Ingersoll 226 User manual

?it->

",/ 'i,,

vngersoil

ELECTRICAL SYSTEM

: MoDEL 226, 446, 449,646, 649

Service Manual No. 9-51721

i

QUALITY IN THE AIIER.ICAN TR,ADIT(XJ

Winneconne, Wisconsin 54986-9576

e

lngersoll Equipment Co., lnc.

Garden

Tractor

Talk

Digitally signed by Garden

Tractor Talk

DN: cn=Garden Tractor Talk,

o=GTtalk.com, ou,

c=US

Date: 2011.10.16 12:05:00

-04'00'

TABLE OF CONTENTS

SafetyMessages ........3

lntroduction .... ..4

TestEquipment... ......4

\Mring Diagrams .. .. ..$g

Troubleshooting Chart .. . ..10-12

BatteryCareand Maintenance .....13-16

BatteryCheckSheet. .....16

Starter Motor Repair .17-24

For Models 226, re,4r18,ffi .17-'tg

For Model646. .. .... ..20-24

FlywheelAlternator .....25

lgnition ......25-25

BreakerPointsService ....25

lgnitionTiming Procedure .......26

CoilService .......n

CondenserService .......21

Spark Plug ... . .. . .29

\,

Printed in U.S.A. -2- 9-91-RP-500-165

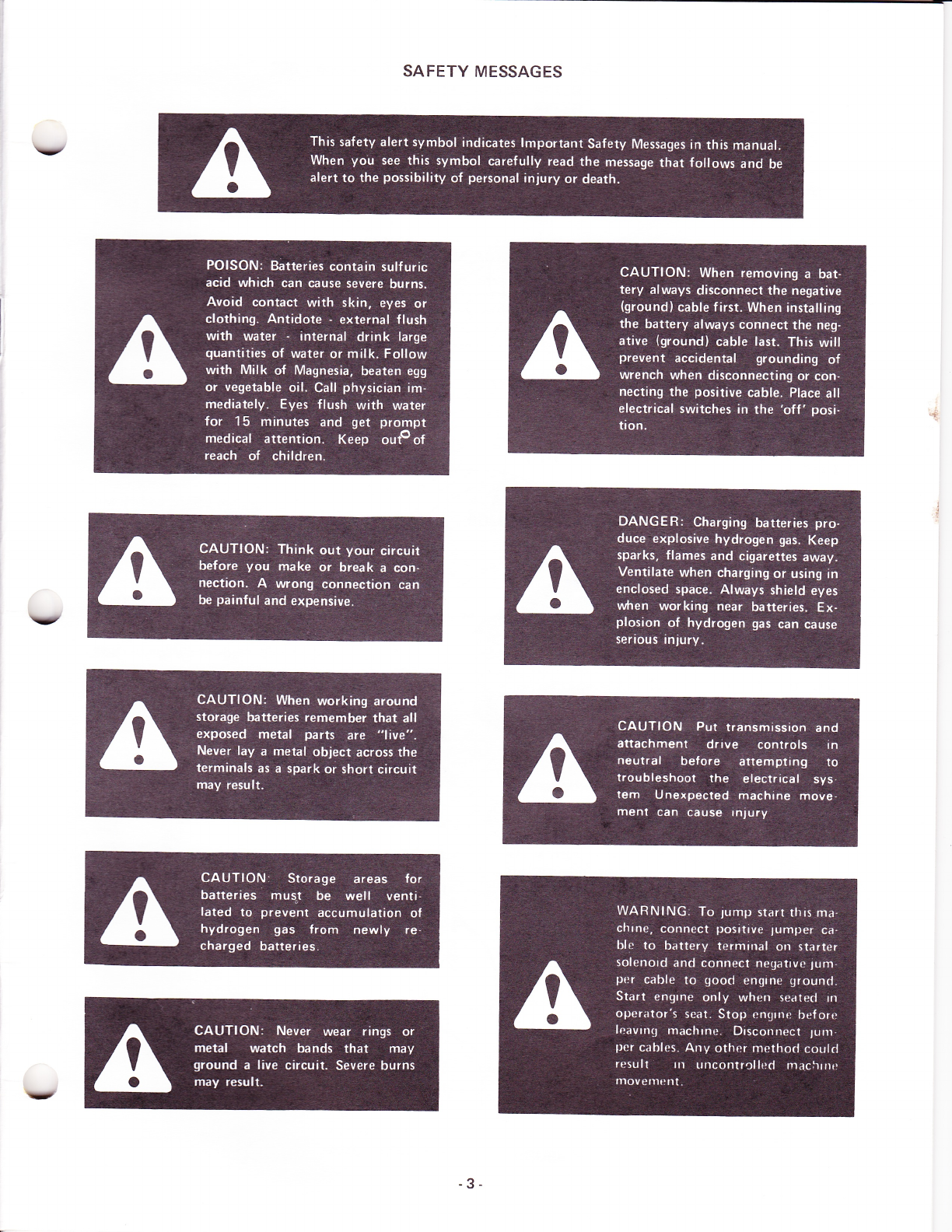

SAFETY MESSAGES

v

-3.

INTRODUCTION

This Service Manual Section applies to tractors and

loaders equipped with Onan engines.

TRACTOR MODEL

26... .......A11

446... ....ALL

uB ... ....ALL

646 .. . ... .ALL

648 . .. ....ALL

TEST EOUIPMENT

The following listing is the minimum suggested test equip-

ment needed to perform the troubleshooting steps out-

lined in this service manual section.

1. VOM Meter

A Volt-Ohm-Milliamp Meter with the following ranges:

Volts - AC - 0 to 30 - Used for measuring alterna-

Volts-DC-0to1-

tor - stator output.

Used for measuring voltage

drops in circuitry.

Volts - DC - 0 to 20 - Used for measuring battery

charging voltage.

Ohms - RXl00G Used for measuring higher

resistance values such as in

ignition coil secondary win-

dings.

Several suitable meters are:

Radio Shack Model22-202 and Model 2Z-2O3

LaFayette Model 99R50734 and Model g9R50841

2. An automotive type ampmeter such as, lngersoll

Part Number C18389, with leads and alligator clips.

3. Spark Tester. such as, Briggs and Stratton Part Number

1 9051.

4. Clip on ampmeter

5. Jumper leads 24" long, 14 gauge wire with alligator

clips.

6. 'l 2 Volt test light

7. Battery Hydrometer

8. DC Power Timing Light

mA-DC-0to3-

Ohms - Rxl -

Used f or measuring current

leakage.

Used for measuring low re-

sistance values such as sta-

tor windings, primary igni-

tion coil winding.

-4-

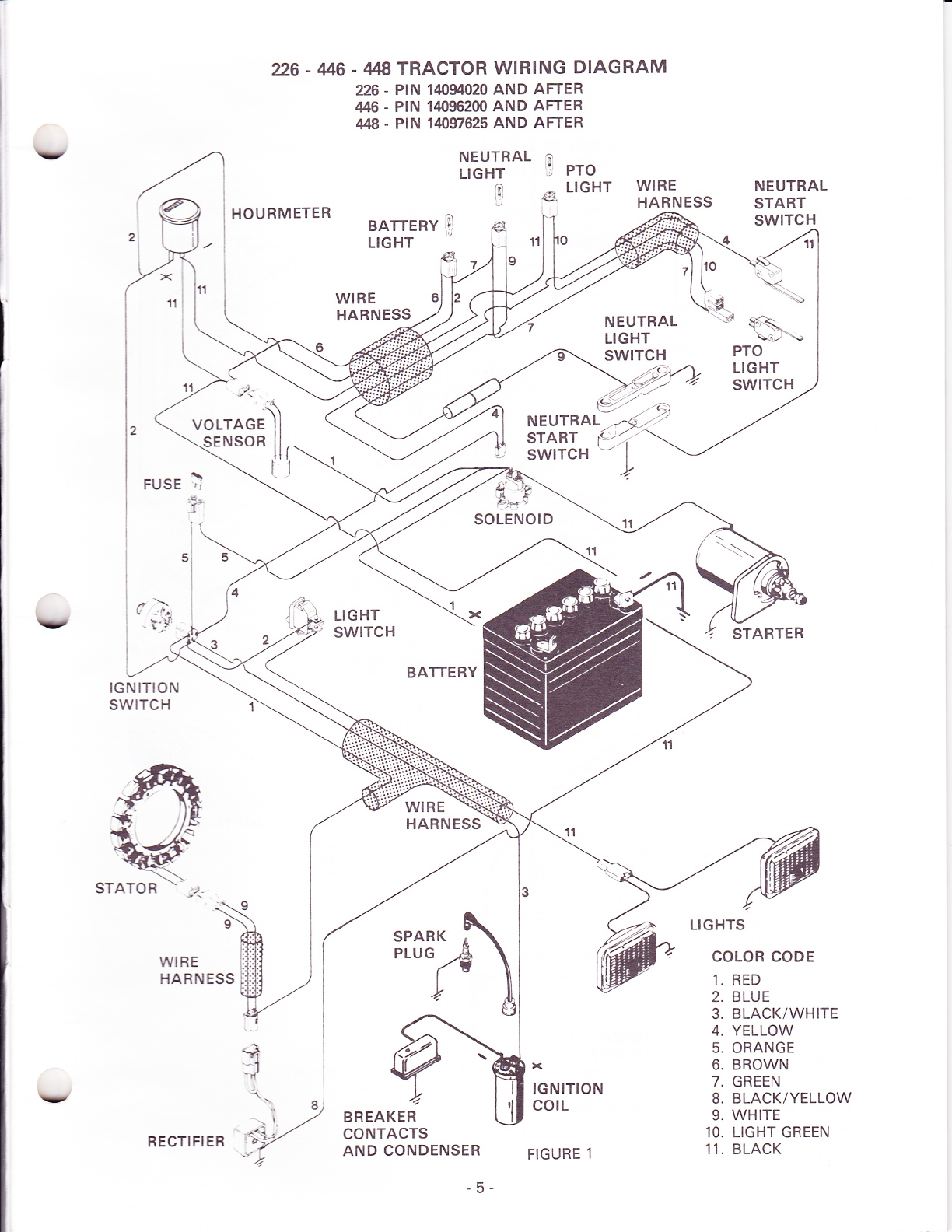

226 - M6 - 448 TRACTOR WIRING DIAGRAM

226 - PIN 140/94020 AND AFTER

446 . PIN 14096200 AND AFTER

448 - PIN 14f/97625 AND AFTER

v

\t

HOURMETER

NEUTRAL ?

LtcHT I Pro

0 s LIGHT

e,

i- 11

^la

14 .'E

,4. !

e*r

WIRE

HARNESS NEUTRAL

START

SWITCH

BAfiERY 9

LIGHT

WIRE

HARNESS s\

-sil2'-'\

FUSE

PTO

LIGHT

SWITCH

STARTER

LIGHTS

COLOR CODE

1. RED

2. BLUE

3. BLACK/WHITE

4. YELLOW

5. ORANGE

6. BROWN

7. GREEN

8. BLACK/YELLOW

9. WHITE

10. LIGHT GREEN

11. BLACK

SOLENOID

d>

- t'{'

IGNITION

SWITCH

I

WIRE

HARNESS

BATTERY

WIRE

HARNESS

BREAKER

CONTACTS

AND CONDENSER

r<

IGNITION

cotL

FIGURE 1

NEU'R^L2'2

START r('i'\

,: iviiiin 11

VY,

STATOR

Y

RECTIFIER

-5-

F

IGNITION SWITCH TERMINALS

RECTIFIER

NEUTRAL

START

SWITCH

COLOR CODE

1. BLACK/WHITE

2. RED

3. ORANGE

4. BLACK

5. YELLOW

6. DARK BLUE

7. WHITE

8. BLUE

26 - 46 - 448 TRACTOR WIRING DIAGRAM

226 _ PtN TO 14094020

446 _ PtN 9742W;3 TO 14096200

It48 _ PtN TO 14097625

NOTE: Wire from "L', terminal on switch to lights can be pink.

WIRE

HARNESS

SPARK

PLUG

BREAKER

CONTACTS IGNITION

corL

FIGURE 1A

-6-

SOLENOID

STARTER

e,1

LIGHTS

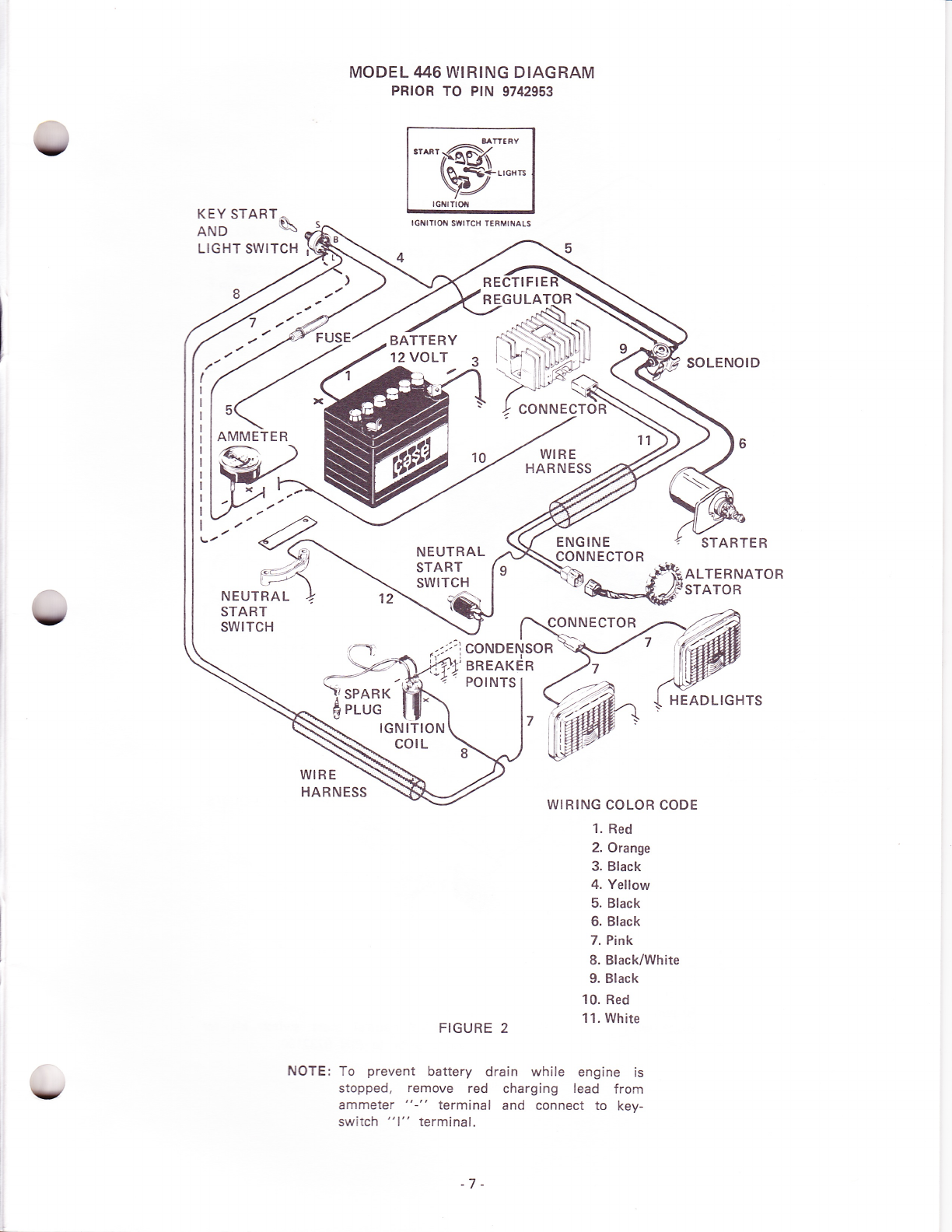

MODEL 1146 WIRING DIAGRAM

PR|OR TO PtN 9742953

Y

5

AMMETER

NEUTRAL

START

SWITCH

,r^rrl@k

v?*''o".

KEY START ^

AND \

LIGHT SWITCH

IGNITI OI{ SITI TCH TERMII{ALS

TIFIE

NEUTRAL

START

SWITCH

ENGINE

CONNECTOR

SOLENOID

STARTER

ALTERNATOR

STATOR

HEADLIGHTS

('= 1

\t :,.ICONDENSOR

-i r

,,I.t,BREAKER

POINTS

SPARK Fiih

PLUGIGNITION

corL

WIRE

HARNESS WIRING COLOR CODE

1. Red

2. Orange

3. Black

4. Yellow

5. Black

6. Black

7. Pink

8. Black/White

9. Black

10. Red

11. White

FIGURE 2

NOTE: To prevent battery drain while engine is

stopped, remove red charging lead frorn

ammeter "-" terminal and connect to key-

switch "1" terminal.

BATTERY

12 VOLT

V

-7-

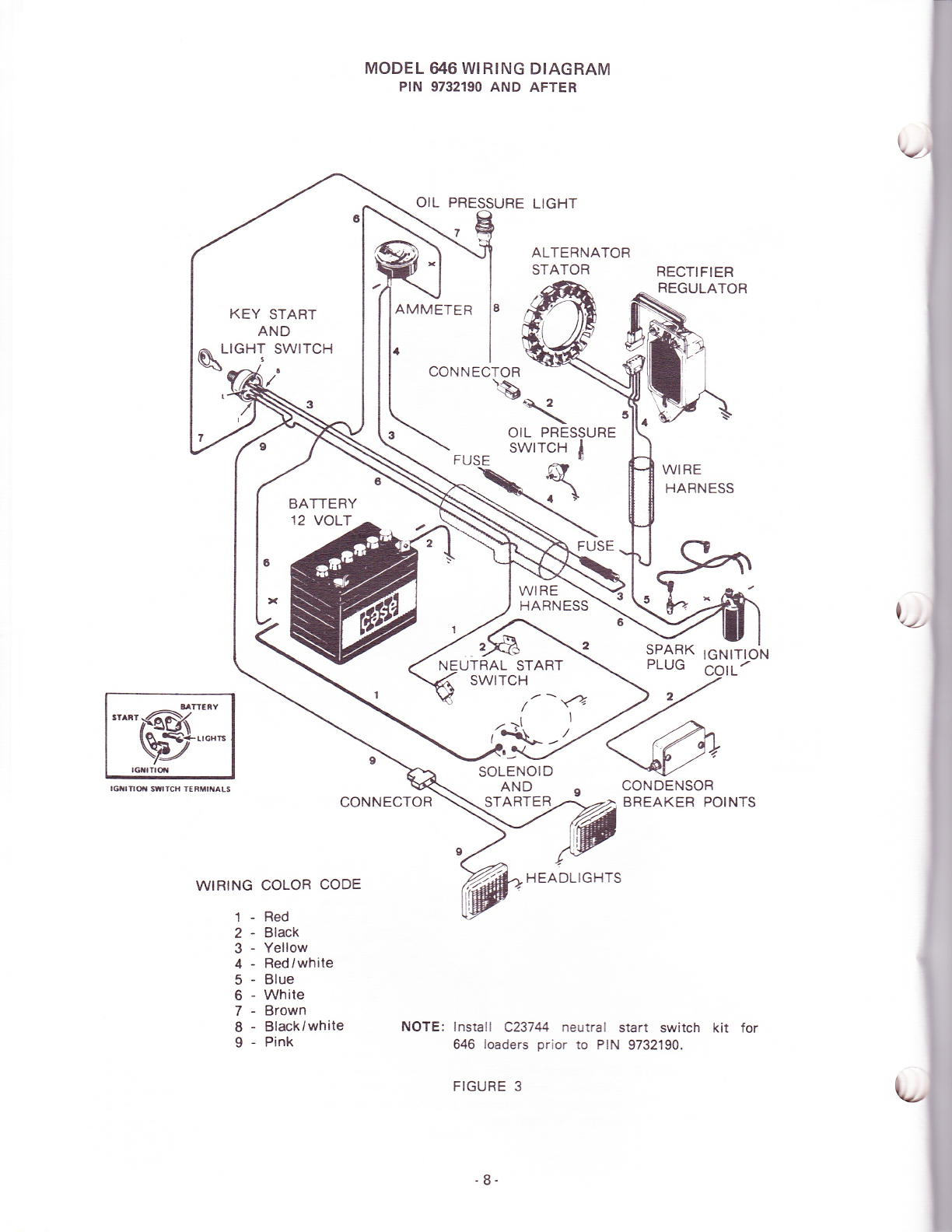

MODEL 646 WIRING DIAGRAM

PIN 9732190 AND AFTER

otL PR

7

LIGHT

ALTERNATOR

STATOR

KEY START

AND

LIGHT SWITCH

AMMETER

CONNECTOR

q*-li

WIRING

1-

2-

3-

4-

c

6-

7-

8-

9-

FUSE

"^,w:."

lclrTrof swrTcH TERiilt{aLs CONNECTOR

WIRE

HARNESS

UTRAL START

SWITCH

/t-?

SOLENOID

AND

STARTER

2

CONDENSOR

BREAKER POINTS

COLOR CODE

Red

Black

Yellow

Red/white

Blue

White

Brown

Black/white

Pink

BATTERY

12 VOLT

*\

OIL PRESSURE

swrrcH I

R

HEADLIGHTS

NOTE: lnstall C23744 neutral start switch kit for

646 loaders prior to PIN 9732190.

FIGURE 3

RECTIFIER

REGULATOR

WIRE

HARNESS

SPARK IGNITION

PLUG

;t

'1\-'-

-8-

MODEL A$ WIRING DIAGRAM

v

COLOR CODE

1. Black and White

2. Red

3. Orange

4. Blue

5. Yellow

6. White

7. Black

8. Brown

9. Dark Blue

IGNITION SWlTCH

"'@;:

IGNITIOTi SIYITCH TERMIiIALS

AMMETER

-ac---)

v

-L; -

SOLENOI D

STATO RSTARTE R

\: -l ig

3

'7

HOUR METEB

WIFI E

H ARN ESS

NEUTRAL

START

SWITCHES

BREAKE R

PO I NTS

P RESSU R E

SWITCH

'h

FIGURE 4

BATTE RY

-9-

I. ENGINE WILL NOT CRANK

SYMPTOM POSSIBLE

TROUBLESHOOTING CHART

CAUSE TEST SOLUTION

A. Solenoid doesn't click or

clicks repeatedly (See "B"

below)

1. Dead or weak battery Hydrometer test. Voltmeter

reading 9.5 minimum at bat-

tery terminals when cranking

Charge or replace battery

2. Poor or open connection at

solenoid, ampmeter, f use,

key switch, or neutral start

switches

Visually inspect Clean and tighten loose or

corroded connections

B. Solenoid doesn't click 1. One or both neutral start

switches oPen All models except 646 PIN

9732190 and after:

Connect jumper wire f rom

solenoid post (Small post

ground side) to ground. Turn

key to start.

646 PIN 9732190 and after:

Brief ly touch wire from batte-

rY "+" terminal to starter

solenoid spade terminal.

Disengage PTO clutch and pul

travel lever in N. Repair or

replace one or both N start

switches if defective

2. Fuse blown Check continuity Replace fuse

3. Open ampmeter Check continuity Replace ampmeter

4. Open solenoid Check continuity Replace solenoid

5. Open ignition switch Connect iumper from batterY

positive to solenoid "+" small

terminal or from B to S ter-

minal on switch

Replace ignition switch

C. Solenoid click but engine

won't crank (See A above) 1. Engine tight Attempt to turn engine man-

ually to check for free rotation Repair engine if found to be

tight

2. Defective solenoid switch Connect heavy jumper wire

across large solenoid posts.

Engine should crank.

Replace solenoid

3. Defective or worn starter Repair or replace. See starter

motor section of this manual.

II. ENGINE CRANKS IN GEAR

*646 PIN 9732190 and after

pedal depressed or PTO "on"

or shorted N-Start switches.

cranking with travel

indicates misadjusted

A. Engine cranks with travel

lever in drive (600 series -

travel pedal depressed)

Grounded N start switch (tra-

vel or PTO) or wire lead Visual inspection. Disconnect

wire from small solenoid post

to PTO N-Start switch.*

Repair or replace wire lead or

N - Start switch {travel or

PTO).

B. Engine cranks with PTO

clutch in gear or both

travel and PTO in gear.

Grounded PTO N Start

switch or wire lead or

grounded starter solenoid

Visual inspection. Disconnect

wire from small solenoid posts

N - Start switch. Attempt to

crank engine.*

Repair or replace lead or N -

Start switch. lf unit cranks

with wire disconnected - R &

R solenoid.

-10-

III. ENGINE CRANKS.

SYMPTOM BUT WON'T START

POSSIBLE CAUSE TEST SOLUTION

v

v

IV. ENGINE RUNS ERRATICALLY

V. BATTERY UNDER CHARGING (OR NO CHARGE)

*NOTE: Be sure to check all connections for con_

tinuity before replacing major components. Be sure

rectifier regulator is grounded to tractor frame.

ITNOTE: Stator output voltage between 14 and 2g

volts AC is adequate to charge battery at reduced

rate. Reciuced stator output could be caused by dirt

accumulations or weak f lywheel magnets. Remove

flywheel, inspect and correct as necessary.

A. Engire c:a:ks s a#.y and

won': s:a-: Erec:ri*t pr.o-

Dle:ns cr v

See A. & C. above

B. Engire cranks but

s'€.: li9 spark) won't 1. Points not opening and

closing Check gap Clean and set gap. Time en-

gine. Refer to specifications

for correct point gap.

2. No (low) voltage to coil Check for battery voltage at

coil + with voltmeter or test-

ing light. Hold switch in

"start" position.

Check wire connections and

ignition switch continuity from

"8" to "1" in both start and

run positions

Replace switch or wires as

requ i red.

646 prior to plN 9732190: ex-

cessive voltage drops at star-

ter solenoid. lnstall C23744 N_

start switch.

3. Spark plug lnspect for grounded high

tension lead or cracked insu-

lator or fouled spark plug

Repair or replace lead or plug

as required

4. Defective ignition coil Use coil tester Replace

5. Shorted to ground conden-

ser Unhook condenser lead. Crank

engine. lf weak spark is now

seen, condenser was shorted.

Replace condenser

A. Engine runs at idle and

erratically (electrical pro-

blems only). Flashing blue

arc at points. Points

bu rned.

Faulty condenser or condenser

connected to coil "+" (points

and condenser should be con-

nected to coil "-")

Condenser test. I nspect con-

nection. Replace or connect condenser

to coil "-".

A. Battery goes dead with

normal usage 1. Defective battery

2. Cold weather, short running

periods

3. Stop start operation Keep engine speed high

enough to charge

4. Dirty or corroded terminals

or wires

5. Excessive electrical loads Total individual loads Reduce total load

No charge to battery (amp-

meter at .0) Battery fully charged Turn head lights on for 5

minutes with engine shut off.

Start tractor.

Ampmeter shows charge. ln-

dicates charging system func_

tioning properly.

Defective rectifier, regulator or

stator- Run engine at 3600 RpM for

3 - 5 minutes. Measure D-C

volts at battery terminal

lf 13.6 volts charging system

okay, check for faulty amp-

meter or fully charged batte-

ry. lf less than ,l3.6 volts,

test stator output.

Run engine at 3600 RpM.

Measure AC volts at slator

output plug* {unplug from

rectifier regulator)

lf less than 28 VAC replace

statort. Retest rectifier regu-

lator. lf more than 28 VAC,

stator okay, replace rectifier

regu lator.

- 11 -

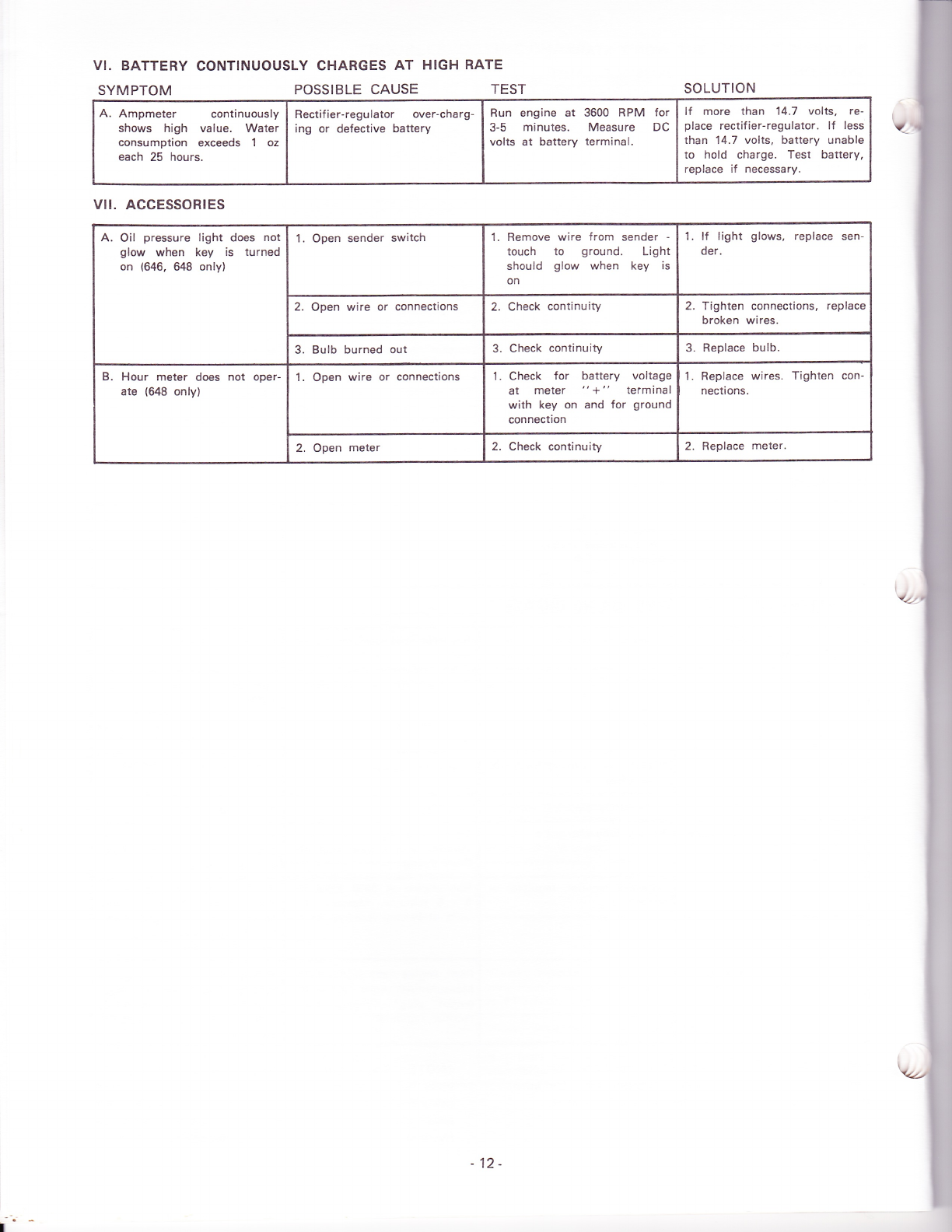

VI. BATTERY CONTINUOUSLY CHARGES AT

SYMPTOM POSSIBLE CAUSE

HIGH RATE

TEST SOLUTION

A. Ampmeter continuously

shows high value. Water

consumption exceeds 1 oz

each 25 hours.

Rectifier-regulator over-charg-

ing or defective battery Run engine at 3600 RPM for

3-5 minutes. Measure DC

volts at battery terminal,

lf more than 14.7 volts, re-

place rectifier-regulator. lf less

than 14.7 volts, battery unable

to hold charge. Test battery,

replace if necessary.

vll. AccEssoRtEs

A. Oil pressure light does not

glow when key is turned

on (646, 648 only)

1. Open sender switch l. Remove wire from sender -

touch to ground. Light

should glow when key is

on

l. lf light glows, replace sen-

der.

2. Open wire or connections 2. Check continuity 2. Tighten connections, replace

broken wires.

3. Bulb burned out 3. Check continuity 3. Replace bulb.

B. Hour meter does not oper-

ate (il8 only) 1. Open wire or connections 1. Check for battery voltage

at meter "+" tetminal

with key on and for ground

connection

1. Replace wires. Tighten con-

nections.

2. Open meter 2. Check continuity 2. Replace meter.

I

12-

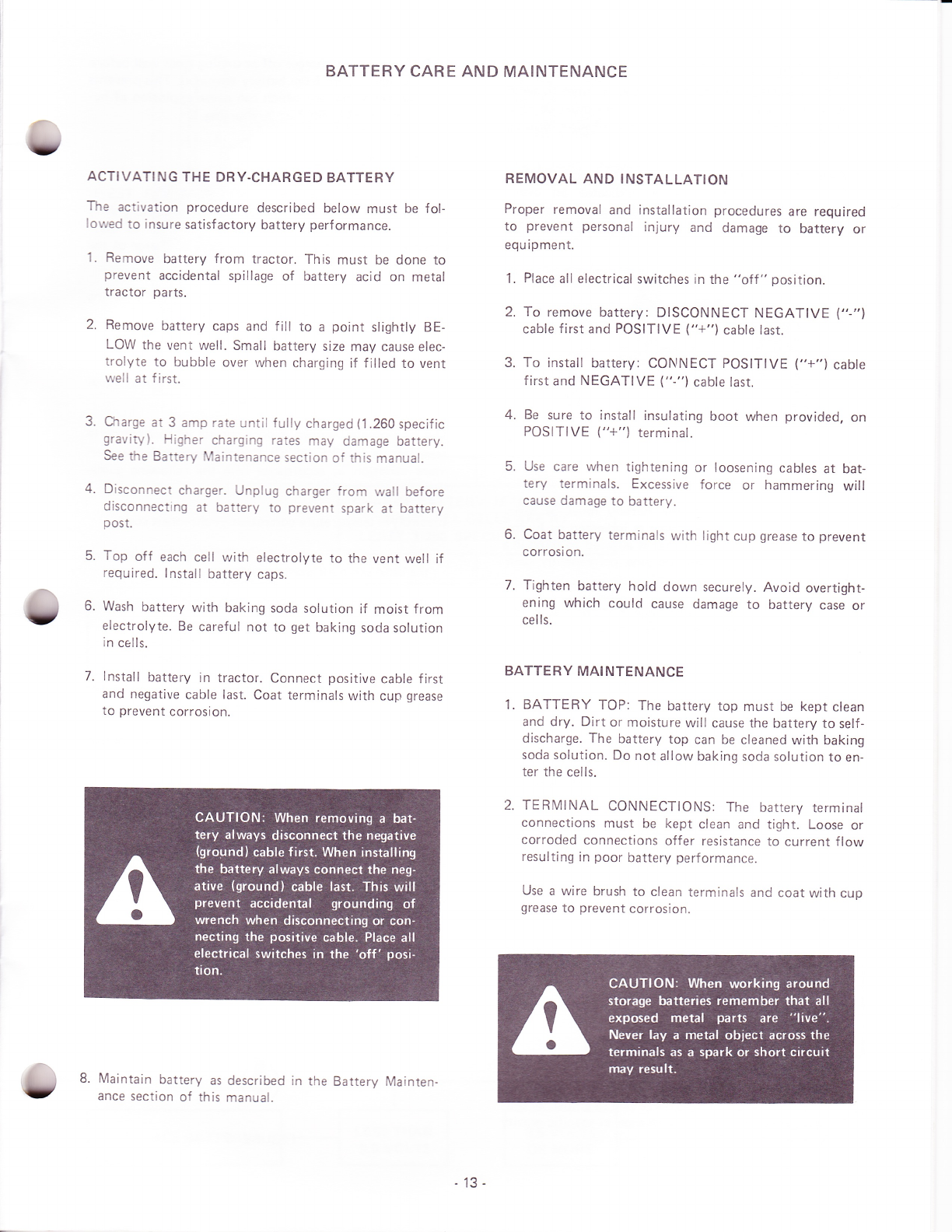

ACTIVATI NG THE DRY.CHARGED BATTE RY

The activation procedure described below must be fol-

lowed to insure satisfactory battery perf ormance.

1. Remove battery from tractor. This must be done to

prevent accidental spillage of battery acid on metal

tractor parts.

2. Remove battery caps and f ill to a point slightly BE-

LOW the vent well. Small battery size may cause elec-

trolyte to bubble over when charging if f illed to vent

well at first.

3. Charge at 3 amp rate until fully charged (1.260 specific

gravity). Higher charging rates may damage battery.

See the Battery Maintenance section of this manual.

4. Disconnect charger. Unplug charger from wall before

disconnecting at battery to prevent spark at battery

post.

5. Top off each cell with electrolyte to the vent well if

required. lnstall battery caps.

6. Wash battery with baking soda solution if moist from

electrolyte. Be careful not to get baking soda solution

in cells.

7. lnstall battery in tractor. Connect positive cable first

and negative cable last. Coat terminals with cup grease

to prevent corrosion.

8. Maintain battery as

ance section of this described in the Battery Mainten-

manual.

BATTERY CARE AND MAINTENANCE

REMOVAL AND INSTALLATION

Proper removal and installation procedures are required

to prevent personal injury and damage to battery or

equipment.

1. Place all electrical switches in the "off " position.

2. To remove battery: DISCONNECT NEGATIVE ('-"1

cable first and POSITIVE ("+") cable last.

3. To install battery: CONNECT POSITIVE ("+") cabte

f irst and NEGATIVE ("-") cable last.

4. Be sure to install insulating boot when provided, on

POSITIVE ("+") terminal.

5. Use care when tightening or loosening cables at bat-

tery terminals. Excessive force or hammering will

cause damage to battery.

6. Coat battery terminals with light cup grease to prevent

corrosi on.

7. Tighten battery hold down securely. Avoid overtight-

ening which could cause damage to battery case or

cells.

BATTERY MAINTENANCE

1. BATTERY TOP: The battery top must be kept clean

and dry. Dirt or moisture will cause the battery to self-

discharge. The battery top can be cleaned with baking

soda solution. Do not allow baking soda solution to en-

ter the cells.

2. TERMINAL CONNECTIONS: The battery terminal

connections must be kept clean and tight. Loose or

corroded connections offer resistance to current flow

resulting in poor battery performance.

Use a wire brush to clean terminals anC coat with cup

grease to prevent corrosion.

13-

3. ELECTROLYTE LEVEL: The electrolyte level must

be maintained above the cell plates at all times to avoid

permanent battery damage. The battery must be kept

filled to the vent well with water f ree of scale forming

minerals.

Water consumption in excess of 1 ounce (29 ml)

every 25 hours of operation indicates an over-

charging problem. See the testing section of this

manual.

FIGURE 5

STATE OF CHARGE: The battery must be main-

tained in a full state of charge as indicated by hydro-

meter readings. A battery that is allowed to stand in a

discharged condition will become permanently dam-

aged.

An idle battery will self discharge. For this reason, idle

batteries should be checked periodically and charged

as necessary.

Discharged batteries will freeze in cold weather. For

example, a battery with specific gravity of 1.175will

lreeze at0oF (-18oC).

CHARGING PROCEDURE:

A. Charging at a rate not to exceed 3 amps is recom-

mended.

B. Charging at higher rates up to 15 amps is permis-

sible as long as:

a. Violent gasing does not occur

b. Electrolyte is not spewed from vents

c. Electrolyte temperature does not exceed 125oF

(510C)

DO NOT exceed 15 amps charge rate.

C. A battery is fully charged when, after two, two

hour intervals at a low charge rate (3 amps), all cells

are gasing freely and no change in specific gravity

occurs.

D. Always turn charger off or unplug from wall before

removing clips from battery terminals. This prevents

arcing at battery wlrich can cause explosion of hy-

drogen gas created while charging.

BATTERY TESTING

SPECIFIC GRAVITY TEST (HYDROMETER TEST):

The hydrometer is used to measure the specific gravity

of battery electrolyte (weight of electrolyte as com-

pared to water). This indicates the state of charge of the

ba tte ry.

Mix newly added water with electrolyte before taking

hydrometer readings by:

a. charging f or 15 minutes at 3 amps and

b. applying a 75 amp load for 15 seconds (about equal

to cranking engine for 1 5 seconds).

The hydrometer reading is only correct when electrolvte

temperature is 80oF (25oC). Correct readings for temper-

ature variation in accordance with the following guide-

lines:

Electrolyte temperature correction - Fahrenheit scale

For every 1OoF below g0oF SUBTRACT .004 from

the observed hydrometer reading.

For every 10oF above 80oF ADD .004 to the observed

hydrometer reading.

Electrolyte temperature correction - Celsius scale

For every 1OoC below 2soc SUBTRACT .007 from

the observed hydrometer reading.

For every 10oC above 2boc ADD.007 to the observed

hydrometer reading.

TEMPERATURE IN 160

oF oF El.tcTROtYtt'5o

t40

rJO

t20

Io

!0o

9l

8)

70 i

50

50

4O

to

20

'O

o

4.

. " ctAvtry potNls

.28 ro ADO ot

. ze 5UIIRACT

. 20 FtoM IEADING

+ 16

at2

+8

o

-8

- t2

-,5

-?o

- 24

- ?8

- lz

ETECITOTYIE TEVII

-14-

FIGURE 6

THOTD HYDROMEIER

VEITICAI,IY STRAIGHI

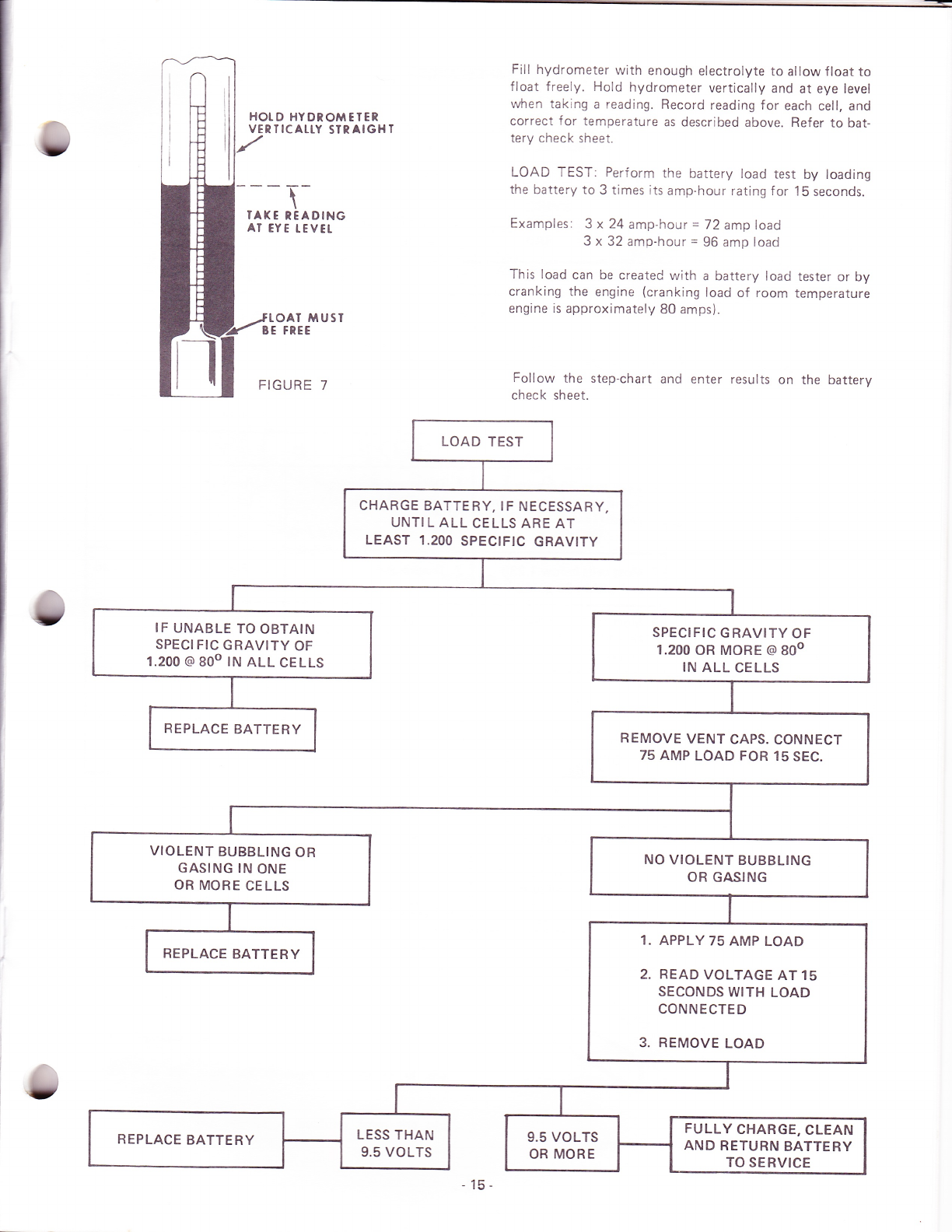

Fill hydrometer with enough electrolyte to allow f loat to

f loat freely. Hold hydrometer vertically and at eye level

when taking a reading. Record reading for each cell, and

correct for temperature as described above. Refer to bat-

tery check sheet.

LOAD TEST: Perform the battery load test by loading

the battery to 3 times its amp-hour rating for 15 seconds.

Examples: 3 x 24 amp-h our = 72 amp load

3 x 32 amp-hour = 96 amp load

This load can be createC with a battery load tester or by

cranking the engine (cranking load of room temperature

engine is approximately 80 amps).

Follow the step-chart and enter results on the battery

check sheet.

--T-\

TAX E TEADING

AT EYE TEVET

fTOAT MUSI

BE FREE

FIGURE 7

LOAD TEST

CHARGE BATTERY, IF NECESSARY,

UNTI L ALL CELLS ARE AT

LEAST 1.200 SPECIFIC GRAVITY

IF UNABLE TO OBTAIN

SPECIFIC GRAVITY OF

1.200 @ 8oo tN ALL CELLS

SPECIFIC GRAVITY OF

1.200 0R MORE @ 8oo

IN ALL CELLS

REPLACE BATTERY REMOVE VENT CAPS. CONNECT

75 AMP LOAD FOR 15 SEC.

VIOLENT BUBBLING OR

GASING IN ONE

OR MORE CELLS

NO VIOLENT BUBBLING

OR GASING

1. APPLY 75 AMP LOAD

2. READVOLTAGEATlS

SECONDS WITH LOAD

CONNECTED

3. REMOVE LOAD

REPLACE BATTERY

REPLACE BATTERY LESS THAN

9.5 VOLTS 9.5 VOLTS

OR MORE

FULLY CHARGE, CLEAN

AND RETURN BATTERY

TO SERVICE

TEST Result

VISUAL INSPECTION

Summary

BATTERY CHECK SHEET

lndication Remedy

1. Dirty battery top- Battery OK Clean

2. Clogged vents- Battery OK Clea n

3. Corrosion lf severe, possible battery

defect- Clean and continue testing.

4. Low water level- Excess water use - Test for

overcharging. Battery OK Add water

5. Cracked case- Defective battery Replace

SPECIFIC GRAVITY CHECK

Cell No. 1

Cell No. 2

'I . More than 30 gravity

points variation between

cells.

'l . Defective, discharged or

worn out batterv. 1. Recharge battery. Repeat

test. lf cell readings still

vary more than 30 points,

replace battery.

Cell No. 4

Cell No. 5

Cell No. 6

2. Most cells below 1.230

and within 30 points. 2. Discharged 2. Recharge and make Load

Test.

3. Most cells at or near f ull

charge (1.260) and within

30 points.

3. Charged 3. Make Load Test

4. Most cells above f ull

charge (1.260) 4. Overcharged 4. Check regulatcr.

NOTE: Specif ic gravity readings apply to original equipment or Case

supplied replacement batteries only. Other makes may vary.

LOAD TEST

Battery must have 1.200

specific gravity. Load e-

quals 2Ghour amp rating

x3forl5seconds

1 2 volt battery- Over 9.5 volts Battery OK Recharge if necessary

Under 9.5 volts Def ective Replace

16-

I

tl,

I

STARTER MOTOR REPAIR - MODELS 26, 4H}6, 4H/8, W

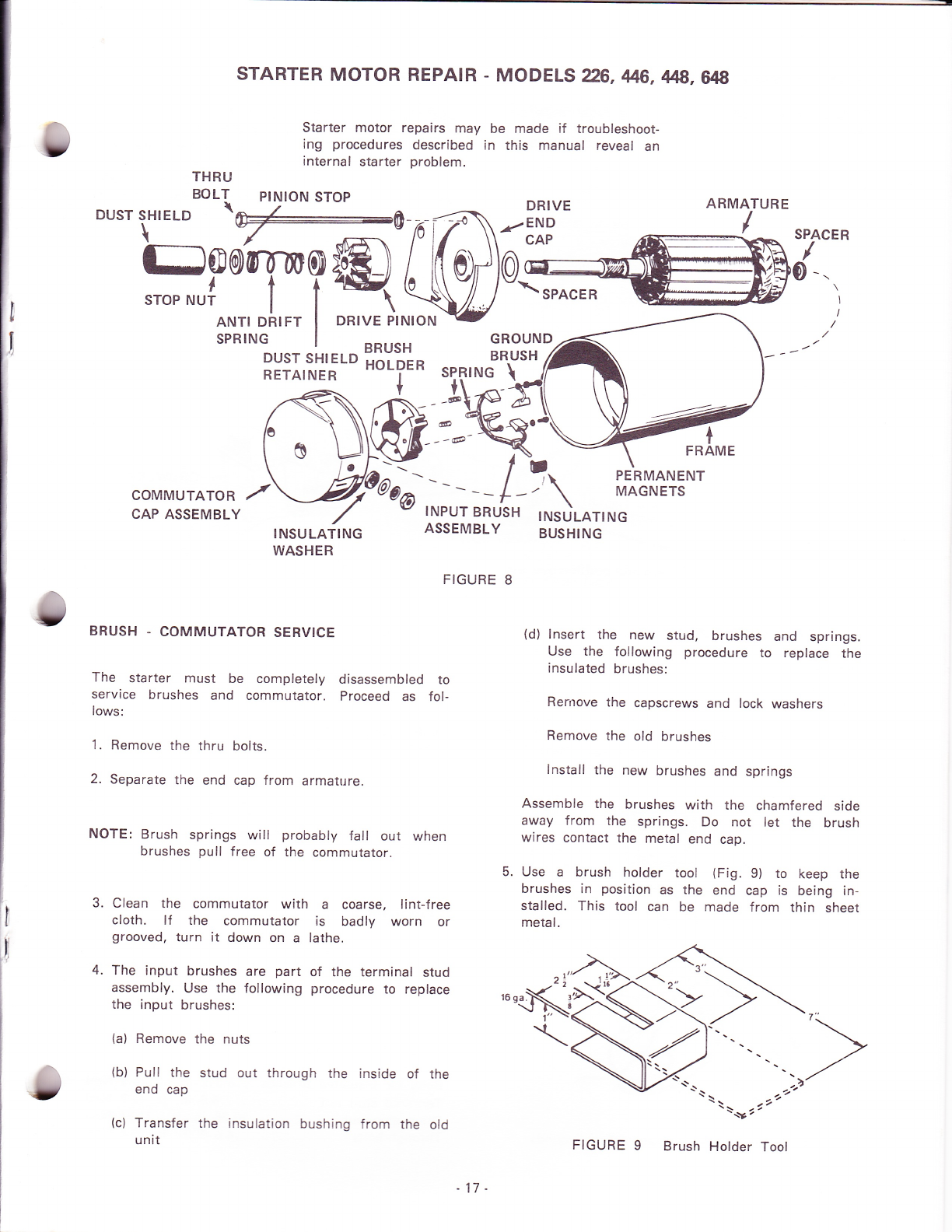

Starter motor repairs may be made if troubleshoot-

ing procedures described in this manual reveal an

internal starter problem.

THRI-'

BOLT ptN|ON STOP

\ - ";'-'- -'-' DRIVE

DUsTsHIELD \-A pf

\."-"

-rplf\_El3

Lurr r",r.o t-lYt^l- BR-usH

RP]ff?RMCIIffi

sPRTNG I ^^..^., cRouND ,4

ARMATURE

/SPACER

/

+

FRAME

r

INSULATING

BUSHING

{d) lnsert the new stud, brushes and springs.

Use the following procedure to replace the

insulated brushes:

Rernove the capscrews and lock washers

Remove the old brushes

lnstall the new brushes and springs

Assemble the brushes with the chamfered side

away f rom the springs. Do not let the brush

wires contact the metal end cap.

5. Use a brush holder tool (Fig. 9) to keep the

brushes in position as the end cap is being in-

stalled. This tool can be made from thin sheet

metal.

ilIio'i,i.*='" HoLDER sPRtNC \

Nffi-'\ PERMANENT

MAGNETS

COMMUTATOR

CAP ASSEMBLY

I

I

INSULATlNG

WASHER

BRUSH . COMMUTATOR SERVICE

The starter must be completely disassembled to

service brushes and commutator. Proceed as fol-

lows:

1. Remove the thru bolts.

2. Separate the end cap from armature.

NOTE: Brush springs will probably fall out when

brushes pull free of the commutator.

Clean the commutator with a coarse, lint-free

cloth. lf the commutator is badly worn or

grooved, turn it down on a lathe.

The input brushes are part of the terminal stud

assembly. Use the following procedure to replace

the input brushes:

(a) Remove the nuts

(b) Pull the stud out through the inside of the

end cap

(c) Transfer the insulation bushing from the old

unit

3.

4.

ASSEMBLY

FIGURE 8

/

-17-

FIGURE 9Brush Holder Tool

DRIVE ASSEMBLY

Replace drive assembly if pinion is badly worn

has broken teeth.

To remove drive assembly:

1. Hold armature shaft.

2. Remove dust shield, stop nut, pinion stop,

drift spring, and dust shield retainer.

3. Slip drive pinion off over spline and armature shaft.

Leave drive off if further disassembly of starter is

quired.

To install drive assembly:

1. Thoroughly clean the drive shaft and pinion and apply

a small amount of lubriplate AERO grease or other dry

lubricant such as graphite.

2. lnstall drive pinion, dust shield retainer, anti drift

spring, pinion stop.

3. Applv Locktite #271 to threads. Tighten stop nut to

20-25 lb. ft. (27-34 Nm). Wipe excess Locktite

from threads.

4. Push dust shield on until it snaps into position over the

shield retainer.

INSPECTION OF PARTS

TESTING ARMATURE FOR GROUNDS

Touch armature shaft or core and the end of each

commutator bar with a pair of ohmmeter leads. lf

the ohmmeter reading is low, it indicates a

grounded armature. Replace grounded armature.

TESTING ARMATURE FOR A SHORT CIRCUIT

Use a growler for locating shorts in the armature.

Put armature in growler. Hold a thin steel blade

(e.g. hacksaw blade) parallel to the core and just

above it. Slowly rotate armature in growler. A

shorted armature will cause the blade to vibrate

and be attracted to the core. Replace shorted

armature.

GROWLER

FIGURE 11 Testing Armature For Short Circuits

INSPECTING FOR AN OPEN CIRCUIT IN ARMA.

TURE

The nrost likely place to check for an open circuit

is at the commutator riser bars. lnspect for loose

connections on the points where the conductors are

joined to the commutator bars.

a nti

BRUSH INSPECTION

lf brushes are worn

mm), replace them.

move smoothlY in the

shorter than 1 /4 inch (6.35

Check to see that brushes

brush holders.

STARTER FASTENER TOROUE SPECIFICATIONS

Bolts for insulated

Terminal stud nut

Drive stop nut

brushes . . .3-3Y2 lb. ft. (4-5 Nm)

.....4-5 lb. ft. (5-7 Nm)

.. .20-25 lb. ft. (27-34 Nm)

FIGURE 10 Testing Armature For Grounds

- 18 -

Through-bolts 4Y2-6 lb. ft. (6-8 Nm)

STARTER REMOVAL

1. Remove the necessary tractor sheet metal and

accessories to enable the engine blower housing

to be removed.

0 020 i 0 0.l0" (0.51 : 0 25 mm)

FLYWHEEL GEAR FREE TRAVEL WHEN

ENGAGED WITH STARTER GEAR

MOUNTING

BOLTS

2. Remove the engine blower housing.

3. Remove the starter wire.

4. Remove the starter mounting bolts.

FLYWHEEL

RING GEAR

STARTING MOTOR

PINION GEAR

FIGUREl2 Checking Starter Gear Lash

STARTER INSTALLATION

1. Clean dirt and oil from the starter mounting

surface on both the starter and engine.

Measure the amount of free travel, or lash. be-

tween the pinion gear teeth and the ring gear

teeth, as shown in Figure 12. The proper lash

is 0.020 + 0.010 (0.51 + 0.25 mm). Loosen

and adjust the starter motor as necessary to ob-

tain the correct setting.

Tighten the starter mounting bolts.

4.

2. lnstall the starter motor and tighten the mount-

ing bolts just enough to hold the starter in its

place. 6. Connect the wire to the terminal on the starter

motor.

3. Pull the starter pinion gear outward on its shaft

so that its teeth mesh fully with those on the 7. lnstall blower housing and tractor accessories

flywheel. and sheet metal.

5.

. 19-

FIGURE 13 Starter Assembly

STARTER DISASSEMBLY

1. Loosen the M terminal nut on the magnetic

switch and remove the connector. Remove the

magnetic switch.

NOTE: The packings for the magnetic switch are

mounted so that the steel packing is located

in the front bracket side.

FIGURE 14 Magnetic Switch Removal

2. After removing the thru bolts, the starting motor

can be divided into three parts the front

bracket, housing and rear bracket.

The spacing washers shown in Figure 15 are

used for adjustment of the thrust gap of the

armature shaft. They are between the rear

bracket and the commutator.

NOTE: These washers are inserted so the steel

washer is located in the commutator side.

FIGURE I5 Removing Through Bolts

3. Remove the armature from the front bracket.

Be careful not to miss a small steel washer

used in the end of the armature shaft. Remove

the shift lever along with the armature. ln this

case, the spring holder. lever springs and re-

tainer can be taken out before the lever.

STARTER MOTOR REPAIRS _ MODEL A16

.20 -

FIGURE 16 Removing Armature

Other manuals for 226

1

This manual suits for next models

4

Other Ingersoll Tractor manuals

Popular Tractor manuals by other brands

Iran Tractor

Iran Tractor ITM 475 Operators instruction book

Simplicity

Simplicity Sovereign 499-3112H owner's manual

Cub Cadet

Cub Cadet Domestic Series 7000 Service manual

MTD

MTD 148-760 10 H.P. manual

Gravely

Gravely CONVERTIBLE 7.6 owner's manual

Briggs & Stratton

Briggs & Stratton 2690816 Setup instructions