Sp Air Construction Series User manual

Instruction and Maintenance Manual

3 Phase - Belt Driven Compressors

IMPORTANT ─

──

─Make certain that persons who are to use this equipment thoroughly

read and understand this Instruction Manual prior to operation.

PV0614

1

CONTENTS

Chapter 1 Technical Specifications

1.1 Parts and Features …………………..………………………………….……3

1.2 General Information …...…………………………………..…………………4

Chapter 2 Operating the Air Compressor

2.1 Important Safet Instructions …...…………..……….…………...…………8

2.2 Preparation Before Starting ….……..…………………………………….…9

Chapter 3

Maintenance of the Air Compressor

3.1 Regular Maintenance ……...……………………………...…………....…14

Chapter 4 Trouble-Shooting for the Air Compressor

4.1 Trouble-Shooting ………..……………………………………….……….…17

Appendixes

Limited Warrant Polic ………..………………….………………….…………23

Please read and understand this manual before operating the compressor. Failure to do so could result in

death, severe injur and/or substantial propert damage.

This manual should be considered a permanent part

of the compressor and should remain with it if resold.

2

NTRODUCT ON

This Owner’s Manual is intended to compl with all Australian Occupational or Workplace Health and Safet

Regulations regarding the manufacturer’s provision of information to the owner or purchaser of work plant. The

information is correct at the date of publication.

APPL CAT ON

Your air compressor is a single stage, oil lubricated, and air cooled reciprocating air compressor. It is t picall

supplied as a compact, self-contained, air receiver (tank) mounted unit that is automaticall regulated and driven b

a 3 phase electric motor.

The compressor is intended to provide compressed air in a multitude of applications, for example, to power

pneumatic tools, operate air dusters and spra guns, inflate tires, and suppl air for pneumatic valves and actuators.

It is commonl used as the primar source of compressed air for home garages, workshops, service stations, t re

shops, factories, farms, mobile service vehicles, and so on. Supplementar duties can include furnishing

compressed air at an isolated location not serviced b the regular shop air s stem, and standb service when

larger compressors are shut down.

Air discharged from an oil lubricated compressor t picall contains small amounts of oil, water and particulates

amongst other contaminants. Virtuall all applications require treatment of the compressor’s output air to make it

suitable for the end use. Air qualit treatments such as filtration and dr ing are the most common requirements

together with pressure regulation. The use of compressed air lubricators to protect pneumatic tools is also

commonplace nowada s. Failing to install appropriate compressed air treatment equipment will likel result in

damage to pneumatic machiner or spra painted finishes.

Where installed, compressed air filtration and/or dr ing equipment should be located downstream from the air

receiver tank and ahead of an pressure regulator. Lubricators, on the other hand, should be installed as the last

stage of treatment and located behind or downstream from an pressure regulator.

FUNCT ON

The pressure switch turns on the motor when the air receiver tank is at or below the minimum “cut-in” pressure.

The compressor then runns until the tank pressure reaches the maximum “cut-out” pressure whereupon the

pressure switch turns the motor off. Air will then be heard (for some seconds), escaping from the unloader valve

(in the base of the pressure switch) releasing residual air pressure in the discharge pipe and on top of the pistons in

the compressor pump. Thereb allowing the compressor to re-start easil , when next required.

The pressure switch is factor preset with cut-in and cut-out pressures of approximatel 120 psi and 150 psi,

respectivel . This range is ideal for the vast majorit of compressed air applications as most pneumatic tools have

been designed for use with a suppl (line pressure) of 90 psi. (6bar). Unless necessar for a special application,

line pressures of more than 90 psi. (6bar) are not recommended.

In the event that a pressure switch were to fail to turn the motor off at the prescribed cut-off pressure, then the

safet valve will protect the air receiver tank against over pressurizing b automaticall releasing air when the

pressure exceeds its preset value (ie 150psi [10bar]) . Air receiver tanks are designed and manufactured to

satisf the requirements of Australian Standards and all Australian Occupational or Workplace Health and Safet

Regulations.

3

Chapter 1

Parts & Features

DESCR PT ON

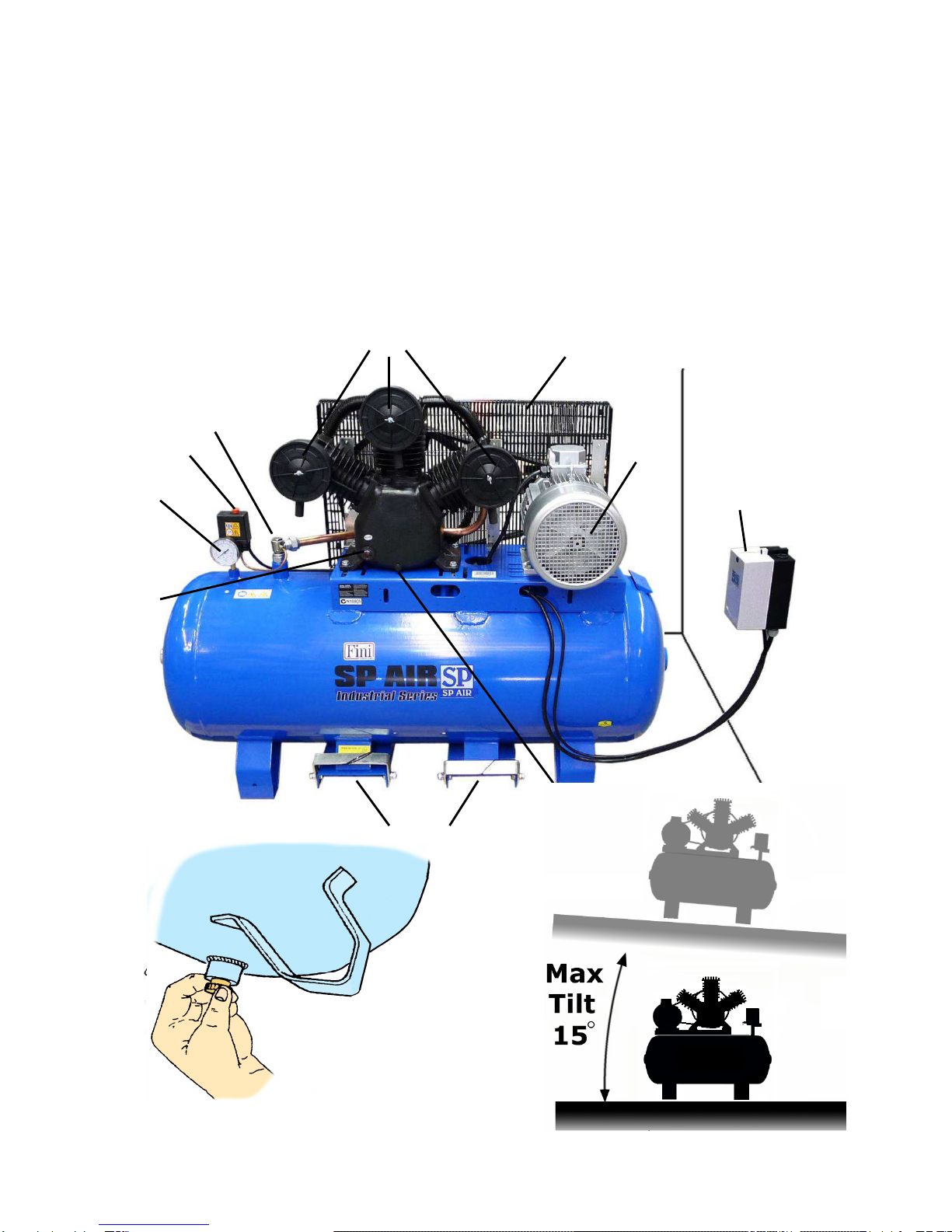

(1) Oil level sight glass (6) Safet cage

(2) Tank Pressure Gauge (7) Electric motor, air intake

(3) Pressure Switch On / Off (8) 3 phase contactor (wall mount)

(4) Non Return Valve (NRV) (9) Oil drain bung

(5) Air filters (10) Lifting Points

MPORTANT ─ mproper operation or maintenance of this air compressor could

result in serious injury and/or property damage, thoroughly read and

understand this nstruction Manual prior to operating the air compressor.

8

2

2

4

10

6

1

5

3

9

7

4

Sight glass

-

Check

Daily

The compressor oil level can be viewed through the sight

glass; the compressor must be on a level surface.

The top of the red dot indicates the full mark the bottom of

the red dot indicates the low mark. Alwa s ensure that

the oil level is correct before operating the compressor.

If the oil is low add Scorpion Compressor oil

or equivalent Aircol PD68.

Drain air tank – Daily

A drain valve is fitted to the bottom of the air receiver tank to permit the release of water condensation that

would otherwise corrode the tank and damage pneumatic devices.

Loosen the drain nut and allow an condensed water to escape, once all the air and moisture has been

released, finger tighten onl the drain valve.

5

Don’t Turn the Compressor on and off at the Wall

Use the Pressure switch – On / Off

The pressure switch automaticall controls the power to the motor and

operates the pressure relief valve. It also allows for manual operation via

the Push/Pull - On/Off switch on top of the pressure switch.

The pressure switch is factor set to turn the compressor on when the tank

pressure drops below 120 psi and turn itself off again when the tank is full.

You will notice that ever time the unit reaches maximum pressure and

turns itself off (or if the unit is manuall turned off); there is a short release

of high pressure air from under the pressure switch.

This is the pressure relief valve venting the air contained within the deliver

tube (the pipe which connects the compressor pump to the non return

valve). Failure to vent the pressurized air between the pump and the tank

will cause excessive current draw on startup which ma lead to motor

failure. For this reason alwa s turn the compressor On and Off via the

pressure switch.

The delivery tube:

Supplies compressed air

from the pump to the tank.

Only Operate the Compressor on a Flat Surface

Maximum Tilt

The maximum safe operating angle in an direction is 15° degrees.

Do not operate the compressor on inclines in excess of 15° degrees. Serious damage to pump components ma result

from insufficient lubrication.

Never use the air compressor on a rooftop or elevated position that could allow the unit to fall or be tipped over.

Alwa s disconnect the power before moving.

The pressure relief valve:

Vents pressure when the

unit is turned off.

The Non Return Valve:

Prevents any back flow from the tank.

6

Power supply

/ 3 phase

, 50Hz

It is essential that the air compressor has an adequate

power suppl .

The air compressor should be operated on a dedicated

3 phase 415 volt circuit.

The compressor must be connected to a properl

grounded circuit of adequate capacit .

•Should ou intend to use an air tool for a long durations ensure that the out put of the compressor (know as the

FAD or Free Air Deliver ) well exceeds the air consumption of the tool being used.

•Remember that our compressor has been designed with a 50% dut c cle in mind; continuous operation ma

cause it to overheat and result in serious mechanical damage to pump components. You should consider a

larger or screw t pe compressor for long term or continuous dut applications.

•

Do not use extension cords

. Using an extension lead on a compressor can cause voltage drop,

overheating the motor and leading to appliance damage or even fire.

•As our Compressor has an air cooled motor as well as an air cooled pump which draws in atmospheric air it is

important not to run the compressor in confined areas with poor ventilation or on loose surfaces such as dirt,

dust or sand, otherwise abrasive particles will be sucked into the air stream and cause the premature wear of

components.

•Your air compressor is not water proof; do not attempt to use or store it in the rain, snow or an other

environment with extreme conditions. It has been designed for use and storage indoors.

•Used and maintained correctl , our Compressor will provide man ears of reliable service.

•Your Compressor has been manufactured to a high standard in order to ensure a long service life. Ultimatel

the realization of the intended service life requires the operator to observe all instructions and servicing

requirements as described in this manual.

•Alwa s wear approved protection equipment such as safet glasses with side shields, ear muffs and gloves

when operating the compressor or using compressed air. Wear a face mask or respirator when spra ing,

blowing down or otherwise creating airborne mists or dust.

•Never point an nozzle or spra er toward an part of the bod or at other people or animals.

•Do not operate the air compressor if an guards or covers are missing, damaged or not installed correctl as

the compressor ma start automaticall . Ensure all maintenance is carried out b qualified personal.

7

•Never allow children, pets or untrained personal to “pla ” with compressed air.

•Keep children, pets or unauthorized personal awa from the compressor at all times.

•Compressed air can contain carbon monoxide, h drocarbons and/or other poisonous contaminants that can

cause death or serious injur . The air compressor is not designed, intended or approved for breathing air. Do

not use compressed air for breathing air applications without proper treatment. Do not use the compressor for

an gas other than air.

•

High voltage electricit can cause death or serious injur . All electrical installation or repair work must be

carried out b a licensed electrician.

• D SCONNECT POWER SUPPLY BEFORE SERV C NG.

•Do not stand on the compressor or use it as a handhold.

•High pressure air can cause death or serious injur . Do not b pass, modif or remove the safet valve. Do

not operate the compressor with a fault safet valve or pressure gauge.

•Do not direct the air stream at bod , high pressure air can stir up dust and debris that ma be harmful.

Release air slowl when draining condensation or depressurizing the compressor. Do not connect the

compressor to air handling equipment that cannot withstand the compressor’s maximum design pressure (refer

to the tank nameplate).

•Rusted, cracked or damaged air receiver tanks can explode and cause death or serious injur and must be

replaced. Drain tank dail or after each use through the valve located at bottom of the tank.

•Release compressed air from tank before servicing, do not weld drill or otherwise modif the air receiver tank.

•Do not spra flammable liquids in a confined area. Do not smoke while spra ing where sparks, flames or

other ignition sources (including the compressor) are present.

•Do not direct paint or other spra ed material at the compressor. Locate the compressor as far awa from the

spra ing area as possible to minimize overspra accumulating on the compressor and/or clogging it’s air filters.

•Motors, electrical equipment and controls can cause electrical arcs that ma ignite a flammable gas or vapor.

Do not operate or repair the compressor in or near a flammable gas or vapor. Do not store flammable liquids

or gases in the vicinit of the compressor.

•Before attempting to install, maintain, repair, store or transport the compressor, switch off the unit, tag and lock

out the power suppl and carefull release all air pressure from receiver tank, air hoses and/or piping.

•Do not permit an one to operate the compressor without proper instruction.

8

Chapter 2 Operating the Air Compressor

2.1 MPORTANT SAFETY NSTRUCT ONS

MPROPER OPERAT ON OR MA NTENANCE OF TH S PRODUCT COULD RESULT N SER OUS

NJURY AND OR PROPERTY DAMAGE.

READ AND UNDERSTAND ALL WARN NGS AND OPERAT NG NSTRUCT ONS BEFORE US NG.

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

Water directed at electrical

connections or switches, or objects

connected to an electrical circuit,

could result in a fatal electrical shock.

Moisture or a liquid of an kind ma

conduct electricit and could result in

a fatal electrical shock.

The air compressor is not

waterproof.

Never attempt to clean the air

compressor while it is running. Direct

an water or spra awa from electric

outlets and switches.

Keep our air compressor out of the

elements and well sheltered from rain,

snow, dew, water or mist of an kind.

Do not use the compressor with the

suppl cord damaged or with poor

qualit connections.

0.5m

Operating the

air compressor

in an

explosive environment could result in

a fire.

Materials placed against or near the

air compressor can interfere with its

proper ventilation causing overheating

and possible ignition of the materials.

Improperl stored paint thinners could

lead to accidental ignition. Thinners

improperl secured could get into the

hands of children or other unqualified

persons.

Good air flow is important as both the

motor and compressor unit are air

cooled. Restrictions to or insufficient

air flow will cause overheating.

Never spra paint in

a confined area

with the air compressor.

Operate the air compressor in well

ventilated areas free from

obstructions. Equip areas with fire

extinguishers suitable for electrical

fires. Do not leave n lon material

shirts or jumpers on the compressor.

Store paint thinners and other

flammable liquids in approved

containers, in a secure location awa

from the work area.

Minimum clearance 0.5m

Maximum ambient operating

temperature 45°C

This air compressor doe

s

not provide

breathable air; the air ma be

contaminated with mineral based oils

and other contaminants which poses

the risk of serious lung infection and or

injur .

Spra ing an material without the use

of a face mask will result in the

ingestion of foreign substances.

Never tr to provide brea

thing air or

refill auxiliar breathing apparatus

using this compressor.

Never spra substances in a closed

location occupied b humans or

animals alwa s use a face mask

when spra ing substances.

Contact with hot surfaces, such as

the

c linder head, cooling fins or

discharge pipe, could result in serious

burns.

These parts will remain hot for some

time after the compressor is shut

down.

During operation, touch onl the

control surfaces of the air

compressor. Keep children and

animals far awa from the air

compressor at all times. The ma not

be able to recognize the hazards of

this product.

Allow the air compressor to cool

before storage.

9

2.2 Preparation before Starting

RECE PT AND NSPECT ON

Ensure that adequate lifting equipment is available for unloading and moving the air compressor to the installation site.

Lifting equipment, slings, etc. must be properl rated for the weight of the compressor.

Lift the compressor from the deliver vehicle b the shipping pallet onl . Do not use the electric motor lifting e ebolt to lift

the entire compressor. The motor lifting e ebolt is onl to be used for removing the motor from the compressor unit.

Do not work or walk under the compressor while it is suspended in the air.

Inspect the compressor upon receipt for an shipping damage or missing parts.

•If an problems are apparent, make an appropriate note on the deliver receipt before signing, then contact

our dealer immediatel .

•Do not operate unit it has been damaged during shipping.

•Read the compressor model label to verif it is the model ordered.

•Check the motor nameplate to verif that it is compatible with the available electricit suppl .

•Make sure that electrical enclosures and components are appropriate for the installation environment.

UNPACK NG

Remove the carton and plastic bag that covers the

compressor. Ensure that children do not pla with the

plastic bag as it is a breathing hazard. Unbolt the

compressor from the shipping pallet. Do not use the

timber shipping pallet for mounting the compressor.

Using a forklift, lift off the shipping pallet using the lifting

points onl and place it close to the 3 phase power outlet.

Fit the air filters and add oil to the pump as necessar .

Fit air tap to end of tank and connect to air suppl line

We recommend that ou store the packaging for the

duration of the warrant period. If necessar , it will be

easier to return the compressor to the service center.

L FT W TH CARE AS THE COMPRESSOR S TOP HEAVY

NSTALLAT ON

Select a clean, dr and well lit area most preferabl indoors with plent of space for proper ventilation, cooling air flow

and accessibilit . The air compressor is designed for operation in ambient temperatures of between 0°C (32°F) and

40°C (104°F). Locate the compressor at least 500 mm from walls for adequate air cooling and to allow for

maintenance access. Ensure that the power suppl is clearl identified and accessible. Alwa s provide sunshade and

shelter from moisture if the compressor has to be located outdoors.

Bolt the compressor to a firm, level foundation such as a concrete floor that is strong enough to support its weight. Do

not bolt uneven feet tightl to the foundation as this will cause excessive stress on the air receiver tank. Use metal shims

to pack under an “short” feet, if necessar . The use of flexible vibration isolators underneath the mounting feet is highl

recommended and will reduce noise emissions.

L FT NG PO NTS

10

Noise Considerations

Check the State Workplace Health and Safet Regulations and/or Local Council regulations regarding acceptable noise

levels. To reduce excessive noise, use vibration isolators, relocate the compressor or construct an enclosure or baffle

walls.

Discharge Piping

All piping, fittings, air receiver tanks, and so on connected to the compressor discharge must be certified safe for the

unit’s discharge pressure and temperature. Do not use PVC plastic in the compressed air discharge line. Use pipe

thread sealant on all threads and assemble joints tightl to prevent air leaks and energ wastage.

Mainline piping used to conve air throughout a s stem should be sized to accommodate the maximum flow rate of the

compressor (also referred to as it’s free air deliver ) in accordance with Table 1. Branch piping should be sized in a

similar manner, but the design flow rate should instead be based on the total air consumption of the tools or appliances

running off that branch. To allow for vibration and to prevent piping stresses being transmitted to the

compressor, the connection between the unit’s discharge valve and the mainline piping s stem should be made using a

flexible air hose or coupling.

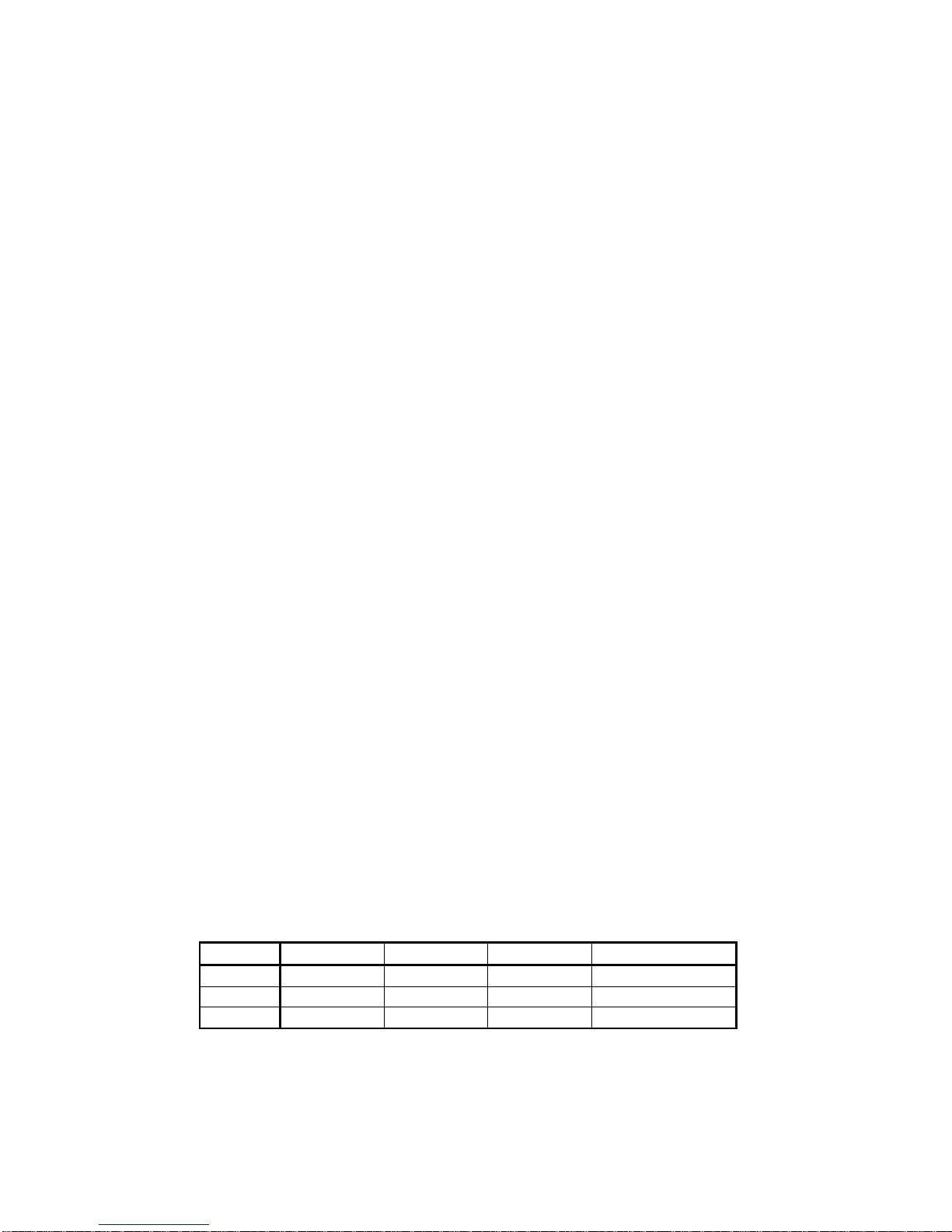

Table 1

RECOMMENDED P PE S ZES FOR COMPRESSED A R L NES

LENGTH OF P PL NE (METRES)

FL

OW

L/M N 7.5m 15m 22.5m 30m 45m 60m 75m 90m

142

½”

½”

½”

½”

¾”

¾”

¾”

¾”

283

½”

½”

½”

¾”

¾’

¾”

¾”

¾”

425

½”

¾”

¾”

¾”

¾”

¾”

¾”

¾”

566

¾”

¾”

¾”

¾”

¾”

¾”

¾”

¾”

708

¾”

¾”

¾”

¾”

¾”

1”

1”

1”

849

¾”

¾”

¾”

¾”

1”

1”

1”

1”

991

¾”

¾”

1”

1”

1”

1”

1”

1”

1132

¾”

1”

1”

1”

1”

1”

1”

1”

1670

1”

1”

1”

1”

1”

1”

1”

1”

2236

1”

1”

1”

1”

1

-

1/4”

1

-

1/4”

1

-

1/4”

1

-

1/4”

2830

1

-

1/4”

1

-

1/4”

1

-

1/4”

1

-

1/4”

1

-

1/2”

1

-

1/2”

1

-

1/2”

1

-

1/2”

Air hose should be sized in accordance with Table 2, and again with consideration as to whether the hose is a

distribution line or a branch line.

Table 2

RECOMMENDED HOSE S ZES FOR COMPRESSED A R L NES

LENGTH OF HOSE (METRES)

FLOW

L/M N 7.5m 15m 60m

566

3/8”

3/8”

½

”

849

3/8”

½”

½”

1698

½”

¾”

¾”

11

ELECTR CAL CONNECT ON

This work must be carried out by a licensed electrician.

All 3 phase compressor are not supplied with a power lead or plug. A licensed electrician is required to wire up the

compressor from the wall mounted contactor box, to a dedicated 3 phase electrical outlet, either with a four pin plug or

hard-wired into the electrical suppl . The circuit must be of adequate capacit and fitted with a circuit breaker.

Mount the contactor box to the wall as close to the compressor as practical.

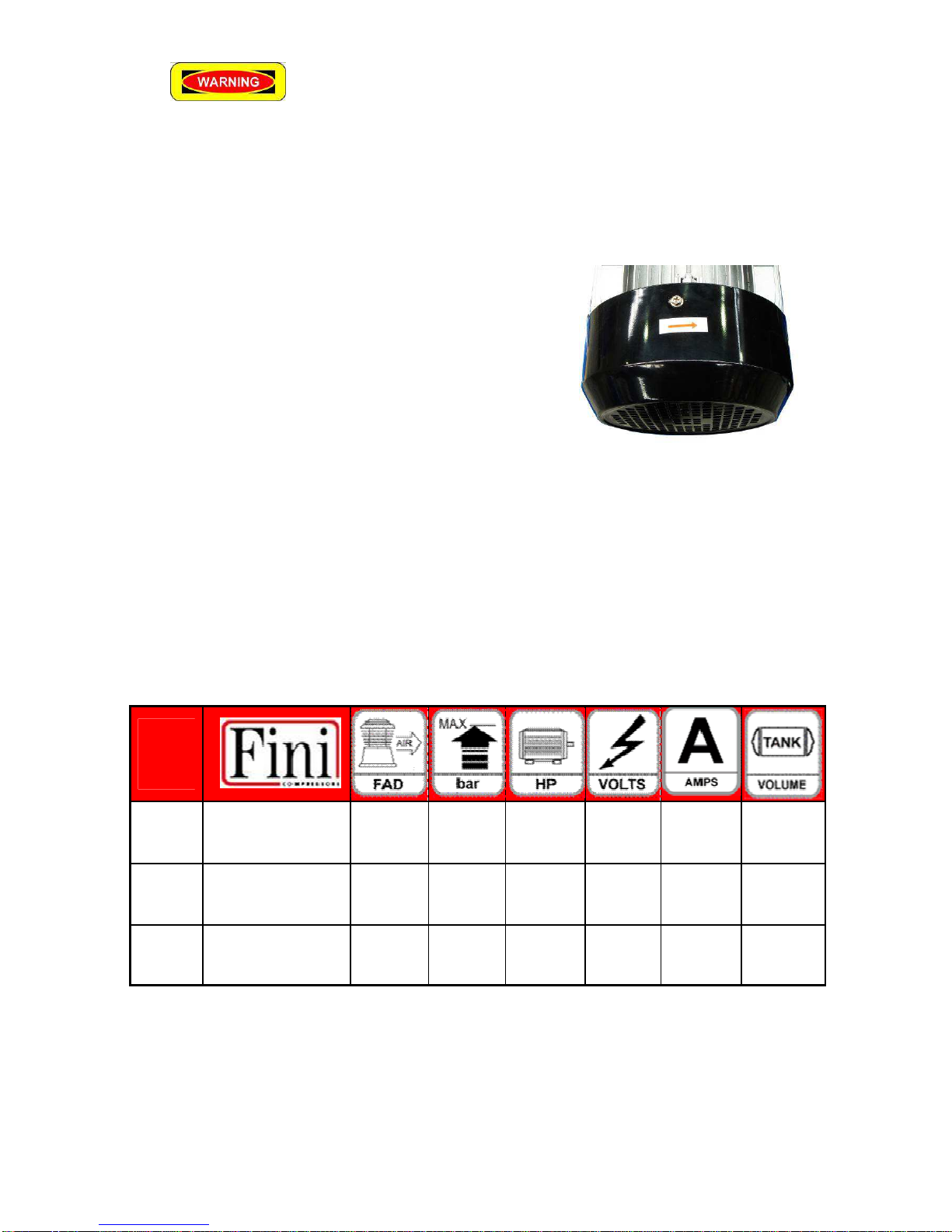

Ensure correct direction of rotation

:

The installing electrician must ensure that when wired in, the motor

is turning in the correct direction. Failure to obtain the correct

direction of rotation will prevent the fan / fl wheel from delivering

the necessar air cooling across the pump.

Electrical Connection

All electrical installation and service work must be performed b a licensed electrician in accordance with all applicable

regulations. The electric motor rating as shown on the motor nameplate and the power suppl must have compatible

voltage, phase and frequenc characteristics.

The required size of electrical wiring between the power suppl and the electric motor varies according to motor power

and other factors, use the table below to understand what power is required to operate each size Compressor.

Adequatel sized wiring must be installed to protect against excessive voltage drop during compressor start-up and

running. If connecting other electrical equipment to the same circuit, consider the total electrical load when selecting

the proper wire size. Overheating, short circuiting and fire damage ma result from undersize wiring.

NB Portable electric generators are not recommended for operating compressors unless the have ample generating

capacit to provide the requisite starting and running currents without appreciable voltage or frequenc drop.

Model:

XRS25

Piston Compressor

50% duty cycle

453L/PM

10 Bar

(150 psi)

5.5 HP

(4 KW)

415V

(3 Phase)

8AMPS

(per Phase)

200 L

XRS35

Piston Compressor

50% duty cycle

708L/PM

10 Bar

(150 psi)

7.5 HP

(5.6 KW)

415V

(3 Phase)

10AMPS

(per phase)

270 L

XRS50

Piston Compressor

50% duty cycle

1132L/PM

10 Bar

(150 psi)

10HP

(7.46 KW)

415V

(3 Phase)

13.5AMPS

(per phase)

270 L

12

OPERAT ON

Before operating the air compressor, alwa s check first to ensure that it has been received, inspected and installed in

accordance with the instructions herein. Rectif an discrepancies before proceeding further.

Check the compressor pump oil level b looking at the sight glass. The oil level should be at the top of the red circle on

the oil sight glass. Add oil, if required, through the oil fill cap and onl when the unit is not operating. Do not overfill with

oil. Refer to the Maintenance and Repair section for recommended oil specifications. Check that the outlet valve, if fitted,

is closed. An connected air hose(s) and/or distribution pipe(s) should not be open to the atmosphere. This is to prevent

an injuries from “hose whip” and/or high pressure air discharge and also to avoid unattended compressed air discharge

to the atmosphere. In the event that an air line is cut or broken, the air suppl must be immediatel closed off at the

compressor either b shutting the discharge outlet valve or switching off the compressor. Do not attempt to “catch” the

loose end of a discharging air hose.

Check that the tank drain valve is closed. Take care when discharging air from the tank, i.e. from the safet valve, the

drain valve or the air outlet, to ensure that it does not cause dirt, stones, metal swarf or other particles to be blown

around.

An unusual noise or vibration likel indicates a problem with the compressor. Do not continue to operate the unit until

the source of the problem has been identified and corrected.

Duty Cycle

To maximize service life, the air compressor should be adequatel sized for its given application. It should ideall

operate in a repeating run-stop or pump-unload c cle, with total compressor “pumping” time not exceeding 50% or 30

minutes in ever hour on average. The elapsed time between the start and finish of an given pumping c cle (i.e. the

continuous duration that the electric motor operates) should not exceed 30 minutes. If the unit cannot suppl the

compressed air demand without exceeding the above dut c cle limits, then either the demand should be reduced or the

compressor should be replaced with a larger unit having greater free air deliver .

The dut c cle limit is intended to protect the compressor pump valves and heads against stabilized high operating

temperatures that can cause premature pump failure.

Run in procedure

When starting for the first time leave the air compressor run for 10 minutes without load, leave the air cock completel

open. After 10 minutes check that the drain cock is closed and shut the main air cock. As tank pressure increases

check that the compressor stops automaticall once maximum pressure is reached.

*Note: All compressors are delivered onl after a successful testing period at the factor .

For the long life of our compressor it is recommended that ou drain and replace the pump lubricant

after 10 hours

of use,

Drain the oil while it is still warm this will help remove an abrasive particles loosened from the initial run in

period. Replace pump oil with Scorpion Compressor oil AC-68.

13

Optional Accessories

(not standard equipment)

Air Dryer:-

A compressed Air Dr er is a device for removing water vapor from compressed air.

The process of compressing air concentrates water vapor from the atmosphere, which raises the dew point of the

compressed air relative to free atmospheric air and leads to condensation within pipes as the compressed air cools

downstream of the compressor.

Excessive water in the compressed air suppl , either in the liquid or vapor form can cause a variet of operational

problems for users of compressed air. These include: corrosion of equipment, fouling of process lines and

contamination of jobs. Water vapor is removed from compressed air to prevent moisture entering tools and/or

interfering in sensitive industrial processes.

Refrigerated air dr ers utilize a mechanical refrigeration s stem to cool the compressed air and condense water vapor.

Refrigerated air dr ers cool the compressed air to a temperature of approximatel 1.6 degree Celsius to 10 degrees

Celsius which results in a pressure dew point range of .5 degrees Celsius to 3.8 degrees Celsius. This range permits

the pressure dew point to fall within limits that are achievable with common refrigeration s stems.

Pre and Post-Filters:

The Pre and Post- filters are designed with progressivel finer filters to limit contamination b trapping the fine particle

matter and separating this matter from the air stream.

The Pre-Filter has a 5 micron filter that will trap most of the bigger contaminates that pass from the compressor.

The Post-filter has a 0.01 micron filter and is designed to remove an finer contaminates that the Air Dr er ma have not

been able to remove.

Filter/Regulator

The filter/regulator is a pneumatic device which is comprised of a pressure regulator, a 25 micron filter and a water trap.

The regulator allows the operator to adjust the output pressure to suit the air tool that is being used.

It is suggested with this t pe of setup to have the filter/regulator mounted near to where the air tool is going to be used,

do not mount a filter regulator at the compressor as this will restrict air flow to the whole building s stem t picall the filter

regulator is fitted where the piping changes to a flexible air line.

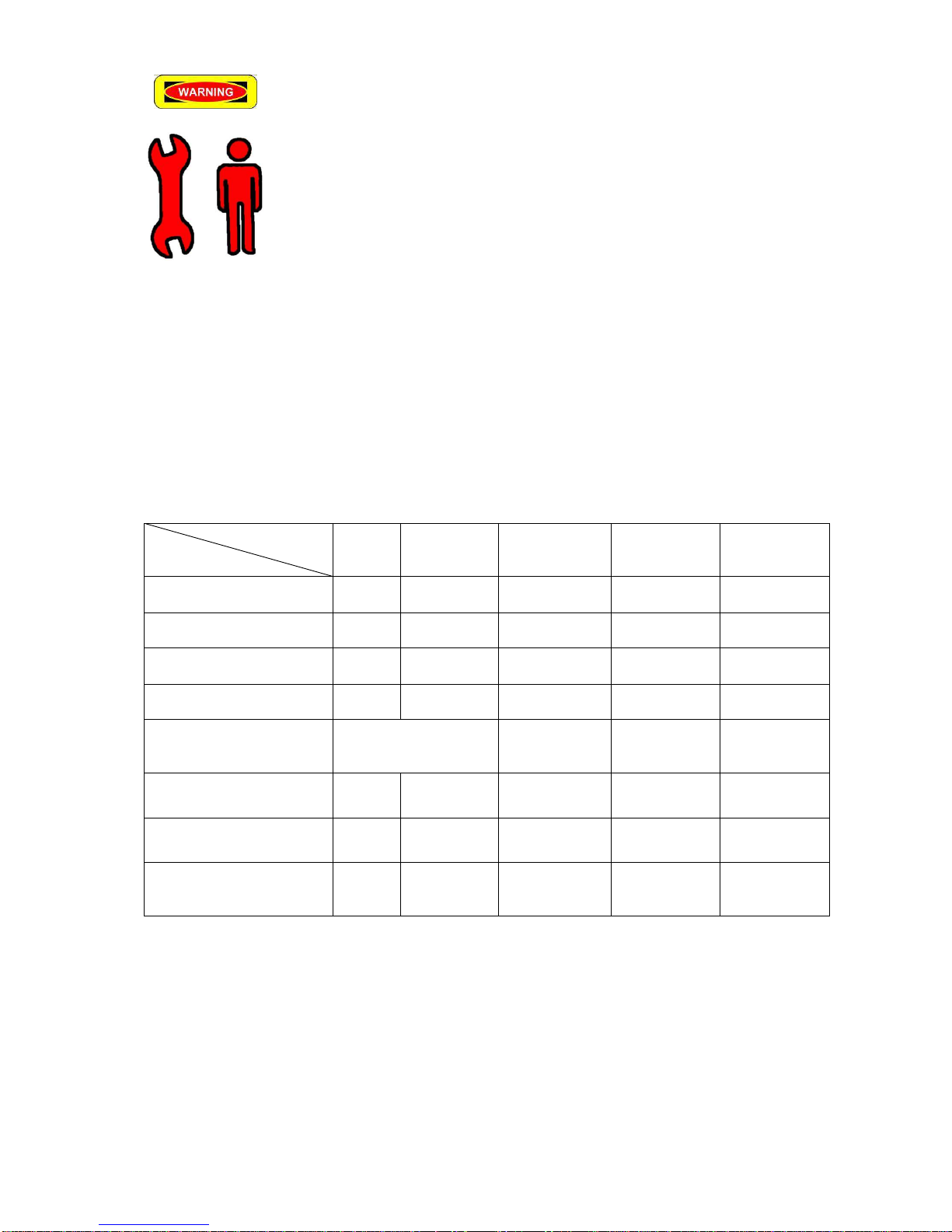

Table 4

shows the suggested Pre-Filter, Air Dr er, Post Filter and Filter/Regulator combination that can be used for each

particular Compressor.

Table 4

Model

Pre

-

Filter

Air Dryer

Post

-

Filter

Filter/Regulator

XRS25

JF

-

C

-

001

LD05SHA

JF

-

A

-

001

SFR

-

404

XRS35

JF

-

C

-

002

LD10SHA

JF

-

A

-

002

SFR

-

404

X

RS50

JF

-

C

-

002

LD10SHA

JF

-

A

-

002

SFR

-

404

14

Chapter 3 Maintenance of the

air compressor

WHEN DO NG MA NTENANCE, YOU MAY BE EXPOSED TO ELECTR C TY, HOT SURFACES, H GH

PRESSURE A R, MOV NG PARTS, OR F RE WH CH MAY RESULT N NJURY OR DEATH. BEFORE

PERFORM NG ANY MA NTENANCE OR REPA R, D SCONNECT ANY POWER SOURCE; LET THE

COMPRESSOR AND MOTOR COOL DOWN COMPLETELY. DRA N ALL A R PRESSURE FROM THE

TANK. CONTACT A SPEC AL ZED SERV CE TECHN C AN FOR ALL ELECTR CAL REPA RS.

Before performing an maintenance or repair work on the compressor, switch off the unit, tag and lock out the power

suppl , and carefull release all air pressure from the receiver tank, air hoses and/or air piping. Use onl genuine spare

parts for maintenance and repair of the compressor to ensure its safe and reliable operation.

The maintenance schedule

shown has been developed for t pical industrial applications in clean indoor environments. The service intervals should

be shortened in harsher working conditions. Regular preventative maintenance is essential for the safet , reliabilit and

performance of the compressor and will add ears to its useful life.

3.1 Regular maintenance schedule

Keep our air compressor in good condition, regular inspection and maintenance is ver important.

Service period

regular

Item

Ever

da After 10 Hrs Ever month Ever 6 months

Ever ear

Check the oil level

Drain tank condensation

Check V belts Tension 1st time

2nd and

thereafter

Test Safet Valve

Clean air intake filter

(Service more frequentl

when used in dust

conditions)

Replace filter

element

Change pump oil 1st time

2nd and thereafter

Check bolt tensions 1st time

General cleaning of the

compressor, check for air and

oil leaks

“

”

The chart above indicates which checks to make and when to make them.

15

Check for any loose

fasteners

after

1

0 hours of operation

•Check that all nuts and bolts are properly tight

•Drain and replace the pump lubricant

Replace pump oil with Scorpion compressor oil.

(this will remove abrasive particles, from initial run in period)

After 10Hrs of use

Air filter maintenance

Remove the outer cover to access the filter element

Paper air filter elements, can be cleaned b gentl

blowing with compressed air (20psi) from the inside out.

Air filter maintenance

Air filter maintenance will be increased when the

compressor is used in dust conditions.

If it cannot be blown clean or is otherwise torn or

damaged, the filter element must be replaced.

Replace the filter ever 12 months.

Do not operate the compressor without an air filter.

Foam air filter elements should be washed in warm soap

water, allow to dr , then re-oiled before use.

16

Check b

elt tension

Correct belt tension is important if the belt is too tight it will

cause the motor to overheat and increase electricit

consumption. If the belt is too loose it ma slip easil ,

whip and break.

The drive guard must first be removed before V-belt

tension can be checked or adjusted, hang a weight of

about 3kg at the mid point of the belt. Deflection should

be about 10mm.

If tension adjustment is necessar , loosen the four fasteners holding the motor to the baseplate. Then either move the

motor awa from or closer to the pump to increase or decrease V-belt tension, respectivel , and retighten the

hold-down fasteners. Alwa s use a straight edge to check that the motor

and pump pulle s are properl aligned and the V-belt(s) runs straight. Do not over tension the V-belt(s). Alwa s

refit the drive guard before operating the compressor.

Correct pulley alignment is extremely important!

Cleaning

Switch off the air compressor and use light air pressure to blow dust and foreign matter off the compressor pump, motor,

piping and air receiver tank. Oil and grease marks should be cleaned off using mild household surface cleaner and a

soft rag. Do not use abrasive cleaners or strong solvents that can damage the compressor’s paint finish.

Air Receiver Tank

To drain condensation from the air receiver tank, slowl open the drain valve and allow the condensation to discharge.

Do not pollute the environment b improper or illegal disposal of the condensation that ma contain lubricating oil and/or

other contaminants. Use extreme caution when opening the drain valve if the air receiver tank is pressurized.

Thumbscrew drain cocks should not be opened more than one full turn.

Certified external and internal inspections of the air receiver tank should be carried out b a licensed in-service inspector

at intervals of no less than two and four ears, respectivel , in accordance with Australian and New Zealand Standard

AS/NZS 3788:2001 or as otherwise specified b our applicable Occupational or Workplace Health and Safet

Regulations.

Do not attempt to repair or modif an air receiver tank. Welding, drilling or an other modification will weaken the tank

and ma result in damage from rupture or explosion. Alwa s replace worn, cracked, corroded or damaged tanks.

Safety Valve

Regularl check the safet valve to verif that it’s operating freel . While the air receiver tank is pressurized to at

least 120 psi, pull the ring on the safet valve and allow it to snap back to its normal position. If air leaks out

after the ring has been released, or the valve is stuck and cannot be actuated b pulling the ring, the safet

valve is fault and must be replaced before operating the compressor.

Take care when testing the safet valve as compressed air will discharge from the valve with high velocit . Do not

tamper with the safet valve. It is designed to automaticall release air if the tank pressure exceeds a preset maximum.

17

Air Tightness

While the air receiver tank is pressurized to at least 120 psi and the compressor is switched off, listen for an audible air

leaks. Squirt soap water around an suspect joint and watch for bubbles indicating a leak. De-pressurize the air

receiver tank carefull and all connected air hoses and/or air piping before commencing an repairs.

Disassemble the leaking joint and clean off all traces of thread tape or sealant using a wire brush. Appl PTFE thread

tape or Loctite™ 243 liquid sealant to the male threaded connection before reassembling and tightening the joint. Allow

approximatel 30 minutes for the liquid sealant to cure, if used. Re-pressurize the air receiver tank and check that the

air leak has been rectified before putting the unit back into normal operation.

Lubricating Oil

Maintain the oil level at the top of the red circle on the oil sight glass fitted to the compressor pump.

Remove the oil fill cap to add oil onl when the compressor is switched off.

Use premium qualit engine oil with an API Service Classification of at least CG or SH, or alternativel use specialized

air compressor oil meeting DIN 51506 specification. Select an oil of monograde or multigrade viscosit that is appropriate

for the ambient temperature in which the compressor will be operating.

The compressor pump has been filled at the factor with SAE 15W-40 mineral based engine oil that is suitable for

ambient temperatures from −15°C (5°F) to over 40°C (104°F). Mineral based, semis nthetic or full s nthetic oils ma

be used, but different t pes of oils should not be mixed together. Regular oil changes in accordance with the

recommended maintenance schedule are crucial to the service life of the compressor pump.

To change the oil, remove the oil fill cap and then remove the oil drain plug. Another wa is to simpl evacuate the oil

through the oil fill hole b inserting a suction probe. Oil flows easier if the pump is warm, but do not touch the oil in case it

is hot. Reinstall the oil drain plug tightl before adding the new oil and then finall screw the oil fill cap back in place.

If the oil changes to a white colour, this indicates water contamination. If it changes to a dark colour, this t picall

indicates compressor overheating. Change the oil immediatel in either case. Do not pollute the environment b

improper or illegal disposal of waste oil. New or rebuilt compressor pumps will discharge higher than normal amounts of

oil until the piston rings are seated in, which can take approximatel 100 operating hours. Some oil ma also

concurrentl accumulate at the crankcase breather openings and this too will diminish with run time.

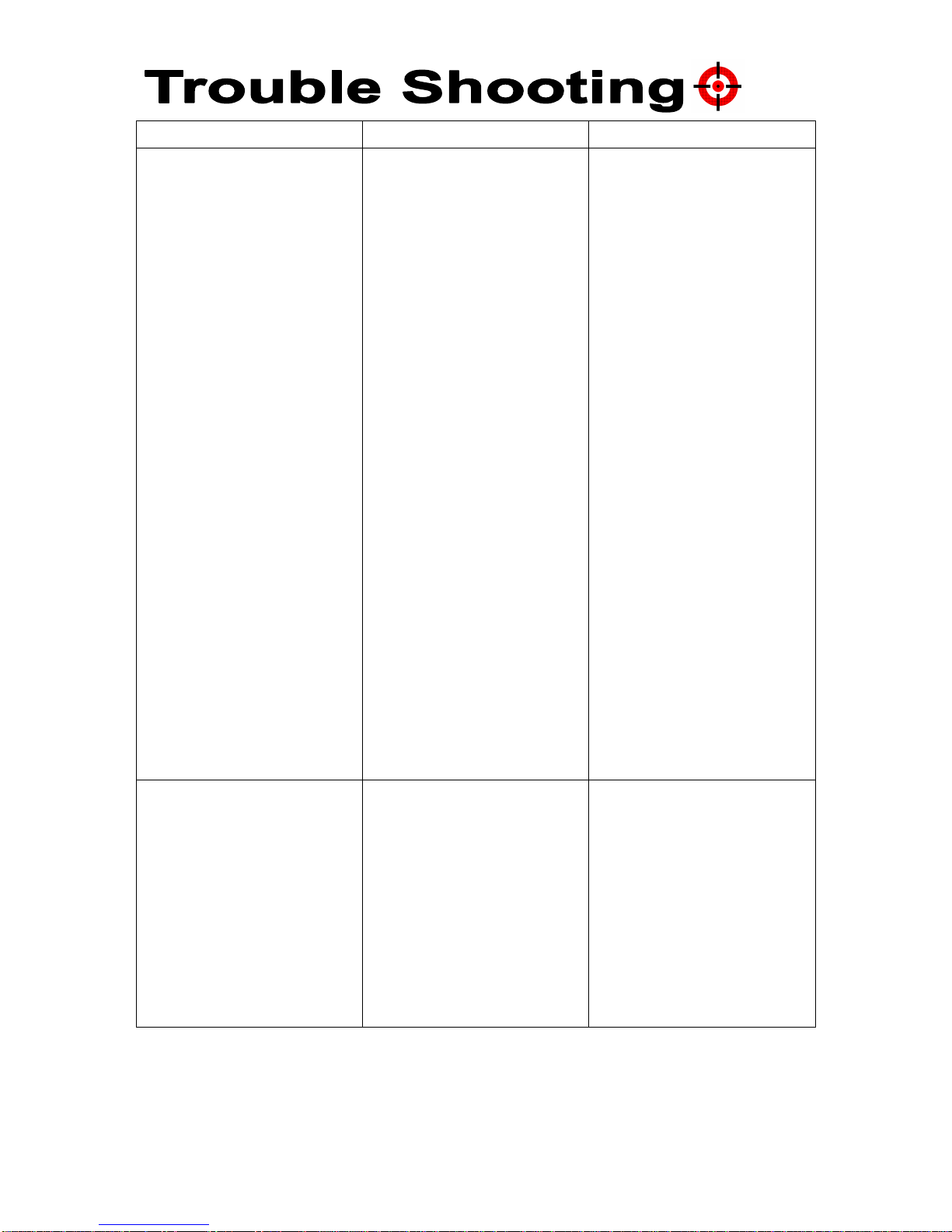

TROUBLESHOOT NG

Before performing an inspection, test or repair work on the compressor, switch off the unit, tag and lock out the power

suppl , and carefull release all air pressure from the receiver tank, air hoses and/or air piping.

Please refer to the troubleshooting guide shown in Table 5 for assistance with diagnosing and repairing an problem that

might occur with our air compressor. Whilst man of the tasks can be undertaken b a mechanicall proficient person

with access to proper tools, all electrical work must b undertaken b a licensed electrician.

It is recommended for our convenience and expedience that the troubleshooting guide is consulted prior to contacting

advice.

Use onl genuine spare parts for maintenance and repair of the compressor to ensure its safe and reliable operation.

For best results, the following repair procedures should alwa s be observed:

Use onl genuine spare parts for maintenance and repair of the compressor to ensure its safe and reliable operation.

•Use new gaskets, seals and O-rings during reassembl .

•Use PTFE thread tape or Loctite™ sealant on threaded joints subject to pressure.

•Use Loctite™ retaining compound when fitting engine or motor pulle s onto their drive shafts.

18

Symptom

Possible

Cause

Corrective Action

Motor will not start, runs slowl or

repeatedl trips out overload

protection.

1.

Pressure switch not turned

on.

2. Air receiver tank pressure

above cut-in pressure.

3. No voltage at the pressure

switch.

4. No voltage at the electric

motor, (fault pressure

switch or DOL starter)

5. No voltage on one or two

phases of 415v suppl .

6. Low suppl voltage.

7. Thermal overload rela in

DOL starter tripped.

8. Fault pressure switch

unloader valve, (nil or

restricted unloading air flow.

9. Nil or restricted discharge air

flow through non-return

valve.

10. Damaged motor cowl and/or

fan, other motor faults.

11. V-belts too tight or

misaligned.

12. Compressor pump partiall

or totall seized.

1.

Turn on pressure switch.

2. Nil (no fault). Unit will start

when pressure drops.

3. Check electricit suppl

including all fuses, circuit

breakers, switches and

wiring.

4. Repair or replace pressure

switch or DOL starter.

5. Check voltage on all three

phases of 415v suppl .

6. Check no load and full load

suppl voltage. Upgrade

power suppl circuit if

required. Disconnect an

other appliances on the

same suppl circuit.

7. Allow motor to cool down

and manuall reset overload

rela (located inside the

DOL starter).

8. Replace unloader valve or

complete pressure switch.

9. Repair or replace non-return

valve.

10. Replace cowl and/or fan,

replace motor.

11. Adjusts belts to proper

tension and alignment.

12. Repair or replace

compressor pump.

Compressor pump does not come

up to speed.

1.

Loose motor pulle , loose

compressor fl wheel or

loose/worn V-belts.

2. Low suppl voltage.

3. Damaged or worn.

4. Compressor pump partiall

seized.

1.

Tighten or replace pulle s as

required, check alignment

and adjust V-belt tension.

2. Check no load and full load

suppl voltage. Upgrade

power suppl circuit if

required. Disconnect an

other appliances on the

same suppl circuit.

3. Replace compressor pump

valves and or blown head

gaskets.

4. Repair or replace

compressor pump.

19

Excessive noise (including

knocking and rattling) or vibration.

1.

Loose motor pulle , loose

compressor pulle , V-belts

too tight or misaligned.

2. Low oil level.

3. Pistons hitting c linder

heads.

4. Damaged or worn crankshaft

bearings, crankshaft,

con-rods, piston pins,

pistons, c linders and /or

valves.

5. Fault non-return valve.

6. Loose fasteners.

1.

Tighten or replace pulle s as

required, check alignment

and adjust V-belt tension.

2. Add oil.

3. Remove c linder heads and

check for foreign matter on

top of pistons.

4. Replace components or

entire pump.

5. Repair or replace non-return

valve.

6. Check and tighten fasteners

(including foot mounts).

Slow pres

sure rise or unable to

reach cut-out pressure.

1.

Air demand exceeds

compressor pump capacit .

2. Air leaks.

3. Blocked or dirt inlet air

filters.

4. Loose motor pulle , loose

compressor fl wheel pulle

or loose/worn V-belts.

5. Head unloaders not full

retracting (usuall indicated

b air blowing out from air

filter inlets).

6. Damaged or worn

compressor pump valves

and/or blown c linder head

gaskets.

7. Damaged or worn piston

rings, pistons and/or

c linders.

8. Fault non-return valve.

1.

Reduce air demand or use

larger or additional

compressor(s).

2. Tighten or refit or replace

leaking connections or

components.

3. Clean or replace air filter

elements.

4. Tighten or replace pulle s as

required, check alignment

and adjust V-belt tension.

5. Repair or replace head

unloaders.

6. Replace compressor pump

valves and/or c linder head

gaskets.

7. Replace components or

entire compressor pump.

8. Repair or replace non-return

valve.

Compressor pump runs

excessivel hot (possibl melts air

filter enclosures).

1.

Incorrect direction of rotation.

2. Ambient temperature too

high or insufficient

ventilation.

3. Low oil level.

4. Excessive dut c cle.

5. Damaged or worn

compressor pump valves

and/or blown c linder head

gaskets.

1.

Check compressor pulle

turns in correct direction

Change electric motor wiring

connections if incorrect.

2. Reduce ambient and/or

improve ventilation (e.g.

move further awa from

walls or other equipment).

3. Add oil.

4. Reduce air demand or use

larger or additional

compressor(s).

5. Replace compressor pump

valves and/or c linder head

gaskets.

Excessive c cli

ng between

pumping mode and off mode.

1.

Excessive dut c cle.

2. Air leaks.

3. Excessive condensation in

air receiver tank.

1.

Reduce air demand or use

larger or additional

compressor(s).

2. Tighten, refit or replace

leaking connections or

components.

3. Drain air receiver tank more

regularl .

Other manuals for Construction Series

2

Table of contents

Other Sp Air Air Compressor manuals

Popular Air Compressor manuals by other brands

Porter-Cable

Porter-Cable CPLDC2540P instruction manual

TRADEair

TRADEair MCFRC230 Installation, maintenance and operation manual

Scheppach

Scheppach 7906100712 Translation of the original instruction manual

Craftsman

Craftsman 919.167220 owner's manual

Stanley

Stanley 8216035SCR011 instruction manual

Powermate

Powermate 200-2425 parts manual