Spacesaver Eclipse Powered System User manual

Thank You For Your Purchase of a Spacesaver Powered System.

For a comprehensive listing of other Spacesaver products and services, please contact your local Spacesaver

representative for a Product Overview Brochure.

Spacesaver Corporation

1450 Janesville Avenue

Fort Atkinson, WI 53538-2798

1-800-492-3434

www.spacesaver.com

Spacesaver Corporation is a division of KI. KI and Spacesaver are registered trademarks of Krueger International, Inc.

© 2007 KI and Spacesaver Corporation. All Rights Reserved. Litho in USA. REV. 1.0/SC-0603 SSC/MAR 11/07

Additional Products:

•Mechanical Assist Systems

•Manual Systems

•Mobile Pallet Racks

•XTend™Mobile High-Bay Storage Systems

•Modular Mobile Systems

•Modular (Bi-File®) Systems

•QuickSpace®Systems

•Mobile Art Rack Systems

•Hang-Glider Pro®Pullout Storage Panel Systems

•Rotary Storage Systems

•Cantilever Bookstack Systems

•XTend™Stationary High-Bay Storage Shelving

•Case-Type Shelving Systems

•4-Post Bin Shelving Systems

•4-Post File Shelving Systems

•Fire Hose Rack Storage Systems

•Modular Drawers & Doors

•Weapon & Pistol Racks

•Hinged Doors

•Museum Cabinets

•Wide-Span Shelving

•ActiveStor®Lateral File Cabinets

•ActiveStor®Storage Cabinets

•ActiveStor®Pedestals

•ActiveStor®Bookcases

•FrameWRX™ Storage Systems

Additional Services:

•Extensive network of local Storage Specialists

•Single-source turn-key project management

•Factory-certified system installation

•Ongoing maintenance and support

KI

1330 Bellevue Street

P.O. Box 8100

Green Bay, WI 54302-8100

1-800-424-2432

www.ki.com

With over 100,000 installed systems – more

than all of our competition combined –

Spacesaver leads the industry in customized,

high-density mobile storage solutions.

Almost any type of material – regardless of its

size, weight or shape – can be stored in

Spacesaver Powered Systems. Designed to

maximize your storage space, they often

more than double storage capacity in the

same floor space. They also provide an

extraordinary level of quality, as our ISO

9001:2000 certification attests.

We alone have the know-how and resources

to develop and perfect the advanced tech-

nology that makes a solution such as Eclipse

possible.

And that makes power easy. To choose. To

use. To afford. To rely on.

No one packs more into

every storage solution.

A tailored storage system

that meets your unique criteria.

Single-source turnkey project management.

Factory-certified system installation.

Ongoing maintenance and support.

15

Eclipse

Powered System™

OWNER’S MANUAL

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Proper System Use . . . . . . . . . . . . . . . . . . . . . . . 3

Improper System Use . . . . . . . . . . . . . . . . . . . . . 3

Recommended Loading Instructions . . . . . . . . . 3

Control Functions . . . . . . . . . . . . . . . . . . . . . . . . 4

System Operation and Reset Options . . . . . . . . 4

Control Options . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Optional Safeties . . . . . . . . . . . . . . . . . . . . . . . . 7

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Programmable Options. . . . . . . . . . . . . . . . . . . 10

Power Outage Options. . . . . . . . . . . . . . . . . . . 11

Lighting Options . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 12

General Maintenance . . . . . . . . . . . . . . . . . . . . 13

Statement of Warranty . . . . . . . . . . . . . . . . . . . 14

2

Table of Contents

3

Spacesaver’s powered mobile storage systems provide a simple and efficient means to increase storage

capacity without expanding the space needed for your materials. The purpose of this manual is to provide the

information necessary to use and maintain your Spacesaver system. This document, combined with your on-

site training will provide you with the ability to use your system properly and efficiently.

As the owner of a Spacesaver high-density mobile storage system, you can be assured that you have

purchased the best in the industry. Its quality, safety, and ease of use are unsurpassed. Together with your

local representative, we stand behind our products with an installation and service team dedicated to

meeting your needs. From all of us, thank you for purchasing Spacesaver.

Introduction

Below is a list of items/tasks that will help to ensure that you get the most out of your mobile storage

system. Please familiarize yourself with these items and establish a routine based on these guidelines.

1. Familiarize yourself with the content of this manual.

2. Ask questions if you are unsure of any operational or safety features.

3. Bring any unusual performance of the system to the attention of your supervisor.

4. Follow the recommended shelf loading instructions found in this section of the owner’s manual.

5. Keep media neatly stored and pushed fully back onto the shelving to help maintain desired

aisle width.

6. Provide needed periodic maintenance according to the recommended schedule.

Ask about a periodic maintenance contract.

7. Make certain that all system safety devices are operational.

8. Call your local Spacesaver representative immediately if a safety device requires attention.

PROPER SYSTEM USE

Proper use of your system will ensure its longevity. In order to maintain proper performance, please

take the following precautions.

1. Do not climb on the shelving – use a stool.

2. Do not leave items in the aisles.

3. Do not operate the system without checking the open aisle(s) for people and/or objects.

4. Do not allow media to extend into the aisle to the extent that the carriages cannot close

together properly.

5. Do not overload your system. Stay within the recommended weight and distribution limits.

6. Do not operate any system under the safety override condition except in the presence of

your supervisor.

IMPROPER SYSTEM USE

1. Do not fully load one side of double entry shelving without counterbalance weight on the other side.

2. Begin loading at the lowest shelf.

3. At no time should the weight difference from one side of the carriage to the other exceed

30 percent.

RECOMMENDED LOADING INSTRUCTIONS

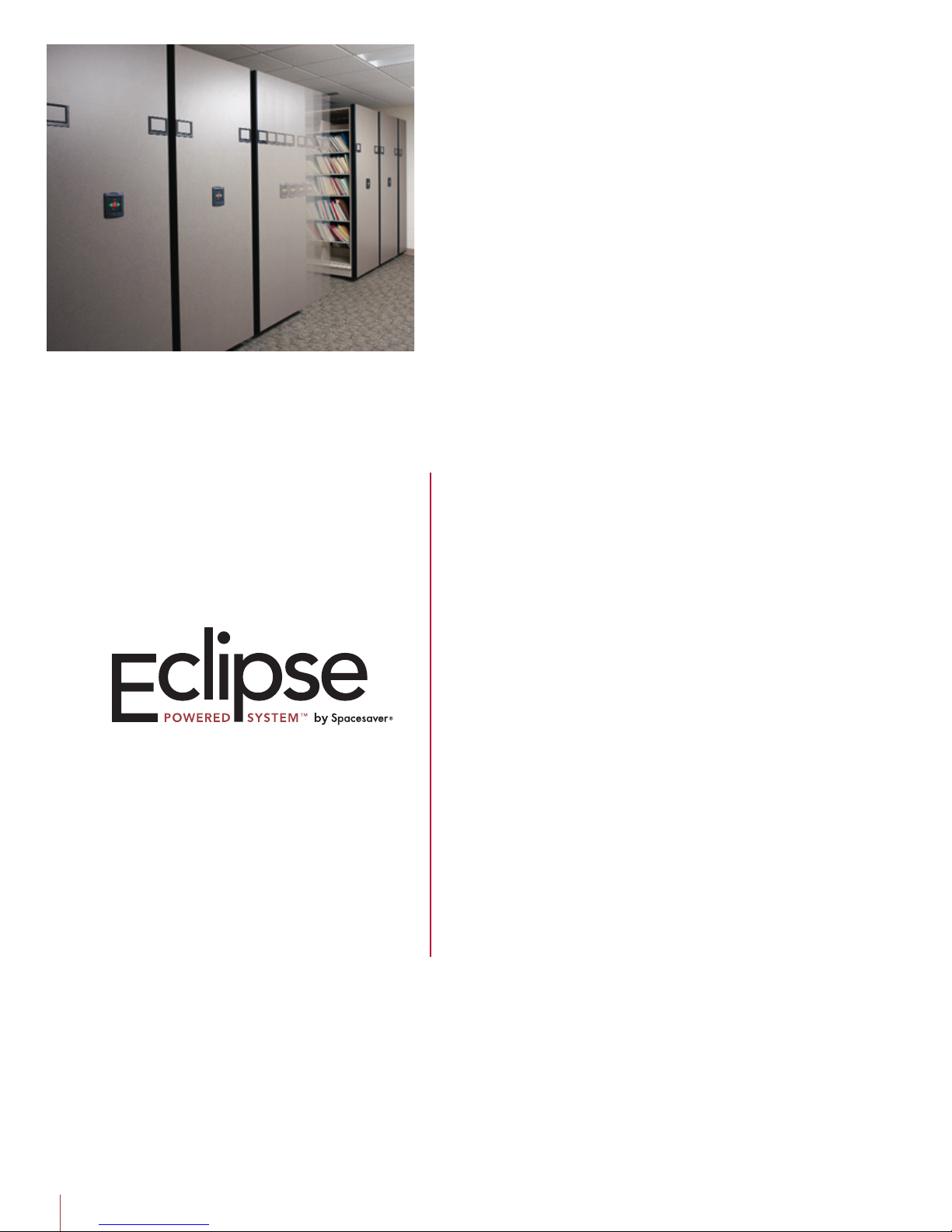

Our push-button control is the standard control for our powered

systems. For your convenience, Spacesaver’s web address is

printed on the front of the control label. The control has easy-

to-use functionality. A simple push of a button will move, stop

or reset the system.

• The “Move” button:

Begins carriage movement in the direction of the arrow

Turns on aisle lights (if applicable)

• The “Stop/Reset” button:

Stops carriage movement

Resets the system after a safety feature is activated

Cancels a locked aisle condition

Turns off aisle lights (if applicable)

• The LED indicator:

(Located directly above the “Stop/Reset” button)

Alerts the user to the status of the carriage with either red

or green lights

An optional infrared-capable control is available. This control

allows the use of remote controls for system access &

programming. (See the Control Options section of this manual

for more information on this feature.)

System Operation and Reset Options

Touch & Hold Operation

Touch & hold operation requires the user to walk with the

carriage continuously holding the directional “Move” button.

One-Touch Operation

When using one-touch operation, the user presses the

directional “Move” button until they hear a beep and the

carriage begins moving.

Manual Reset

Manual reset requires the user to visually check the open aisle

and press the “Reset” button on the open aisle control. The

system can be programmed to re-lock (go red) after 15 seconds

of inactivity.

Automatic Reset

On a system with automatic reset, the controls automatically

clear after an action or move is completed. If a safety is

activated, the user will need to reset the system once the safety

is cleared of any obstruction.

Carriage Spacing Adjustments

See the Safety Override Key section on page 6 for more details.

4

Control Functions

5

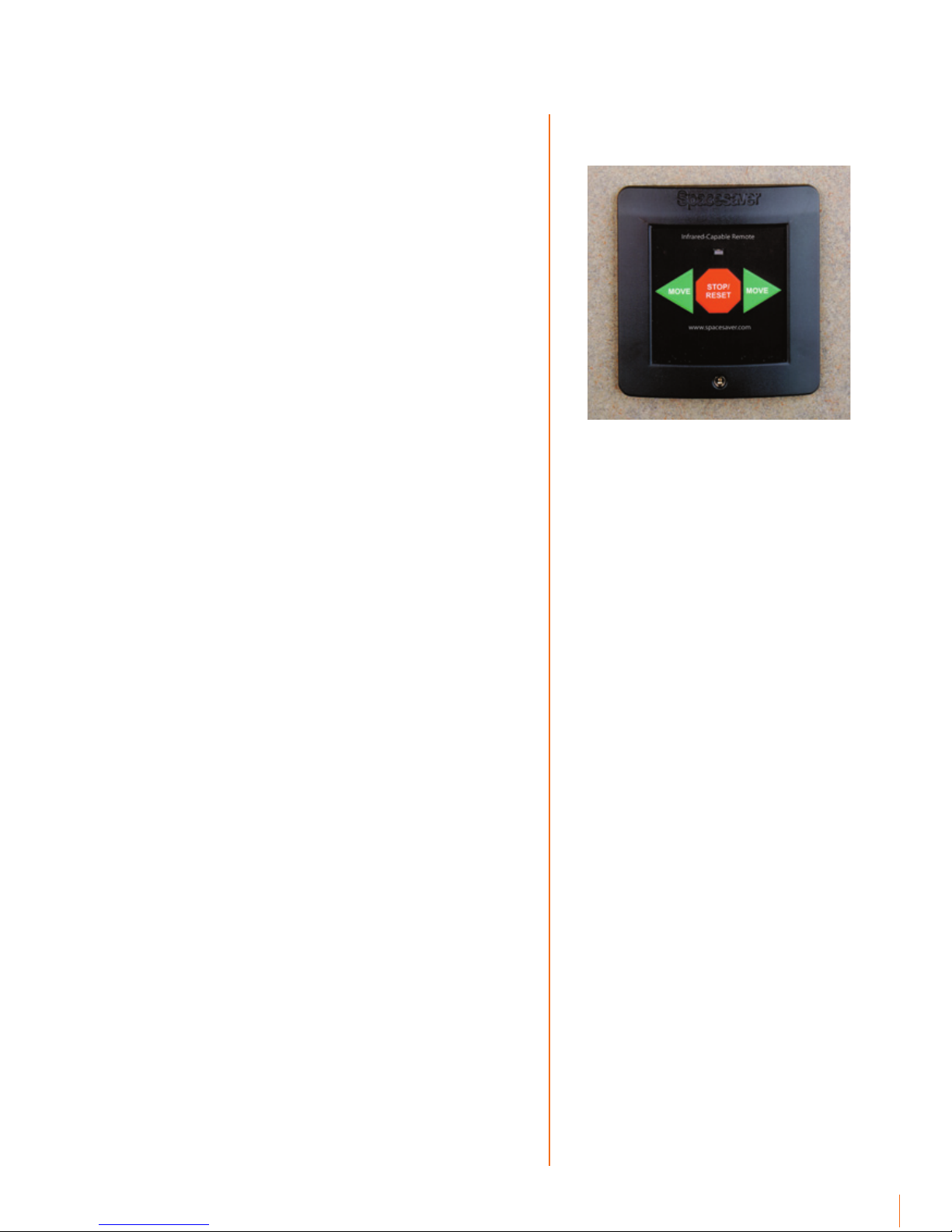

Infrared-Capable Control

An optional control is available that allows the user to move a

carriage, program aisles, and conduct the auto move functions.

The buttons on the control itself function identically to the

standard controls. (See Control Functions section of this manual.)

Remote Controls For Use With Optional Infrared-Capable

Control

There are two remotes available for use with this control.

User Key

The user key allows the user to move, stop and reset your

mobile system without making contact with the control. To

use this remote, point the remote at the aisle control you wish

to operate. A touch of either of the directional move buttons

on the remote will begin carriage movement in the direction

desired. If your system is equipped with the touch and hold

feature, continue to hold the move button until the carriage

move is completed. To stop or reset the carriage, simply press

the appropriate button on the remote.

Managerial Key

The managerial key provides additional functionality when

used in conjunction with the infrared-capable control.

System On/Off

A press of the button will turn the entire system on and

off. To initiate this function, point the remote at any

infrared-capable control and press the “On/Off” button.

No further action is necessary to accomplish this task.

Fixed/Stationary Carriage

This feature allows you to make any carriage a temporary

stationary unit, in effect creating two systems from one, or

securing items on one side of the carriage. Please

remember when creating two systems from one to

maintain a realistic/proper aisle width. To use this feature,

position the temporary fixed carriage in the desired

location. Do this by moving it into position and pressing

the “Stop/Reset” button. Point the remote at the control

on the temporary fixed carriage and press the “Fixed”

button. The back lighting on the control will display

“Stationary Carriage”. To cancel the fixed carriage, press

the same button on the managerial key. When using the

fixed carriage function, all safety features remain fully

functional.

NOTE: You need to be within three feet (one meter) of the

control when using the remotes.

Control Options

6

A floor-level safety sweep is considered the system’s primary

safety. Every aisle is required to have a minimum of one sweep.

Spacesaver has two options available for safety sweeps; Photo

Sweep®and mechanical sweep.

Photo Sweep®

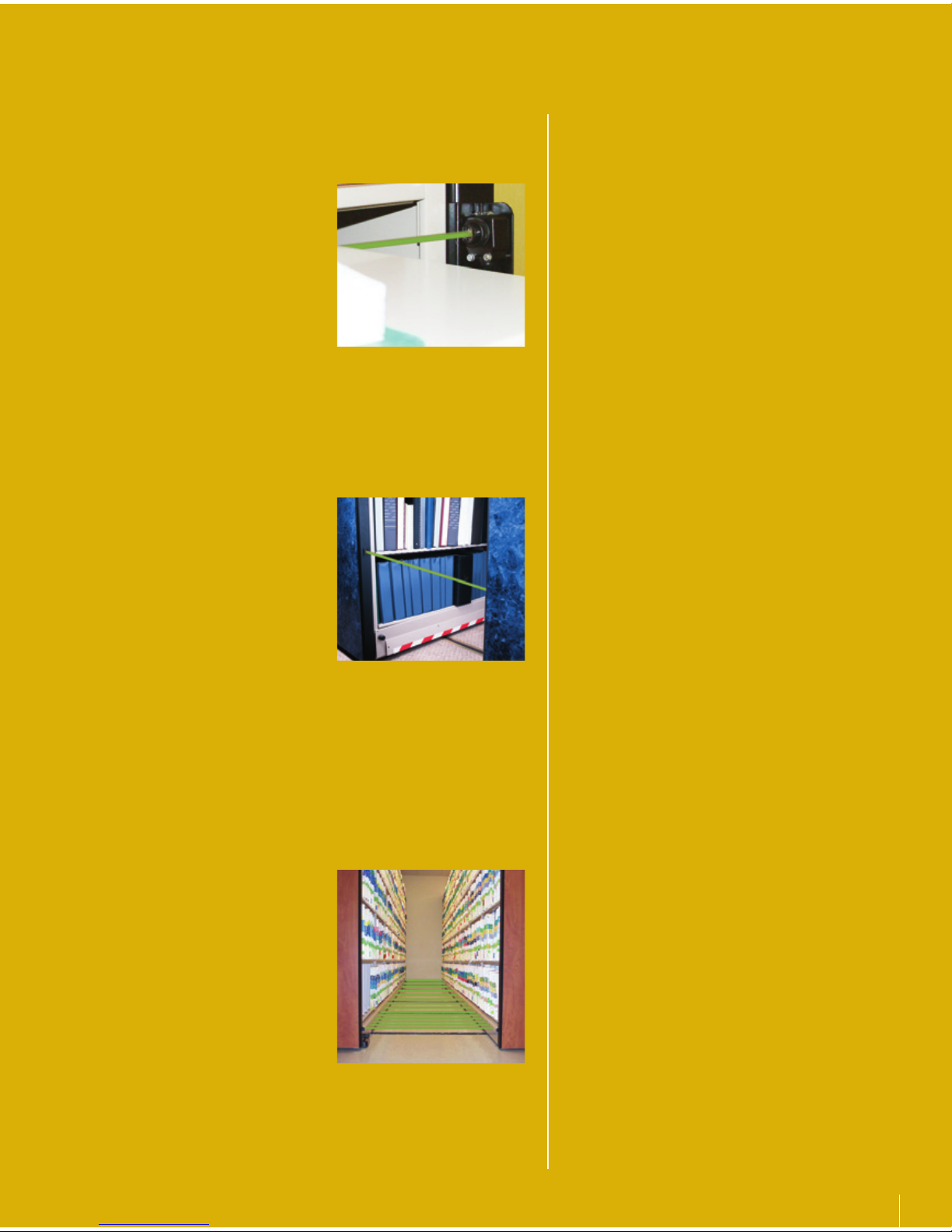

An infrared light beam sweeps

for obstructions close to the

floor. If a carriage begins to

move while you are in the aisle, it

can be stopped by breaking the

light beam that is constantly

projected along the entire length

of the carriage. To accomplish

this, simply place your foot in the

area defined by the red and white safety tape. When the

sweep beam has been broken, the control affected will display

“aisle in use”, and the control LED will flash red. All other

controls will go dark. Once the safety sweep has been cleared,

press the “Stop/Reset” button to resume normal system

activity.

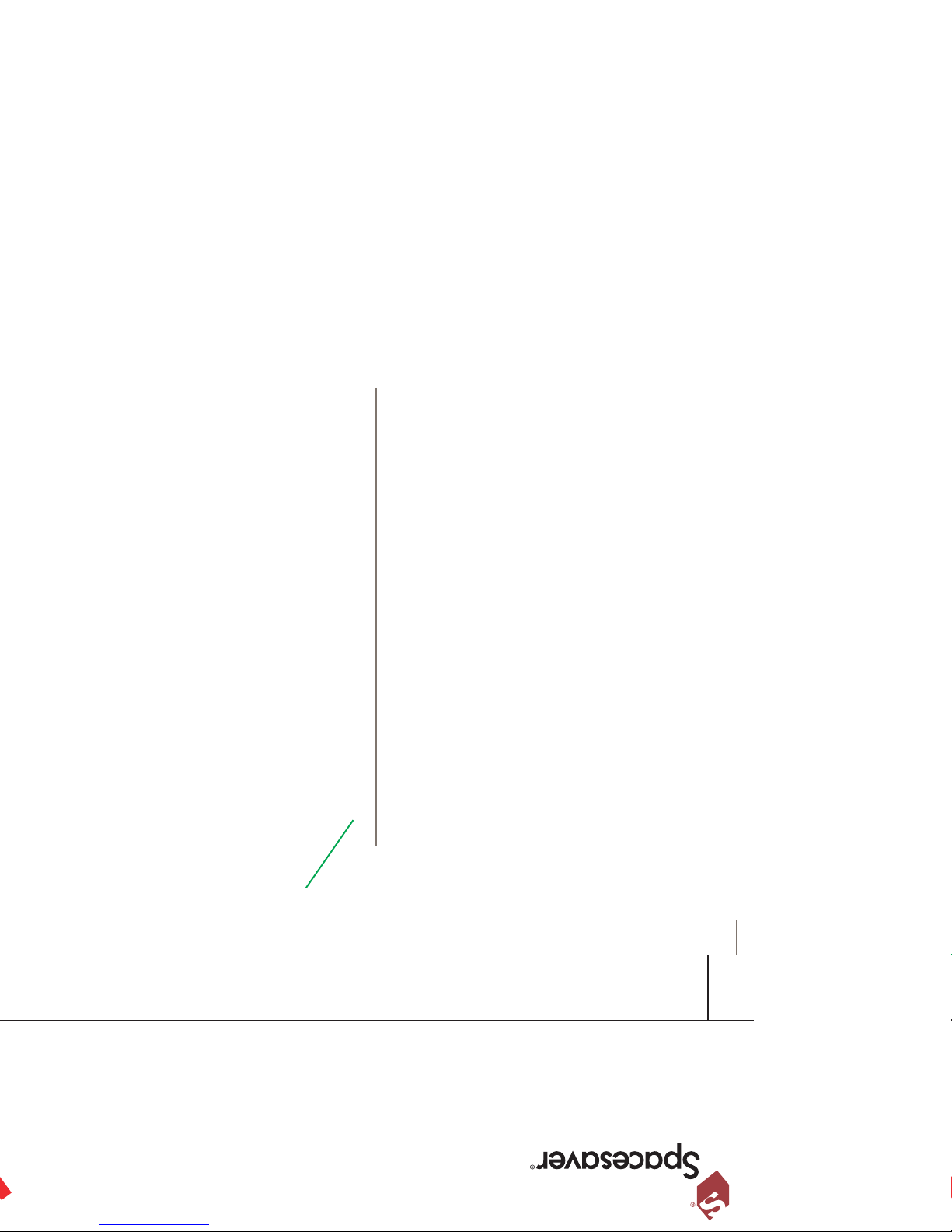

Mechanical Sweep

The mechanical sweep functions

by applying pressure to the

sweep located along the length

of the carriage. If a carriage

begins to move while you are in

the aisle, it can be stopped by

depressing the metal sweep

plate with your foot in the area

defined by the red and white

safety tape. When the sweep has been activated, the control

affected will display “aisle in use”, and the control LED will flash

red. All other controls will go dark. Once the safety sweep has

been cleared, press the “Stop/Reset” button to resume normal

system activity.

Safety Override Key

To adjust carriage spacing, insert the safety override key into a

control head on a carriage with an open aisle next to it. Touch

and hold the “Stop/Reset” button. After 5 seconds, the LED

with flash red and green and the “Aisle in Use” will be lit.

Continue pressing the “Stop/Reset” button and press the

“Move” button in the direct you wish to adjust the aisle. Once

the desired spacing is reached, release the “Stop/Reset”

button and remove the safety override key.

Extreme caution must be exercised while operating

under this condition. This should only be used when

the user cannot correct the problem causing the

carriage to fail safe. Please note that this device

should be used only by trained supervisors and/or

service personnel.

The safety override key is inserted

into the jack in the face panel control. Touch and hold

the “Move” button in the direction you wish to move

the carriage. The system will move at a greatly reduced

speed. An audible “beep” alerts users that the system

is operating without safeties. To resume system

function, the safety override key must be removed.

CAUTION: no safeties are functional when the system

is operated using the safety override key.

Safety

In addition to a floor-level safety sweep, your system may be

equipped with one or more of the following safety options:

Waist-High Photo Sweep

An additional set of Photo

Sweep sensors can be mounted

at waist level for additional

safety. This is typically mounted

at reference shelf height. For

this safety, shelving elevations

need to be consistent, and

overhanging media should not

be present as it could block the

beam. This DOES NOT replace the floor-level sweep.

Hinged Door Protection Photo Sweep

Another Photo Sweep can be added to detect if a hinged

door is open. Again, this DOES NOT replace the floor-level

sweep.

Aisle-Entry Sensor

This feature has an invisible

beam that crosses each aisle.

The following actions occur

when using this safety feature:

• Entering an open aisle

will break the beam, and

prevent the system from

moving.

• Entering an opening aisle will have no effect on the

opening of the aisle, but will prevent the system from

moving once the aisle is fully opened, until the system

is reset.

• Entering a closing aisle breaks the beam stopping

system movement.

In all of the above situations, when you leave the aisle, you

will have to press the “Stop/Reset” button at that aisle in

order to return the system to normal operation.

Zero Force Sensor®System

This safety feature requires no

effort on your part. As you

enter the aisle, you are

detected by invisible light

beams. As long as you remain

in the aisle, no carriage

movement is possible, and the

“aisle in use” message is

displayed on the control along

with a solid red light.

As you leave the aisle, the system will automatically return

to a “green light” condition, meaning that it is ready for

use. If it does not go to “green”, please check the aisle for

any obstruction and then press the reset button for normal

operation.

Optional Safeties

7

A variety of options exist to secure materials stored on the system.

TouchPad Aisle Access requires a 4-

digit Personal Identification

Number (PIN) to access a specific

aisle, limiting it only to authorized

individuals. Upon exiting the open

aisle, the user must depress the

“Close” button on the system

module to re-secure the system.

One or all of the carriages may have

this control in place of the standard

or infrared-capable control.

TouchPad System On/Off is used

in addition to the standard control

and functions as follows. When

placed on a platform, it can be

used to turn the system on and off.

TouchPad Stationary Control is used in addition to the

standard control and functions in the following ways to create a

stationary carriage within a powered system.

• Install the TouchPad Stationary Control on the extreme

left (or right) carriage. Park the carriages to the right (or

left). Enter the preset code and the system will remain

locked in that configuration (back lighting on the control

will indicate “Stationary Carriage”) until the code is

entered once again, allowing normal operation to resume.

• Install the TouchPad Stationery Control on any carriage

within the system. Park that carriage in the desired

location. Enter the preset code and the carriage will remain

locked in that position (back lighting on that control will

indicate “Stationary Carriage”) until the code is entered

once again, allowing normal operation to resume.

In all these situations, a 4-digit PIN is required. The following

procedure allows you to program the TouchPad control with

your own 4-digit code. This programming must take place

within a 10-second interval. NOTE: The factory-default code

is 1-2-3-4.

To change the 4-digit PIN;

1. Press the “#” key, then press the “*” key. The green

LED will being to blink.

2. Enter in the current code within the 10 seconds allotted.

Once the current code is entered, the LED will flash red.

3. Enter in the new code within the 10 seconds allotted.

4. The solid green LED will return.

Keyed System On/Off turns the entire system on and off with

a key located above the control.

Security

8

Carriage Lock

The carriage lock is placed on

the carriage and interfaces with

the system’s controls to provide

security for stored materials. It

features a key-controlled dead

bolt that locks into a floor-

mounted strike plate. It can be

used to lock all of the system’s

aisles closed or to secure one or more selected aisles.

A special key is required to release the lock handle. Once

the lock handle releases, turn it 180 degrees to unlock the

system. Push the handle back into its housing. NOTE:

Failure to return the handle to its housing may cause

damage to the lock, floor covering or carriage.

Waist-High Lock

Waist-high lock is conveniently

located on the front of the

system at waist level. It features

a key-controlled dead bolt that

locks into a floor-mounted strike

plate. A special key is required

for locking and unlocking.

Insert the key into the lock and

rotate the key 180 degrees to

lock or unlock. Rotate the

polished chrome handle ⁄ turn to engage or disengage the

lock. It can be used to lock all of the system’s aisles closed

or to secure one or more selected aisles.

Stop All Carriages on Safety Fault

With this option, all carriages stop at once when a safety is

tripped. Where security is king,

Stop All Carriages on Safety

Fault

is an option, to be used in conjunction with

TouchPad

Aisle Access

and

Block Move

, which helps keep carriages

packed closely together limiting access to only the aisle that

was commanded open. Without this option, mobile

carriages “downstream” from a safety fault will complete

their move.

Forced Entry Alert

Used in conjuction with

Stop All Carriages on Safety Fault,

Block Move

and the

Auto Move Interface

, the

Forced Entry

Alert

option sounds an audible alarm when someone pries

open a closed aisle. Additionally, a

TouchPad

(or other key

switch) must be ordered with the system as a means to

silence the alarm.

9

Security

Continued

10

Your system may be equipped to provide one or more of

several automated movements when prompted by a

preprogrammed period of inactivity or “building interface

signal.” These functions may be programmed through your

local Spacesaver service technician.

Auto Move Functions

•System Priority Aisle – Opens a specified aisle (or two)

after a period of inactivity.

•System Closed Park – Closes the system left or right.

•System Ventilation Park – Opens the system at evenly

spaced intervals.

•System Auto Cycle – Opens each aisle in sequence.

During automatic move functions, all safety features are

fully functional.

System Fire Park – Typically will evenly space your system in

response to an alarm activation. Requires that your system be

connected to your fire alarm system.

System Night Park – Prompts your system to perform an auto-

move function in response to a building interface signal.

Programmable

Options

System Priority Aisle System Closed Park

System Ventilation Park System Auto-Cycle

11

Spacesaver has two options that allow the system to operate

during power outages. You can be assured of continuous access

to your stored material.

Automatic Battery Backup

switches the system to battery

power if AC power is lost. It

provides for full system function,

including the safeties. The system

can operate for approximately 60

accesses on one charge.

When running on the automatic

battery backup, the system

beeps to let the user know it is running on battery power. As

the battery charge runs low, the system beeps faster. The

automatic battery backup provides the added benefit of

surge protection. When the system is back running on AC

power, the unit automatically recharges itself.

The Power Override Unit is a hand-held rechargeable

battery pack that serves as a backup option during power

outages. This must be plugged into a wall outlet to

recharge. The power override unit moves one carriage at a

time at a reduced speed. The hand-held power override unit

will beep during operation for safety.

CAUTION: system

safeties are not functional when using this power option.

Each charge yields approximately one hour of system use. A

battery pack with replaceable D-Cell batteries is also available.

Power Outage

Options

Rechargeable Battery Override Unit

Replaceable D-Cell Battery Override Unit

Your system may be equipped with optional overhead lights.

Use of these lights usually requires no effort on your part. The

lights will come on when the aisle is opened or when an aisle is

entered. The lights will shut off automatically shortly after you

leave the aisle.

If the lights do not turn on when an open aisle is entered, simply

press the “Move” button on the controls on either side of the

aisle.

If the lights are not timed to turn off automatically after leaving

the aisle, they can be turned off by pressing the “Stop/Reset”

button on the controls on either side of the aisle.

Lighting Options

CONTROL INDICATION

Abnormal Carriage Movement

Controls on both sides of the

open aisle display “Aisle in Use”

and the LED is flashing red

None of the controls work;

None of the LED’s are lit

All or most controls display a

blinking red LED

SOLUTION

• Check rails for debris; clean

rails

• Check the aisle for people or

materials obstructing safeties

• Press the “Stop/Reset” button

• If there is no apparent

obstruction, check the LED

on one end of the Photo

Sweep. If the LED is not

flashing green, call for

service.

(The safety override

key may be used in the

interim – see the Safety

section of this manual)

• Is the system locked (via

remote, key, etc.)?

• Is power supplied to the

system? In the event of a

power outage, use your

power outage option (if

purchased).

• Call Service

• Call Service

Troubleshooting

12

Rails

•Vacuum the rails and track regularly.

•Some flaking may be seen on the rail surface. This is normal

and no cause for alarm. A light application of a silicon or

teflon spray to the top of the rail is recommended to reduce

this type of wear. Avoid sweeping or mopping over freshly

lubricated rails.

Controls

•Check all the functions of every control.

Carriage Bumpers and End Stops

•Please notify your local Spacesaver service technician if you

observe any missing or damaged bumpers and/or stops.

Stored Media

•All materials must be pushed onto the shelves and be flush

with the shelf front. Any media overhanging the shelf front

will interfere with normal system operation. This media is

very likely to become damaged by normal system operation

as well. Looking for evidence of media interference can help

identify potential problems.

Laminate Panels

•To clean and restore the surface apply a countertop or

laminate cleaner (found at most hardware stores.)

Metal Surfaces

•All metal surfaces are painted with the powder coat system.

This is a high luster and scratch resistant paint.

•To remove surface dust, wipe with a damp cloth.

•To clean soiled surfaces, wash with a mild soap and water

mixture.

•To remove finger prints, an orange-based cleaner or NON-

ammonia window cleaner will work on some colors. Test a

small area before using it on a large surface.

Miscellaneous

•Move the carriage in both directions. Look, listen, and feel

for smooth travel. Please inform your local Spacesaver

service technician of any unusual sounds or vibrations.

•All carriages should move easily across the aisle in both

directions.

•Make sure the floor covering does not interfere with carriage

movement or function.

•All carriages should track properly across the aisle. If one

end of the carriage lags behind, please inform your local

Spacesaver service technician.

General

Maintenance

13

Spacesaver has an emphasis on customer satisfaction and continuous

improvement. The statement of warranty is our continued

commitment that Spacesaver is dedicated to serving our customers.

Lifetime Limited Warranty: Subject to the conditions stated below,

Spacesaver Corporation (”Spacesaver”) warrants to the original

purchaser exclusively that the shelving and mobile carriages (”structural

frames”) manufactured by it will be free from defects in materials and

workmanship for the lifetime of the structural frames. For the purposes

of this warranty, structural frames shall be deemed to exclude all

moving parts, controls and guides that have immediate contact with any

moving parts.

10-Year Limited Warranty: Spacesaver also warrants that all carriage

drive motors, shall be free from defects in materials and workmanship

for ten (10) years from the date of the customer‘s written acceptance of

installation. During the 10-year warranty period, all parts are included

at no cost for 10 years. Labor is included at no cost during the first year

of the 10-year warranty period. After the first year, all labor will be

charged at the current rate.

5-Year Limited Warranty: Spacesaver also warrants that all

equipment, other than structural frames and carriage drive motors, shall

be free from defects in materials and workmanship for five (5) years

from the date of the customer‘s written acceptance of installation.

During the 5-year warranty period, all parts are included at no cost for

5 years. Labor is included at no cost during the first year of the 5-year

warranty period. After the first year all labor will be charged at the

current rate.

If any warranted equipment shall be proved to Spacesaver‘s satisfaction

to be defective, such equipment shall be repaired or replaced at the

option of Spacesaver. All warranty service for any equipment

manufactured by Spacesaver must be performed by an authorized

Spacesaver factory representative. This warranty shall be void if any

portion of the purchase price shall be due but unpaid in accordance

with the terms pursuant to which the equipment was sold. This

warranty shall not apply to equipment repaired by any party other than

an authorized Spacesaver factory representative or to defects or

damage caused by (a) acts of God or other circumstances beyond

Spacesaver‘s control, (b) improper installation (unless installation was by

certified factory trained installer), (c) improper electrical supply or

environmental conditions, (d) improper operation, maintenance or

storage, or (e) other than normal use or service. EXCEPT FOR THE

EXPRESS WARRANTIES SET FORTH ABOVE, SPACESAVER MAKES

NO WARRANTIES, IMPLIED OR OTHERWISE, AND SPACESAVER

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Limitation of Liability: Repair or replacement of any defective

equipment, or refund of the purchase price paid by the customer in the

event Spacesaver determines such equipment cannot be repaired or

replaced, shall be the customer‘s exclusive remedy for breach of the

warranty for product defects, however caused, and in no case shall

Spacesaver be liable for incidental, consequential, special or other

damages, or loss of profits or revenues whether as a result of breach of

contract or warranty, Spacesaver‘s negligence, or otherwise.

Spacesaver shall have no liability for any advice or assistance rendered

by any party outside the scope of Spacesaver‘s written specifications

for the manufacture, operation or maintenance of the warranted

equipment. Original installation must be performed by Spacesaver

trained and certified installers.

Statement of

Warranty

14

WARRANTY ACTIVATION

Please follow the instructions below

to activate your warranty:

1. Visit our website at

www.spacesaver.com.

2. Click on “Warranty” in the

bottom right hand corner.

3. Enter the required information

in the Customer Profile Section

which includes the your

Customer Job Number. This

number may be found on the

System Acceptance Form

located in the back of this

manual.

Note: You MUST complete the online

form to activate your warranty.

Thank You For Your Purchase of a Spacesaver Powered System.

For a comprehensive listing of other Spacesaver products and services, please contact your local Spacesaver

representative for a Product Overview Brochure.

Spacesaver Corporation

1450 Janesville Avenue

Fort Atkinson, WI 53538-2798

1-800-492-3434

www.spacesaver.com

Spacesaver Corporation is a division of KI. KI and Spacesaver are registered trademarks of Krueger International, Inc.

© 2007 KI and Spacesaver Corporation. All Rights Reserved. Litho in USA. REV. 1.0/SC-0603 SSC/MAR 11/07

Additional Products:

•Mechanical Assist Systems

•Manual Systems

•Mobile Pallet Racks

•XTend™Mobile High-Bay Storage Systems

•Modular Mobile Systems

•Modular (Bi-File®) Systems

•QuickSpace®Systems

•Mobile Art Rack Systems

•Hang-Glider Pro®Pullout Storage Panel Systems

•Rotary Storage Systems

•Cantilever Bookstack Systems

•XTend™Stationary High-Bay Storage Shelving

•Case-Type Shelving Systems

•4-Post Bin Shelving Systems

•4-Post File Shelving Systems

•Fire Hose Rack Storage Systems

•Modular Drawers & Doors

•Weapon & Pistol Racks

•Hinged Doors

•Museum Cabinets

•Wide-Span Shelving

•ActiveStor®Lateral File Cabinets

•ActiveStor®Storage Cabinets

•ActiveStor®Pedestals

•ActiveStor®Bookcases

•FrameWRX™ Storage Systems

Additional Services:

•Extensive network of local Storage Specialists

•Single-source turn-key project management

•Factory-certified system installation

•Ongoing maintenance and support

KI

1330 Bellevue Street

P.O. Box 8100

Green Bay, WI 54302-8100

1-800-424-2432

www.ki.com

With over 100,000 installed systems – more

than all of our competition combined –

Spacesaver leads the industry in customized,

high-density mobile storage solutions.

Almost any type of material – regardless of its

size, weight or shape – can be stored in

Spacesaver Powered Systems. Designed to

maximize your storage space, they often

more than double storage capacity in the

same floor space. They also provide an

extraordinary level of quality, as our ISO

9001:2000 certification attests.

We alone have the know-how and resources

to develop and perfect the advanced tech-

nology that makes a solution such as Eclipse

possible.

And that makes power easy. To choose. To

use. To afford. To rely on.

No one packs more into

every storage solution.

A tailored storage system

that meets your unique criteria.

Single-source turnkey project management.

Factory-certified system installation.

Ongoing maintenance and support.

15

Eclipse

Powered System™

OWNER’S MANUAL

Thank You For Your Purchase of a Spacesaver Powered System.

For a comprehensive listing of other Spacesaver products and services, please contact your local Spacesaver

representative for a Product Overview Brochure.

Spacesaver Corporation

1450 Janesville Avenue

Fort Atkinson, WI 53538-2798

1-800-492-3434

www.spacesaver.com

Spacesaver Corporation is a division of KI. KI and Spacesaver are registered trademarks of Krueger International, Inc.

© 2007 KI and Spacesaver Corporation. All Rights Reserved. Litho in USA. REV. 1.0/SC-0603 SSC/MAR 11/07

Additional Products:

•Mechanical Assist Systems

•Manual Systems

•Mobile Pallet Racks

•XTend™Mobile High-Bay Storage Systems

•Modular Mobile Systems

•Modular (Bi-File®) Systems

•QuickSpace®Systems

•Mobile Art Rack Systems

•Hang-Glider Pro®Pullout Storage Panel Systems

•Rotary Storage Systems

•Cantilever Bookstack Systems

•XTend™Stationary High-Bay Storage Shelving

•Case-Type Shelving Systems

•4-Post Bin Shelving Systems

•4-Post File Shelving Systems

•Fire Hose Rack Storage Systems

•Modular Drawers & Doors

•Weapon & Pistol Racks

•Hinged Doors

•Museum Cabinets

•Wide-Span Shelving

•ActiveStor®Lateral File Cabinets

•ActiveStor®Storage Cabinets

•ActiveStor®Pedestals

•ActiveStor®Bookcases

•FrameWRX™ Storage Systems

Additional Services:

•Extensive network of local Storage Specialists

•Single-source turn-key project management

•Factory-certified system installation

•Ongoing maintenance and support

KI

1330 Bellevue Street

P.O. Box 8100

Green Bay, WI 54302-8100

1-800-424-2432

www.ki.com

With over 100,000 installed systems – more

than all of our competition combined –

Spacesaver leads the industry in customized,

high-density mobile storage solutions.

Almost any type of material – regardless of its

size, weight or shape – can be stored in

Spacesaver Powered Systems. Designed to

maximize your storage space, they often

more than double storage capacity in the

same floor space. They also provide an

extraordinary level of quality, as our ISO

9001:2000 certification attests.

We alone have the know-how and resources

to develop and perfect the advanced tech-

nology that makes a solution such as Eclipse

possible.

And that makes power easy. To choose. To

use. To afford. To rely on.

No one packs more into

every storage solution.

A tailored storage system

that meets your unique criteria.

Single-source turnkey project management.

Factory-certified system installation.

Ongoing maintenance and support.

15

Eclipse

Powered System™

OWNER’S MANUAL

Table of contents

Popular Accessories manuals by other brands

Omron

Omron F400 - 06-1999 Operation manual

Efergy

Efergy Engage hub Quick start manual

Philips

Philips HR 2577 user manual

PCB Piezotronics

PCB Piezotronics ICP E106B/061A60 Installation and operating manual

DuroZone

DuroZone MB Series Multi-Blade Damper installation instructions

Trigano

Trigano Auvents Panoramic 300 Erection Instructions

Wulian

Wulian WL-ZSKWNPW-W3140-01 user manual

Collingwood Lighting

Collingwood Lighting BT4SS40 installation instructions

Siemens

Siemens 5WG1 201-2DBx3 Series Technical product information

Quincy lab

Quincy lab 140AE-1 operating manual

Prima-Temp

Prima-Temp PRIYA Instructions for use

Vaisala

Vaisala WMS302 user guide