Leave a space between articles on a shelf to allow the unit's horizontal air flow

to circulate around each article. (FIG. 3)

Don't block the return air port located at the back of the lower plenum/shelf.

Avoid extremely large (in quantity or size) or high-density loads. This will show

by non-uniform processing and long or impossible "heat-through" times. To help

determine a large load's suitability, use the set-point recovery time (the time it

takes for the temperature to recover to the original set temperature once load is

placed), as a guide. To reduce recovery time, reduce load proportionally. When

possible, measure large loads or solution temperatures directly with an ancillary

thermometer or probe. Probes can be inserted at top port.

Article processing times and temperature uniformity are largely dependent on

load density and positioning. Load the incubator so that air circulation within the

incubator is not impaired. Here are some general guidelines:

A B

C D

FIG. 1

Set-up & Installation

Read Operating Instructions Thoroughly Prior to Operation

Safety Precautions

Read Operating Instructions thoroughly prior to operation and observe the following safety precautions:

• Use only a grounded outlet that is rated for your model's electrical requirement.

• Do not modify the oven or factory control settings to operate the oven above the stated maximum operating temperature.

• Exterior surfaces on the 180AE-1 models may become hot to the touch when operating at higher set temperatures.

• Conduct periodic maintenance as required.

WARNING: Do not place volatile or combustible materials into incubators.

CAUTION: This unit is not intended for use with any flammable liquids or vapors, or with chemicals that produce toxic gases.

General Operation

Chamber Loading

Position unit in its ultimate operating location. Keep a minimum of 3" of airspace

around the unit and a minimum of 6" above the unit. The port hole at the top of the

unit will expel a small amount of warm air through natural convection. This port can

also be used as an access way for external temperature measurement of a solution for

example.

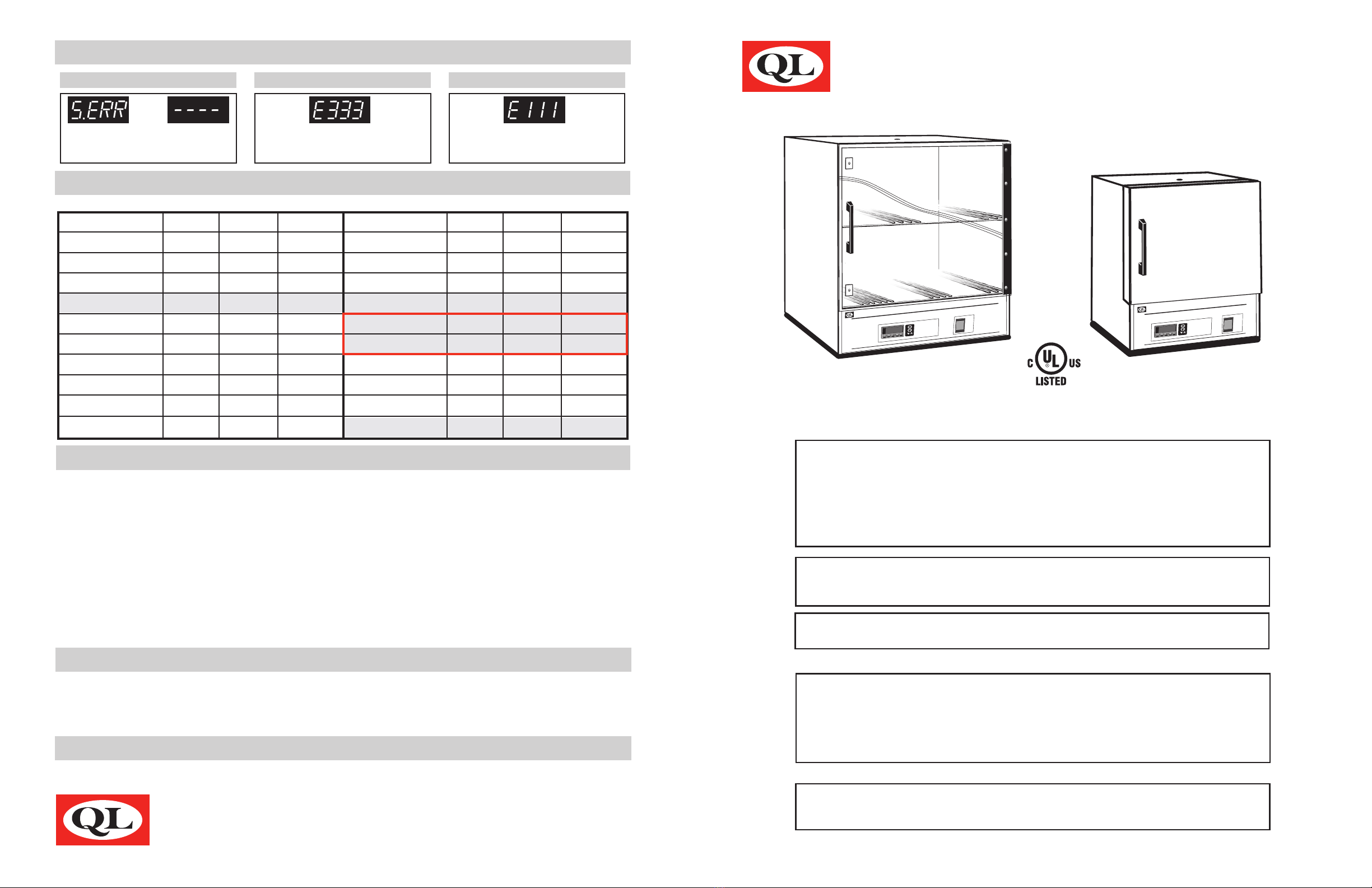

Install adjustable shelf by placing the ends of the wire shelf bracket into the

corresponding holes located on the inner sides of the oven at the desired height. Push

the ends of the bracket into the holes until the first bends in the bracket are against the

wall, then rotate the bracket down. Place the shelf on the brackets. (FIG 1)

Place drip tray on lower shelf.

Plug the unit into a grounded outlet for your unit's rated voltage.

The unit is ready for your immediate use. All control parameters, calibration

and tuning has been done at the factory, no adjustments are necessary.

Push the illuminated power button. All LED's on the temperature control will

light up and display the current chamber temperature and the set

temperature.

Set temperature is constantly displayed in the lower right-hand corner of the

display. To change the set temperature, simply press either the up arrow key

or the down arrow key until desired set temperature is reached. (FIG 2) The

temperature control is set at the factory to read in 1/10 degree F, or

Fahrenheit units. To change Controller functions see: Menu Level Functions

(page 3).

Once the unit nears the desired temperature, allow the unit to cycle for 20

minutes at set point before temperature becomes fully stable.

FIG. 2

Upon each initial powering-up, the control may typically overshoot the set temperature by 1 or 2 degrees, especially if the

temperature set point is close to the operating ambient temperature. After equilibrium is achieved the control will hold set

temperature within 1 unit degree.

PAGE 2

Menu Level Functions Guide

To adjust control to read in C or F temperature units

Hold 3 sec View

To calibrate control to independent probe/sensor

To lock setpoint temperature

To Auto-tune oven

Hit ONCE

Default set to 0

Enter / Exit MENU MENU Scroll Decrease Increase

To set setpoint temperature

Decrease Increase

Up and down arrow

keys (shown left) are

used to increase or

decrease set-point

control temperature

as desired by user

Hold together 3 seconds

Lock setpoint by

changing to '3'

Use keys to

change setting

Default set to 40%

To access menu for common menu functions, please refer to the easy-to-use Menu Guide below: Menu setting changes are

quick and easy with our new 5-button digital microprocessor. Through the use of these controls you can:

Changes digit

cursor on set

temperature

Digital Controller Function Buttons

All units are Auto-tuned at the factory using the 'At-1' option for faster response time. You

may, however, want to Auto-tune your oven to your specific application. To do this, once at

the 'At' prompt (at left), use arrow keys to initiate either Auto-tune option: 'At-1' (for 40%

Auto-tune), or 'At-2' (for 100% Autotune). The 40% Auto-tune (At-1), will stabilize the oven

temperature quicker and with less 'overshoot' than the 100%, but will be somewhat less

precise. The 100% Auto-tune (At-2), will take longer to stabilize oven temperature but will

be more precise, and take a little longer to complete the Auto-tune process.

When at the d-U "Degree Units"

prompt, you can change the

temperature units to F for Farenheit,

or C for Celcius, by using the

buttons.

Default set to F

After most changes to the configuration,

return to normal operating mode by holding

the enter/exit key for 3 seconds.

Set the operating temperaure Lock the set-temperature

Select either degrees Farenheit or Centigrade Auto-tune your Incubator for maximum efficiency

Calibrate your unit to your independent temperature-sensing device

M E N U G U I D E

For returning from setting the set-point temperature lock,

hold both and for 3 seconds.

Hit ONCE Hit ONCE Use keys to

enter temperature

shift in degrees

To calibrate unit

add (or subtract)

the temperature

differential, to the

existing iNS value

shown at prompt

When the oven exceeds its maximum operating temperature by 3°C a safety alarm in the

controller will cut power to the heating elements. Allow the units temperature to drop

below its maximum temperature and/or cool before reset. To reset unit, power OFF and ON

to clear alarm status. If problem remains, please contact technical support for assistance.

ALARM “Over Maximum Temperature”

PAGE 3

Returning to Main Display and Clearing Controller Safety Alarm

FIG. 3