Sovereign Simplicity 572-3212H User manual

5»/mii//cily

SOVEREIGN

RIDING

TRACTORS

HYDROSTATIC

DRIVE

m

I

1

f

iiiiii

1

,

1970

PRODUCTION

YEAR

Mfrs.

No.

572-3212H

MANUAL

LIFT

Mfrs.

No.

573-3212H

POWER

LIFT

SIMPLICITY

MANUFACTURING

COMPANY

UTHO

W

U.lA

Should

warranty

service

lie

necessary,

the

Information

below

should

be

presented

to

the

author¬

ised

SIMPLICITY

Dealer.

Customers

Name_

Address

_

Mtfj.

No._Serial

No._

DilLu

J

*urt:hnsui

I_

I’urL'hj^l

KfOm_

Address_

_

_____

.

^nj^ini'

Model

No._Serial

No.

_

_

_

_

T

ype

No._

To

oirtain

nupiucemiml

parts

from

dealer,

advise

quantity,

part

number

and

description.

Re

*

e

m

b

*'

i

i

FOR

YOUR

SAFETY

]

ALWAYS

STOP

ENGINE

BEFORE

LEAVING

MACHINE

2

ALWAYS

STOP

ENGINE

BEFORE

SERVICING

OR

ADJUSTING

MACHINE

OR

EQUIPMENT

y

ALWAYS

KEEP

HANDS,

FEET

AND

CLOTHING

AWAY

FROM

POWER-DRIVEN

PARTS

i

i

LJ

PACKING

This

tractor

is

delivered

complete

in

one

car-

ion.

Thecarlori

contains:

1

-

Tractor

Assembly

1

-

Steering

Wheel

(in

skin

pack)

1

-

Hardware

Pack

Should

any

shortages

of

the

above

items

oc-

cur,

advise

by

stating

packers

number

listed

on

green

packing

slip,

serial

number

of

tractor,

part

number

and

description

of

items

missing.

ASSEMBLY

BATTERY

Remove

battery

from

tractor.

Service

as

stated

in

the

battery

instructions.

Replace

and

secure

battery

in

tractor.

STEERING

WHEEL

Assemble

steering

wheel

on

the

steering

shaft

using

the

woodruff

key

and

setscrew

which

is

pro¬

vided

in

the

hardware

pack.

Assemble

steering

cap

over

hub

of

steering

wheel.

SHORT

TIME.

A

funnel

and

extension

are

included

with

the

tractor

for

use

in

changing

oil.

The

bevel

gear

housing

has

a

capacity

of

one

pint

of

5AE

90

oil

and

is

filled

at

the

factory.

It

will

not

normally

require

replenishment,

but

occa¬

sionally

check

drain

plug

for

tightness

and

oil

seals

for

leakage.

Keep

oil

up

to

level

of

filler

plug-

See

Figure

8.

TRACTOR

LUBRICATION

The

tractor

has

a

total

of

3

grease

fittings

which

require

Lubrication

with

general

purpose

au¬

tomotive

grease.

Use

a

standard

grease

gun

for

the

following

fittings:

(2)

Front

Spindles

(1)

Rear

Axle

Tube

Before

lubricating,

wipe

each

grease

fitting

with

a

rag

to

prevent

grit

and

dirt

from

being

car¬

ried

into

bearings

with

new

grease.

ENGINE

LUBRICATION

Service

air

cleaner

and

crankcase

as

recom¬

mended

in

FngincService

Manual.

Be

sure

air

clean¬

er

is

maintained

in

dean

condition.

Never

use

oil

in

crankcase

for

more

than

25

hours

of

operation.

See

Figure

It.

CLEAN

AIR

AND

CLEAN

ENGINE

OIL

WILL

GIVE

LONG

TROUBLE

FREE

OPER¬

ATION.

DIRT

WILL

RUIN

VOUR

ENGINE

IN

A

The

transmission

hasa

capacity

of

1-1/2

qts.

of

SAE90

oil

and

is

filled

at

the

factory.

It

will

not

normally

require

replenishment,

but

occasionally

cheek

drain

plug

for

tightness

and

axle

tube

oil

seals

for

leakage.

Maintain

oil

level

at

lower

edge

of

fill¬

er

plug

hole.

Remove

vent

plug

from

top

of

trans¬

mission

and

allow

oil

to

settle

to

normal

Level

be¬

fore

checking.

See

Figure

7.

GREASE

FITTING

ROLLER

BEARING

ft...

In

hctaiY

irtnd.

At

list

vtiilv,

dtan

and

rapack

with

buring

petit,

GREASE

FITTING

l\

LUBRICATION

POINTS

FIGURES

1

TO

G

DELETED

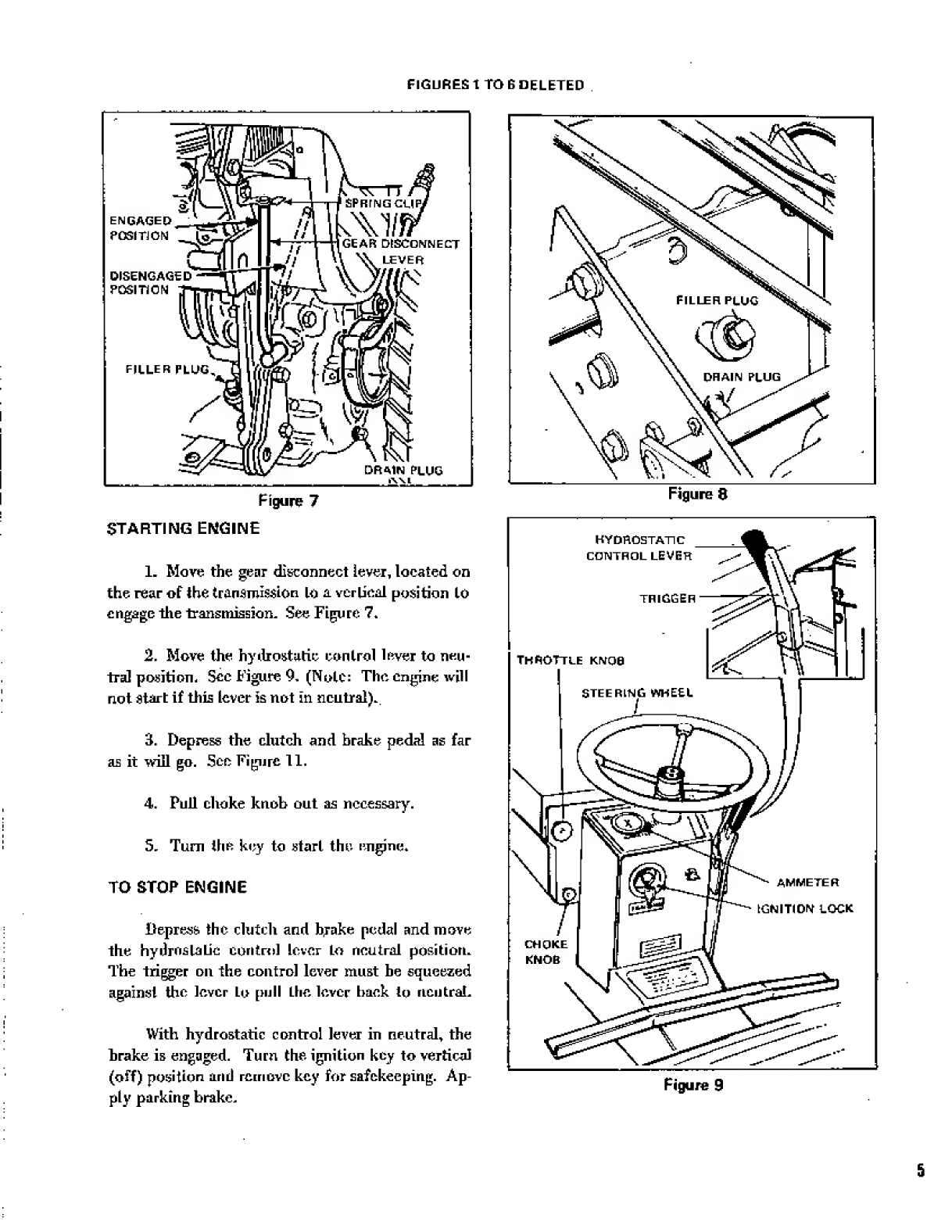

Figure

7

STARTING

ENGINE

1.

Move

the

gear

disconnect

lever,

located

on

the

rear

of

the

transmission

Lo

a

vertical

position

to

engage

the

transmission-

See

Figure

7*

2.

Move

the

hydrostatic

control

lever

to

neu¬

tral

position-

Sec

Figure

9.

(Note:

The

engine

will

not

start

if

this

lever

is

not

in

neutral).

3.

Depress

the

clutch

and

brake

pedal

as

far

as

it

will

go.

See

Figure

11.

4.

Pull

choke

knob

out

as

necessary.

5.

Turn

the

key

to

start

the

engine*

TO

STOP

ENGINE

Depress?

the

dutch

and

b,rake

pedal

and

move

the

hydrostatic

con

in

>1

lever

Lo

neutral

position.

The

trigger

on

the

control

lever

must

be

squeezed

against

the

lever

to

pull

the

lever

back

to

neutral.

With

hydrostatic

control

lever

in

neutral,

the

brake

is

engaged.

Turn

the

ignition

key

to

vertical

(off)

position

and

remove

key

for

safekeeping.

Ap¬

ply

parking

brake.

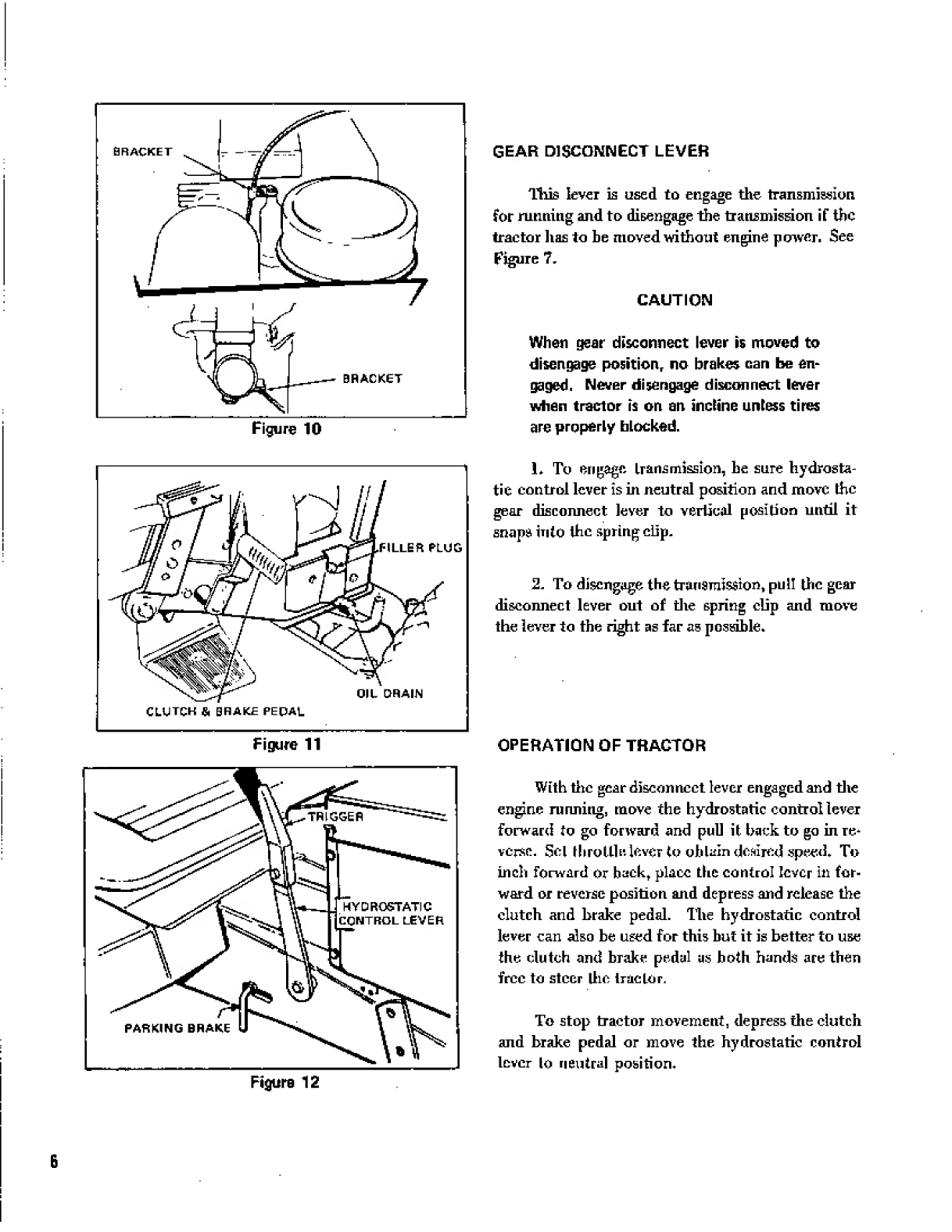

Figure

8

Figure

9

5

BRACKET

GEAR

DISCONNECT

LEVER

lliis

lever

is

used

to

engage

the

transmission

for

running

and

to

disengage

the

transmission

if

the

tractor

lias

to

be

moved

without

engine

power.

See

Figure

7,

CAUTION

When

gear

disconnect

lever

is

moved

to

disengage

position,

no

brakes

can

be

en¬

gaged.

Never

disengage

disconnect

lever

when

tractor

is

on

an

incline

unless

tires

are

properly

blocked.

L

To

engage

transmission,

he

sure

hydrosta¬

tic

control

lever

is

in

neutral

position

and

move

the

gear

disconnect

lever

to

vertical

position

until

it

snaps

into

the

spring

clip.

2.

To

disengage

the

transmission,

pull

the

gear

disconnect

lever

out

of

the

spring

clip

and

move

the

lever

to

the

right

as

far

as

possible.

Figure

11

Figure

12

OPERATION

OF

TRACTOR

With

the

gear

disconnect

lever

engaged

and

the

engine

running,

move

the

hydrostatic

control

lever

forward

to

go

forward

and

pull

it

back

to

go

in

re¬

verse.

Sol

throttle

lover

to

oh

lain

desired

speed.

To

inch

forward

or

back,

place

the

control

lever

in

for¬

ward

or

reverse

position

and

depress

and

release

the

clutch

and

brake

pedal.

The

hydrostatic

control

lever

can

also

he

used

for

this

but

it

is

better

to

use

the

dutch

and

brake

pedal

as

both

hands

are

then

free

to

steer

ihc

tractor.

To

stop

tractor

movement,

depress

the

clutch

and

brake

pedal

or

move

the

hydrostatic

control

lever

lo

neutral

position.

6

CLUTCH

ADJUSTMENT

If

the

tractor

creeps

forward

or

back

when

the

hydrostatic

control

Lever

is

in

neutral,

the

turn-

buckle

on

the

control

linkage

should

he

adjusted.

See

Figure

13.

Loosen

the

locknuts

at

each

of

the

turnbtmklcs

and

rotate

the

tumbucfcle

clockwise

or

counter¬

clockwise

as

necessary

until

the

tractor

does

not

creep.

Re

tighten

the

locknuts

using

Lwo

wrenches

so

turn

buckle

will

110

L

Lie

moved

and

observe.

tractor

to

he

sure

it

does

not

creep.

Readjust

if

necessary.

BRAKE

ADJUSTMENT

The

brake

sLiouLd

he

adjusted

to

provide

full

braking

when

the

clutch

brake

pedal

is

completely

depressed.

Place

the

hydrostatic

control

lever

in

neutral

position.

Repress

clutch

L>rake

pedal

completely

and

turn

the

brake

band

adjusting

nut

until

the

brake

band

is

tight

against

the

brake

drum.

See

Fig¬

ure

13.

HYDRAULIC

SYSTEM

MAINTENANCE

To

be

sun

1

of

satisfactory

performance

it

is

important

thal

flic

hydraulic

oil

is

kept

absolutely

dean

and

that

the

level

of

oil

in

the

oil

reservoir

be

maintained.

See

Figure

13,

Before

checking

the

hydraulic

oil

level,

be

sure

the

outside

of

the

hydraulic

oil

reservoir

is

clean

end

no

debris

will

enter

the

reservoir.

(llicck

hydraulic

oil

level

hy

removing

Mir

in¬

spection

plug

on

thr

side

and

near

the

tup

of

the

reservoir.

If

oil

runs

out

of

Mu-

bole,

the

reservoir

is

full

and

the

plug

should

be

replaced.

IF

oil

does

not

rim

out

of

the

hole,

replace

the

in

spec

I

ion

plug,

remove

the

nut

and

cover

from

lop

of

the

reservoir

and

add

oil

to

the

reservoir

until

it

reaches

I

he

level

BRAKE

BAND

ADJUSTING

NUT

Figure

13

of

the

inspection

plug,

Use

only

Uexron

A.T,F.

{Automatic

Transmission

Fluid)

which

is

available

locally

from

several

major

oil

companies.

Capacity

of

Mir

System

is

1-3/4

quarts,

A

Tier

every

five

(5)

hours

of

operation

(more

often

in

dusty

conditions)

remove

the

snap-oul

plug

from

the

fan

and

oil

cooler

housing

and

clean

fan

and

housing

with

air

or

wafrr

under

pressure.

Replace

the

plug

hy

pressing

it

unto

the

hole.

The

hydraulic

uEl

filler

in

the

bottom

of

the

reservoir

has

lo

lie

changed

only

when

dirt

gets

info

the

hydraulic

oil

in

the

reservoir.

To

change

flic

filter,

remove

the

nut

and

cover

from

lop

of

reser¬

voir,

Have

a

container

ready

to

catch

the

oil

and

disconnect

one

of

the

hoses

at

the

hoi

lorn

of

the

oil

reservoir,

Raise

the

end

of

the

hose

and

tie

it

up

so

oil

will

not

run

out

of

the

transmission.

Drain

the

oil

from

the

reservoir

into

the

container.

Remove

the

111

ter

and

replace

with

a

new

one-

Add

Dexron

Automatic

Transmission

Fluid

to

the

reservoir

up

Lo

the

level

of

the

inspection

plug.

Re¬

place

the

cover

and

nut

on

the

reservoir.

7

DIFFERENTIAL

The

tractor'is

equipped

with

a

controlled

trac¬

tion

differential.

Tightening

the

hex

head

capserews

in

the

right

hand

wheel

huh

(See

Figure

14.),

pro¬

vides

pressure

against

a

nylon

plug

and

sleeve

around

the

tractor

axle

and

prevents

excessive

wheel

slip¬

page

when

the

tractor

is

being

used

under

abnormal

conditions

The

adjusting

capscrews

are

set

at

the

factory

to

a

torque

of

25

ft.

lbs-

As

the

nylon

sets

itself

tlirough

use,

it

may

he

necessary

to

readjust

the

capscrews

a

few

times

to

maintain

25

ft.

lbs.

of

torque

(25

lbs.

weight

on

wrench

1

ft,

long).

ADJUSTING

CAPSCREWS

RIGHT

HAND

WHEEL

HU&Sr

CAUTION

DO

NOT

APPLV

MORE

THAN

30

FT.

LBS*

TO

THE

ADJUSTING

CAPSCREWS1

Figure

14

POWER

TAKE-OFF

LUBRICATION

TTie

power

take-off

is

lubricated

by

means

of

one

grease

fitting

located

on

the

bottom

front

of

the

drive

bracket

assembly*

Occasionally

apply

grease

by

means

of

a

standard

grease

gun

loaded

with

automotive

type

grease.

Be

sure

to

wipe

dirt

and

grit

from

grease

fitting

before

applying

grease

gun.

Lubricate

all

pivot

points

and

idler

pulley

bearings

with

SAE

20

oil

every

few

hours

of

opera¬

tion.

OPERATION

Operation

of

the

power

take-off

is

controlled

by

movement

of

the

dutch

lever

assembly.

See

Fig¬

ure

15.

When

the

dutch

lever

is

in

the

forward

raised

position,

the

clutch

rod

releases

the

tension

holding

the

idler

pulley

against

the

drive

bell

and

power

will

not

be

transmitted

to

the

driven

pulley

of

the

power

take-off

assembly.

When

the

dutch

lever

is

in

the

back,

depressed

position,

lhe

clutch

rod

applies

tension

to

the

idler

pulley

and

as

the

id¬

ler

pulley

takes

up

the

stack

in

the

drive

belt,

power

is

transmitted

from

the

drive

pulley

on

bevel

gear

box

shaft

to

the

driven

pulley

of

the

power

take¬

off-

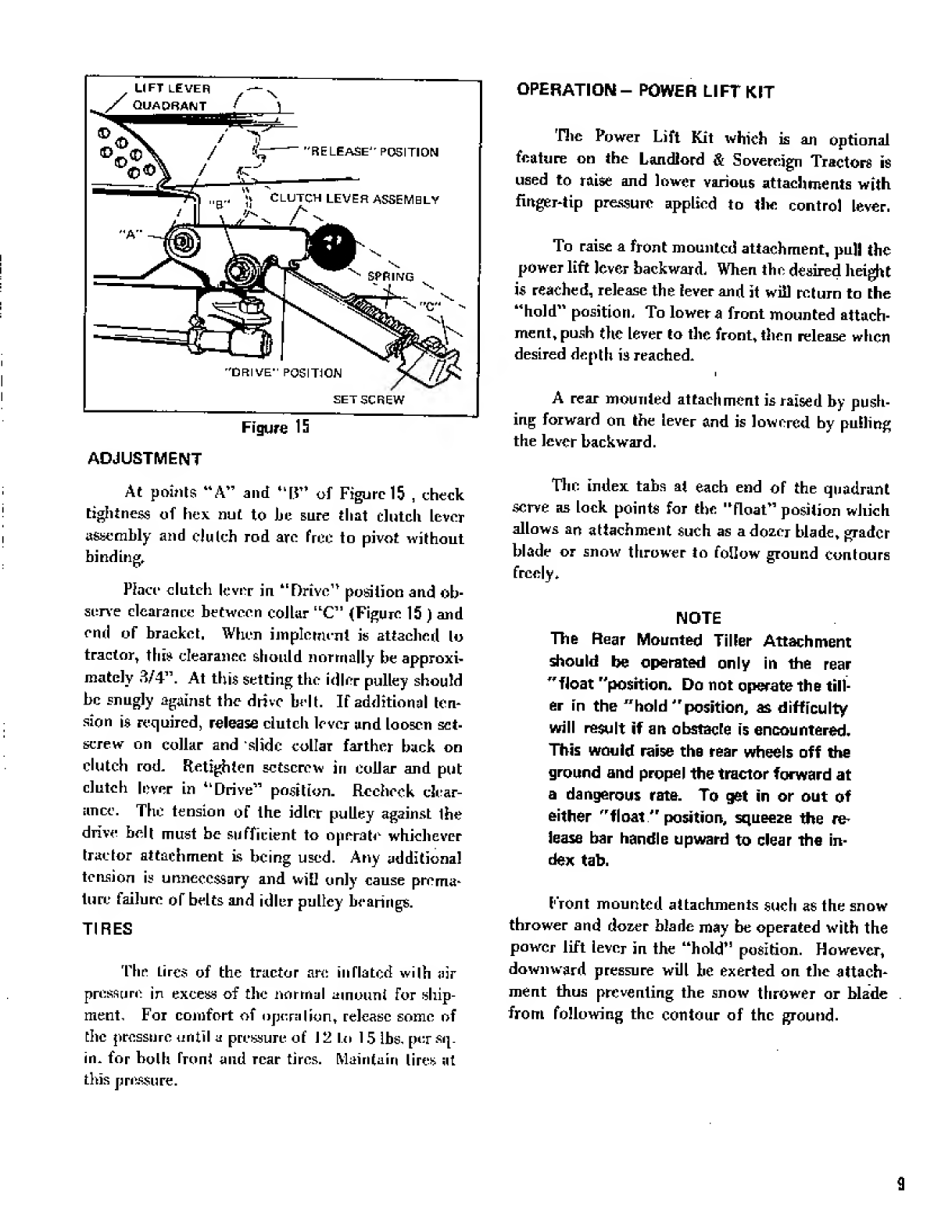

Figure

15

shows

clutch

lever

in

drive

position*

|___

SET

SCREW

Figure

15

ADJUSTMENT

At

points

“A”

and

“li”

of

Figure

15

,

check

tightness

of

hex

nut

to

be

sure

that

clutch

lever

assembly

and

clulch

rod

are

free

to

pivot

without

binding.

Place

clutch

lever

in

“Drive

1

*

position

and

ob¬

serve

clearance

between

collar

“C”

(Figure

15

)

and

end

of

bracket.

When

implement

is

attached

lo

tractor,

this

clearance

should

normally

be

approxi¬

mately

3/4”.

At

this

setting

the

idler

pulley

should

be

snugly

against

the

drive

belt.

If

additional

tern

sion

is

required,

release

clutch

lever

and

loosen

set¬

screw

on

collar

and

slide

collar

farther

back

on

dutch

rod.

Ftetighien

setscrew

in

collar

and

put

clutch

lever

in

“Drive”

position.

Rccbeek

clear¬

ance.

The

tension

of

the

idler

pulley

against

ihe

drive

belt

must

be

sufficient

to

operate

whichever

tractor

attachment

is

being

used.

Any

additional

tension

is

unnecessary

and

will

only

cause

prema¬

ture

failure

oT

belts

and

idler

pulley

bearings.

TIRES

The

tires

of

the

tractor

are

inflated

with

air

pressure

in

excess

of

the

normal

amount

for

ship¬

ment,

For

comfort

of

opera

I

ion,

release

some

of

the

pressure

until

a

pressure

of

1

2

In

15

lbs,

per

sq.

in.

for

both

front

and

rear

tires.

Maintain

lires

at

this

pressure.

OPERATION-

POWER

LIFT

KIT

r

Hic

Power

Lift

Kit

which

is

an

optional

feature

on

the

Landlord

&

Sovereign

Tractors

is

used

to

raise

and

lower

various

attachments

with

finger-tip

pressure

applied

to

tlic

control

lever.

To

raise

a

front

mounted

attachment,

pull

the

power

lift

lever

backward.

When

the

desired

height

is

reached,

release

the

lever

and

it

will

return

to

the

“hold"

position.

To

lower

a

front

mounted

attach¬

ment,

push

tire

lever

to

the

front,

then

release

when

desired

depth

is

reached.

I

A

rear

mounted

attachment

is

raised

by

push¬

ing

forward

on

the

lever

and

is

lowered

by

pulling

the

lever

backward.

The

index

tabs

at

each

end

of

the

quadrant

serve

as

lock

points

for

the

“float”

position

which

allows

an

attachment

such

as

a

dozer

blade,

grader

blade

or

snow

thrower

to

follow

ground

contours

freely,

NOTE

The

Rear

Mounted

Tiller

Attachment

should

be

operated

only

in

the

rear

"float

"position.

Do

not

operate

the

till¬

er

in

the

"hold

"position,

as

difficulty

will

result

if

an

obstacle

is

encountered.

This

would

raise

the

rear

wheels

off

the

ground

and

propel

the

tractor

forward

at

a

dangerous

rate.

To

get

in

or

out

of

either

"float

"

position,

squeeze

the

re¬

lease

bar

handle

upward

to

clear

the

in¬

dex

tab.

E'ront

mounted

attachments

such

as

the

snow

thrower

and

dozer

blade

may

be

operated

with

the

power

lift

lever

in

the

“hold”

position.

However,

downward

pressure

will

he

exerted

on

tire

attach¬

ment

thus

preventing

the

snow

thrower

or

blade

from

following

the

contour

of

the

ground.

9

O

yn,-

-

i

“K

SO

l

«^7

/

/

/

/

L

_

/

"7,

A*

r

t

//

wA-a

4

/

/

/

$L

_

s"

/

/

/

^Aj;

a

/

/

/

j8\

/

v

/,

7"

5

/

r

<hj

s

/

<44

^

/

°

-

\

\

V

l

j

)

^

'

i-u,

■

\

\

y

i

/

*3

\

Tx

\

/

5^'.

;

\

S£wT

A-^

/

-"XMh/

,

/

_^v

\K$'

;

I

.'Mf

X'

u

or

<6

/

(

£

j

C

A

visrsx

4

uiOVfi

ThIZ

o

J

J

14

^

JO,

£^

u

i

“Q*J"

*

u

HI

Hi

<J

u

>

-5**

«

1U

■

?

i-

-1

O

Otu>-

™

LU

■

*.

,^oo

U

T

^

IT

III

4

^

^

s

G_

K

BC

si-

t

i_

1

ij

ji

w

.

rs

b

ii

h

>

-T^

h

t-ILLL^h

ORDER

fir

PART

DUMBER

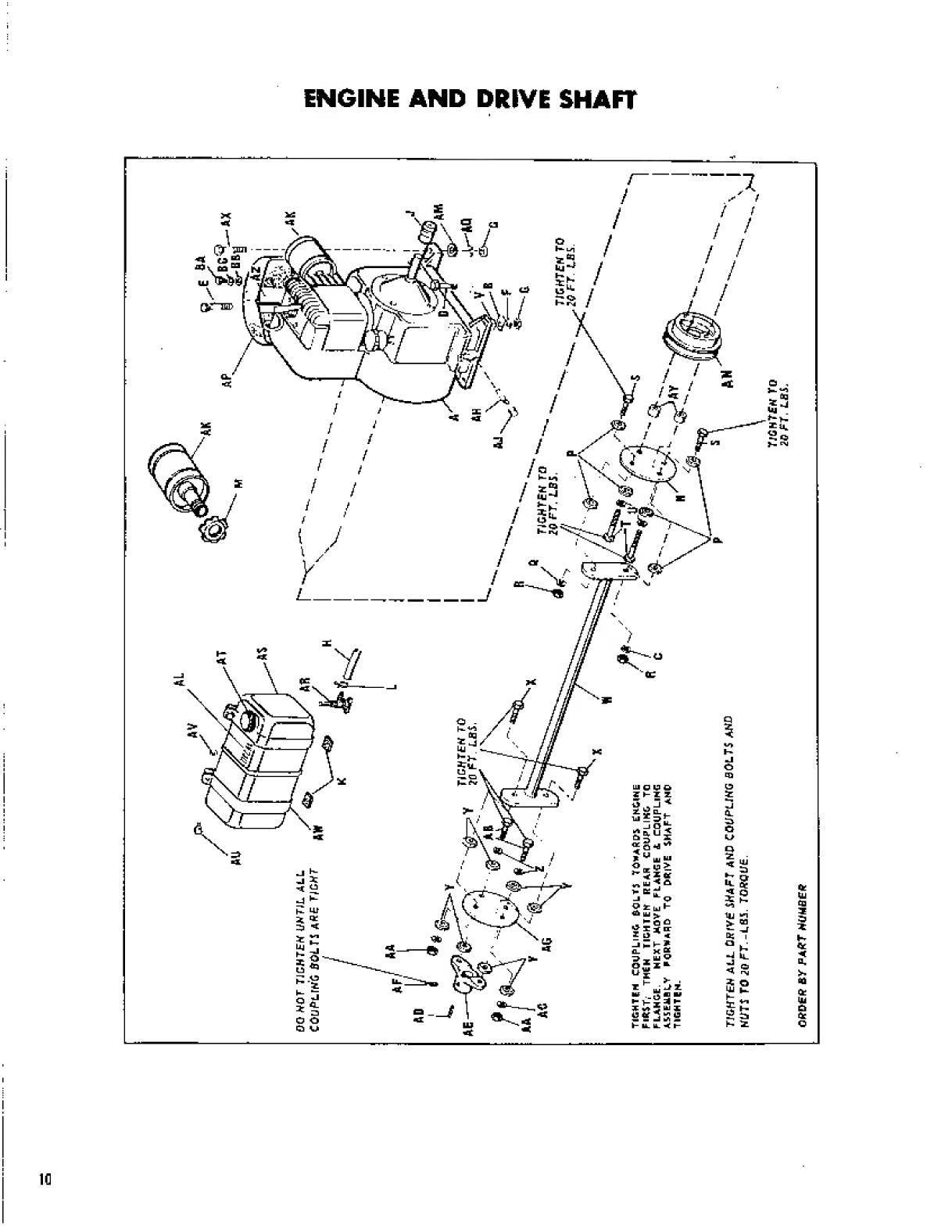

ENGINE

AND

DRIVE

SHAFT

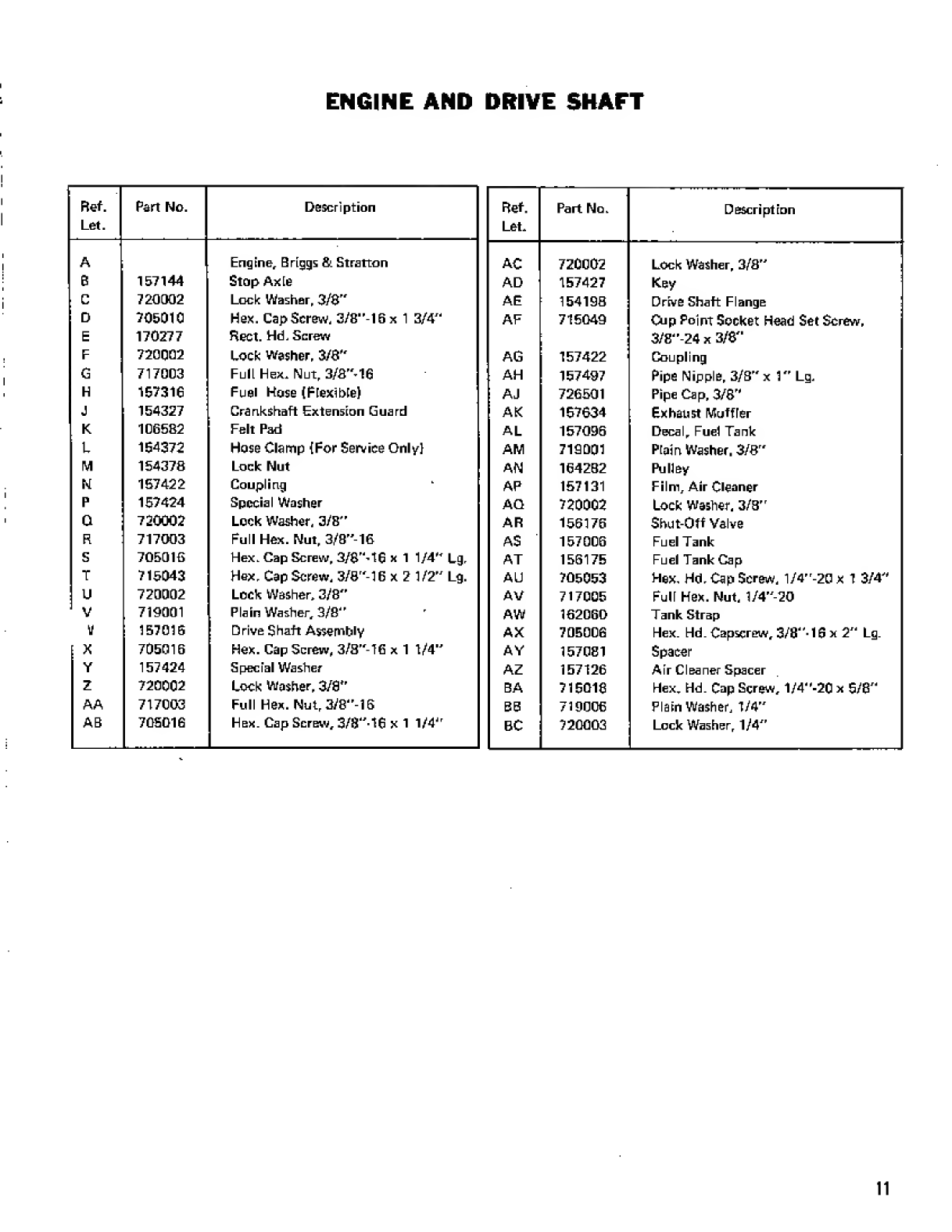

Ref.

Let.

Part

No.

Description

A

Engine,

Briggs

&

Stratton

B

157144

Stop

Axie

C

720002

Lock

Washer,

3/8"

D

705010

Hex.

CapScrew,

3/8"-16x

1

3/4"

E

170277

Rect.

Hd,

Screw

F

720002

Lock

Washer,

3/8"

G

717003

Full

Hex.

Nut,

3/8^16

H

157316

Fuel

Hose

(Flexible)

J

154327

Crankshaft

Extension

Guard

K

106582

Felt

Pad

L

154372

Hose

Clamp

(For

Service

Only)

M

154378

Lock

Nut

N

157422

Coupling

P

157424

Special

Washer

G

720002

Lock

Washer,

3/B"

R

717003

Full

Hex.

Nut,

3/8"-16

S

705016

Hex.

Cap

Screw,

3/8'M6

x

1

1/4"

Lg.

T

715043

Hex.

Cap

Screw,

3/8"-16

x

2

1/2"

Lg.

U

720002

Lock

Washer,

3/8"

V

719001

Plain

Washer,

3/8"

V

157016

Drive

Shaft

Assembly

X

705016

Hex.

Cap

Screw,

3/8"-TG

x

1

1/4"

Y

157424

Special

Washer

z

720002

Lock

Washer,

3/S"

AA

717003

Full

Hex.

Nut,

3/8"-16

AB

705016

Hex.

Cap

Screw,

3/8"-16

x

1

1/4"

Ref.

Let.

Part

No.

Description

AC

720002

Lock

Washer,

3/8"

AD

157427

Key

AE

154198

Drive

Shaft

Flange

AF

715049

Cup

Point

Socket

Head

Set

Screw,

3/8"-24

x

3/8"

AG

157422

Coupling

AH

157497

Pipe

Nipple,

3/B"

x

1"

Lg,

AJ

726501

Pipe

Cap,

3/8"

AK

167634

Exhaust

Muffier

AL

157096

Decal,

Fuel

Tank

AM

710001

Plain

Washer.

3/8"

AN

1642B2

Pulley

AP

157131

Film,

Air

Cleaner

AG

720002

Lock

Washer,

3/B"

AR

156176

Shut-Off

Valve

AS

157006

Fuel

Tank

AT

156175

Fuel

Tank

Cap

AU

705053

Hex,

Hd.

Cap

Screw,

1/4"-20

x

1

3/4"

AV

717005

Fuli

Hex.

Nut,

1/4"-20

AW

162060

Tank

Strap

AX

705006

Hex.

Hd.

Capscrew,

3/8"-16

x

2"

Lg.

AY

157081

Spacer

AZ

157126

Air

Cleaner

Spacer

BA

715018

Hex.

Hd.

Cap

Screw,

1/4"-20

x

5/8"

88

719006

Plain

Washer,

1/4"

BC

720003

Lock

Washer,

1/4"

11

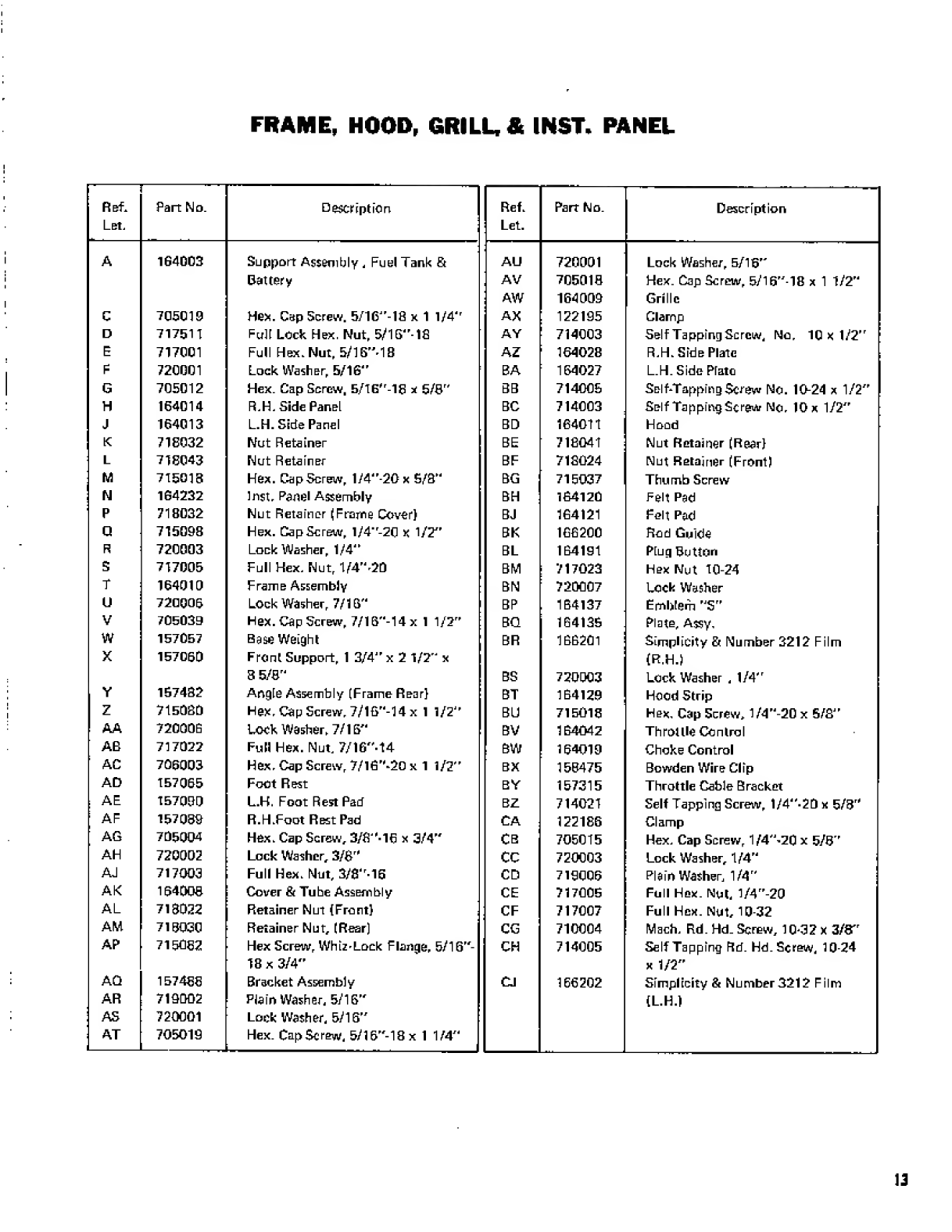

FRAME

iTali

,

GRILL,

&

INST.

PANEL

FRAME,

HOOD,

GRILL,

&

INST.

PANEL

Ref.

Let.

Part

No.

Description

Ref.

Let.

Part

No.

Description

A

1G4003

Support

Assembly

,

Fuel

Tank

fit

AU

720001

Lock

Washer,

5/15"

Battery

AV

705018

Hex.

Cap

Screw,

5/15"-18

x

1

1/2"

AW

164009

Grille

C

705019

Hex.

Cap

Screw.

5/1G"-1fi

x

1

1/4'

r

AX

122195

Clamp

D

717511

Full

Lock

Hex.

Nut,

5/1G"-16

AY

714003

SelfTappingScrew,

No,

10x1/2"

E

717001

Full

Hex.

Nut,

5/16"

18

AZ

164028

R,H.

Side

Plate

F

720001

Lock

Washer,

5/16"

BA

164027

L.H.

Side

Prato

G

705012

Hex.

Cap

Screw,

5/16

Hr

-16

x

5/8"

3B

714005

Self-Tapping

Screw

No.

10-24

x

1/2”

H

164014

R,H,

Side

Panel

BC

714003

Self

Tapping

Screw

No,

10

x

1/2”

J

164013

L.H.

Side

Panel

BD

164011

Hood

K

71E032

Nut

Retainer

BE

71E041

Nut

Retainer

(Rear)

L

71E043

Nut

Retainer

BF

716024

Nut

Retainer

(Front)

M

715013

Hex.

CapScrew,

1/4"-20x

5/3"

BG

715037

Thumb

Screw

N

1G4232

Inst,

Panel

Assembly

BH

164120

Felt

Pad

P

718032

Nut

Retainer

(Frame

Cover)

BJ

164121

Felt

Pad

Q

715098

Hex.

CapScrew,

l/4"-2G

X

1/2"

BK

166200

Rod

Guide

R

720003

Lock

Washer,

1/4"

BL

164191

Plug

Button

S

717005

Full

Hex,

Nut,

1/4"

20

BM

717023

Hex

Nut

10-24

T

164010

Frame

Assembly

BN

720007

Lock

Washer

u

720005

Lock

Washer,

7/16"

BP

164137

Emblem

,J

S”

V

705039

Hex.

Cap

Screw,

7/16"-14xl

1/2”

BQ

164135

Plate,

Assy,

w

157057

Base

Weight

BR

166201

Simplicity

&

Number

3212

Film

X

157050

Front

Support,

1

3/4"

x

2

1/2”

x

(R.H.)

8

5/8"

BS

720003

Lock

Washer

,

1/4"

Y

157432

Angie

Assembly

(Frame

Rear)

BT

164129

Hood

Strip

z

715030

Hex,

Cap

Screw,

7/16"-14

x

1

1/2"

BU

715016

Hex,

Cap

Screw,

1/4"-20

x

S/S"

AA

720005

Lock

Wesher,

7/16"

BV

164042

Throttle

Control

AB

717022

Full

Hex.

Nut,

7/16"-14

BW

154019

Choke

Control

AC

705003

Hex,

Cap

Screw,

7/l6"-20

x

1

1/2"

BX

153475

Bowden

Wire

Clip

AD

157055

Foot

Rest

BY

157315

Throttle

Cable

Bracket

AE

157000

L.H.

Foot

Rest

Pad

BZ

714021

Self

Tapping

Screw,

1/4"-2D

x

5/3"

AF

157030

R.H.Foot

Rest

Pad

CA

122186

Clamp

AG

705004

Hex.

Cap

Screw,

3/fi"-16

x

3/4"

CB

705015

Hex,

Cap

Screw,

1

/4"'2C

x

5/3”

AH

720002

Lock

Washer,

3/8

rH

CC

720003

Lock

Washer,

1/4"

AJ

717003

Full

Hex.

Nut,

3/8"16

CD

719005

Plain

Washer,

1/4”

AK

154003

Cover

&

Tube

Assembly

CE

717005

Full

Hex.

Nut,

1/4”-20

AL

713022

Retainer

Nut

(Front)

CF

717007

Full

Hex.

Nut,

10

32

AM

713030

Retainer

Nut,

(Rear)

CG

710004

Mach,

Rd.Hd.

Screw,

10-32

x

3/8"

AP

715062

Hex

Screw,

Whiz'Lock

Flange,

5/16"-

CH

714005

Self

Tapping

Rd.

Hd.

Screw,

10-24

18

x

3/4"

x

1/2”

AQ

157466

Bracket

Assembly

CJ

166202

Simplicity

St

Number3212

Film

AR

719002

Plain

Washer,

5/16"

(L.H.)

AS

720001

Lock

Washer,

5/16"

AT

705019

Hex.

CapScrew,

5/16

F

'-1Bx

1

1/4

Jd

L—^_,_

1

13

i

!

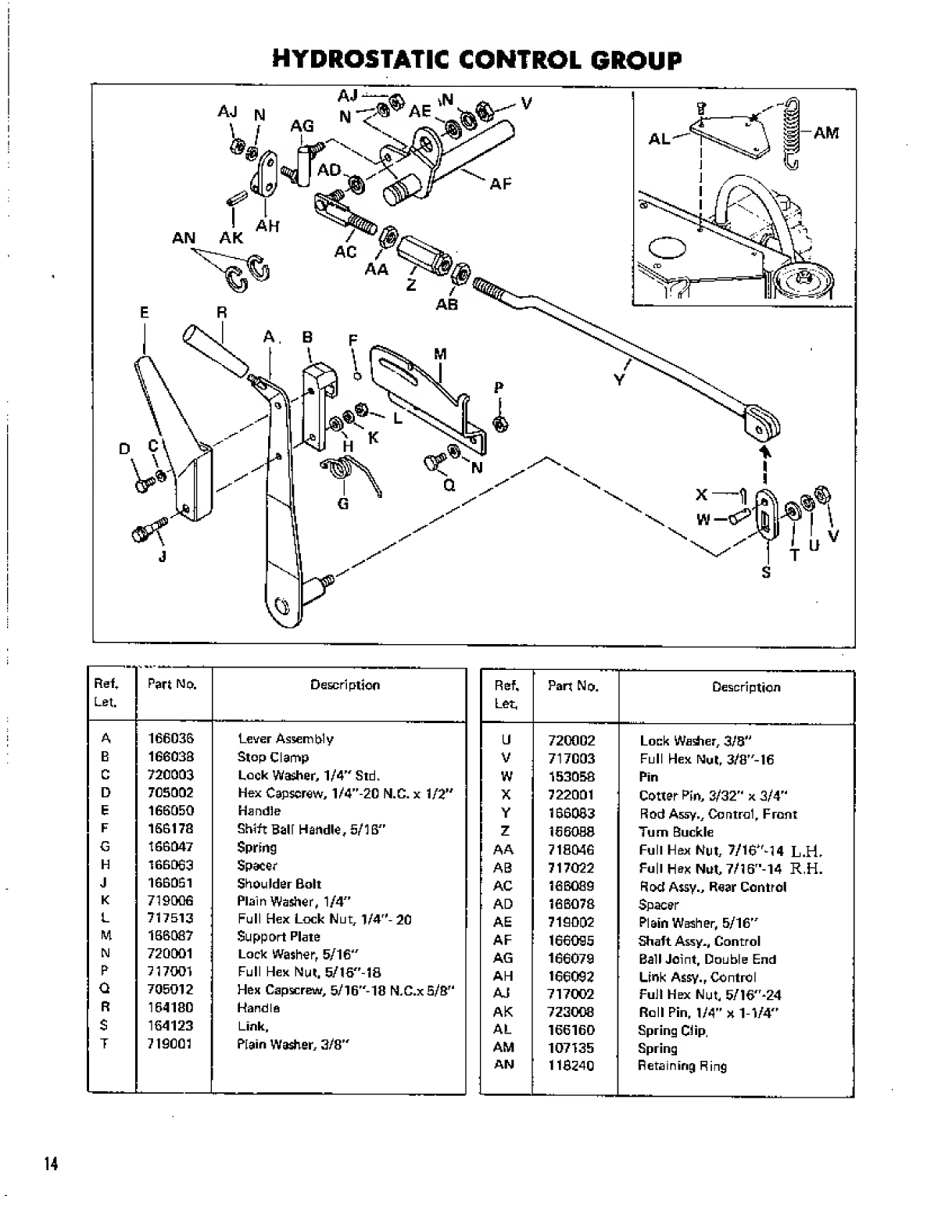

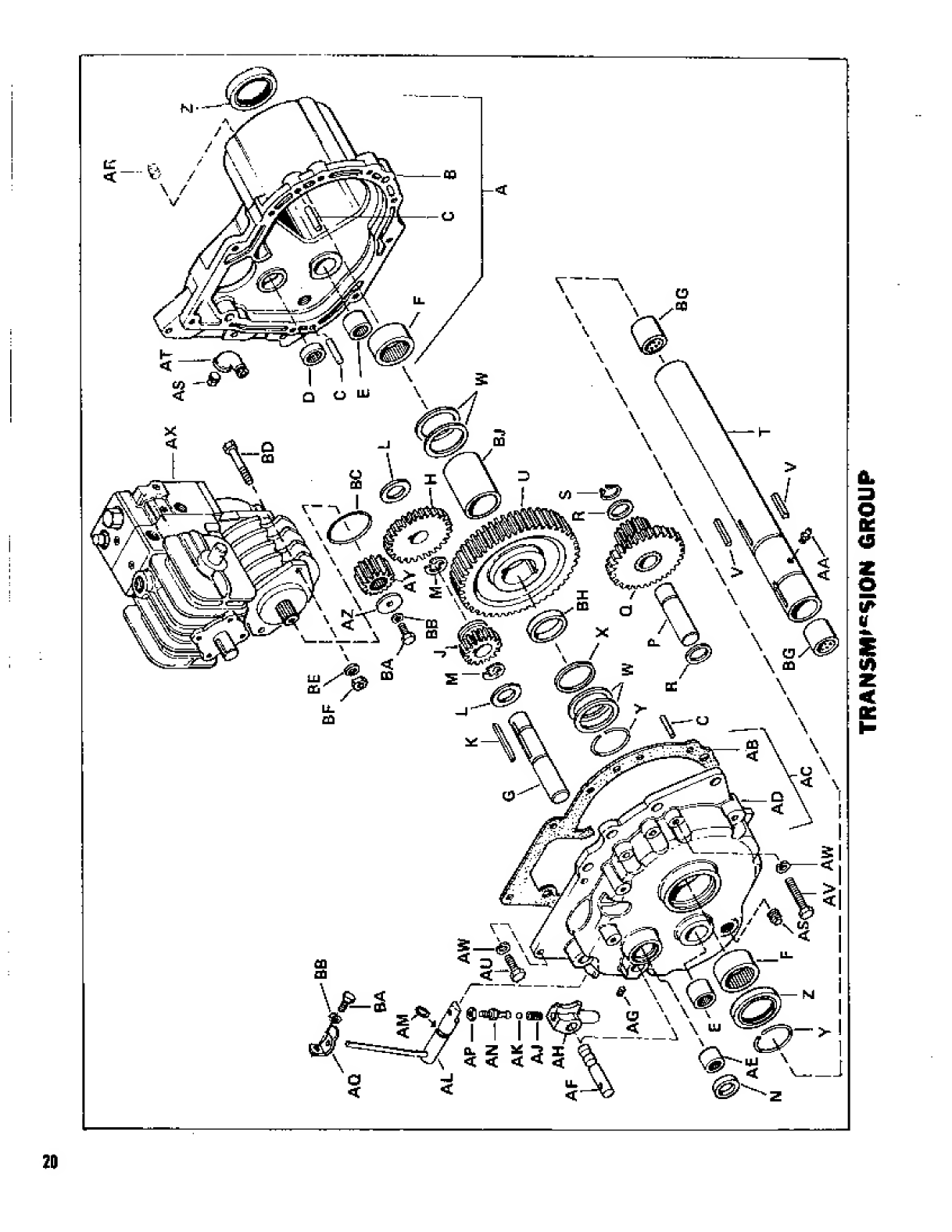

HYDROSTATIC

CONTROL

GROUP

Ref*

Let.

Part

No.

Description

A

166036

Lever

Assembly

E

1G6033

Stop

Clamp

C

720003

Lock

Washer,

1/4"

Std.

D

706002

Hex

Capscrew,

1/4”-20

N.C.

x

1/2"

E

166050

Handle

F

166178

Shift

Ball

Handle,

5/16"

G

166047

Spring

H

166063

Spacer

J

166061

Shoulder

Bolt

K

719006

Plain

Washer,

1/4"

L

717513

Full

Hex

Lock

Nut,

1/4

rH

-

20

M

166087

Support

Plate

N

720001

Lock

Washer,

5/16"

P

717001

Full

Hex

Nut,

5/16"-1B

G

705012

Hex

Capscrew,

5/16"-18

N.C.xS/S"

R

164180

Handle

$

164123

Link,

T

719001

Plain

Washer,

3/8"

Ref*

Part

No.

Description

Let,

U

720002

Lock

Warier,

3/8"

V

717003

Full

Hex

Nut,

3^8"-16

W

153068

Pin

X

722001

Cotter

Fin,

3/32"

x

3/4"

Y

166033

Rod

Assy.,

Control,

Front

z

IS

6088

Turn

Buckle

AA

718046

Full

Hex

Nut,

7/16"

14

L.H.

AB

717022

Full

Hex

Nut,

7/16"-14

R.H.

AC

166089

Rod

Assy.,

Rear

Control

AD

166078

Spacer

AE

719002

Plain

Washer,

5/16"

AF

166095

Shaft

Assy,,

Control

AG

166079

Ball

Joint,

Double

End

AH

166092

Link

Assy.,

Control

AJ

717002

Full

Hex

Nut,

5/16"-24

AK

723008

Roll

Pin,

1/4”

x

1-1/4"

AL

166160

Spring

Clip.

AM

107135

Spring

AN

113240

Retaining

Ring

------J

14

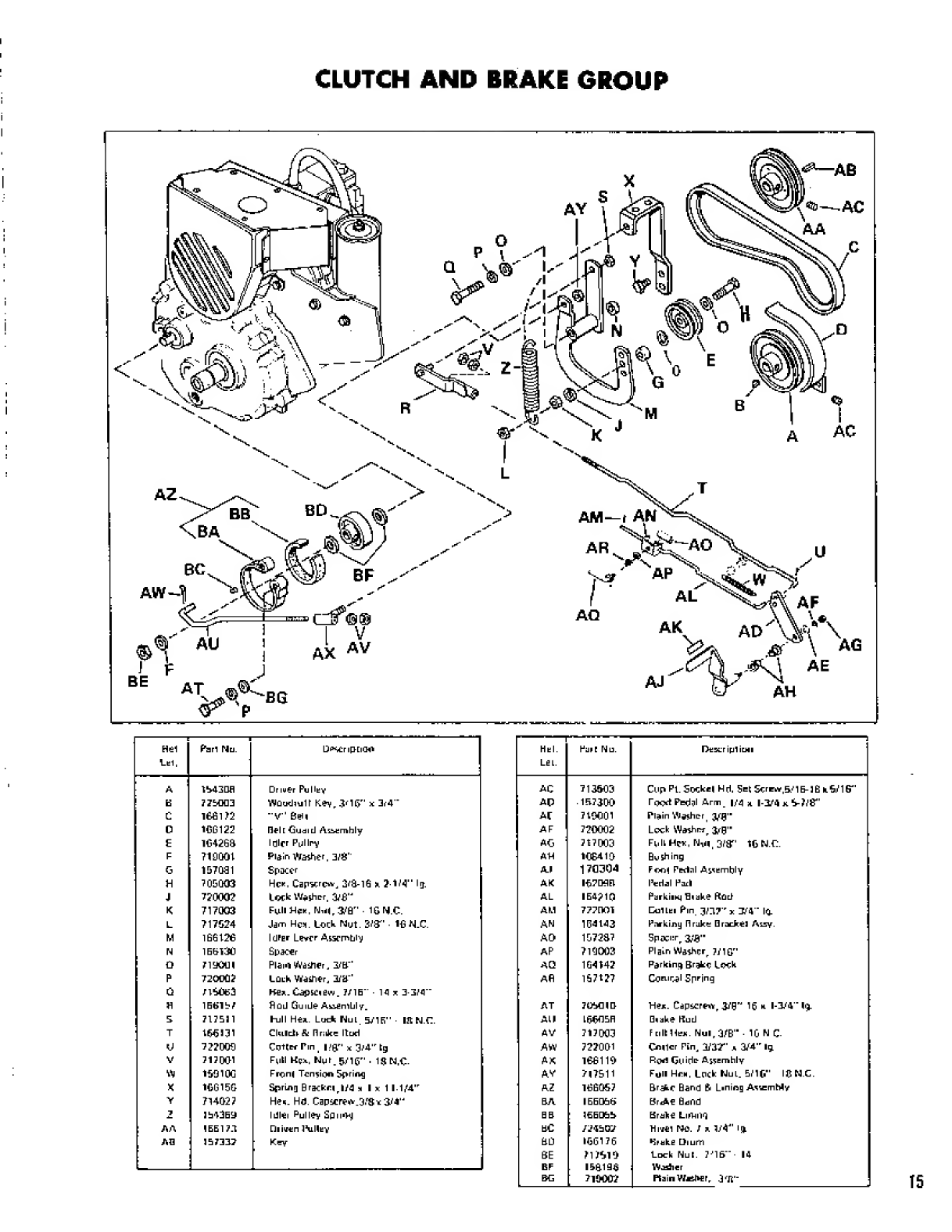

CLUTCH

AND

BRAKE

GROUP

Hel

Lai,

Pirl

Nli.

LJ^riptidO

A

mjDfl

Driver

Pi

May

E

775003

WOudquU

Key,

3'l&

r

'

x

3r4"

C

166172

"V"

OeH

0

16(5122

Belt

Guaid

Aiiemhly

E

16426a

Idler

Pulley

F

719001

Plain

Washer,

3/8"

G

157031

Spacer

H

705003

He*.

Capscrew,

3/3-16

k

2-1/4"

Iff.

J

720002

Lock

Washer,

3/£"

K

717003

FuIiHck,

Nii|,

3/6"

■

1GN.C.

L

717624

Jam

Hcm.

Lock

Nut.

3/3-

■

1GN.C.

M

166126

IdFar

Layer

Assrmtiiy

N

1EE130

Spacer

O

719O0I

Plain

Washer,

3/E"

P

72OO0J

Luuh

Washer,

3/E"

u

716063

Her.

CapSCiew.

771E"

■

14

*

3-3/4”

H

1E6157

Sou

Guide

AnfinlUly.

S

717E11

hull

He*.

Ludk

HuL

57IE"

■

l!t

N.C.

T

166H1

CkLlclrSi

Brake

Itud

V

722009

Cutter

Tin,

|/9

r

'

x

0M

,r

tg

V

717001

Full

Kc*.

Ngr.syic-

.

1SN.C-

W

169100

Front

Tension

Spring

X

166150

Spring

B

racket

,

m

I

x

1

l-1/4

,r

V

714027

Hes.

Ha.

Capserew.B/g

*

3/4"

1E43E9

Idlei

Pul

lev

SpmiHj

A

A

1

EE

17.1

□

liven

IVHey

AD

IE

7337

Key

—

Hal.

Lel.

Fair

Nu.

Dtser

i|ul

imi

AC

713603

Cup

Pi.

Socket

Hd.

Set

Screw,5/

1E-16

b

6/1G"

AP

■

1

E

73DO

rood

Pbdal

Arm_

|/4

a

1-3/4

n

6-7/6"

Ar

716001

Plain

Washer,

3/fl"

AF

720002

Lock

Wisher,

AG

717003

Full

Hck.

Nsn,

3

/gr'

tON.C.

AH

10E410

Bushing

AJ

1

70304

Foot

Fertnl

AssEmhly

AK

I67D9E

l^edal

Foil

AL

IE4J1Q

ParkiiKj

Hiake

Rod

AM

777001

DulLai

Pm

3/37

r

x

324

"

la

AN

104143

Pnrkiisg

Brake

Bracket

Assy.

AO

157237

Spacer,

3vfl"

AP

719003

Plain

Washer,

J/10

r

'

AQ

164142

Parking

Brake

Lock

Afi

157127

Coniral

Spring

AT

J1MIQ

He*.

Capscrew,

3/0"

16

*

1-3/4

"

1

$.

All

1660ER

□

lake

Hud

AV

717003

Frill

He*.

Nul,3/B"

■

10

N

C-

AW

722001

COtlcr

Pin,

'HW

*

3/4

,r

Ig

AK

166110

Rovl

Gtiidc-

AsSEmhly

AV

717511

Foil

Hon,

Lock

NuL.

5/If

ICN.C.

AZ

166067

Brake

Band

6

Lining

AssemMy

BA

IEED66

BrJkE

Hdi’id

BE

10E066

Brake

LuViii'd

EC

/24BE7

HivEI

NO.

7

r.

1/4"

lj

ED

160176

*3rabE

DiuiTi

SE

717610

Luck

Nur.

7-

,

1

6

”

■

14

BF

150196

W

jailer

EG

710002

Plain

Wester,

3

f

Jl'"

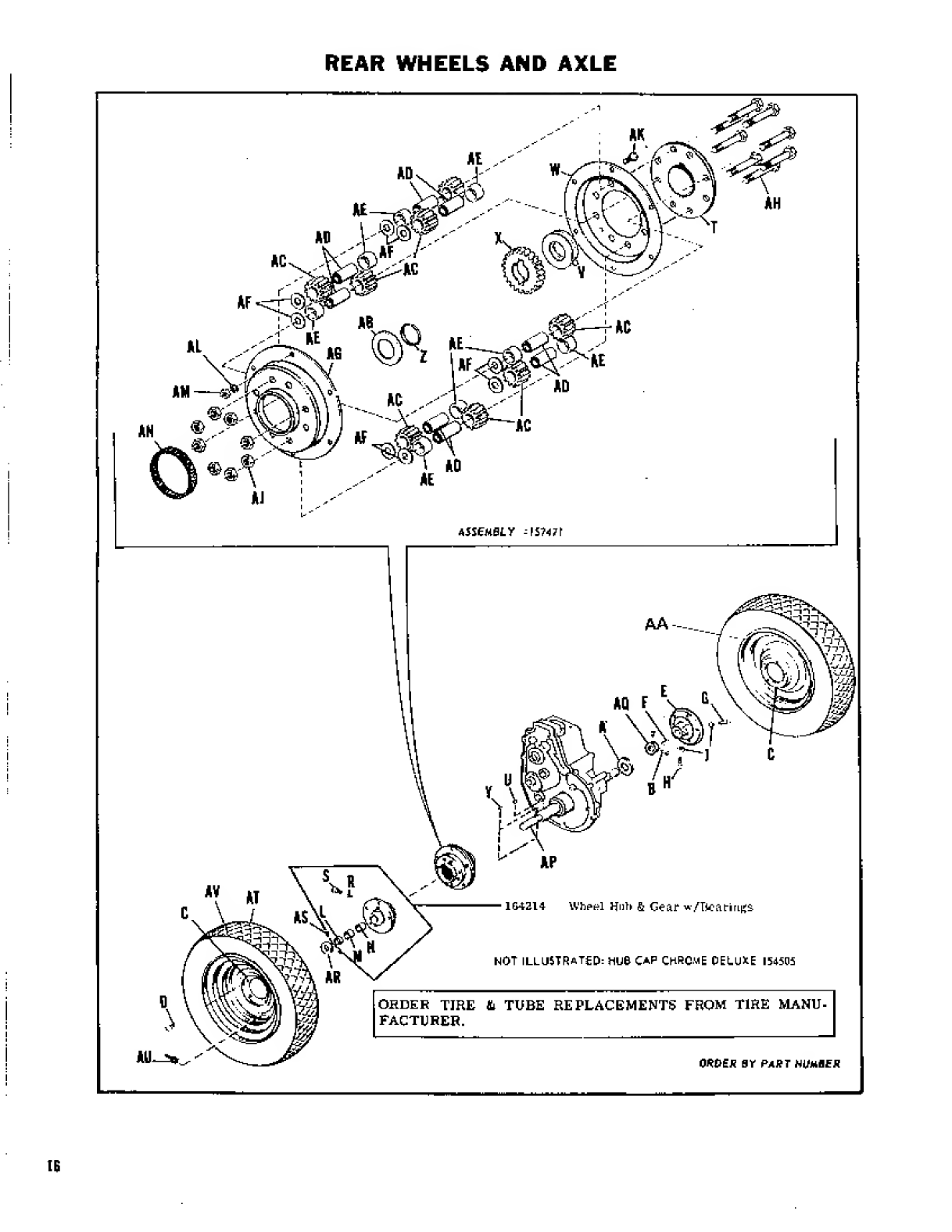

REAR

WHEELS

AND

AXLE

s\f

\"4

H

f

v

w\

164214

\Vhpt?l

Hub

fi

Gear

w/Bearings

NOT

ILLUSTRATED:

HUG

CAP

CHRC.uE

DELUDE

154505

;

ORDER

TIRE

&

TUBE

REPLACEMENTS

FROM

TIRE

MANU¬

FACTURER.

OWES

BY

PART

HUMBER

REAR

WHEELS

AND

AXLE

Ref.

Let.

Part

No.

Description

A

105050

Washer

B

713002

Set

Screw,

5/16"-18

X

3/8"

Lg.

C

170278

Wheel

Drive

D

131138

Hub

Bolt

E

154208

LH

r

Wheel

Hub

F

159129

Key

G

715022

Set

Screw,

3/8"-16

x

1

1/2"

Lg.

K

7T3004

Set

Screw

3/8"-16

x

1"

Lg.

J

717021

Hex.

Jam

Nut,

3/8"-16

i_

10505B

Bearing

M

152041

Nylon

Bearing

N

153083

Bearing

R

152042

Nylon

Plug

5

713508

Control

Traction

Bolt,

7/16"'20

x

1/2"

Lg.

T

164217

Differential

Carrier

U

157120

Drive

Key

V

154035

Axle

Washer

w-

1G4213*

Differential

Cover

X

1G4219

Differential

Gear

Y

725501

Hi-Pro

Key

z

154291

Retaining

Ring

AA

157638

Tube

(For

Service

Only)

AB

154277

Axle

Washer

AC

121311

Differential

Pinion

AD

1210B3

Pinion

Differential

Spindle

AE

1210B4

Differential

Spacer

AF

719002

Plain

Washer

AG

16422

(T

Differential

Cover

AH

715043

Hox.

Cap

Screw,

3/8"

1G

x

2

1/2”

AJ

717510

Full

Lock

Hex.

Nut,

3/8"-16

AK

705015

Hex.

Cap

Screw,

1/4"-2C

x

5/8"

AL

720003

Lock

Washer,

1/4"

AM

717005

Full

Hex,

Nut,

1/4"^20

AN

T21190

Differential

Cover

Seal

AP

164221

Rear

Axle

AQ

154055

Axle

Collar

AR

154065

Axle

Collar

AS

713002

Set

Screw,

5/1G"-18

x

3/8"

AT

157637

Tire

10

1/2"

x

12

AU

157020

Valve

Stem

AV

170280

Wheel

&

Tire

Assy.

—-CAUTION

'

‘

‘

-—

-

DO

NOT

EXCEED

2&ft.

POUNDS

OF

TORQUE

ON

PART

NUMBER

7135CS.

REFERENCE

LETTER

(5},

CONTROL

TRACTION

BOLTS.

Reference

let

Cert

"W"

and

m

A

g"

must

be

replaced

in

pairs

if££JfJNC

GEAR

CLEARANCE

ADJUSTHENT

FRONT

WHEELS,

AXLE,

TIE

ROD

&

STEERING

FRONT

WHEELS,

AXLE,

TIE

ROD

&

STEERING

Ref.

Let.

Part

No.

Description

A

157505

Wheel

and

Tire

Assembly

B

154307

Bearing

Cone

w/seal

c

154303

Bearing

Cup

.

D

1081

SI

Washer

E

157506

Wheel

w/Bearing

Cup

F

157490

Tire

G

153038

Tube

H

157494

Spindle

Assembly,

R.H.

J

157611

Spindle

Assembly,

L.H,

K

8061012

Washer

L

8021010

Set

Collar

M

713503

Cup

Point

Socket

Head

Set

Screw,

5/16"-18

x

5/16"

Lg.

N

8021010

Set

Collar

P

727001

Grease

Fitting

Q

167616

Axle

Assembly,

Front

R

157618

Spacer

s

719004

Plain

Washer,

1/2"

T

705037

Hex.

Cap

Screw,

1/2"-13

x

1"

Lg.

U

717518

Full

Lock

Hex.

Nut,

1/2"-13

V

705016

Hex.

Cep

Screw,

3/B"-16

x

1

1/4

,J

Lg.

w

710001

Plain

Washer,

3/8"

X

154177

Spacer

Y

720002

Lock

Washer,

3/8'*

z

717003

Full

Hex.

Nut,

3/8'-16

AA

154280

Bearing

AB

157013

Arm

Assembly.

Steering,

L,H.

AC

71300S

Screw,

Set

Cup

Point,

Square

Head,

5/16"-18x

1/2"

Lg.

AD

157427

Key

AE

717528

Full

Hex.

Lock

Nut,

1/2"-2Q

AG

164272

Ball

Joint

AH

164271

Tie

Rod

AJ

717010

Nut,

1/2"'20

N.F.

AK

157702

Steering

Wheel

AL

725003

Woodruff

Key

No.

9

Ref.

Let.

Part

No

r

-

———“-

■

-

Description

AM

713503

Socket

Head

Cup

Point

Set

Screw,

5/16"-18x

5/1G"

Lg.

AN

713502

Socket

Head

SetScrew,

E/16"-18

x

1/4"

Lg.

AP

157259

Steering

Shaft

Assembly

AG

153081

Spacer

AR

719001

Plain

Washer,

3/S"

AS

720002

Lock

Washer,

3/B"

AT

715030

Hex.

CapScrew,

3/8"-1G

x

3/4"

Lg.

AU

154153

Universal

Joint

Pin

AV

157254

Bushing

Assembly

AW

157268

Bushing

AX

157253

Pin

Eccentric

AY

158399

Retainer

Ring

AZ

720002

Lock

Washer

BA

717003

Full

Hex.

Nut,

3/8^16

BB

713012

Sq.

Hd.

Set

Screw,

1/4"-20

x

3/4"

BC

157302

Steering

Bracket

BD

154258

Needle

Searing

BE

720001

Lock

Washer,

5/16"

BE

705012

Hex.

Cap

Screw,

5/16"-18x

5/8"

BG

8861012

Washer

BH

164263

Steering

Arm

Assembly

BJ

164235

Gear

Steering

BK

188182

Arbor

Washer

BL

154487

Hub

Cap

BM

717519

Gripco

Center

Lock

7/16"-14

BN

715026

Hex

Cap

Straw

BP

717511

Full

Hex.

Nut,

5/16"-ia

BG

154264

Snap

Ring

BR

15728G

Retaining

Ring

BS

157499

Drag

Link

BT

154486

Outside

Bearing

BD

157305

Valve

Stem

BV

157077

Steering

Bushing

IS

This manual suits for next models

1

Table of contents