Sp Air Construction Series User manual

Operation and Maintenance Manual

Belt Driven Compressors

IMPORTANT ─ Please make certain that persons who are to use this equipment

thoroughly read and understand this Instruction Manual prior to operation.

PV0614 OM-Comp BD

Belt Drive Compressors / Single Phase

1

CONTENTS

Chapter 1 Technical Specifications

. Parts and Features ………………..………………………………….…2

.2 General Information …………………………………………….………3

Chapter 2 Operating the Air Compressor

2. Important Safety Instructions ……………..……….…………....………7

2.2 Preparation Before Starting ….……………………………………….…8

Chapter 3

Maintenance of the Air Compressor

3. Regular Maintenance …………………………………...…………...….9

Chapter 4 Trouble-Shooting for the Air Compressor

4. Trouble-Shooting …………………………………………….…..…..…

Appendixes

Limited Warranty Policy…………………….……………………..……….…12

Belt Drive Compressors / Single Phase

2

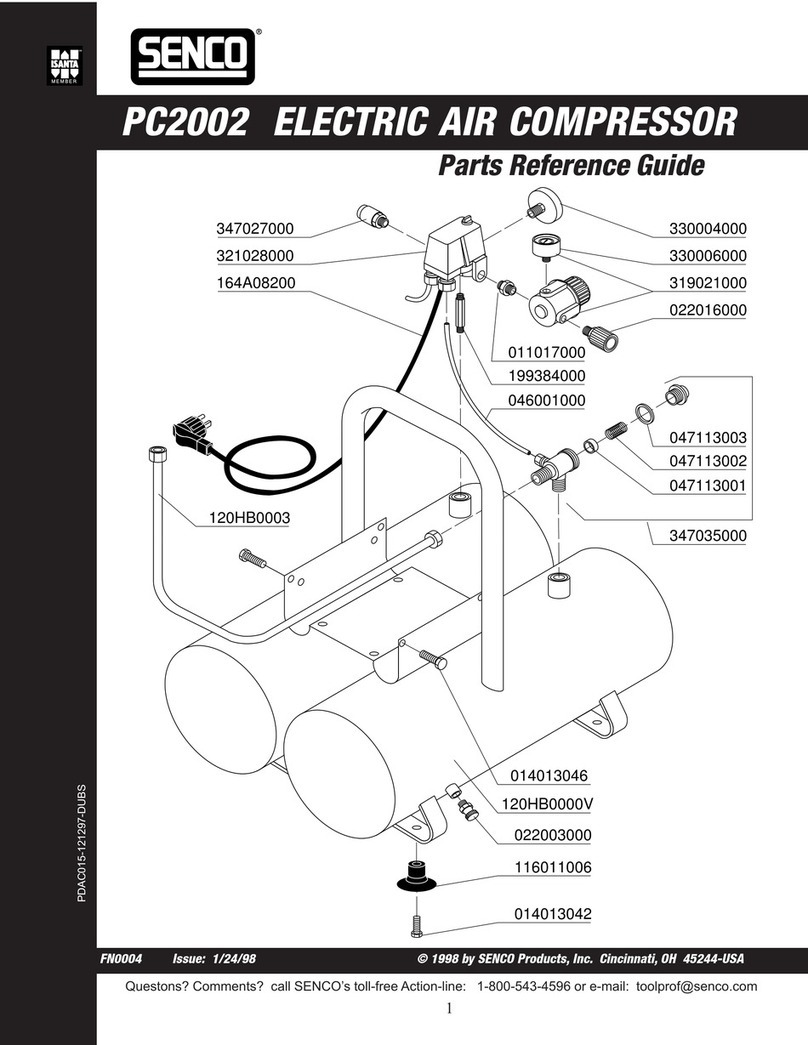

Chapter 1 Parts & Features

DESCRIPTION

(1) Oil sight glass (8) Line pressure gauge

(2) Air inlet, motor cooling (9) Air Outlet connection

(3) Motor reset switch (10) Filter drain cock

(4) Oil filler cap / Breather (11) Non Return Valve (NRV)

(5) On / Off Pressure Switch (12) Oil drain bung

(6) Pressure Regulator (13) Air Tank drain cock

(7) Tank pressure gauge

IMPORTANT ─Improper operation or maintenance of this air

compressor could result in serious injury and/or property

damage, thoroughly read and understand this Instruction

Manual prior to operating the air compressor.

1

2

3

5

6

10

13

9

7

8

11

12

4

Belt Drive Compressors / Single Phase

3

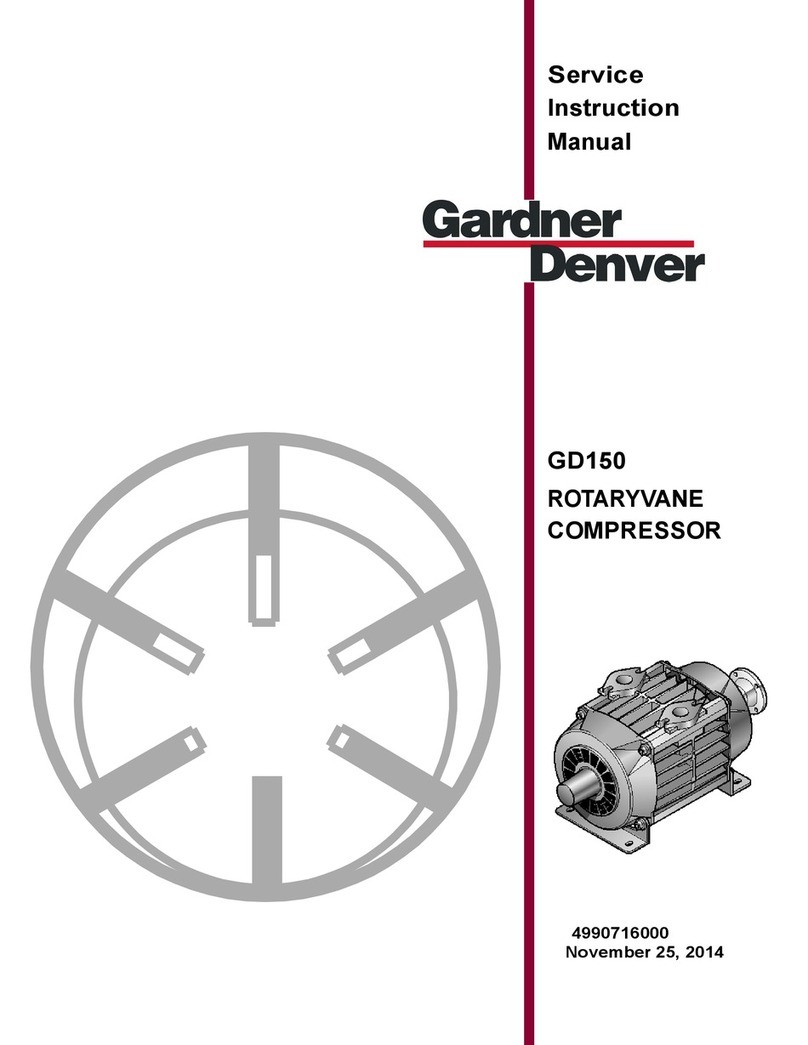

Sight glass

Check

Daily

The compressor oil level can be viewed through the sight

glass; the compressor must be on a level surface.

The top of the red dot indicates the full mark the bottom of

the red dot indicates the low mark. Always ensure that

the oil level is correct before operating the compressor.

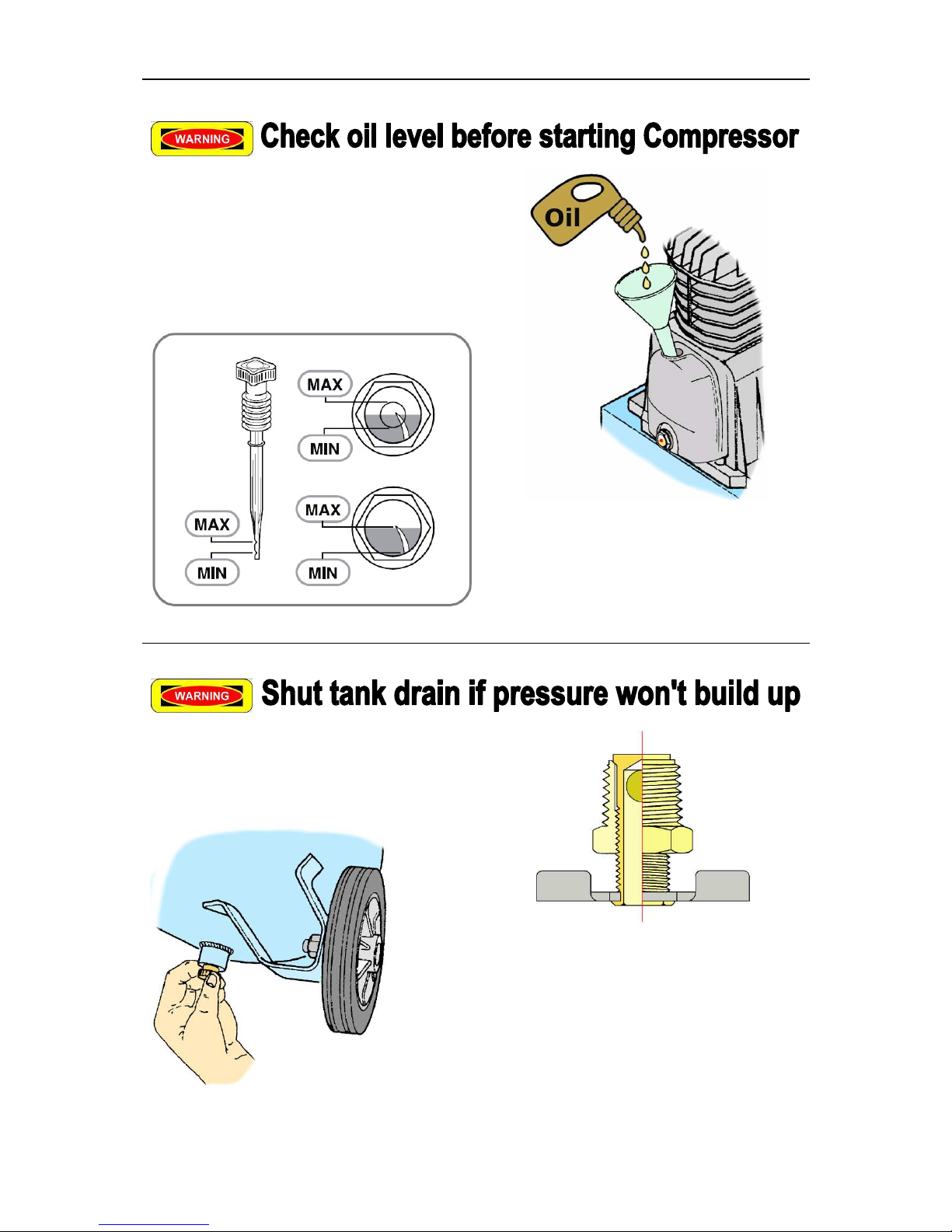

Drain air tank

-

Daily

Section view of drain cock

The water in the tank comes from the atmosphere (it is

not made by the compressor), operating the

compressor on very humid days will result in

comparatively more water collecting in the tank than

operation on less humid days.

Loosen the drain nut and allow any condensed water

to escape, then close the drain cock again.

If the oil is low add Scorpion Compressor

oil or (equivalent to Aircol PD68)..

Belt Drive Compressors / Single Phase

4

Pressure switch

On / Off

The pressure switch automatically controls the power to

the motor and operates the pressure relief valve. It also

allows for manual operation via the Push/Pull - On/Off

switch on top of the pressure switch.

The pressure switch is factory set to turn the compressor

on when the tank pressure drops below 85 psi and turn

itself off again when the tank is full.

You will notice that every time the unit reaches maximum

pressure and turns itself off (or if the unit is manually

turned off); there is a short release of high pressure air.

From under the pressure switch.

This is the pressure relief valve venting the air contained

within the pump and delivery tube (the pipe which

connects the compressor pump to the non-return valve

and tank). If this pressurized air is not vented before the

next startup It will cause excessive current draw which

may lead to motor failure. For this reason always turn the

compressor On and Off via the pressure switch

Pressure

switch

Any repairs to the pressure switch must be carried out by

qualified personnel.

The pressure relief

valve: Vents delivery

tube pressure when

the unit is turned off.

Non Return Valve:

Prevents back flow from the tank

The delivery tube:

Supplies compressed air

from the pump to the tank

Belt Drive Compressors / Single Phase

5

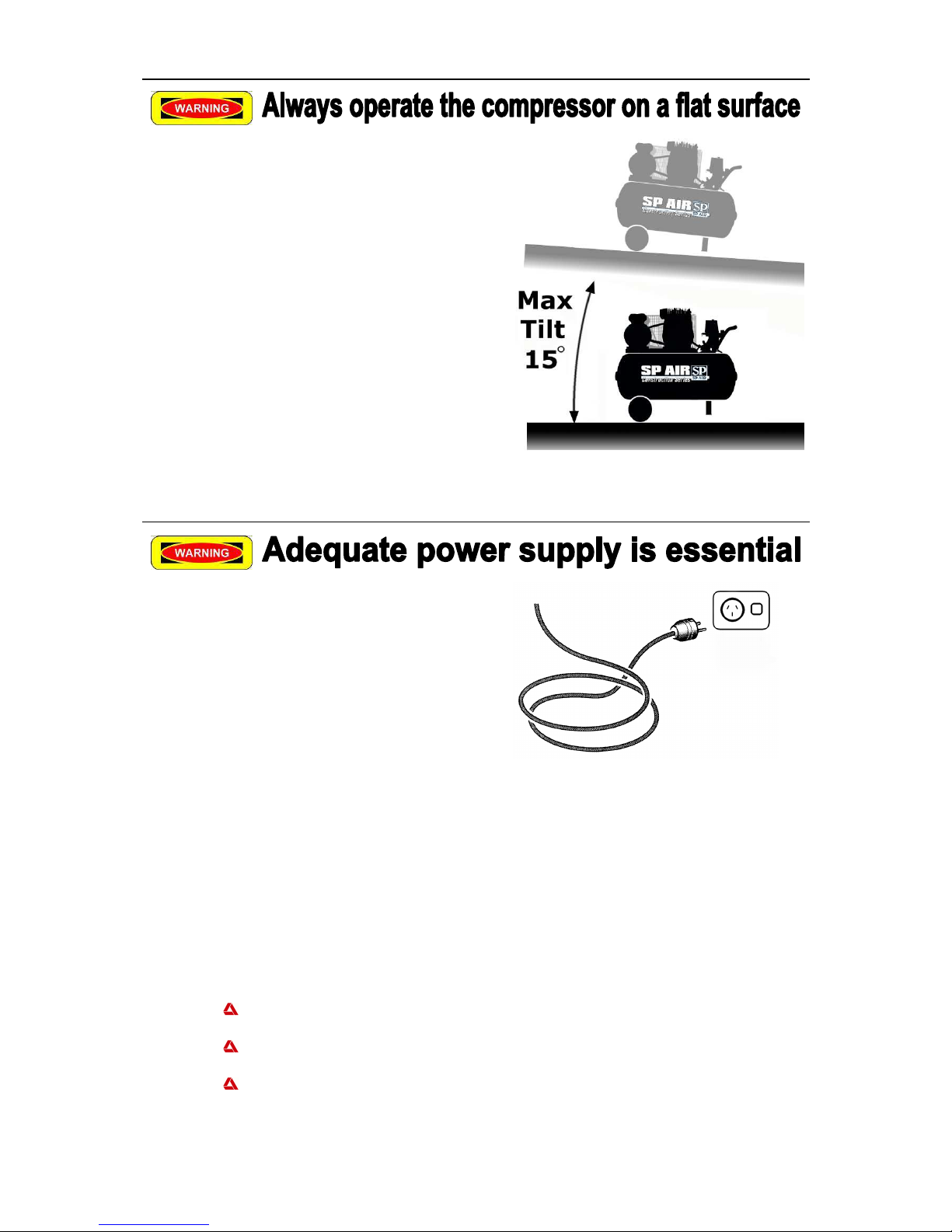

Maximum Tilt

The maximum safe operating angle in any direction is

5° degrees.

Do not operate the compressor on inclines in excess of

5° degrees. Serious damage to pump components

may result from insufficient lubrication.

Never use the air compressor on a rooftop or elevated

position that could allow the unit to fall or be tipped

over.

Use additional air hose for elevated jobs.

Always turn the compressor off before moving.

Power supply

It is essential that the air compressor has an adequate

power supply.

Air compressors up to 2.2Hp should be operated on a

0 amp 240 volt circuit. Air compressors 2.5Hp or

larger should be run on a 5amp 240 volt circuit.

Always use a longer air hose before choosing to use an

extension lead, as low voltage could cause damage to

the motor. (Low voltage damage is not a warrantable

failure)

Expected use

:

In addition to pneumatic tools, your compressor may be connected to several accessories

suitable for blowing, washing and spraying. Please see the instructions provided with such accessories for

safe operation.

We recommend that the compressor duty cycle never exceed 50% and continuous operation never exceed 30

minutes.

Your belt driven compressor is intended for the following applications:

Domestic spray painting

Light industrial use, tyre inflation, Household, cleaning, pruning, drying

Air tools such as nail guns, staplers, spray guns, impact tools, etc.

Belt Drive Compressors / Single Phase

6

•Should you intend to use an air tool for a long durations ensure that the output of the compressor

(known as its FAD or Free Air Delivery) well exceeds the air consumption of the tool being used.

•Remember that your compressor has been designed with a 50% duty cycle in mind; continuous

operation may cause it to overheat and result in serious mechanical damage to components. You should

consider a larger or screw type compressor for long term or continuous duty applications.

•Use extension cords sparingly - and only use ones with an adequate current rating. Using an ordinary

(light duty) extension lead on a compressor can cause voltage drop, overheating the motor and

leading to appliance damage or even fire.

•As your Compressor has an air cooled motor as well as an air cooled pump which draws in atmospheric

air for cooling, it is important not to run the compressor in confined areas with poor ventilation or

elevated temperatures. Never use on loose surfaces such as dirt, dust or sand, otherwise abrasive

particles will be sucked into the air stream and cause the premature wear of components.

•Your air compressor is not water proof; do not attempt to use or store it in the rain, snow or any other

environment with extreme conditions. It has been designed for use and storage indoors.

•Used and maintained correctly, your compressor will provide many years of reliable service.

•Your Compressor has been manufactured to a high standard in order to ensure a long service life.

Ultimately the realization of the intended service life requires the operator to observe all instructions and

servicing requirements as described in this manual.

•Always wear approved safety glasses with side shields when using compressed air. Never point any

nozzle or sprayer toward any part of the body or at other people or animals.

•Do not operate the air compressor if any guards or covers are missing, damaged or not installed

correctly. Ensure all maintenance is carried out by qualified personal.

•Never allow children or untrained personal to “play” with compressed air.

The Compressors are equipped with an overload cut-out

(E) which operates as a safety device to protect the motor.

When the motor overheats, because of any electrical or

physical overload, the cut-out switch automatically

releases and cuts off power, thus preventing the motor

from being damaged. If tripped, wait a few (about 5)

minutes before resetting the device, then restart again.

If you restart the compressor and the overload safety

switch releases again, turn the main switch OFF, unplug

the equipment, and contact an Authorized Service Centre.

Belt Drive Compressors / Single Phase

7

Chapter 2 Operating the Air Compressor

2.1 IMPORTANT SAFETY INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OFTHIS PRODUCT COULD

RESULT IN SERIOUS INJURYAND OR PROPERTY DAMAGE.

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING.

HAZARD

WHAT CAN HAPPEN HOW TO PREVENT IT

Water

directed at electrical

connections or switches, or

objects connected to an electrical

circuit, could result in a fatal

electrical shock.

Moisture or a liquid of any kind

may conduct electricity and could

result in a fatal electrical shock.

The air compressor is not

waterproof.

Never

attempt

to clean

the

air

compressor while it is running.

Direct any water or spray away

from electric outlets and

switches.

Keep your air compressor out of

the elements and well sheltered

from rain, snow, dew, water or

mist of any kind.

Do not use the compressor with

the supply cord damaged or with

poor quality

connections.

0.5m

Operating the

air compressor

in

an explosive environment could

result in a fire.

Materials placed against or near

the air compressor can interfere

with its proper ventilation causing

overheating and possible ignition

of the materials.

Improperly stored paint thinners

could lead to accidental ignition.

thinners improperly secured

could get into the hands of

children or other unqualified

persons.

Good air flow is important as

both the motor and compressor

unit are air cooled. Restrictions to

or insufficient air flow will cause

overheating.

Never spray paint in

a confined

area with the air compressor.

Operate the air compressor in

well ventilated areas free from

obstructions. Equip areas with

fire extinguishers suitable for

electrical fires. Do not leave

nylon material shirts or jumpers

on the compressor.

Store paint thinners and other

flammable liquids in approved

containers, in a secure location

away from the work area.

Minimum clearance 0.5m

Maximum ambient operating

temperature 45°C

This air compressor

doe

s

not

provide breathable air, the air may

be contaminated with mineral

based oils and other contaminants

which poses the risk of serious

lung infection and or injury.

Spraying any material without the

use of a face mask will result in

the ingestion of foreign

substances

.

Never try to provide breathing air

or refill auxiliary breathing

apparatus using this compressor.

Never spray substances in a

closed location occupied by

humans or animals always use a

face mask when spraying

substances.

Contact with hot surfaces, such as

the cylinder head, cooling fins or

discharge pipe, could result in

serious burns.

These parts will remain hot for

some time after the compressor is

shut down.

During operation, touch only the

control surfaces of the air

compressor. Keep children and

animals far away from the air

compressor at all times. They

may not be able to recognize the

hazards of this product.

Allow the air compressor to cool

before storage.

Belt Drive Compressors / Single Phase

8

2.2 Preparation before Starting

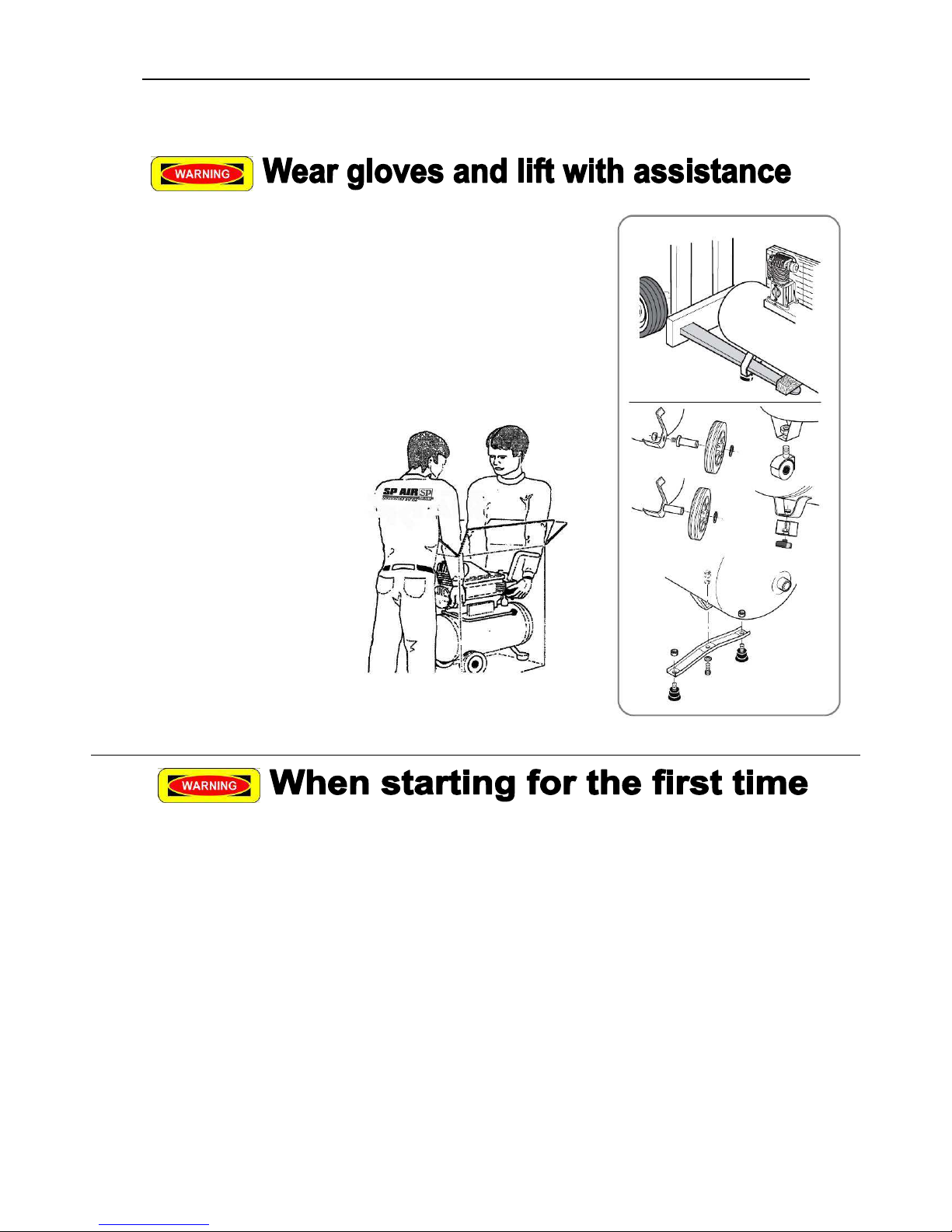

Unpacking

Depending from the model, the compressor can be supplied on a wooden

pallet and protected by a top cover; or in a carton box. Wear safety gloves

and cut straps with scissors and withdraw any staples with long nose pliers

and open the top cardboard flaps from the machine top, or lift the compressor

with the help of mechanical assistance. When handling compressors with

tanks holding over 50 litres and be sure to keep the machine well balanced at

all times. Hoist the compressor using suitable lifting power. Clear the

area of any possible hindrance, These compressors should be handled by

skilled personnel trained to operate lifting equipment.

Fit the wheels and/or the anti-vibrating

elements. Once the compressor is in

the designated place of installation, fit

the vibration dampers and/or the

wheels supplied with it.. Pay attention

to the accessories contained in the

packing and verify the integrity of your

compressor. Carefully lift the

compressor and place it on the work

surface.

We recommend that you store the

packaging for the duration of the

warranty period. If necessary, it will be

easier to return the compressor to the

service centre.

Run in procedure

When starting the compressor for the first time leave the air compressor run for 0 minutes with the air cock completely

open. After 0 minutes check that the drain cock is closed and shut the main air cock. Make sure that the compressor

stops automatically once its maximum pressure is reached. The compressor will start again once the pressure drops

below the minimum threshold pressure (approx. 2bar (30psi) lower than the cutoff pressure).

*Note: All SP Compressors are delivered only after a successful testing period at the factory.

For the long life of your compressor it is recommended that you drain and replace the pump lubricant after 10 hours of

use, Drain the oil while it is still warm this will help remove any abrasive particles loosened from the initial run in period.

Replace pump oil with Scorpion Compressor oil AC-68.

Chapter 3 Maintenance of the air compressor

Belt Drive Compressors / Single Phase

9

WHEN DOING MAINTENANCE, YOU MAY BE EXPOSED TO ELECTRICITY, HOT

SURFACES, HIGH PRESSURE AIR, MOVING PARTS, OR FIRE WHICH MAY

RESULT IN INJURY OR DEATH. BEFORE PERFORMING ANY MAINTENANCE

OR REPAIR, DISCONNECT ANY POWER SOURCE; LET THE COMPRESSOR AND

MOTOR COOL DOWN COMPLETELY. DRAIN ALL AIR PRESSURE FROM THE

TANK. CONTACT A LICENCED SERVICE TECHNICIAN FOR ALL ELECRTICAL

REPAIRS.

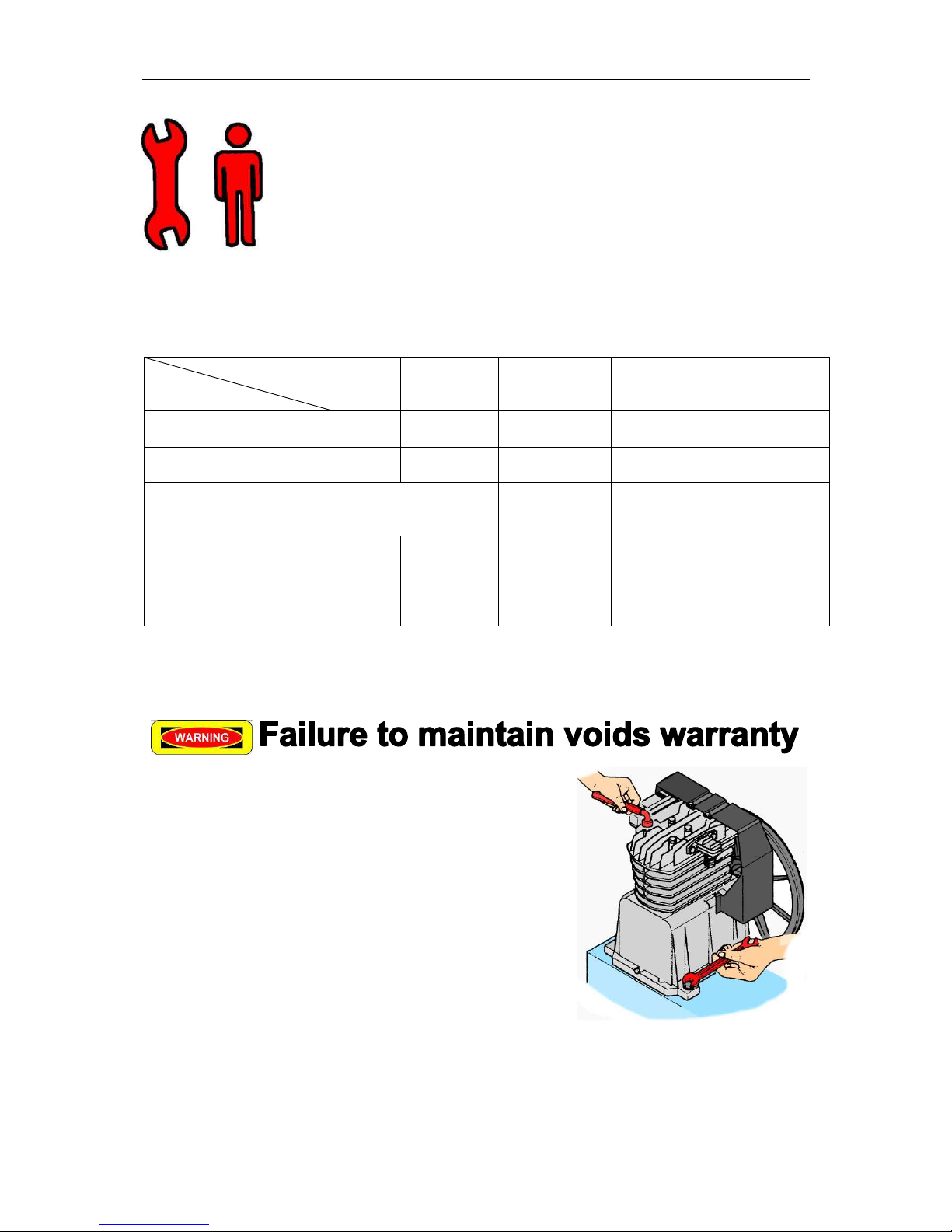

3.1 Regular maintenance schedule

Keep your air compressor in good condition, regular inspection and maintenance is very important.

Service period

regular

Item

Every

day After 10 Hrs Every month

Every 6 months

Every year

Check the oil level

Drain tank condensation

Clean air intake filter (Service more

frequently when used in

dusty conditions)

Replace

filter element

Change pump oil 1st time 2nd and

thereafter

General cleaning of the

compressor, check for leaks

“

”

The chart above indicates which checks to make and when to make them.

Check for any loose

fasten

ers

after

1

0 hours of operation

•Check that all nuts and bolts are properly tight

•Drain and replace the pump lubricant

Replace pump oil with Scorpion compressor oil.

(this will remove abrasive particles, from initial run in period)

After 10Hrs of use

Belt Drive Compressors / Single Phase

10

Air filter maintenance

Remove the outer cover to access the filter element

Paper air filter elements, can be cleaned by gently

blowing with compressed air (20psi) from the inside out.

Air filter maintenance

Air filter maintenance will be increased when the

compressor is used in dusty conditions.

Replace the filter every 2 months.

Do not operate the compressor without an air filter.

Foam air filter elements should be washed in warm soapy

water, allow to dry, then re-oiled before use.

Check b

elt tension

Correct belt tension is important if the belt is too tight it will

cause the motor to overheat and increase electricity

consumption. If the belt is too loose it may slip easily,

whip and break.

Hang a weight of about 3kg at the mid point of the belt.

Deflection should be about 0mm. If necessary retention

the belt taking care not to disturbed the pulley – flywheel

alignment.

Correct pulley alignment is extremely important!

Belt Drive Compressors / Single Phase

11

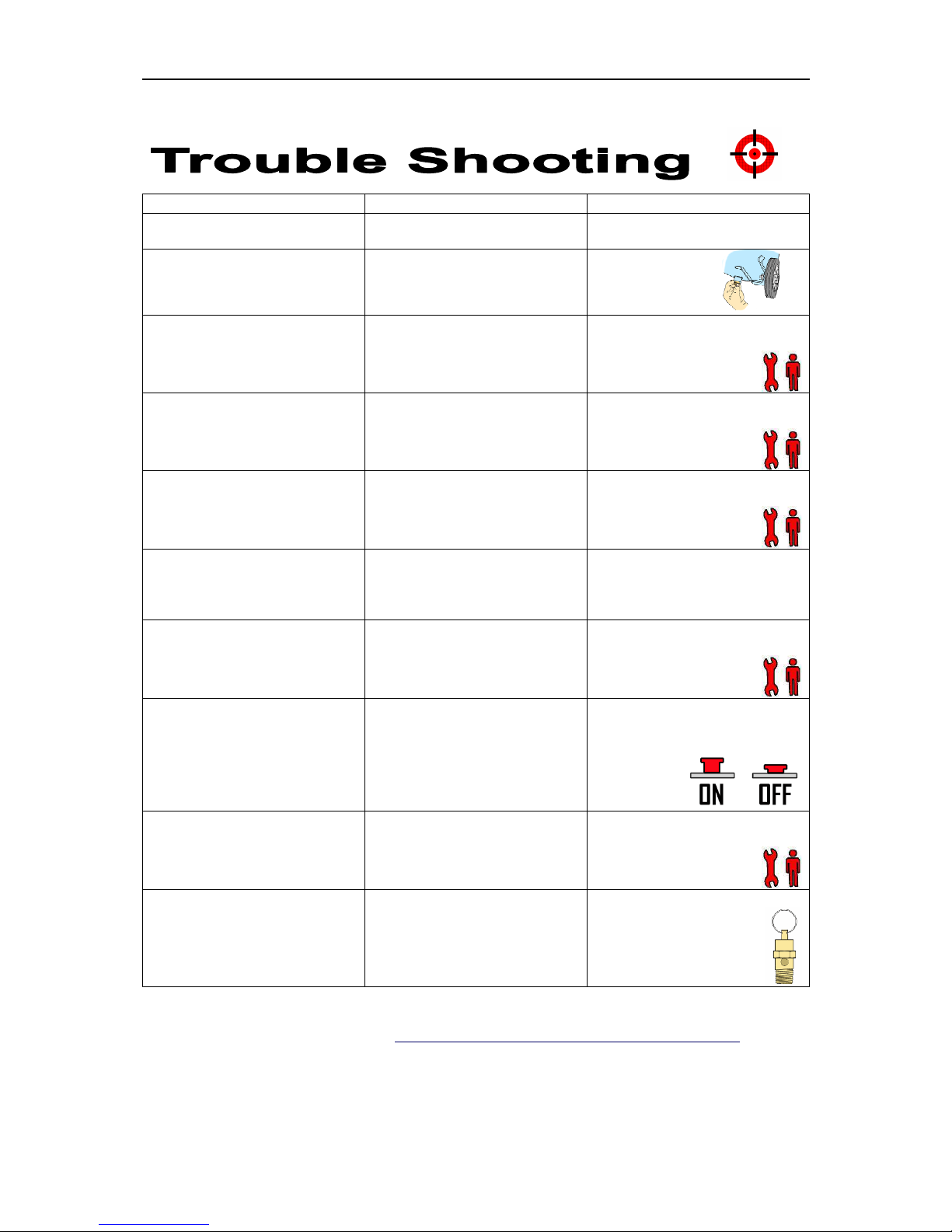

Fault

Cause

Reme

dy

Tank pressure

continually

drops

.

Air leak

, check all connections

.

Locate and rectify leak

.

Tank pressure won’t build up.

Drain valve is open

.

Close tank drain valve.

The compressor won’t switch off

.

The safety valve blows off.

Pressure switch fa

ils to stop motor

Faulty pressure switch.

Contact a specialized service

technician.

Tank pressure won’t build up

and the

pump is getting hotter than normal,

inlet suction is poor.

The compressor head gasket

or

valve plate is faulty.

Contact a special

ized service

technician.

There is a leak from the base of the

pressure switch when the

compressor is running.

Failure of the pressure relief valve

.

(in base of pressure switch)

Contact a specialized service

technician.

There is a leak from the bas

e of the

pressure switch when the

compressor is stopped.

The Non Return Valve

(from the

tank) is leaking.

Disassemble and clean if necessary

replace valve insert.

The compressor is noisy with

metallic clangs.

Bearing or loose part problem

.

Stop the comp

ressor and contact a

specialized service technician.

The compressor sounds like it is

trying to start (motor makes a

humming noise).

Air pressure trapped on piston is

resisting the starting effort.

Turn unit off and on again using the

pressure switch. This will vent air

from the delivery tube.

The compressor sounds like it is

trying to start (motor makes a

humming noise).

The capacitor is faulty

.

Stop the compressor and contact a

specialized service technician.

Air leaks from the safet

y valve at

a

pressures less than its rating.

The safety valve is faulty

.

Replace the Safety

valve.

To obtain local service agent locations: http://www.austechindustries.com.au/html/service.html

or email: service@austechindustries.com.au

Austech Industries Pty Ltd A.B.N. 19 010 548 464

23 Iris Place,Acacia Ridge, 4110

PO Box 715

Archerfield Qld 4108

Brisbane Australia

T: (07) 3723 1500

F:

(07) 3723 1555

Effective 1

st

Day of December 2013

Limited Warranty Policy

This Limited Warranty applies only to new products* distributed by Austech Industries Pty Ltd (“Austech Industries”). It is a

condition of this Limited Warranty Policy that the purchaser read the owner’s manual for the product and only use the product to

the extent or for the purposes stated therein. The purchaser must also ensure that all servicing requirements are completed as

listed in the owner’s manual (said servicing is at the owner’s expense). We recommend that all servicing is completed by an

authorised service agent and that records of said servicing are retained by the purchaser as proof in the event of a warranty claim.

Whilst the owner’s manual, packaging, and/or other documentation supplied with Austech Industries’ products may provide details

in respect of a Limited Warranty, the terms set out herein supersede these matters, and this Limited Warranty applies in their

place. This warranty is no less advantageous than otherwise described in such other documentation.

Austech Industries agrees, subject to the terms and conditions specified below, to repair or replace at Austech Industries’ cost, the

product purchased by you when the product does not perform in accordance with its specifications during the limited warranty

period, due to any fault in manufacturing, materials and/or workmanship. Austech Industries is not liable to repair or replace

products that the purchaser uses in a manner that is inconsistent with the owner’s manual or in the circumstances set out in

paragraphs 1.1 – 1.7 below.

The benefits to the purchaser under this warranty are in addition to other rights and remedies under the Competition and

Consumer Act 2010 (Cth).

The limited warranty period, within which a defect in the product must appear, commences from the date of purchase and ceases

on expiration of the specified term below.

The Limited Warranty Period

•

Engine Powered Equipment - 12 months

•9 & 10 Bar Belt Drive Compressor Pumps - 36 months

•Refrigerated Air Dryers - 12 months

•8 bar Compressors - 12 months

•Generators & Compressors - 12 months

•Tool Boxes – 12 Months

•SP Cordless – Tool 24 months

•

SP Air Tools -12 months

•SP Nail Guns - 36 months

•Scorpion Air Tools - 12 months

•SRT Air Tools - 12 months (DIY)

•Torini Engines - 36 months

•Hand Tools – Lifetime

•SP Cordless – Battery 12 months

The purchaser’s attention is drawn to the following

To the extent permitted by law and subject to this Limited Warranty, and as part of the terms of the sale of the equipment or

part thereof: Austech Industries shall not be liable for any form of loss, damage, cost, injury or harm of any kind (whether

direct, indirect, special or consequential) howsoever arising from the use or supply of the equipment to the purchaser.

Exclusions to Limited Warranty Policy

This Limited Warranty will not apply where the equipment or any part thereof:

1.1

1.2

1.3

1.4

1.5

1.6

1.7

Fails due to an accident (including liquid spillage), abuse, misuse, neglect or normal wear and tear;

Has been used in a manner other than for which it was originally designed;

Has been tampered with or is otherwise than as supplied by Austech Industries;

Where any damage, malfunction or other failure of the equipment or any part thereof resulted directly or

indirectly from unauthorized persons, adjusting or failing to adjust any part requiring normal maintenance and

service (examples include adjustment of tappets, air filter maintenance, lubrication and tightening of screws nuts

and bolts);

Malfunctions due to the use of defective or incompatible accessories;

Is damaged by lightning or thunderstorm activity; or

Has been transported to a country where no authorised Service Agents exist.

Claiming warranty

This Limited Warranty may be claimed on in the following manner:

2.1

2.2

2.3

In order to make a claim under this Limited Warranty, the purchaser must deliver the equipment or any part

thereof to an Austech Industries authorised repair agent and pay all costs of transportation and all costs

incidental to making a claim under this Limited Warranty. The purchaser must first contact Austech Industries

(contact details described above) and request the delivery address of an Austech Industries authorised repair

agent.

The purchaser must deliver to the repair agent written reasons why the purchaser considers that the purchaser

has a claim under this Limited Warranty and must provide all necessary details, including:

•The place, date and from whom the unit or part was purchased.

•The unit or part involved, Model and Serial Number.

•The defect, malfunction or failure in respect of which the claim is being made.

•Proof of service of the unit or part (if applicable)

•Proof of purchase in respect of the unit or part.

If the Limited Warranty claim is valid, the repair agent will carry out repairs and return the product at no charge to

the purchaser. These repairs are limited to the Limited Warranty fault identified and as such will not include any

other faults due to misuse, abuse, failure to maintain, fair wear and tear or the replacement of serviceable items

such as oil, spark plugs, air filters, fuel etc.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

* SP, Scorpion, Torini, & SRT are all brand names of products distributed by Austech Industries

Note

#

Units which are failing to perform in accordance with specifications due to non-warrantable causes will be subject to freight, repair and or quote charges.

Other manuals for Construction Series

2

Table of contents

Other Sp Air Air Compressor manuals

Popular Air Compressor manuals by other brands

Little Labs

Little Labs LL2A Operator's manual

Craftsman

Craftsman 919.176502 Operator's manual

Sanborn Mfg

Sanborn Mfg 200-2357 Operator's manual

Craftsman

Craftsman 919.167362 owner's manual

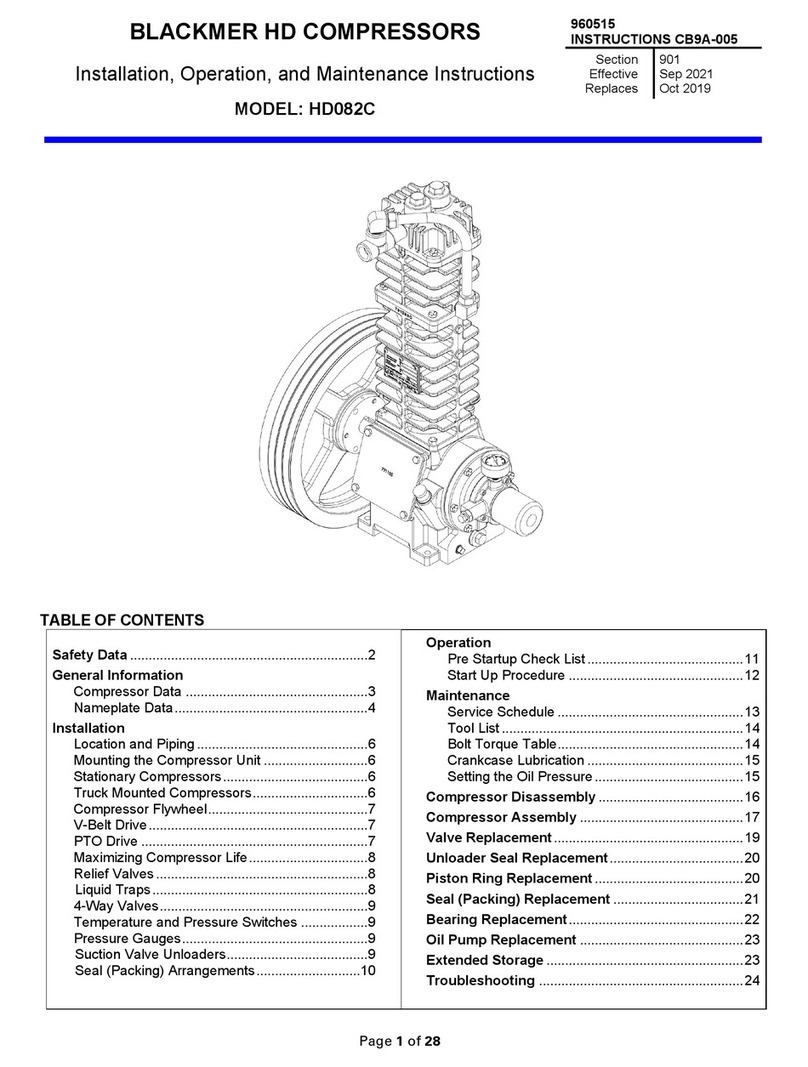

BLACKMER

BLACKMER HD082C Installation, operation and maintenance instructions

GÜDE

GÜDE 231/10/24 12-TLG Translation of the original instructions