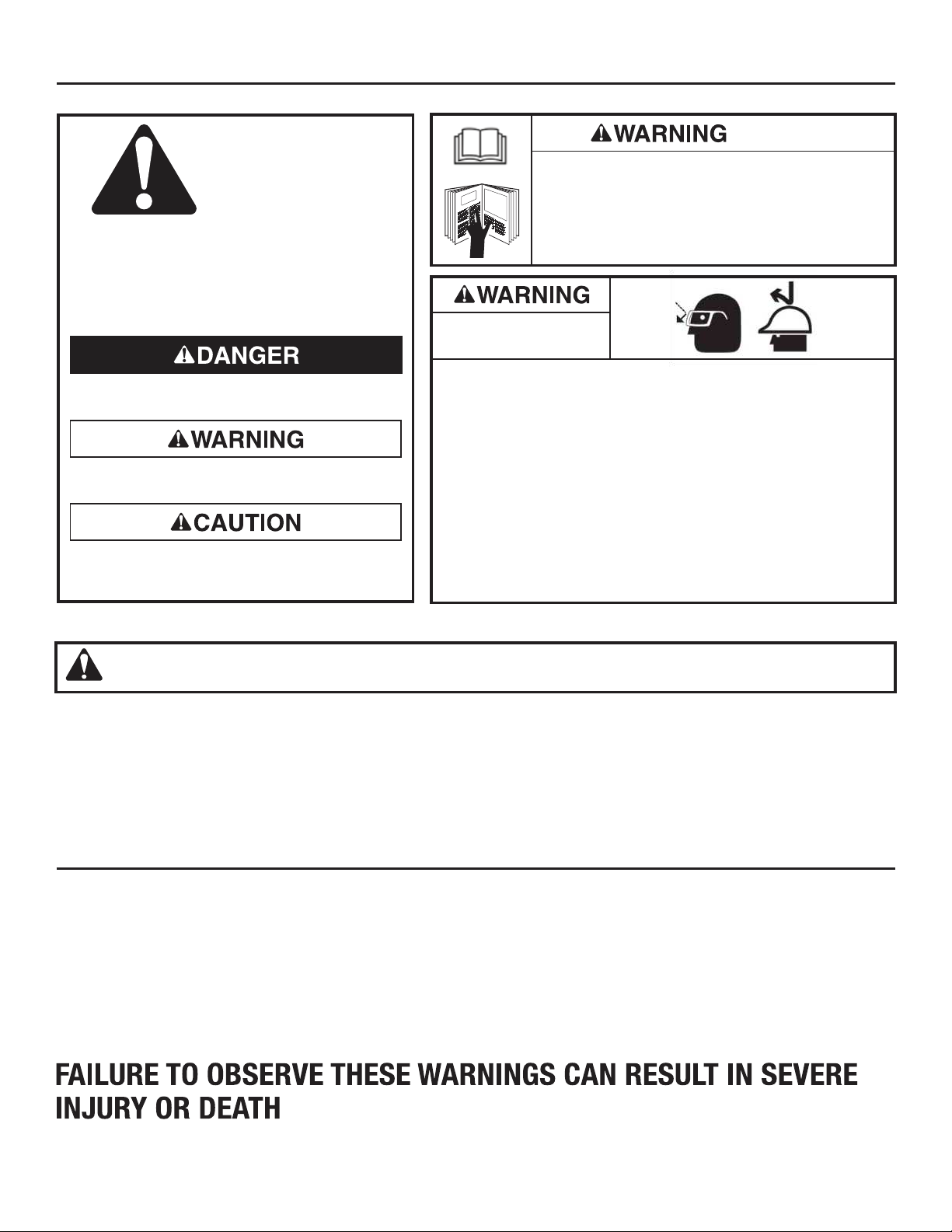

SAFETY ALERT SYMBOLS

These symbols are used to call attention to related

hazards or unsafe practices related that could result

in injury or property damage. The three safety words

defined below indicate the severity of the hazard.

The message after the signal word provides

information for preventing or avoiding the hazard.

Hazards or unsafe practices which, if not avoided,

MAY result in injury or property damage.

Hazards which, if not avoided, COULD result in

severe injury or death.

Immediate hazards which, if not avoided, WILL

result in severe injury or death.

SAFETY

ALERT

SYMBOLS

Personal

safety hazards

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

• Only qualified persons should use SIMpull™ Cable Guide System

• Wear eye protection when using this tool.

• Do not use tool while tired or under the influence of drugs, alcohol,

or medication.

• Keep body parts and loose clothing away from moving parts.

• Always wear gloves when handling SIMpull™ Cable Guide

System parts.

• Keep all body parts clear of cable path while the SIMpull™ Cable

Guide System is in use.

• When using this tool, always follow the safety procedures

set forth in this manual as well as all other safety procedures

necessary and proper when using tools of this type.

Failure to observe this warning could result in

severe injury or death.

WARNING

:Personal Safety Hazards.

• Use this tool for manufacturer’s intended purpose only. Any use other than

described in this manual can result in injury or property damage.

• Only qualified persons should use the SIMpull™ Cable Guide System.

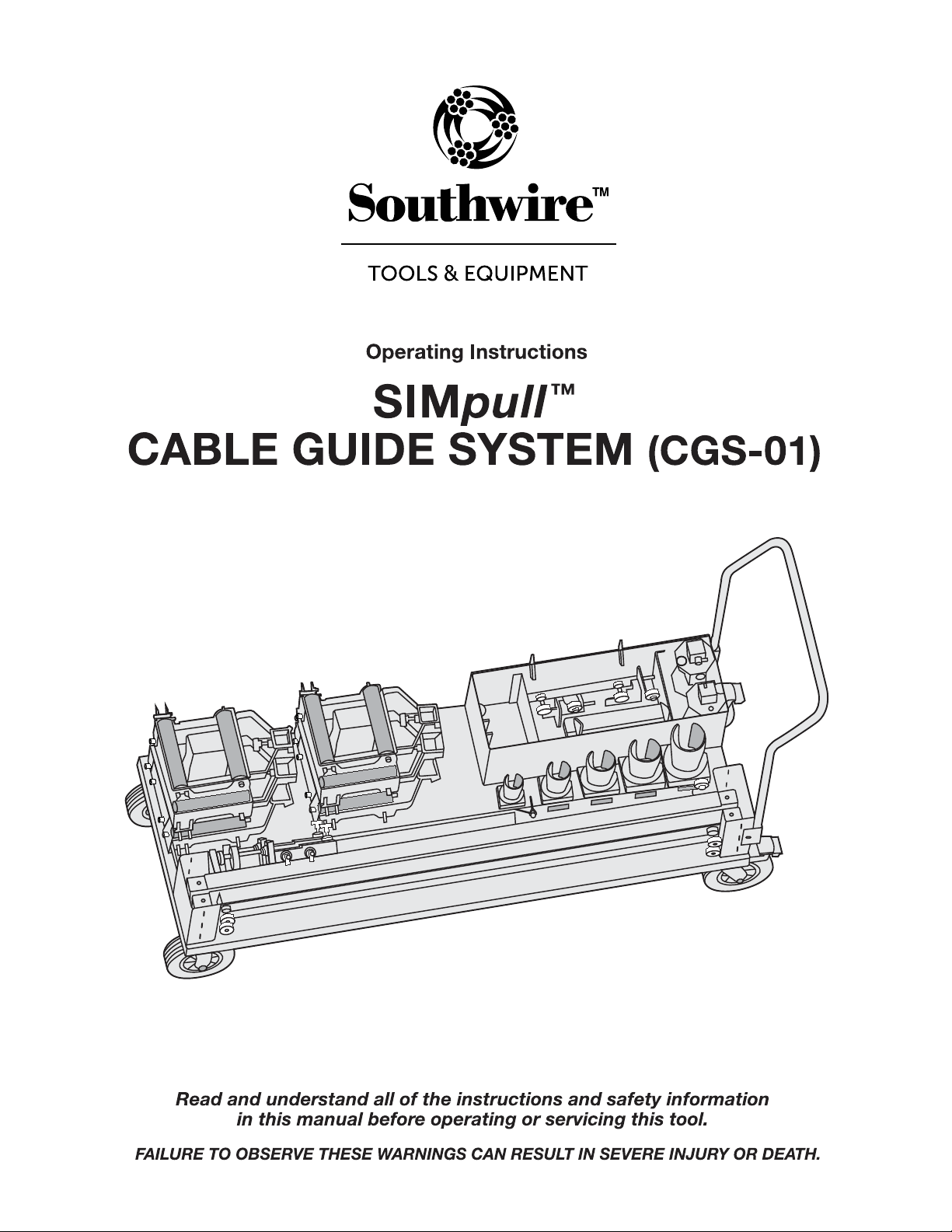

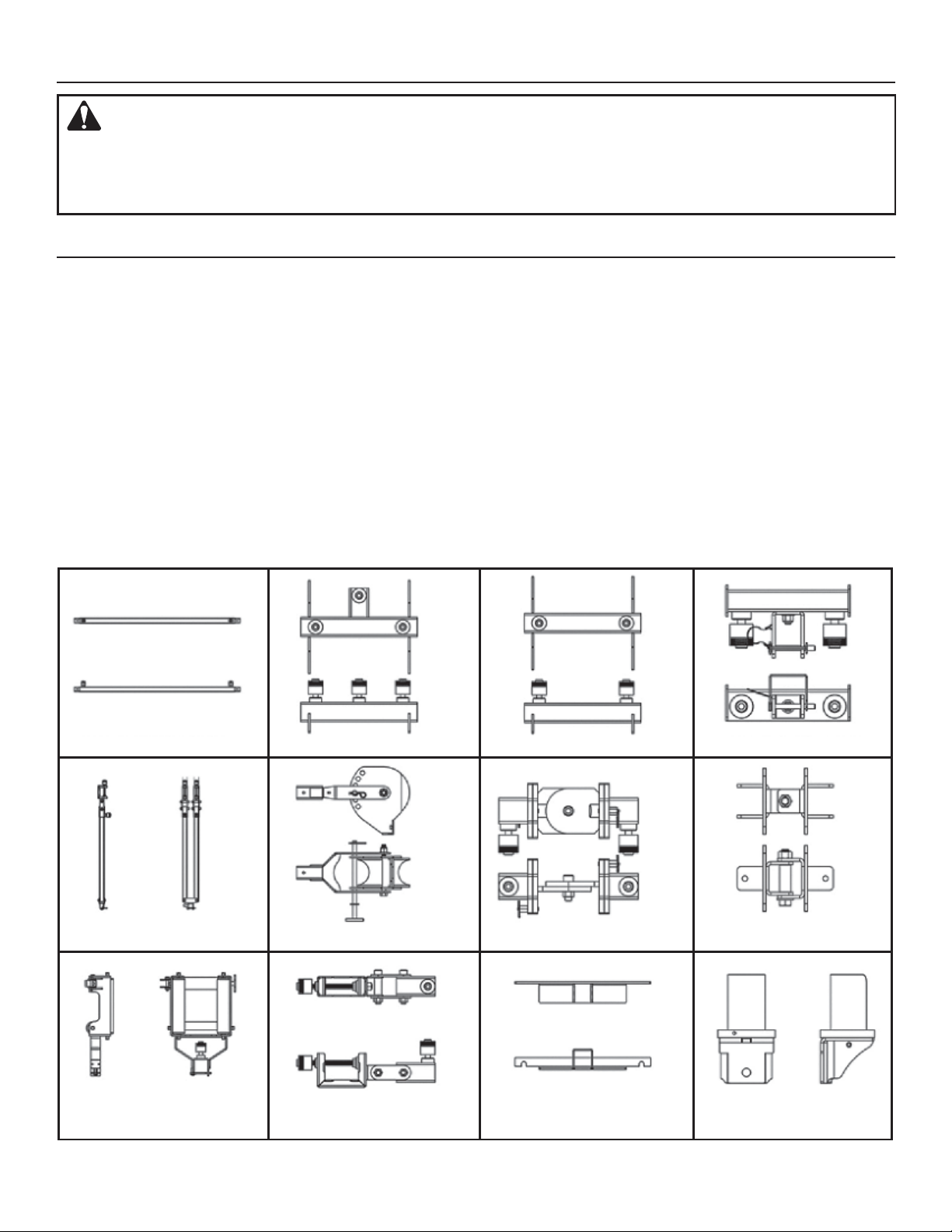

This instruction manual is intended to familiarize personnel with the safe

operation and maintenance procedures for the SIMpull™ Cable Guide

System. Keep this manual available to all personnel.

Replacement manuals are available upon request at no charge

at www.southwiretools.com

PURPOSE OF THIS MANUAL

2