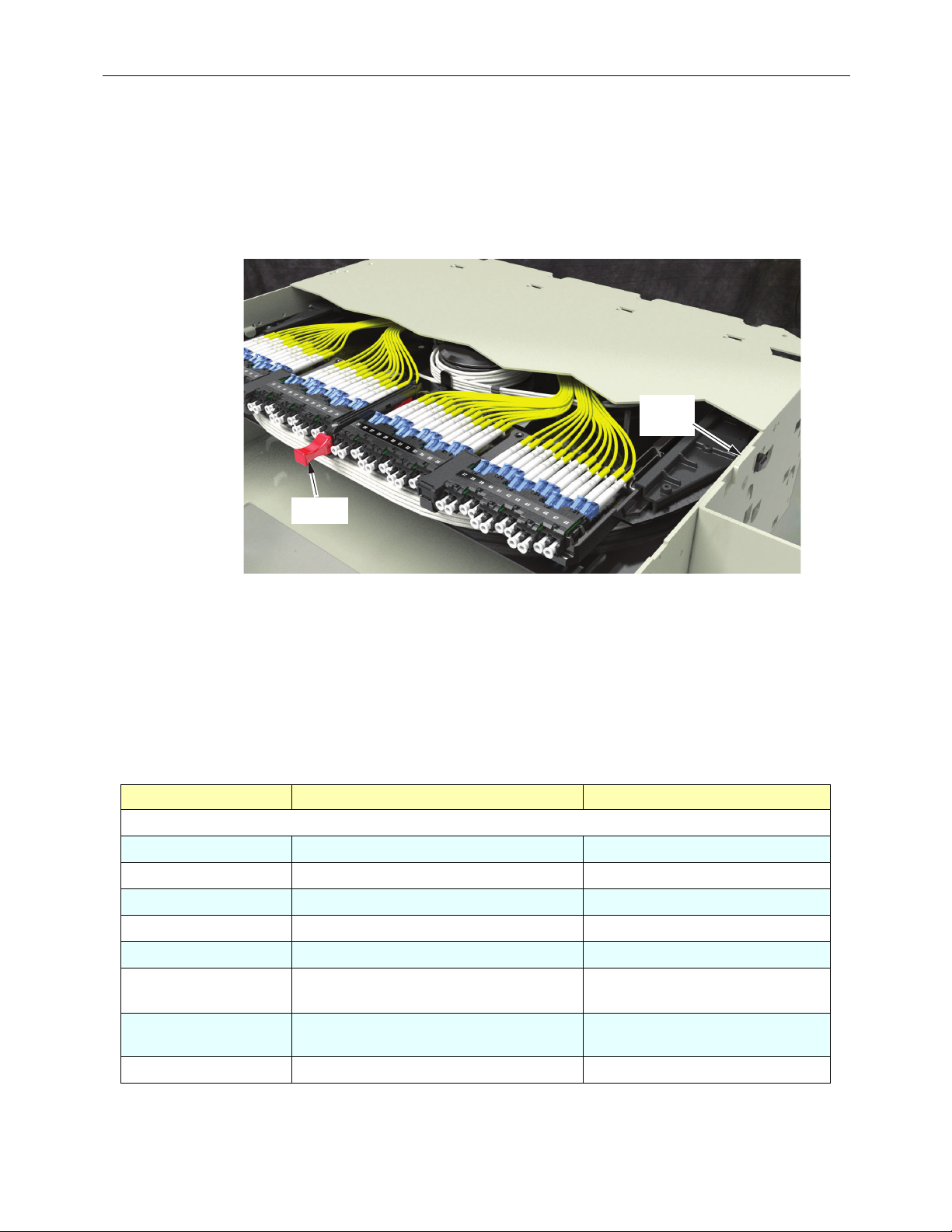

CommScope Rapid Fiber 1RU User manual

Other CommScope Cable Box manuals

Popular Cable Box manuals by other brands

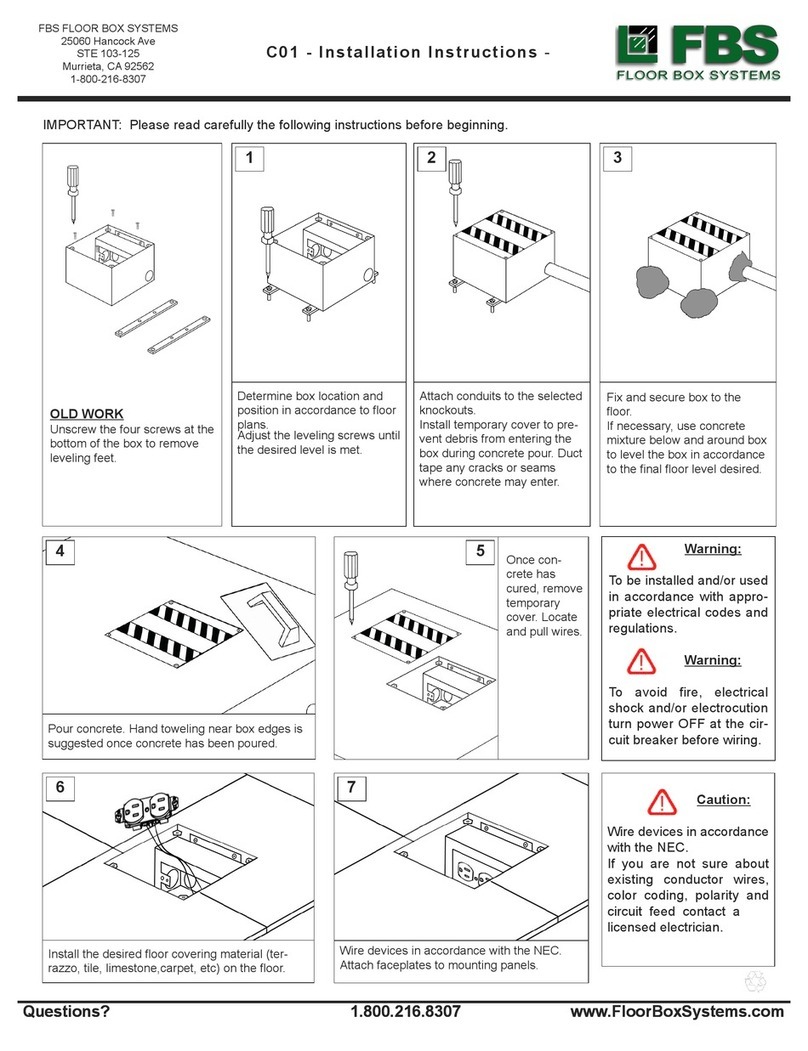

FBS

FBS C01 installation instructions

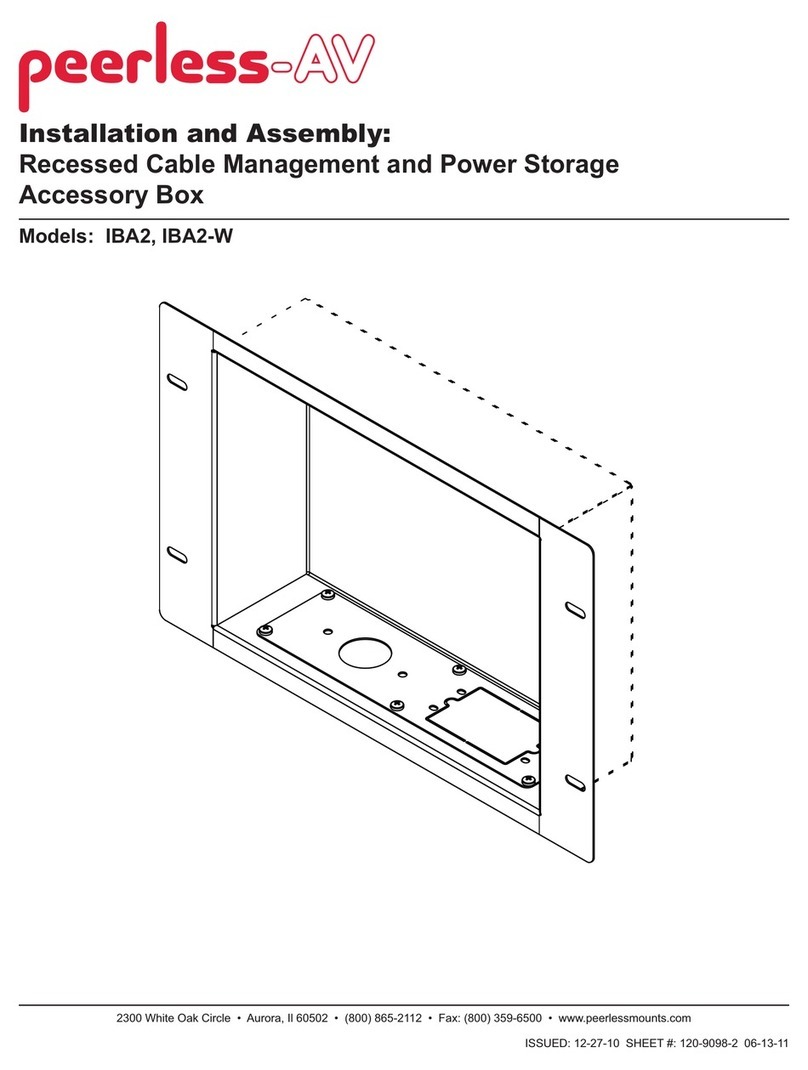

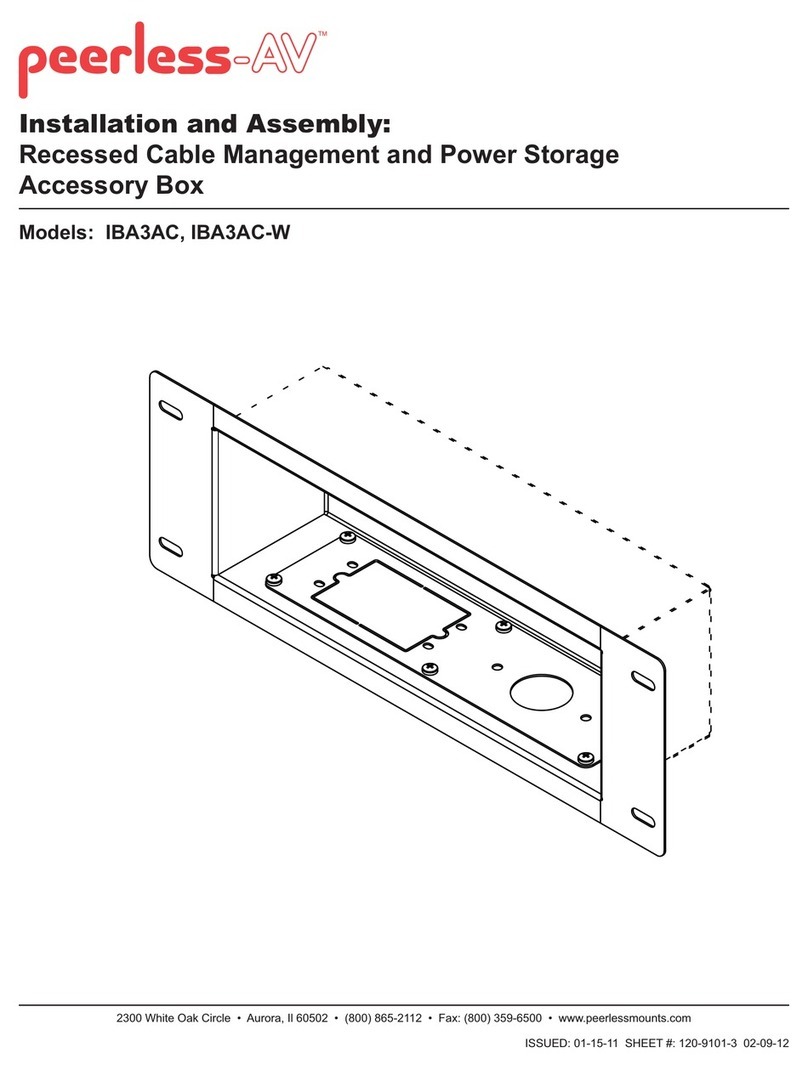

peerless-AV

peerless-AV IBA2 Installation and assembly

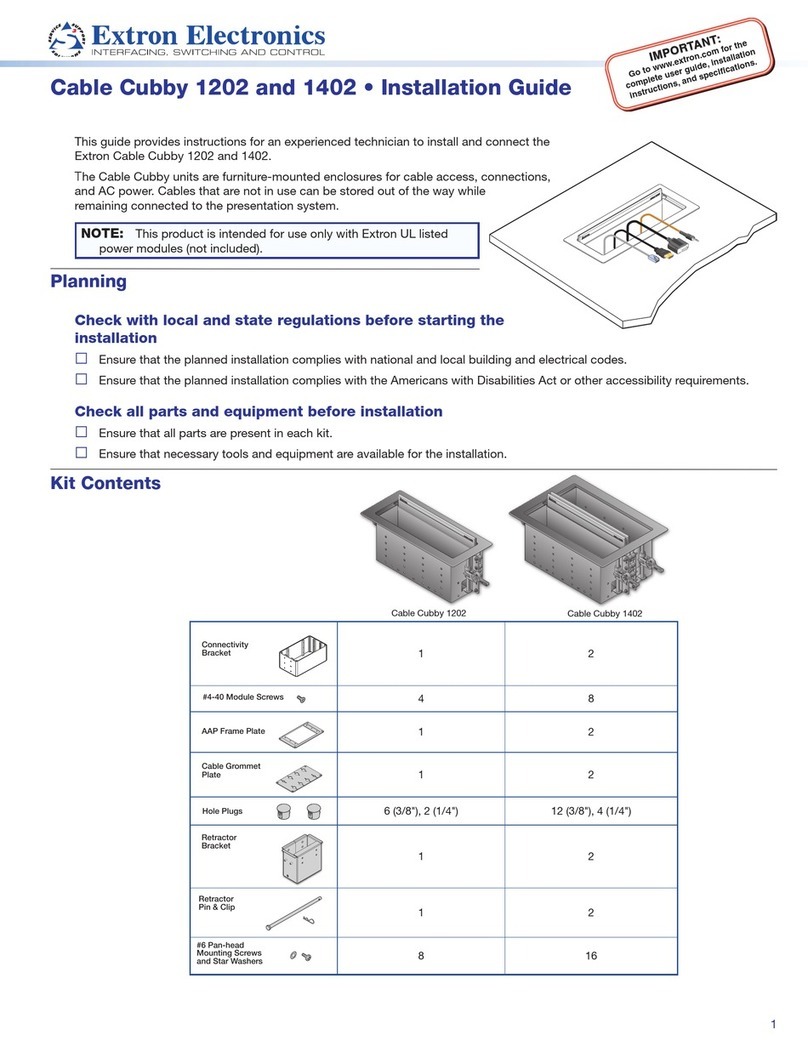

Extron electronics

Extron electronics Cable Cubby 1202 installation guide

peerless-AV

peerless-AV IBA3AC Installation and assembly

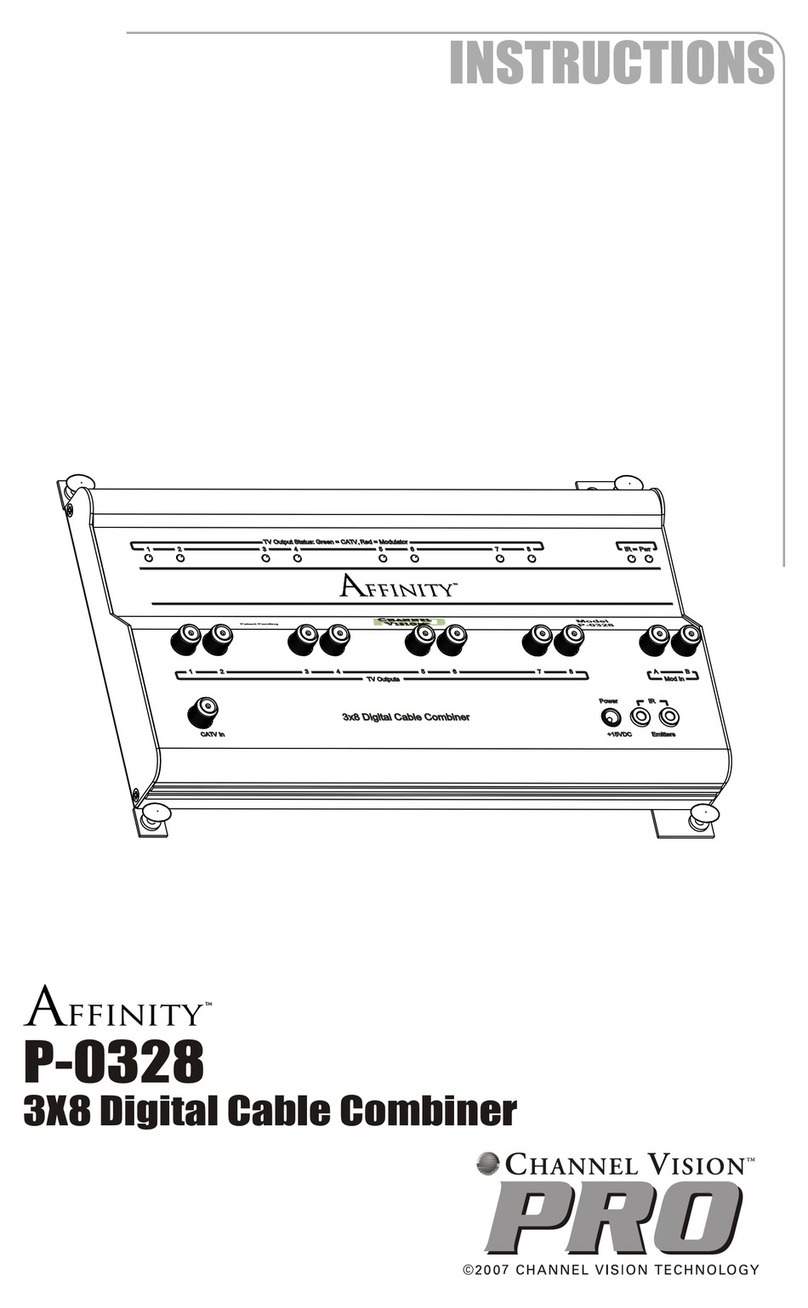

Channel Vision

Channel Vision AFFINITY P-0328 instructions

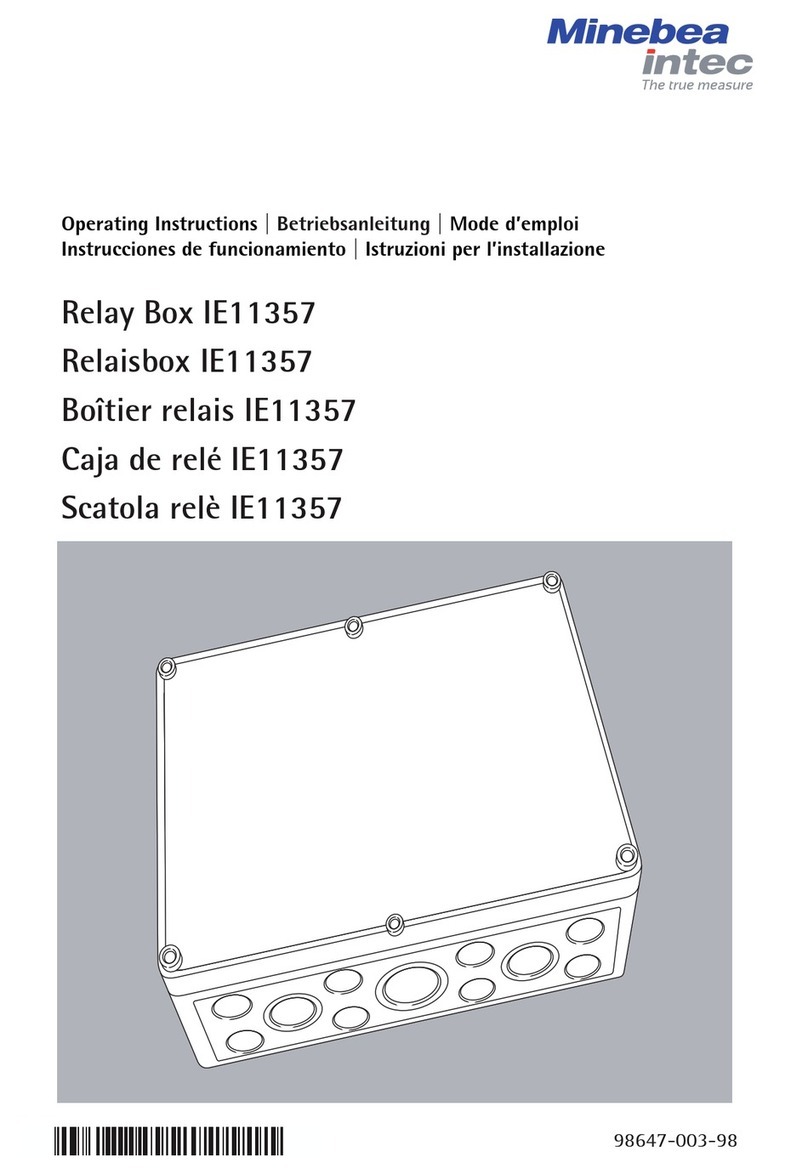

Minebea Intec

Minebea Intec IE11357 operating instructions

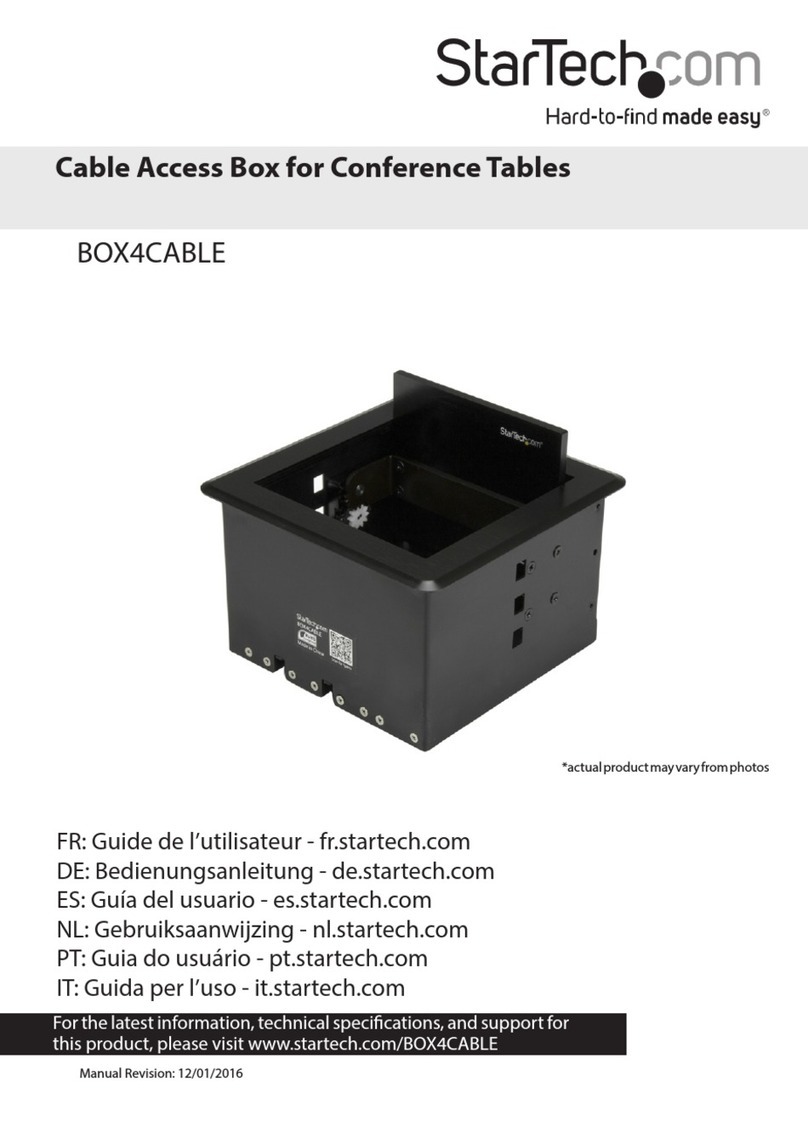

StarTech.com

StarTech.com BOX4CABLE manual

Commercial Electric

Commercial Electric 5053-WH installation guide

Motorola

Motorola DCT6412 DUAL-TUNER DVR AND HD SET-TOP - MICROSOFT... User's reference manual

Renkforce

Renkforce 1395556 operating instructions

Huawei

Huawei FAT9102SD-32G Quick installation guide

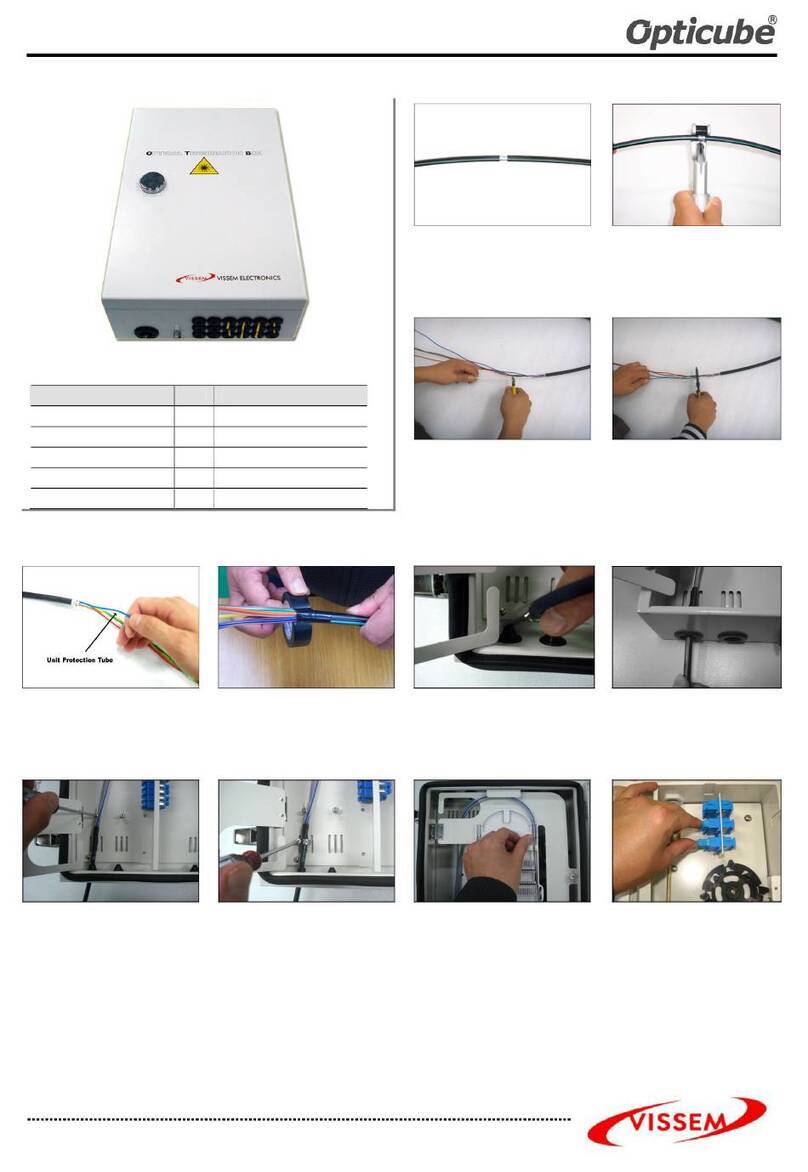

VISSEM Electronics

VISSEM Electronics Opticube VSOF-OTB-E manual

Beta

Beta 1844 15-H05/SCK Instructions for use

FSR

FSR FL-1550 installation instructions

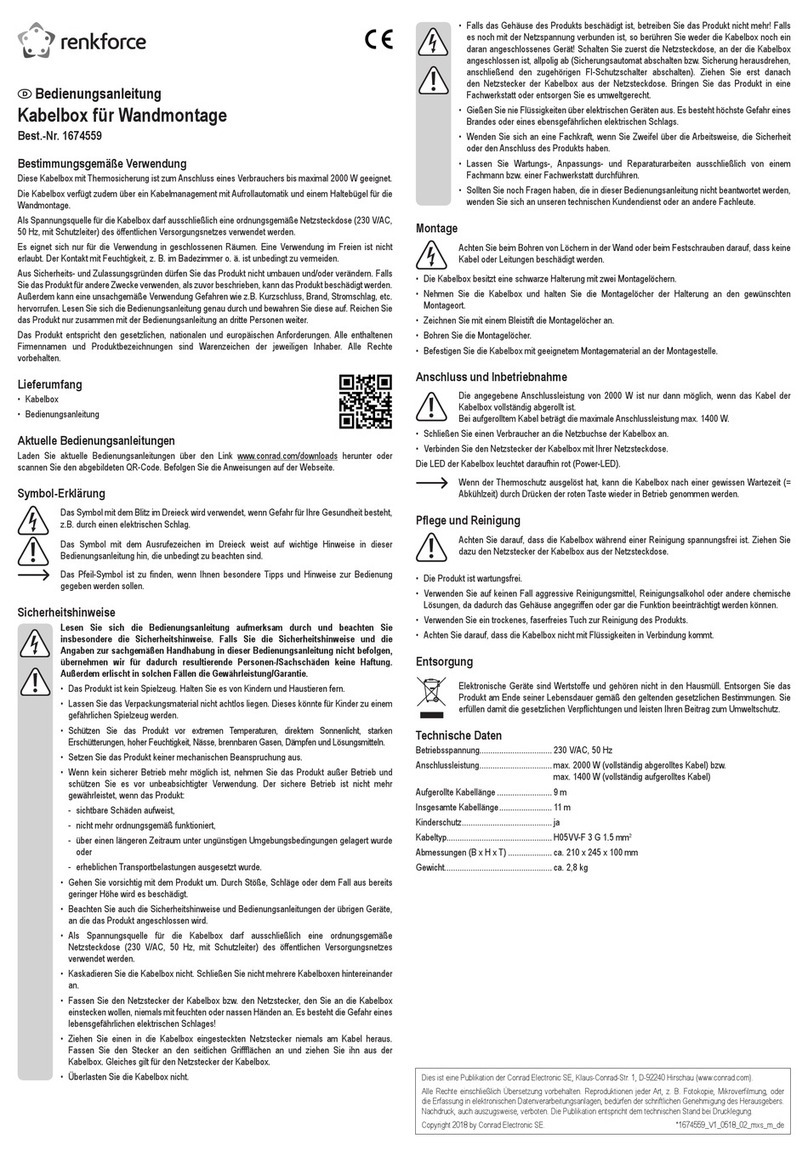

Renkforce

Renkforce 1674559 operating instructions

Minebea Intec

Minebea Intec PR 6130/64Sa installation manual

KS Tools

KS Tools efuturo Wallbox operating instructions

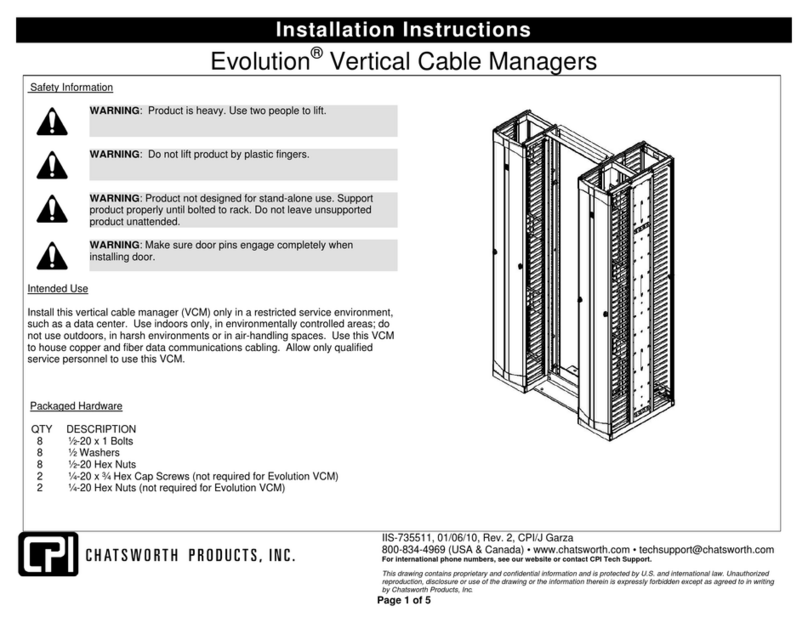

Chatsworth Products

Chatsworth Products Evolution installation instructions