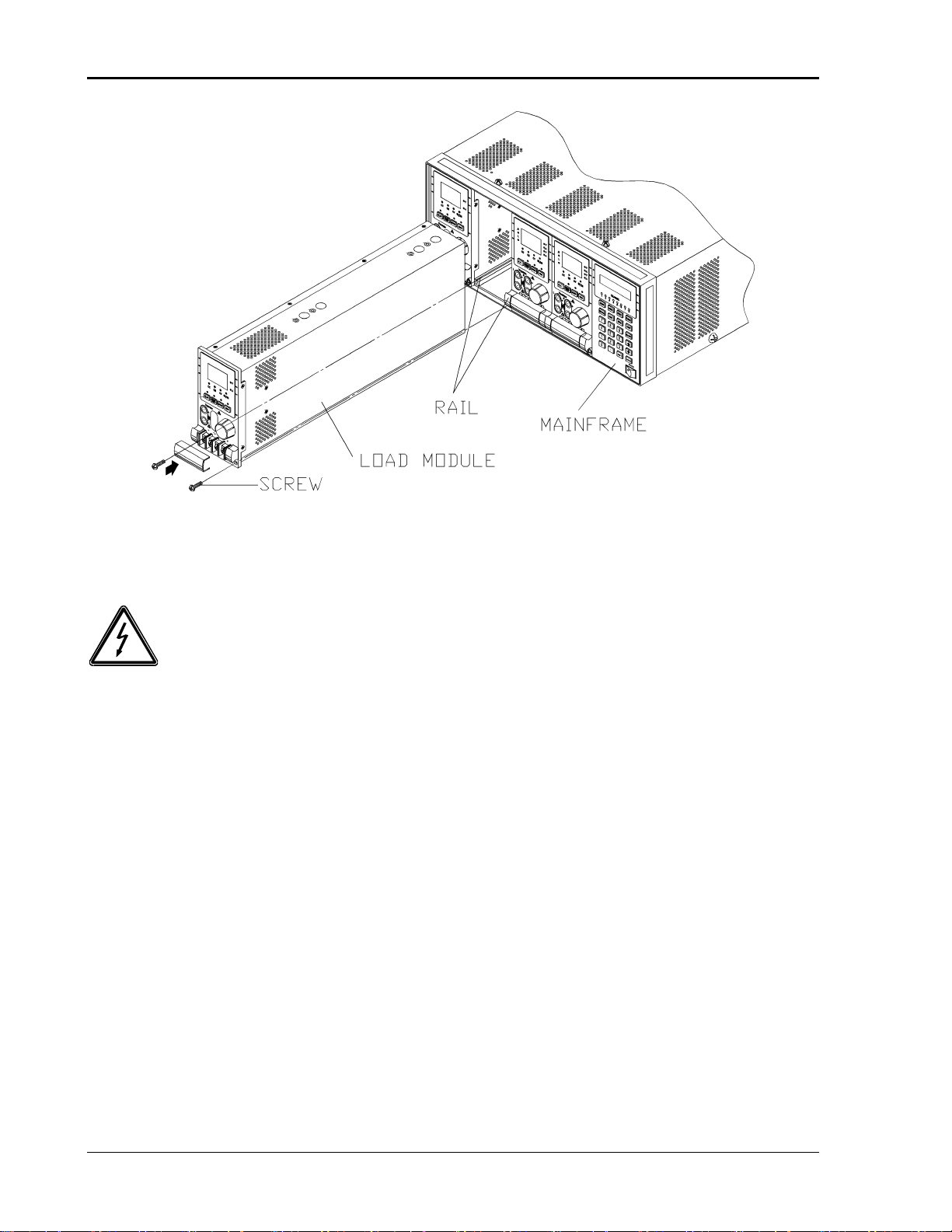

2.3 Installing the Modules

CAUTION!

Load module can be damaged by electronic discharge (static electricity).

Use standard anti-static work practices when you handle and install modules.

Avoid touching the connector and the circuit board.

The Sorensen MML-4 Mainframe can accommodate four single-width Loads

(MML-80-20-102, MML-80-60-301), or two double-width Loads (MML-80-120-601).

Loads can be combined in the Mainframe in any order. The Sorensen MML-2

mainframe can accommodate two single-width Loads or one double-width Load.

Module installation procedures in both Mainframes are the same. Installing Loads to

the Mainframe requires only a screwdriver.

Procedures

1. Disconnect the power cord with the Mainframe power off.

2. Remove any packing materials from the Mainframe.

3. Start installing the modules in the slot (see Figure 2-1).

4. Plug the load module into the slot of the Mainframe along the rail.

5. Lock the module in place by use of the screwdriver (see Figure 2-1).

6. Install each additional module in the slot next to the previous one.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Sorensen MML Series Operation and Programming Manual

2-2

Figure 2-1 Installing Modules in the Electronic Load

WARNING!

If the Mainframe is not installed with all modules, the empty module position

must be installed with the panel cover (Sorensen part no. 5361527-06) for safety

and airflow.

2.3.1 Channel Number

The channel number of a specific Load is determined by the location of that module in

relation to the farthest left side of Mainframe. Because some Load (MML-80-20-102)

has two channels in one module, channel 1 and 2 are always on the farthest left slot of

the Mainframe, and channel 7 and 8 on the farthest right. The channel number is fixed

for Mainframe even Load module is empty. Figure 2-2 shows the channel

assignments for a Sorensen MML-4 Mainframe containing two Loads of

MML-80-60-301 single channel/module, and two Loads of MML-80-20-102 double

channel/module. Channel number is automatically assigned to each channel: 1, 3, 5,

6, 7, 8. At this moment, channels 2 and 4 are empty. MML-2 Mainframe has only

four channels (1, 2, 3, 4).

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Installation

2-3

Figure 2-2 Channel Number Example

2.4 Installing the Mainframe

The electronic Load operates properly within a temperature range of 0 to 40º C.

However, you must install the electronic Load in a location that has enough space at

the top, four sides, and the rear of the unit for adequate airflow. Leave at least 3 cm

(1 inch) above the unit for adequate air circulation. Note that the feet of the unit

provide vertical space for air circulation when it is stacked. The feet of the Mainframe

can be removed for rack mounting.

If you install equipment above the electronic Load in the cabinet, you must use a filter

panel above the unit to ensure adequate air circulation. A 1U (EIA standard) panel is

sufficient.

2.4.1 Changing Line Voltage

The electronic Load can operate with a 115/230 Vac input as indicated on the rear LINE

label. The 100/200 line voltage input model is used only in Japan. If the factory set

switch on this label does not correspond to your nominal line voltage, turn the

Mainframe power off, and disconnect the power cord. Set switch to the correct line

voltage as shown in Figure 2-3.

NOTE: Line fuses do not need to be changed when the line voltage is changed. The

line fuses will protect the electronic Load in any indicated voltage setting.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

6

Table of contents

Popular Industrial Electrical manuals by other brands

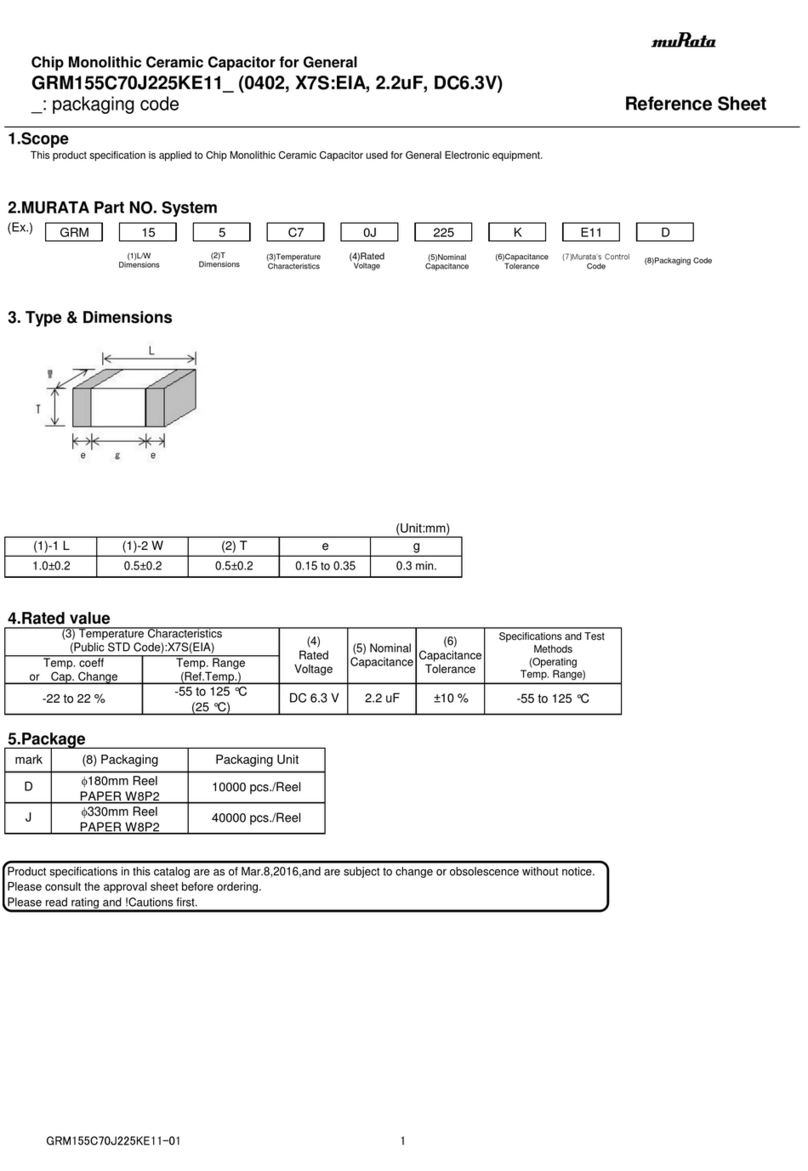

Murata

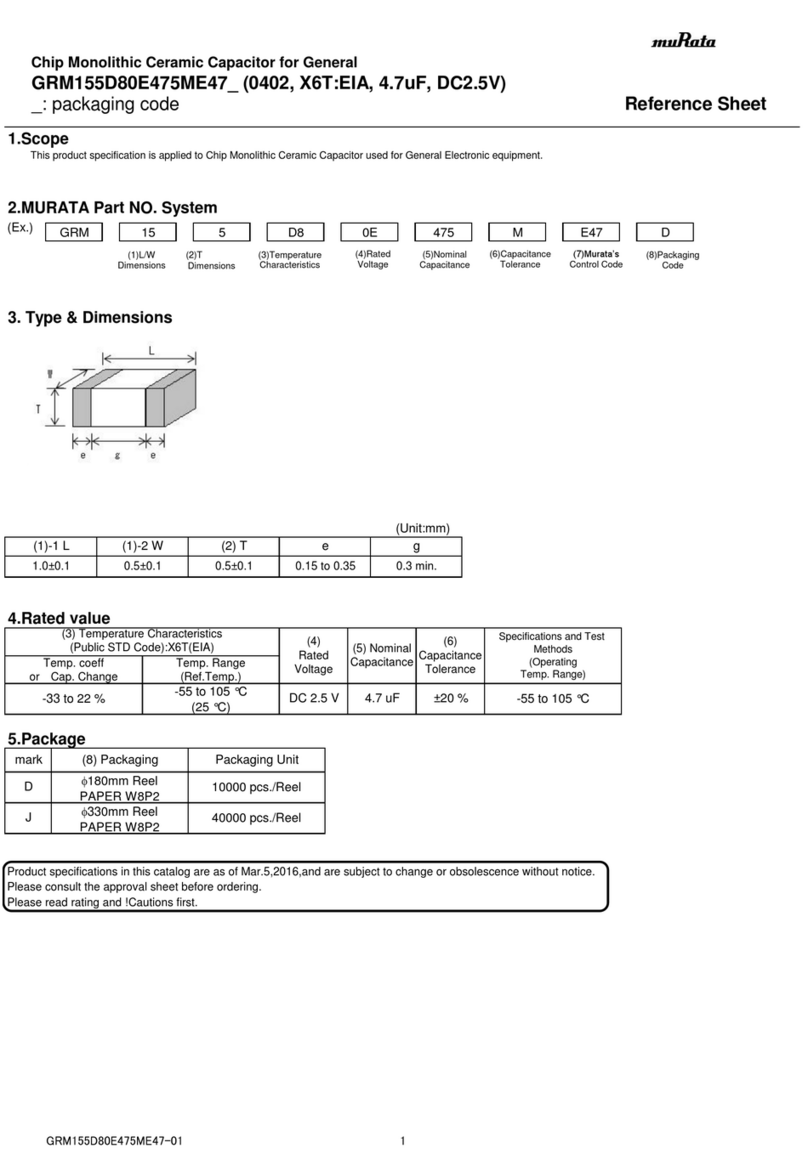

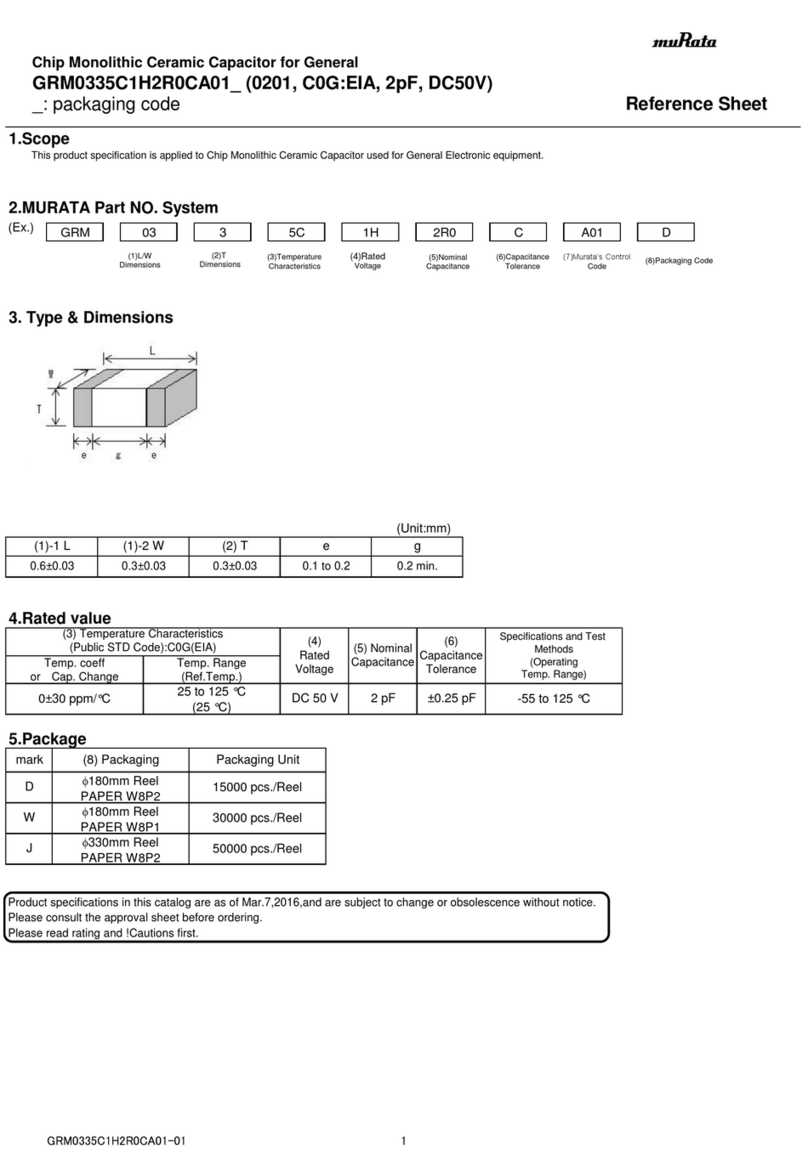

Murata GRM155C70J225KE11 Series Reference sheet

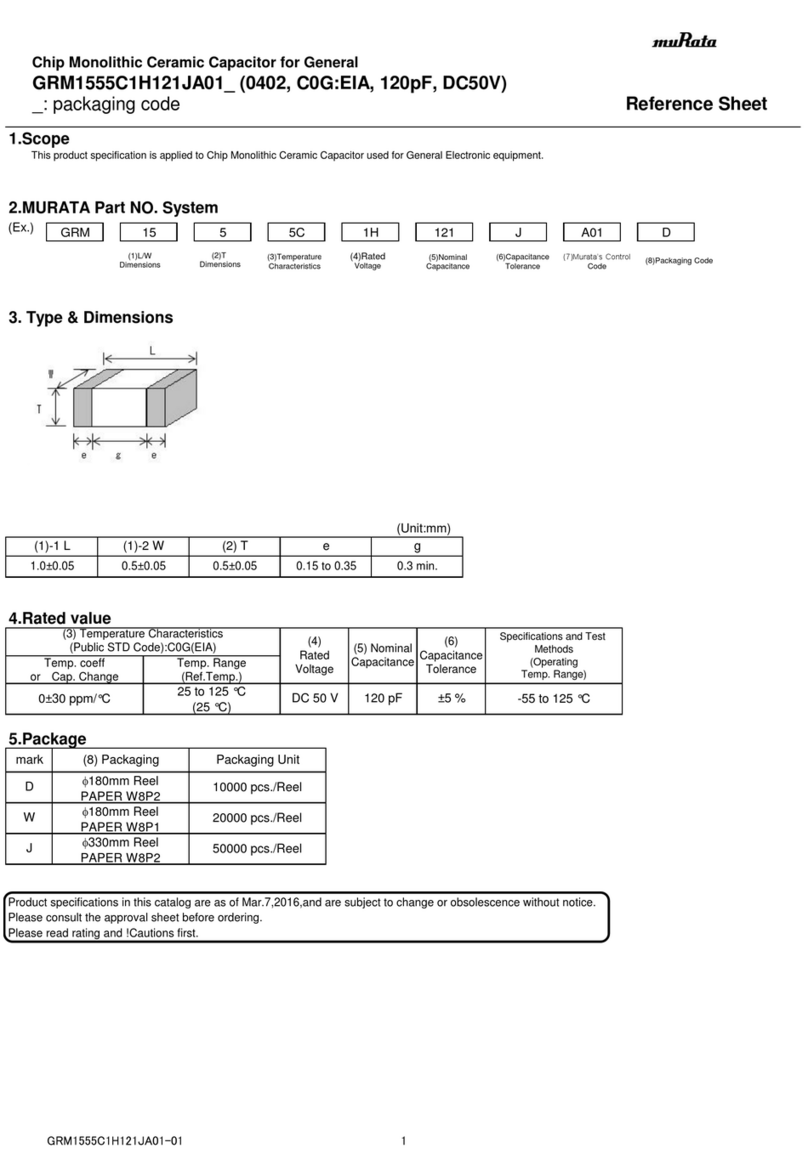

Murata

Murata GRM1555C1H121JA01 Series Reference sheet

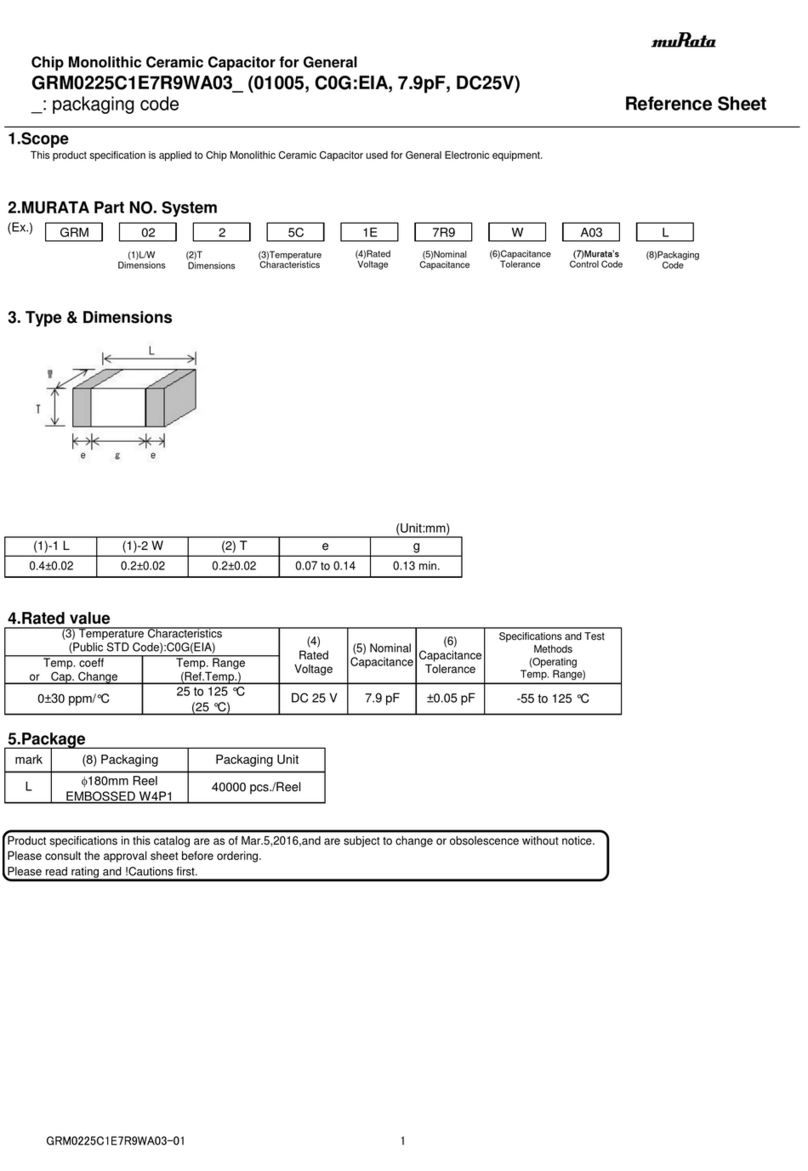

Murata

Murata GRM0225C1E7R9WA03 Series Reference sheet

Siemens

Siemens 3TF68 Q Series operating instructions

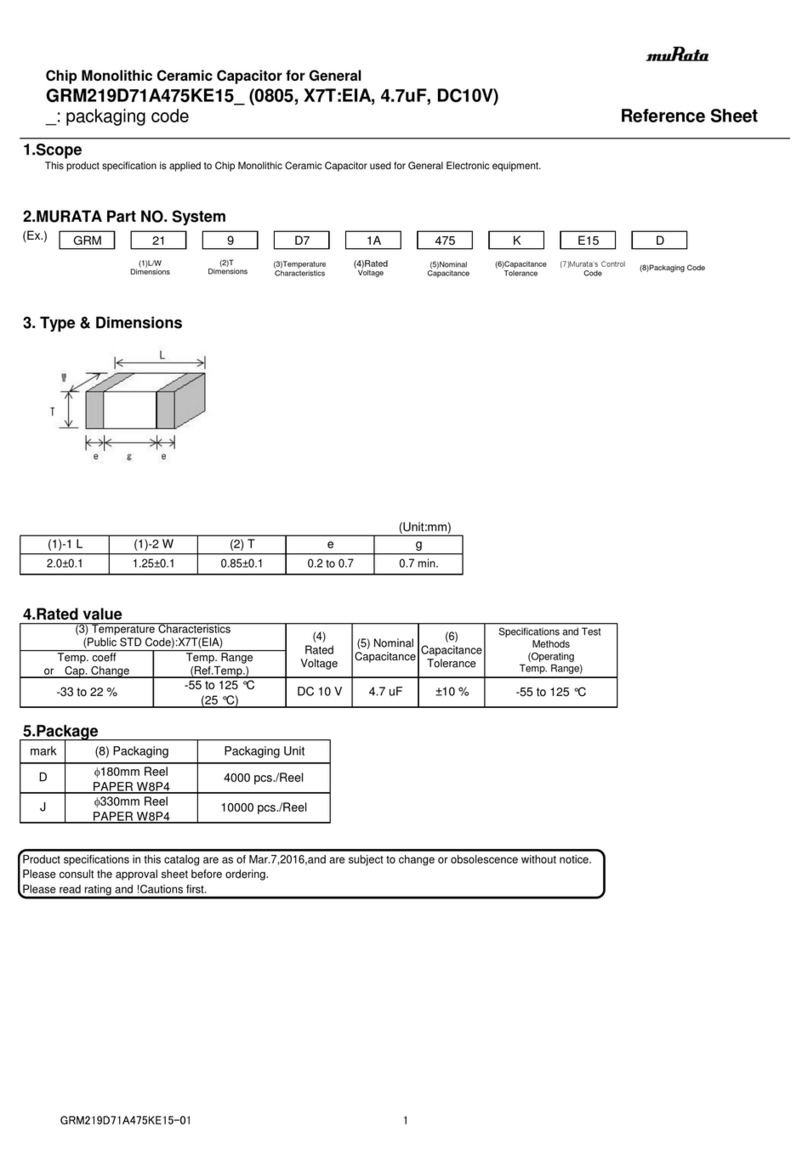

Murata

Murata GRM219D71A475KE15 Series Reference sheet

Murata

Murata GRT31CR60J156KE01 Series Reference sheet

Murata

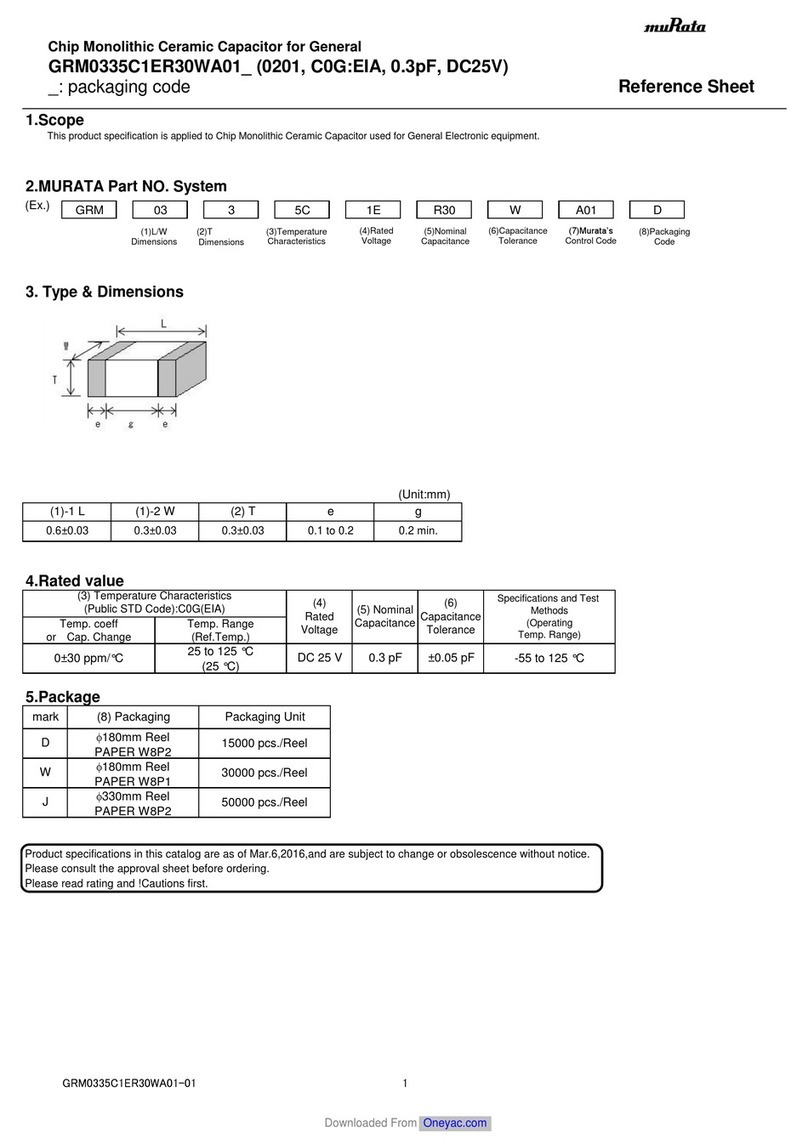

Murata GRM0335C1ER30WA01 Series Reference sheet

Murata

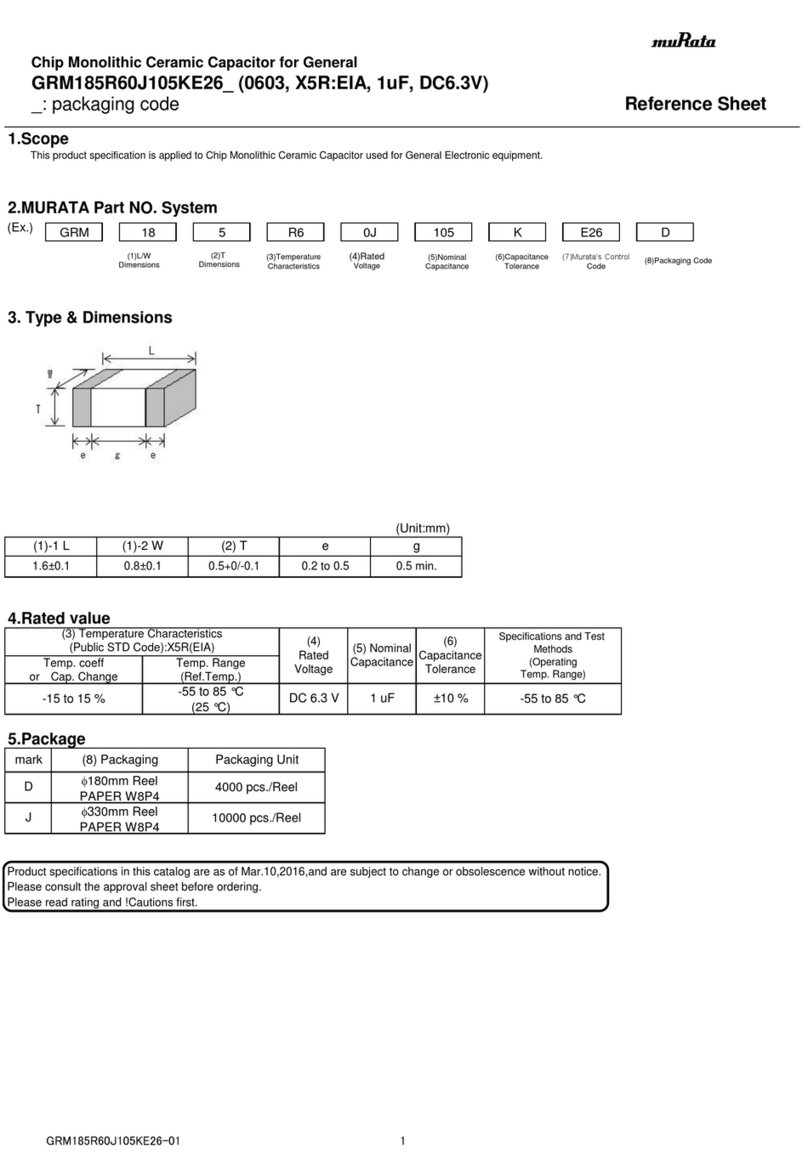

Murata GRM185R60J105KE26 Series Reference sheet

Multi-Mover

Multi-Mover XL35 User manual and parts list

OEZ

OEZ CS-BL-A015 Instructions for use

Murata

Murata GQM2195C2E1R8WB12 Series Reference sheet

Murata

Murata GRM31CR60J476ME19 Series Reference sheet