Southbend Wheel Horse 604 Troubleshooting guide

•

•

•

•

•

•

•

,.

..

f$

..

..

:

:

..

•

:

OPERATION AND I

SERVICE

MANUAL

WITH PARTS LIST

•

•

•

•

•

•

:

•

•

•

•

•

•

•

models

604, 654, 704

WHEEL-HORSE

PRODUCTS,

INC.

:

SOUTH

BEND,

IND.

•

•

•

•

•

•

THINGS YOU SHOULD KNOW

The

transmission

is

powered

on

needle

bearings

and

roller

bearings.

The

reduction

is

108

to

1I

and

both

final

drives

are

steel

forgings.

All

shafts

are

turned,

ground,

hardened,

and

polished

for

greater

strength

and

best

oil

sealing.

Speeds

are

from

1

mph

to

6

mph

with

3

speeds

forward

and

1

reverse.

WARRANTY

We

warrant

WHEEL

HORSE

PRODUCTS

for

ONE

YEAR

from

date

of

purchase

against

defective

parts

and

workmanship.

We

will

replace,

free

of

charge,

any

defective

part

if

returned

to

the

factory

PREPAID*.

Wheel

Horse

Products, Inc.,

reserves

the

right

to

make

changes

or

improvements

upon

its

products

without

imposing

any

obligations

upon

itself

to

install

the

same

upon

its

products

that

have

been

previously

manufactured.

The

engine

and

battery

carry

a.

separate

warranty

by

the

manufacturer.

FOR

ENGINE

OR

BATTERY

SERVICE, CONTACT

YOUR

LOCAL

ENGINE OR

BATTERY

SERVICE

HEADQUARTERS.

*All

warranty

claims~

work,

shipments,

must

be

handled

through

your

authorized

Wheel

Horse

deol"r.

NOTE:

90

Day

Warranly

for

Commercia'

Use.

BEFORE

YOU

START

There

is

NO

OIL

in

the

crankcase

of

the

engine

when

shipped

from

the

factory.

Read

Engine

Man-

ual

and

follow

all

instructions

pertaining

to

type

of

lubrication

specified.

The

engine

is

the

heart

of

your

tractor

and

it is

very

important

that

you

keep

it in

good

condition.

lubricate

all

grease

fittings

with

a

regular

pres··

sure

gun

lubricant

every

eight

to

ten

hours

of

operation.

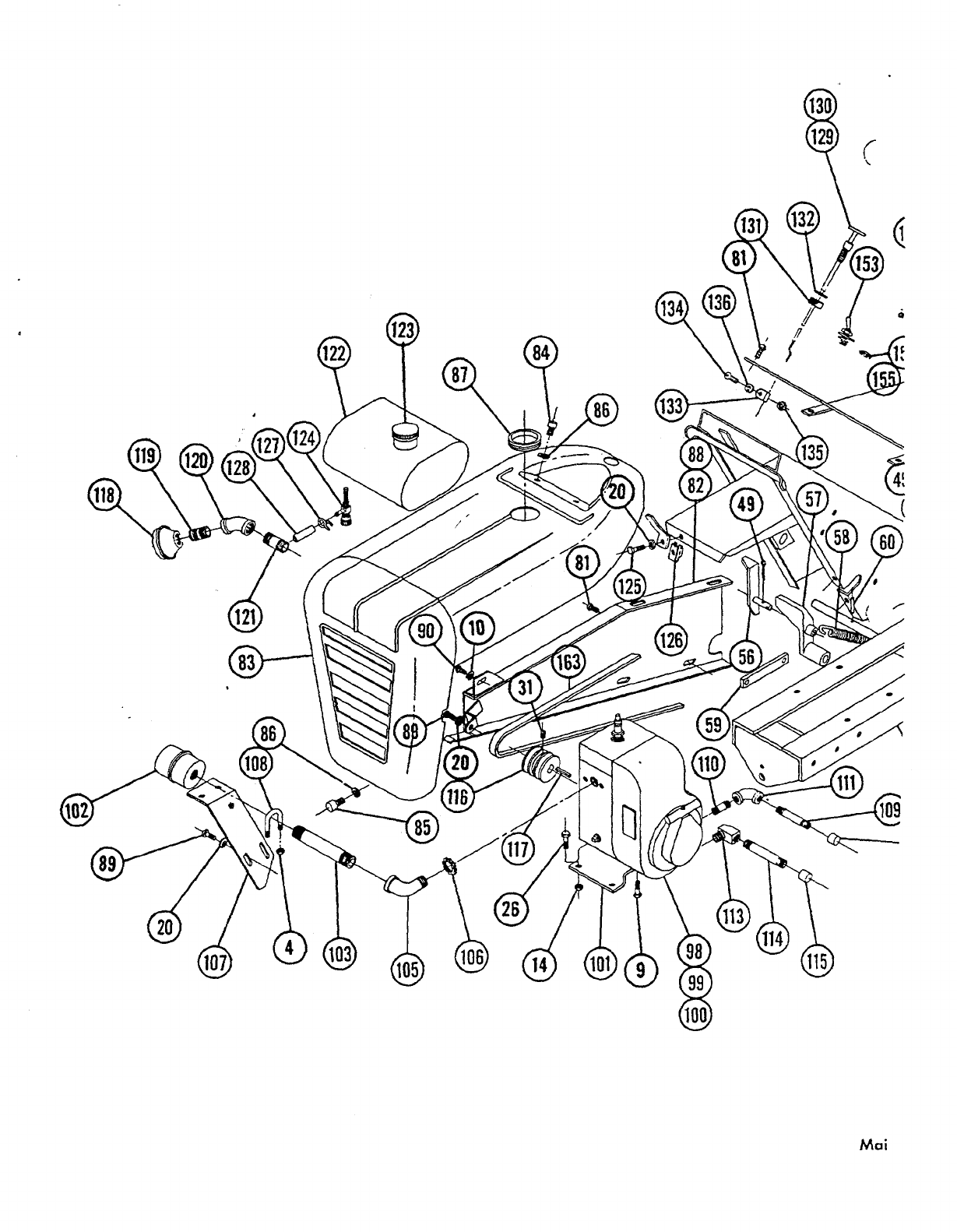

Refer

to

Figure

1

for

the

location

of

grease

fittings.

A

light

machine

oil

should

be

used

on

all

moving

parts

to

keep

joints

from

wearing

and

squeaking.

Remove

oil filler

plug,

located

at

the

left

rear

side

of

the

transmission,

and

fill

to

level

of

hole

with

a

good

grade

of

S.A.E.

40

Gear

Lube (will

require

about

3

pints).

The

transmission

should

be

checked

after

every

40

hours

of

use.

The

transmission

should

be

drain-

ed

once

a

year

by

removing

plug

on

bottom

to

drain

oil. Refill

as

above

paragraph.

This is a

regular

automotive

type

transmission

with

sliding

gears

and

should

have

the

same

care

as

your

car.

BATTERY

The

battery

installed

in

the

654

tractor

is a

dry

charged

battery.

It

is

important

that

you

properly

prepare

this

battery

to

insure

good

service

and

long

life.

1. Remove

vent

caps"

Remove

or

destroy

any

seal·

ing

device

which

may

have

been

used

to close

or

restrict

the

vent

openings.

2. Fill

each

cell

of

the

battery

to

the

proper

level

with

the

battery

electrolyte.

NOTE.

Temperature

of

battery

and

electrolyte

at

time

of

filling

should

be

above

60°F.

Never

fill

bat.

tery

in

the

vehicle

..

3.

BOOST CHARGE:

15

amps.

for

10

minutes

or

"1

amps.

for

30

minutes.

Adjust

electrolyte level, if

necessary,

after

charge.

4.

Install

battery

with

battery

posts

toward

the

rear

of

tractor.

Start

motor.

Check

to

see

if

generator

is

charging

properly.

After

battery

has

been

in ser-

vice,

add

only

approved

wafer.

DO NOT ADD ACID.

TIRES

The

front

tires

are

4:00 x 8

and

should

be

in-

flated

to

20

pounds

of

air

pressure.

The

rear

tires

are

6:00

x

12

and

should

have

6

to

8

pounds

of

air

pressure.

The

tires

can

also

be

filled

with

bal-

last

if

desired.

Ordinarily

this is

nat

necessary

as

the

weight

of

the

operator

will

add

sufficient

weight

for

adequate

traction.

STARTING ENGINE

L Before

starting

the

engine

fill

gas

tank

with

a

good

grade

of

regular

gas

and

open

valve

on

sediment

bowl.

2.

Place

gear

shift

lever

in

neutral

position.

3.

Pull

throttle

lever·

X

way

out

and

turn

to

the

right

to

lock it in position.

Note:

The Throttle

can·

trol

has

a locking

device.

Turn

the

throttle

control

to

the

left

to unlock,

adjust

to

the

desired

position

and

turn

to

the

right

to

lock.

4.

Pull

choke

lever

ell

the

way

out

to

choke

en-

gine.

If

engine

is

warm

end

has

been

running,

choking

will

not

be

necessary.

S.

A.

Model

604

and

704

tractors

have

a recoil

starter

with

an

OFF

and

ON

switch.

To

start

push

switch

to

ON

position

and

pull recoil

starter.

B.

Model

654

tractor

has

an

OFF

and

ON key,

also

a

starter

button.

Turn

key

to

ON

position

and

push

starter

button.

6.

When

engine

starts

push

choke

in

to

off posi·,

tion

and

regulate

throttle

control

by

turning

to

the

left

to unlock

and

push

in

or

out

to

desired

speed

..

7.

Depress

clutch

pedal

on

left

side

of

tractor

before

selecting

desired

gear

range.

S.

When

starting

tractor

in

winter

it is

desirable

to

depress

clutch so

engine

does

not

have

to

turn

transmission

..

CLUTCHING

Don't force

the

gear

shift

lever

if

the

gears

do

not

immediately

mesh.

Depress

clutch

pedal

all

the

way

down

and

let

up,

then

depress

again

and

shift.,

To

avoid

sudden

storts,

release

clutch

pedal

slowly

..

While

in

motion

do

not

shift

gears

without

depressing

clutch

pedal.

The clutch

pedal

also

operates

the

brakes

WHEN

DEPRESSED

ALL

THE

WAY

DOWN. For this

reason,

you

should

depress

the

clutch

pedal

ONLY

% OF

THE

WAY DOWN WHEN SHIFTING

while

in motion

..

This

clutch-brake

pedal

combination

makes

clutch

..

ing

automatic

as

you

apply

the

brakes

to

stop.

PARKING

BRAKE

The

parking

brake

is

located

on

the

left

side

of

Ihe

tractor

as

shown

in

Figure 1. To

set

the

park.

ing

brake

depress

the

dutch·brake

pedal

as

for

as

possible

and

push

the

parking

brake

forward.

To

release

the

brake

depress

the

clutch··brake

pedal

and

pull Ihe

parking

brake

back..

ATTACHING TOOLS

Complete

information

on

the

assembly,

attach-

ment,

operation

and

service

of

the

many

attach

ing

tools will

be

provided

with

each

attachment.

All

drawn

implements

attach

in

seconds.

Simply

lift

the

tractor

hitch

pin,

insert

the

tongue,

and

re-

place

pin.

All

power

implements

will

use

the

attachment

clutch

pedal

located

on

the

right

side'

of

the

tractor.

CARE

OF

TRACTOR

1.

Keep

tractor

greased

and

oiled

regularly.

Re-

fer

to

Figure

1

for

the

location

of

grease

fittings.

Check

transmission

and

engine

case

oil levels.

2.

Keep

engine

air

cleaner

clean.

This will

add

to

engine

life.

3.

Keep

tires

properly

inflated.

See

previous

in-

structions.

4.

Keep

tractor

covered

and

in a

dry

place

when

not

in

use.

S.

Keep

grass

and

dirt

out

of

engine

cowling

as

these

will

stop

the

flaw

of

air

and

decrease

en-

gine

life.

6.

BRAKE

ADJUSTMENT.

The

brake

band,

lo-

cated

on

the

left

side

of

the

transmission,

brakes

the

transmission

and

in

turn

stops

the

wheels.

To

adjust

first

set

the

parking

brake

then

adjust

the

nut

on

the

brake

rod

until

it locks

the

rear

wh

...

els.

Disengage

parking

brake,

remove

cotter

SP~CH!CAT}ONS

(Specifications

subiect

to

change

without

notice.'

length

overall

.•.....•..........•....

60

inches

Wheelbase

.........................

41~

inches

Width

at

rear

wheels

...................

30

inches

Width

at

front

wheels

...

.

.............

31

%l

inches

Height

................................

37

inches

Height

to

top

of

hood

....................

32

inches

Approx.

weight:

(604)

345

Ibs

..

-

(654)

440

Ibs. -(704)

395

Ibs.

Crop

clearance

..........................

7~~

inches

Frame

clearance

......................

13Yi

inches

Engine

(4·cycle.

single

cylinder.

air

cooled) 6

or

7

hp.

Fuel

capacity...

.

..

. . .

..

.....

4

quarts

Tires (fronl)

...

4:00

x

8"

pneumatic

(16"

wheel

dio.)

Tires

(rear)

Cleat-Iype

or

All

Purpose

tread

6:00

x

12"

pneumatic

(22"

wheel

dia.)

Speeds:

3

forward

to

6

mph.;

1

reverse

to

2~~

mph

Turing

radius

(to

outside

of

outside

wheel)

.

61~'

pin

from

dutch

rod

at

clutch

brake

pedal

and

by

turning

in

or

out

adjust

dutch

broke

pedal

to

operators

desired

position.

7.

When

replacing

belts

or

mounting

drive

im·

plements

make

sure

all

pulleys

are

in

line.

8.

On

the

654

tractor

Which

has

a

battery,

check

liquid

after

every

40

hours

of

use.

If

tractor

has-

been

in

storage

it

may

be

necessary

to

recharge.

9.

Your

tractor

is

only

as

good

as

the

service

you

give

it.

See

your

Wheel

Horse

Dealer

for

a

through

check-up

after

each

season

of

use.

10.

When

replacing

belts

be

sure

to

purchase

them

from

your

Wheel

Horse

Dealer,

as

these

belts

are

specifically

designed

for

each

application.

(NOTE:

Make

sure

all

pulleys

are

in line.)

FOR YOUR

SAFETY

A. Keep

all

guards

on

at

all

times.

B.

Never

abuse

your

tractor

by

improper

handling.

C. Keep

hands

and

feet

from

moving

parts.

D.

Remove

key

when

not

in

use.

E.

8e

careful

on

high

uneven

ground.

=(;.)~s

r--'-

~

:,!~;

;;/

Wiring for

654

-:

.....

T.-

'J_

,r"''-'H

~

~."".l(H

Mai

e Ass/y.

Ref.

No

..

2

3

"

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

71

22

23

2~

2.5

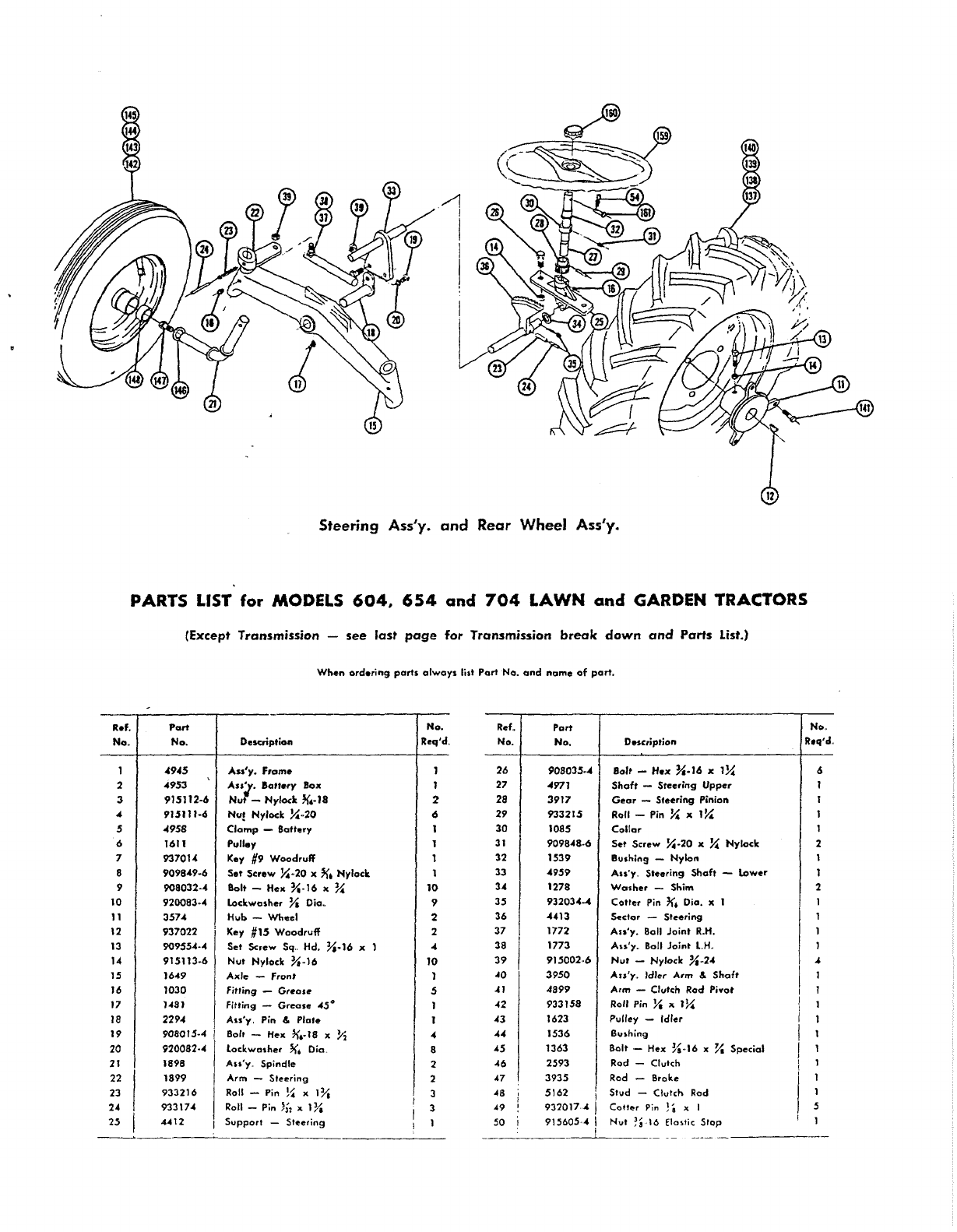

Steering

Ass'y.

and

Rear

Wheel

Ass'y.

PARTS LIST

for

MODELS

604,

654

and

704

LAWN

and GARDEN TRACTORS

(Except

Transmission

-

see

last

page

for

Transmission

break

down

and

Parts

List.)

When

ord.ring

paris

always

li,t

Pari

No.

and

name

of

part.

----~------~----------------------.---

Part

No.

4945

4953

915112·6

915111.6

4958

1611

93701"

909849·6

908032·"

920083,,4

3574

937027

909554·4

915113·6

1649

1030

H8)

22114

908015·4

920082·4

1898

1899

933216

933174

4~12

Description

Ass'y.

Frame

A

..

'.1.

!oll.ry

Box

Nur

-

Nylod:

,<,.18

Nu! Nylock X:,,20

Clamp

-Battery

PuU.y

Key

#9

Woodruff

S.t

Screw

x:

,,20 X

~.

Nylock

Bolt -

Hex

X·16

"

~

lockwosher

Ya

Oio"

Hub

-

Wheel

Key

#15

Woodruff

Set

Screw

Sq

..

Hd. Ya.16 "

Nut

Nylock

X·,16

A"I"

-Front

Fitting -

Grea.e

Fitting -

Grease

4,s°

Au'y,

Pin &

Plale

Bolt -

H""

k'

•.

18 x

Y,

lock

washer

k'.

Dia.

Au'y

..

Spindle

Arm

-

Steering

Roll -Pin

!~

"

IYa

Roll

-Pin

)32

" lYa

Support

-

Steering

No.

Req'd.

I

Z

6

10

9

2

2

01

10

I

S

4

8

2

2

3

Ref..

No.

26

27

28

29

30

31

32

33

34

35

36

37

38

39

~O

~I

~2

43

44

"S

016

~7

48

49

50

Part

No.

908035,,4

4971

3917

933215

1085

909848·6

1539

4959

1278

932034"'"

""13

1772

1773

915002

..

6

3950

4899

933158

1623

1536

1363

2593

Bolt -

Hex

M·Il>

" IX:

Shaft

-

Steering

Upper

Gear -Sfeering Pinion

Roll -Pin

x:

"

1l{

Collar

Set

Screw

V.

.20

"

x:

Nylock

Bushing -Nylon

Au'y.. Steering

Shaft

-

lower

Wa.her

-Shim

Cotter

Pin

'<.

Die. " 1

Sector -

Steering

Au'y.

8011

Joint

R.H.

Au'y

..

8011

Joint

l.H

..

Nut

-Nylock

Ya,,24

Au'y

..

Idl~r

Arm &

Shafl

Arm -CIvIc" Rod Pivot

Roll Pin

Yt

" IV.

Pulley -Idler

B<uhing

Bolt

.-

Hex

K,16

x

Va

Special

Rod -Clulch

3935

Rod -Broke

5162

I

Stud

-Clutch Rod

932017.'"

Cotler

Pin

).

" I

9156054

I

Nul;~

·16 Ela,'ic

Stop

______

.-L

__

._

._

No.,

Req'd.

6

1

2

2

"

I

1

R.f.

No.

51

52

53

54

55

56

57

58

,

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

7.4

7.5

76

77

78

79

80

81

82

83

a.4

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

10.4

105

106

107

108

109

110

PARTS LIST for MODELS

604,

654

and

704

LAWN

and GARDEN TRACTORS

(Except Transmission -

see

last

page

for

Transmission

break

down

and

Parts

list.)

Port

No.

1129

4417

2267

5-52.3

4421

.4246

4239

1014

3933

933188

2266

4438

4439

933168

3624

3578

3680

1000

5-52

..

6

2274

2179

2196

3931

932120-.4

3926

3988

5-50·75

3537

908034··4

4892

1385

4993

4975

1345

1346

920081·4

2767

4962

1432

909082··4

4419

3973

900113.4

915115·6

4972

4973

4895

4980

4981

5150

4416

1739

1754

4985

1755

1756

2297

1240

4943

4218

Wh.n

ord

...

ing

part.

olways

lill

ParI

Ho.

and

name

of

part.

D.scription

Spring

-Clulch

Ass'y.

l....

"r

& Knob -Brake

Pedal

-Clutch

Hairpin -

Cott.r

Fool,..,

Ass'y.

Trip l.....r (654.704)

P.dol

-

Altach

..

Clutch (654.704)

Spring

(654

..

704)

link

(654.704)

Roll Pin

K,

" I (654.704)

Au'y.

Lift

Le

....r

Plunger

Rod

Roll' Pin

~

x lK.

Spring

Guid.

-Rod

Cop

Grip

-

Handle

Hairpin

-

Colter

Quadranl

Rod -

Height

Conlrol

Knob

-Height

Control

Au'y..

Coble

.-

Lift

.

Clevi.

!{

Dia.

Hitch

Pin -Hitch

Shaft

Snap

Ring ~

Shoft

Spring

-

Sea'

IIQlt

-

Hu

K·16

x

A

..

'y

..

Tool

So><

Screw

'-

SemI

!{:.20 "

V,

Ass'y.

S.1t

Guard

(704)

A

..

'y.

Hood -

Complete

Thumb

-

Screw

K·20

)(

Y.

Thumb

-Screw X

.20

x

~

lockwa.her

Y.

Dio.

Grommet

2Y, 1.0.

Al:'y

..

Belt

Guord

(604.654)

Screw

-

Rd..

Hd.

~

...

24

" Y,

Screw

Rd. Hd

..

%

..

16 x

Y,

Shield

Sea,

Bolf -

Carriage

~~

..

13

x IV.

Nut

-Nylcck

Y,

..

ll

fender

R

..

H

..

fender

l

..

H

..

Ass'y.

Cover

Ass'y.. Engine - 6 H

P..

(604)

A

..

'y

..

Engine

-.

6 H

.P..

(654)

Ass'y.

Engine - 7 H

P.

(704)

8ase

.-

Engine (604·654)

Mume'

(604·654)

Nipple

~

Pipe x

5!1

(604-654)

D..cal -

In.trument

Panel

No.

Req'd.

4

2

1

2

1

2

2

1

2

18

1

2

3

1

3

Elbow

~

Pipe

x

90'

Street

EI

(60

....

654)

1

Nul

lock

~

Pipe (604.654) 1

Brace

-Exhaust (604

..

654)

"U"

Bolt

(604.654)

Nipple

-

~~

Pipe ,. 4 (60,(

..

654)

Nipple

-

y.

Pipe

x 1

!.~

(604·654)

Ref.

No.

III

112

113

114

115

116

117

118

119

l20

121

122

123

124

125

126

127

128

129

130

131

132

133

134

13S

136

137

138

Il9

140

141

142

1-13

144

145

146

147

148

149

ISO

151

152

ISJ

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

Port

No.

4216

4217

5222

5223

5224

1621

13.49

17«

3947

3939

943366-·4

2676

5186

4941

908019·4

..

897

950141

..

4

1796

5171

5170

1364

920127

..

4

2879

909000

..

4

915562·'"

920078

..

4

1667

1700

1662

1654

1004

1709

1712

1656

1657

28«

908033

..

6

2816

4987

4882

.4881

3668

3279

4856

3757

3653

4979

908002

..

4

4983

2897

9329,(8

..

4-

1813

1576

5

..

56

..

6

3978

5147

4969

4970

4410

4984

D.scription

!lbGw -X Pip.

It

90°

(604-65-4)

Cop

X

Pi~

(604-654)

Elbow -

90°

Specio'

(704)

Nipple

~

Pipe

It

4 - Special (704)

Cap

-

Yo

Pi~

(704)

pun.y

-

Engine

I<ey

y.

It

X

It

l}~

Muffl.r

(704)

Nipple

I"

Cia

..

Pi~

(704)

Elbow

I"

It

45" (704)

Nippl.

I"

Pipe

It

2"

(704)

Ass'y. Fuel Tonic

Cap

-Fuel

Tonk

Valve

-

fuel

Shut

011'

& Filter

80lt

-

Hex

K.·18

It

1

Speed

Nut

~,.18

Clamp

K.

Oio

..

Corbin

(704)

fuel

Line (704)

Au'y..

Control

-Throttle

Au'y.

Control

-

Choke

Nut

-Round

X.·18

lockwasher

J{.

Dia

..

(Ext. Toolh)

Clip

(704)

IIQlt

-

Rd

..

Hd

..

#8.32

x

Y,

(704)

Nut

-Hex

#8.32

(704)

Lockwasher

#8

(704)

Au'y.

Wheel

Tire &

Tube

.-

Rea,

Wheel

Tire

Tube

lug

-

IIQlt

Au·y

..

Wheel,

Tire & Tube -Front

Wbeel

-

With

Two 1521 Bearings

Tire

Tube-

Washer

Bolt Nylock

~"'.16

It

Ya

Hubcap

A

..

·y

..

Switch -Ignition (654)

Nut

-Hex

~~.32

-Special (654)

Lockwa.he,

Yt

Dia

..

-Special (654)

Key -Ignition (654)

Au'y.

Switch

(604.704)

Plug Button _ . .500

Hal.

(654)

Plug Button -

..

625

Hole (604

..

704)

Battery

Wiring Harness

8alt

-Hex

!{.20

x

Yt

(654)

Steering

Wheel

In,eft

p;

.. -

CI".i,

Tool Pin

"V"

Belt

Wrench

Allen

!~

Hex

Cushion

(654.704)

Decol (704)

Oecol

(654,

Decal (6{)4)

Decal -

Wh~el

Horse Emblem

Oecol -

Hood

Ponel

2

2

2

2

2

2

2

2

2

2

6

2

2

2

2

2

2

2

2

1

2

.

R.f.

..

Part

No.

No.

1

3900

2

1533

3

3915

4

1532

S

1529

6 1508

7

1528

8

1232

9 1303

10

3503

11

3515

12

3516

13

933156

14

3517

15

3518

16

3573

17

3522

18

1518

19 3907

20

$-·50··75

21

3523

22

352-C

23

3526

24

3910

25

937014

26

3525

'17

1504

28

3128

29

3527

30

4204

31

1516

j

[

32

3909 I

Transmission

TRANSMISSION

PARTS

LIST

When

ord.ring

ports

alway.

li.t

Part

No.

and

nom.

of

port

•

No

..

R.f.

o..cription

Req'd.,

No.

COlO

• T

ransmiuion

1

33

IHc"ing

• Boll I

34

Pin

locating

2

35

Beo,ing

•

Needle

1

36

a.ct."ing •

Needle

2

37

Bea,ing

•

Needle

2

38

Bearing

•

Needl.

2

39

Seal·

Oil

3

40

Seal·

Oil

I 41

fork.

Shift

2

42

Roil

..

',ont

Shiff

1

43

Roil·

Rear

Shifl

I 44

Pin • Roll

y.

,.

1 2

45

BolI.Stop

2

46

Spring.

Stop

, ,(7

Shift

Pin.

Stop

1

48

Gear·

Input

O,i

••

1

49

Bearing.

Needle

I

50

Shaft·

Splino

I 51

Snap

Ring T

ruorc

~

Shaft

I

52

Gear

(Hi & Intor.) 1

53

Gear

(low

&

Reve"e)

1

54

Gear

•

Spline

Shaft

I

55

Clu.t",

•

Shaft

1 56

Koy

•

#9

Woodruff

2

57

G""r

..

Cluller

I

58

8u.shin9

..

8,on:e> I 2

59

Pinion

..

Cluster

Shaft

Reduclion

I 1

60

Gear.

Clu,'er

Shaft

Reduction 1

61

GeD'

..

Reve,ut

IdJ",. I I

62

Bushing

...

Bronte

I I

63

I

Pi"

..

Reverse

Idler

5 I

Part

No.

3903

3906

3905

3904

3908

933217

4235

1329

1316

3912

3901

1530

1531

943460

..

4

9.013420·.01

908038·4

908043·4

915113

..

6

4898

3514

933168

909854

..

4

915111

.....

3577

1001

3902

937022

5-50

..

100

«37

908002·4

noon·'

D.lcription

N

....

lIeq'd.

.-------f-.

Gear·

Brake

Shaft

1

Gea,

~

Bull 1

Cal

••

Diff.,.

nlial

2

A,,1e •

Rear

Gear.

Axl.

Pi"

• Roll ~

2

2

"I~

2

Gear

•

Diff.r.

ntial

Pinion 4

Cap

Screw.

H."

JJ',

-18

J(

3X

4

Nut·

H.,.

..

toe

kK

•.

II

4

Ga.ket

1

CQ,S.

rron.mi.

tion 1

Bearing·

N

••

dl.

I

!Haring.

N

...

d

~

1

Y.

S,d.

Pipe

Yo

Std.

Pip.

Bolt.

Hex • l

Plug

I

"ug

1

Yo

..

16

" 2 5

80lt

..

H.,,,

.)

Yo

• 16 " 3)1 1

Nut·

Nylock

Yo.

16 6

Slick.

Shift

Collar

..

Shift

1

1

,.

'~

I

Pin.

Roll

~2

Screw

• Soc., Hd

.•

Sel

Yo

•

20

"

~~

1

Nul.

Hu

Lac

k X .

20

1

800t

..

Shift

to

...

er

1

Knob.

Shift

Drum _

B,ak.

K.y

#1$

Woo

Snap

Ring 1 •

lIand

..

S.oko

Boh •

He-I(

!~

druff

Sho(t

20

)(

~~

Wo,hel"

..

lode

1

I

2

2

8·963

Form

No

..

163

..

164

..

165

This manual suits for next models

2

Table of contents

Popular Tractor manuals by other brands

Egimotors

Egimotors RZR XP CREW 1000 owner's manual

Jodale Perry Corporation

Jodale Perry Corporation Jacobsen HR9016 Mounting instructions

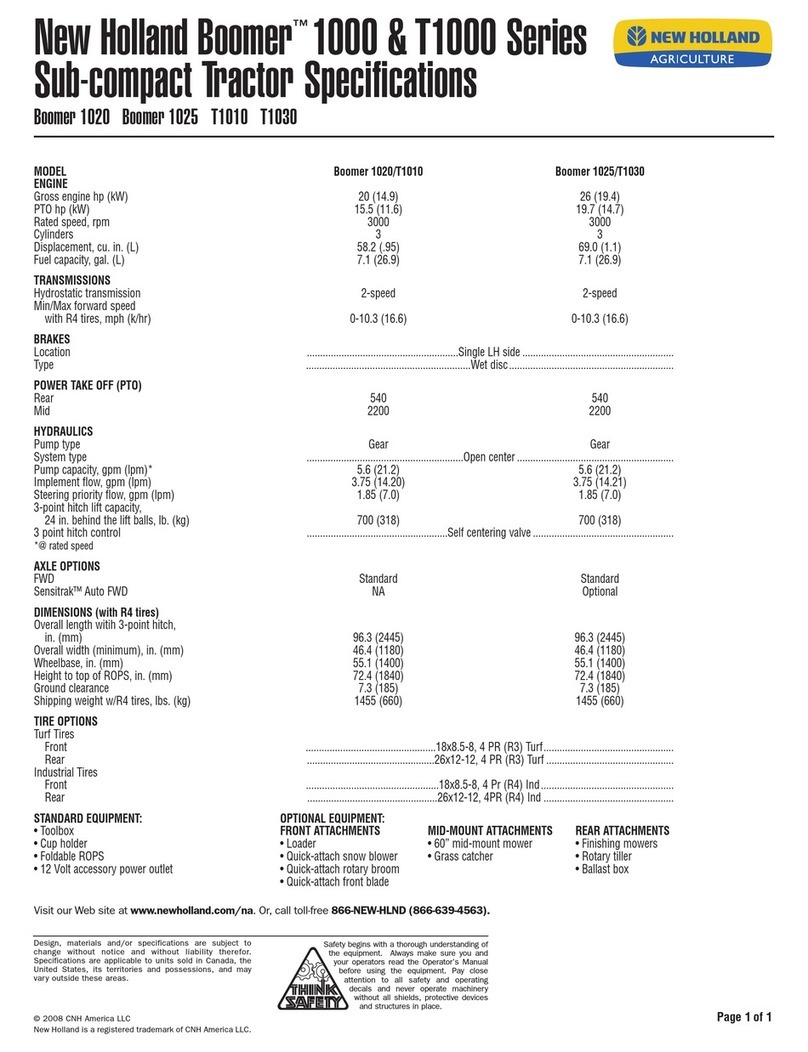

New Holland

New Holland Boomer 1020/T1010 Specifications

Ingersoll

Ingersoll 226 manual

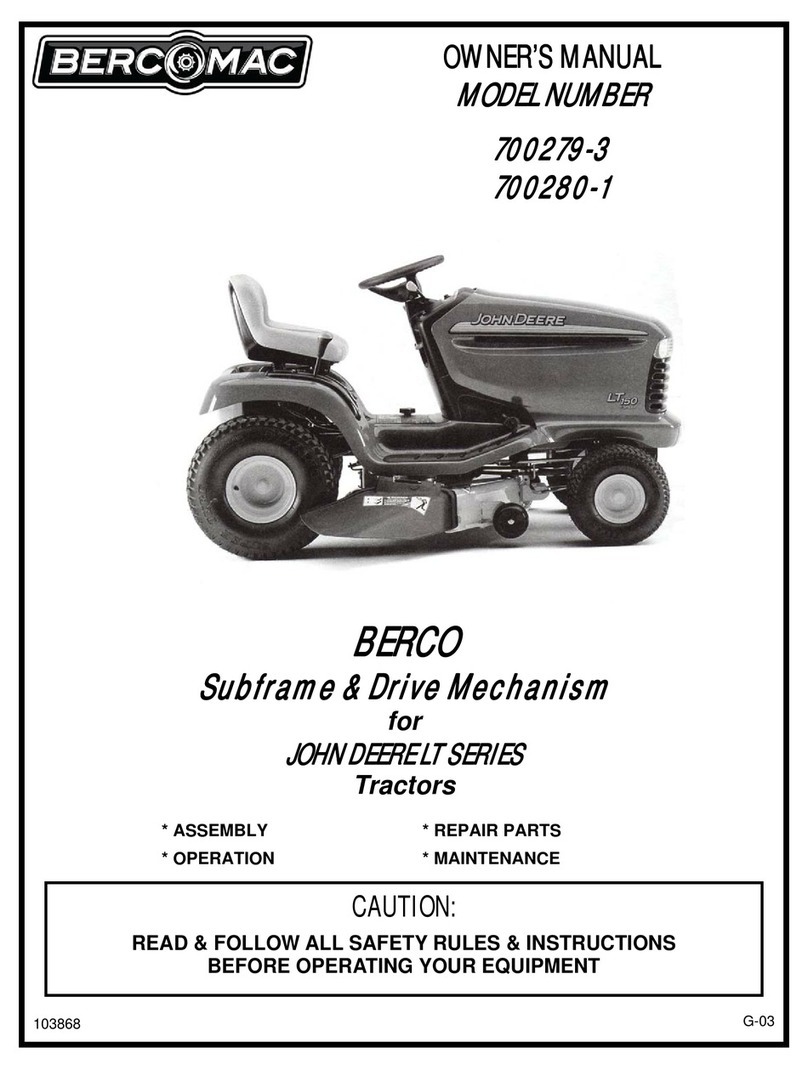

Bercomac

Bercomac 700279-3 owner's manual

Simplicity

Simplicity Sovereign 3416H owner's manual