Spartus Pro CUT HD Guide

CNC PLOTTER

SPARTUS Pro CUT HD Technical documentation

Content

1. BASIC INFORMATION .......................................................................................................... 3

1.1 THE USE IN CONFORMITY WITH THE INTENDED PURPOSE .............................................. 3

1.2 FIRST START-UP AND OPERATION .................................................................................... 3

1.3 USER'S OBLIGATIONS ........................................................................................................ 3

1.4 THE USE NOT IN CONFORMITY WITH THE INTENDED PURPOSE ...................................... 3

1.5 WARRANTY AND LIABILITY ................................................................................................ 3

1.6 CONSTRUCTION ................................................................................................................ 4

1.7 OPERATION PRINCIPLES ................................................................................................... 4

1.8 ISSUE DATE ....................................................................................................................... 4

2. TECHNICAL DATA ................................................................................................................ 4

2.1 MACHINE IDENTIFICATION ............................................................................................... 4

2.2 COMPLIANCE WITH STANDARDS ...................................................................................... 4

2.3 TECHNICAL PARAMETERS ................................................................................................. 4

2.4 DELIVERY RANGE .............................................................................................................. 5

2.5 CONNECTIONS .................................................................................................................. 5

2.6 EQUIPMENT OPTIONS ...................................................................................................... 5

3. BASIC SAFETY INDICATIONS ............................................................................................... 5

3.1 INSTRUCTIONS …………………………...................................................................................... 5

3.2 IMPORTANT SAFETY INDICATIONS ................................................................................... 5

3.3 GENERAL INFORMATION .................................................................................................. 5

3.4 GENERAL OPERATOR RESPONSIBILITIES ........................................................................... 6

3.5 HAZARDS DURING THE OPERATION OF THE MACHINE .................................................... 6

3.6 POTENTIAL GENERAL HAZARDS DURING THE USE OF THE MACHINE .............................. 6

3.7 WORKPLACE ..................................................................................................................... 6

3.8 POTENTIAL HAZARDS DURING PROCESS OF CUTTING WITH PLASMA BURNER

OR GAS BURNER .............................................................................................................. 7

3.8.1 HAZARDS THAT MIGHT BE CAUSED BY HIGH TEMPERATURE ...................................... 7

3.8.2 HAZARDS THAT MIGHT BE CAUSED BY SPARKS AND SPLITS ........................................ 8

3.8.3 HAZARDS THAT MIGHT BE CAUSED BY GASES AND SMOKES ....................................... 8

3.8.4 RISK OF INFRARED, UV PROTECTION AND VISIBLE RADIATION ………………………...……… 8

3.8.5 EXPLOSION HAZARD DURING CUTTING WITH A GAS BURNER ..................................... 9

3.8.6 NOISE RISK ................................................................................................................... 10

3.9 PROTECTION DEVICES AND ELECTRIC SHOCK PROTECTION ........................................... 10

3.10 ELECTRICAL SAFETY DURING NORMAL OPERATION ..................................................... 11

3.11 DANGER OF ELECTRIC SHOCK ....................................................................................... 12

3.12 PROTECTION OF ELECTRICAL INSTALATION AGAINST HIGH VOLTAGE ……………………… 12

3.13. ELECTROMAGNETIC FIELDS (EMF) ............................................................................... 12

4. TRANSPORT AND STORAGE .............................................................................................. 13

4.1. EXTERNAL DIMENSIONS AND WEIGHT .......................................................................... 13

4.2. PACKAGE ........................................................................................................................ 13

4.3. INSPECTION ON RECEPTION .......................................................................................... 13

4.4. STORAGE ........................................................................................................................ 13

5. SETTING UP, INSTALLATION, STARTING ............................................................................ 14

5.1. INSTALLATION AND SETTING UP THE MACHINE ............................................................ 14

5.2. CLEANING ....................................................................................................................... 14

5.3. CONNECTION OF ELECTRICITY ........................................................................................ 14

5.4. CONNECTION OF VENTILATION (applies to sectional table) ........................................... 14

5.5. WATER TABLE ................................................................................................................. 15

6. WORKING PROCESS ........................................................................................................... 15

6.1. START-UP, WORKING CYCLE ........................................................................................... 15

6.2. MACHINE RECONFIGURATION …..................................................................................... 15

6.3. SHUTDOWN DURING NORMAL OPERATION AND EMERGENCY ..................................... 15

6.3.1. NORMAL SHUTDOWN .................................................................................................. 15

6.3.2. EMERGENCY STOP. ....................................................................................................... 15

6.4. CONTINUATION OF WORK AFTER EMERGENCY STOP OR FAULT .................................... 15

6.5. INTERFERENCE AT WORK, ERRORS .................................................................................. 15

7. MAINTENANCE ………………………………................................................................................... 16

7.1 PERIODIC GREASING ......................................................................................................... 16

7.2 REMOVAL AND DISPOSAL ................................................................................................. 16

7.3 SERVICE ............................................................................................................................. 17

8. LIST OF SPARE PARTS .......................................................................................................... 17

8.1. LIST OF SPARE PARTS THAT WEAR OUT ........................................................................... 17

8.2. DAILY MAINTENANCE LIST OF ACTIONS BEFORE STARTING WORK ................................. 17

8.3. DAILY MAINTENANCE LIST OF ACTIONS AFTER ENDING WORK ...................................... 17

9. PERIODIC SERVICE ............................................................................................................... 17

1. BASIC INFORMATION

1.1. THE USE IN CONFORMITY WITH THE INTENDED PURPOSE

The CNC table adapted to work with the plasma cutter are numerically controlled devices designed

for thermal cutting of metal sheets using a plasma or gas torch (depending on the selected model).

Cutters allow cutting shapes according to previously prepared programs entered into the computer

in the form of a file.

1.2. FIRST START-UP AND OPERATION

Installation, commissioning and training can only be carried out by an authorized SPARTUS service

center. The buyer is obliged to prepare the place for installation of the device in accordance with the

manufacturer's instructions described in the manual. The investor is obliged to prepare access to

electricity, compressed air (in the case of using a gas burner - gases) and running water. The media

parameters are specified by the manufacturer. The device may only be used after the operator has

been trained in the field of use by an authorized representative of the manufacturer. Installation and

training are completed by signing the technical acceptance protocol. The device may only be used by

personnel trained by the manufacturer. Any interference or modification of the machine will end up

in voiding the warranty. During the first start-up, pay attention to the phase sequence in the

electrical system. Incorrect wiring may cause the device to react unintentionally. To avoid risks from

moving parts, the installer must move away from them during commissioning and checking.

1.3. USER'S OBLIGATIONS

For proper and safe operation, the device must be located in a room where the temperature is not

less than + 5°C and does not exceed + 40°C with max. humidity of 60%. The room in which the device

is located must be equipped with ventilation.

1.4. THE USE NOT IN CONFORMITY WITH THE INTENDED PURPOSE

Any other use of the machine (in particular the use of undersized raw material) is not intended. In

this case, the manufacturer is not responsible for any damage caused while using the machine.

1.5. GUARANTEE AND LIABILITY

The manufacturer guarantees buyer that the delivered machine corresponds to the catalog data and

can correctly fulfill all tasks intended for its type. If in the production process, during the warranty

period, an error occurs in the machine due to the fault of the manufacturer, they will carry out a

repair of the damage free of charge. The manufacturer is not liable for damages resulting from:

improper use of the machine

improper connection, assembly, setting up, operation and maintenance of the machine

using the machine with damaged, incorrectly adjusted or removed safety and protective devices

disregarding the instructions of means of transport, storage, assembly, commissioning, working

safety, maintenance, reconfiguration of the machine

changes in the construction of the machine not agreed with the manufacturer

incorrect repairs

natural disasters as a result of majeure force

the warranty does not cover the loss of profits associated with low production or lack of production

due to any machine failure or delays in the delivery of spare parts and damage to third parties for

these reasons

any possible direct or indirect damage resulting from the use of the machine

In addition, the components considered to be wearing off quickly (described further in the

instruction) which have worn out as a result of the operation of the machine, are not subject to

replacement.

The manufacturer provides a 12 month warranty of the machine.

1.6. MACHINE CONSTRUCTION

The machine consists of the following assemblies:

numerically controlled table

cabinet or control panel

1.7. OPERATION PRINCIPLES

A sheet of metal (e.g. 1500x3000 mm) is placed on the plasma cutter table, the cutting program is

loaded into the computer controller. After starting, the pieces of sheet metal are automatically cut

out according to cutting program. The height of the plasma torch is automatically adjusted during the

operation, ensuring an equal distance between the torch nozzle and the material being cut out.

The machine is controlled based on an industrial CNC controller, microprocessor controllers that are

controlling drives of X and Y axes as well as module maintaining the same height of the torch from

the material. Servo motors are used as drives.

1.8. ISSUE DATE

This documentation was developed in 2018.

2. TECHNICAL DATA

2.1. MACHINE IDENTIFICATION

Name: CNC table

The type / model and serial number of the device are given on the nameplate located on the CNC

table and in the declaration of conformity attached to the documentation.

2.2. COMPLIANCE WITH STANDARDS

SPARTUS CNC tables meet the essential requirements of the Machinery Directive 2006/42/EC.

The EC declaration of conformity is attached to the documentation supplied with the device.

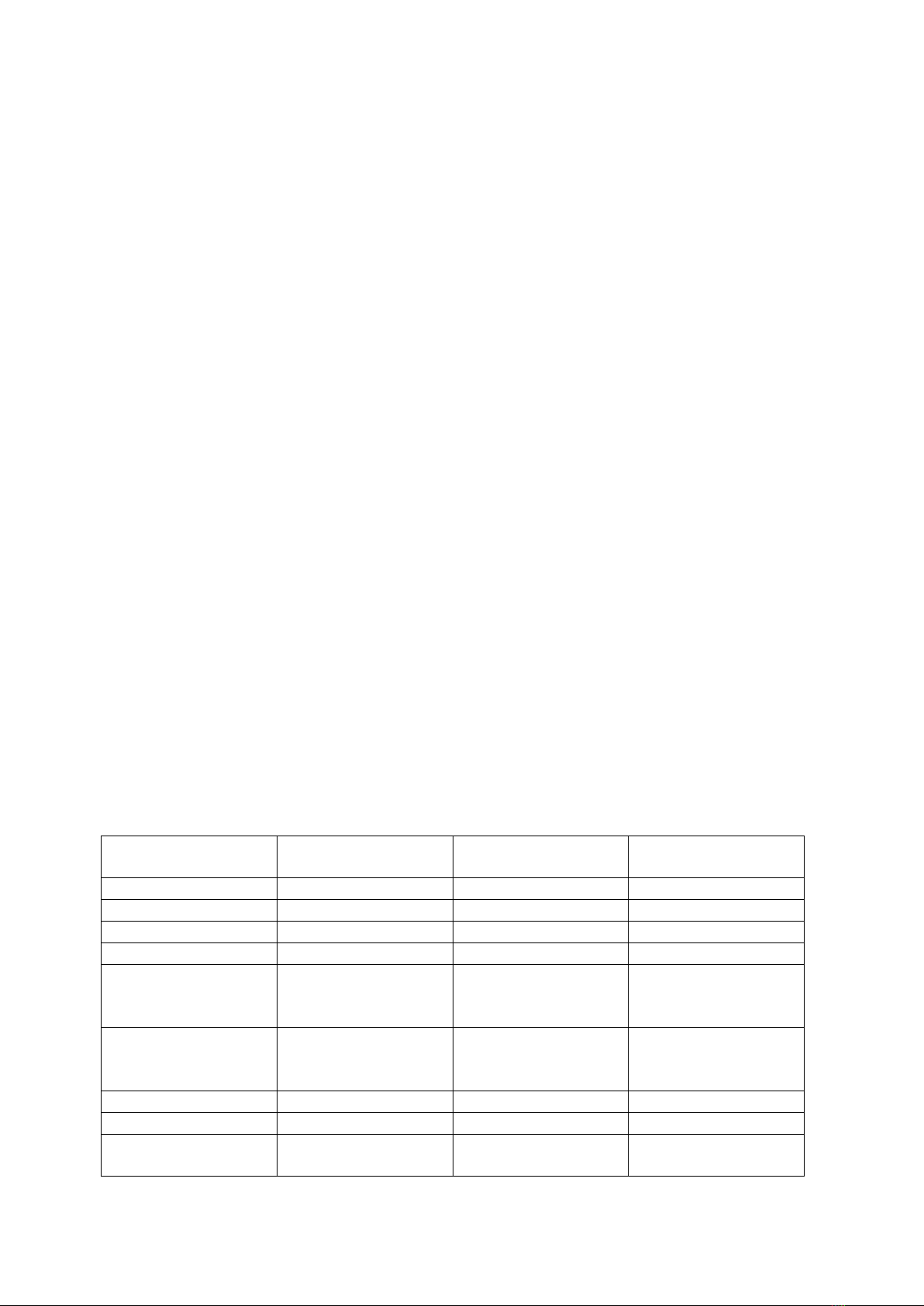

2.3. TECHNICAL SPECIFICATIONS

Machine Type

SPARTUS Pro CUT HD

2050

SPARTUS Pro CUT HD

2550

SPARTUS Pro CUT HD

2550

Transmission method

3M belts / tooth bar

3M belts / tooth bar

3M belts / tooth bar

Working field

1050x2050mm

1050x2050mm

1050x2050mm

Max speed

2500mm/min.

2500mm/min.

2500mm/min.

Scope of work - Z axis

90mm

90mm

90mm

Max cutting thickness

for CUT 65 CNC

plasma source

12mm

12mm

12mm

Max cutting thickness

for CUT 105 CNC

plasma source

20mm

20mm

20mm

Control Type

4 axis CNC controller

4 axis CNC controller

4 axis CNC controller

File format

PLT

PLT

PLT

Clearance in the Z axis

80mm / optional

130mm / 180mm

80mm / optional

130mm / 180mm

80mm / optional

130mm / 180mm

2.4. DELIVERY RANGE

The scope of delivery is presented in the handover report, which is attached to the table

documentation.

2.5. CONNECTIONS

The plasma burner for proper operation requires:

400V / 50Hz

Current protection:

B25 fuse

Compressed air supply:

8 bar pressure (flow depends on plasma source)

2.6. EQUIPMENT OPTIONS

1. CNC table with control

2. Plasma source Spartus CUT 65 CNC or Spartus CUT 105 CNC

3. Corel DRAW X5 graphics program

4. Section table

5. Water table

6. Voltage THC torch height regulator

Table equipment and option of additional equipment depend on individual orders placed by the

customer. The equipment options listed above are informative.

3. BASIC SAFETY INSTRUCTIONS

3.1. INSTRUCTIONS

The basis of safe machine usage is knowledge of basic safety regulations and safety instructions. All

persons operating the machine are obliged to follow the instructions, and in particular, the safety

rules contained in this manual. In addition, the accident protection regulations apply at the place

where the machine is being used. The following information does not release the operator from the

obligation to comply with the occupational health and safety rules at work.

3.2. IMPORTANT SAFETY INDICATIONS

Safety indications are described in instructions which, if not followed, may endanger life or health.

These guidelines should be followed with extreme caution. These instructions should be given to all

machine operators.

3.3. GENERAL INFORMATION

In order to avoid possible accidents and to ensure trouble-free operation of the device, observe the

applicable health and safety regulations, fire regulations and the provisions of this manual.

The operating temperature in the room should be at least 5°C. A good visibility should be

guaranteed. The floor must be rough and even. Electrical and pneumatic supply lines must not be a

tripping hazard

Only trained (by the manufacturer) operators may be designated to operate the plasma burner

Any defects of the device should be reported immediately to those responsible for maintenance,

while the device should be absolutely shut down until the defect is repaired

Damaged or defective equipment must be repaired or taken out of service immediately

Any modifications or interventions in the construction of the machine will void the warranty

The use of non-genuine consumable parts may present a risk of electric shock or explosion, and

may also damage machine parts

The use of non-genuine consumable parts is prohibited and will void the warranty

3.4. GENERAL OPERATOR RESPONSIBILITIES

The machine operator is only permitted to run the machine with professionally trained*personnel:

having appropriate knowledge in the field of CNC machinery

knowing the general safety regulations and instruction of the machine manual

knowing and understanding "Basic Safety Instructions" and the instructions on safe operation

system concluded in this manual

*Qualified person (def.) - a person who has acquired appropriate technical education, received

training and / or experience to enable predicting risks and avoiding these risks while using the

machine (IEC 60204-1)

3.5. HAZARDS DURING THE OPERATION OF THE MACHINE

The following hazards may occur when using plasma burners:

general threats

hazards when cutting with a plasma torch

danger during pneumatic tapping

3.6. POTENTIAL GENERAL HAZARDS DURING THE USE OF THE MACHINE

CNC table is made to eliminate situations that are hazardous to health or life. Nevertheless, there

might be some hazards that will occur for the machine operator or bystanders

Keep away from a gas / plasma torch when it is operating. During cutting, the flame temperature of

the torch exceeds several thousand °C

Be extra careful when material is pierced with the plasma torch because sparks of molten metal are

blown out in every direction.

The working burner moves during operation along three axes X, Y, Z. The speed is up to 25m/min.

Standing in the working area of the device can cause the risk of crushing hand, leg or other body part.

The manufacturer prohibits:

performing any maintenance operations with the device powered on

removing any covers protecting the machine

interfering with the connection or changing location of device sensors

removing stickers informing about hazards from the burner's structural elements

leaving any objects within machine's work that could cause a collision during work

entering the burner's work area during operation of the device (operator can approach the

machine table only after stopping the work by pressing the STOP button and pressing the safety

button located on the control panel)

Malfunctions in the operation of the machine, in particular, the removal of covers and protective

devices can lead to health-threatening situations. All deficiencies in this area should be immediately

replaced.

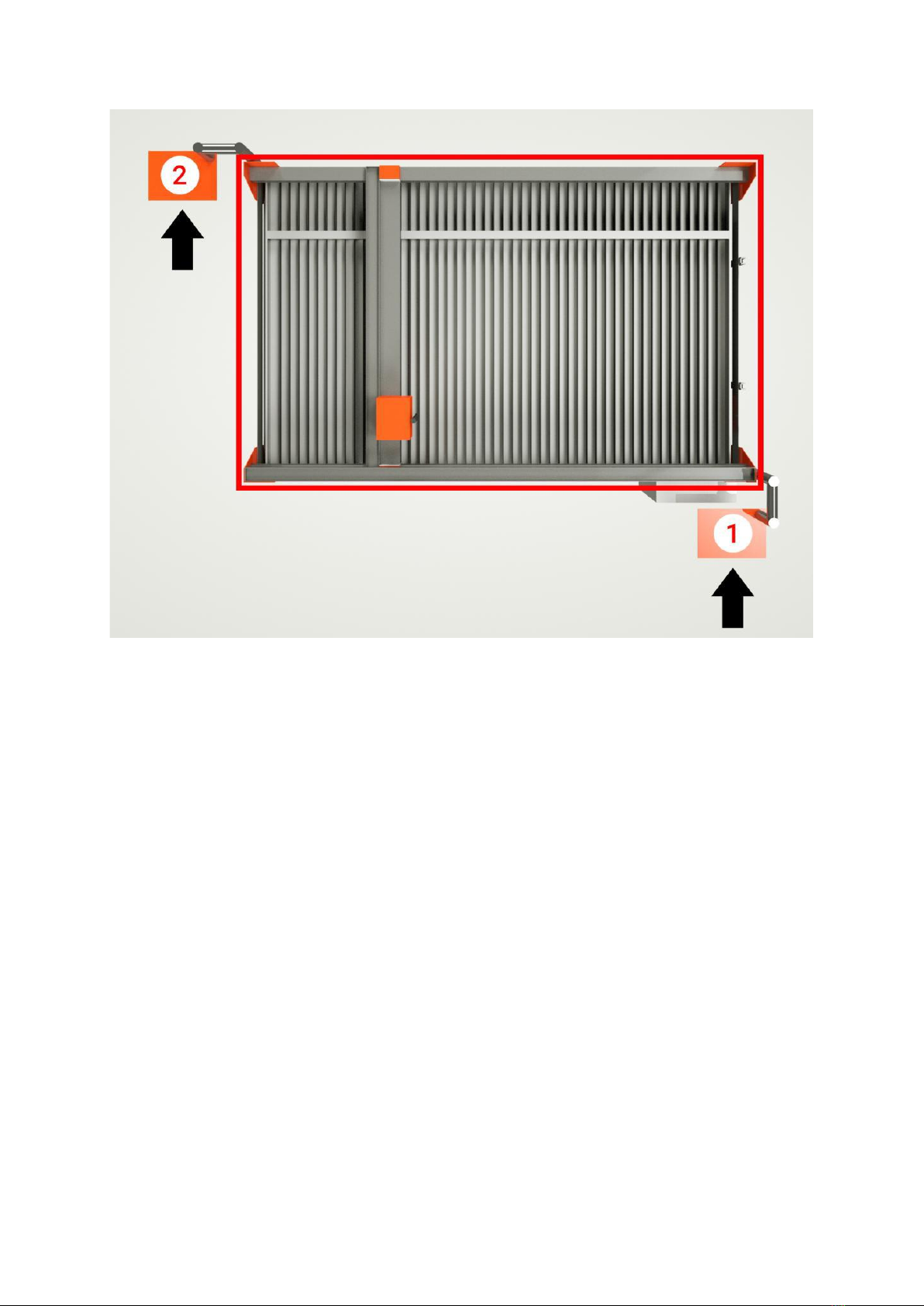

3.7. WORKPLACE

The picture below indicates the place where the operator should be during the work.

There should be enough space around the machine for convenient and safe cleaning and adjustment

works.

The operator must not enter the machine working area after the work process has started.

During work or loading process only authorized persons are allowed in the working area.

Working area. The correct position of operators outside the working zone

1. Main working area

2. An additional workplace for cutting profiles

3.8. POTENTIAL HAZARDS DURING PROCESS OF CUTTING WITH PLASMA BURNER OR GAS BURNER

CNC table is made to eliminate situations that are hazardous to health or life. Nevertheless, there

might be some hazards that will occur for the machine operator or bystanders.

When cutting with plasma and gas burners the following hazards might take place:

during cutting, the temperature of the torch flame exceeds several thousand °C

when cutting, there is a high radiation due to the burning of gases and the formation of an electric

arc

molten metal splinters may occur during piercing and cutting

gases and fumes are present during the cutting process

there is a risk of explosion when cutting with gas torches

3.8.1. HAZARDS THAT MIGHT BE CAUSED BY HIGH TEMPERATURE

The sources of high temperature that occur during the cutting process may come from:

burner flame

high burner temperature

hot sheet metal element

sparks and metal spatters

liquid drop of the cutting element

cracked gas hoses

The effect of high temperature can be:

skin burn - complete destruction of the scarfskin

deep burn - destruction of a part of the skin along with sebaceous glands

total burn - complete destruction of the skin

Means of protection against the hazards mentioned above are:

wearing of protective clothing marked as flame-retardant. These are gloves, a leather apron,

protective footwear, a hat as well as face and eye protection.

using of manual or mechanical methods of loading/unloading a hot material to protect the

operator against high temperature;

protecting the operator's eyes by using special protective glasses with a darkness level of min. 6

DIN.

3.8.2 HAZARDS THAT MIGHT BE CAUSED BY SPARKS AND SPLITS

During cutting and piercing, sparks or splinters are produced which can cause burns or a fire.

As a means of protection against spatters you should:

use protective clothing marked as flame-retardant. These are gloves, a leather apron, protective

footwear, a hat, face and eye protection

not storing flammable substances near the device's working area

separate the work place with special protective curtains from other work stations

comply with fire regulations

ensure that the fire extinguisher is in place

3.8.3. HAZARDS THAT MIGHT BE CAUSED BY GASES AND SMOKES

When machine operator is exposed to the fumes generated during cutting process for a long time, it

might cause various diseases of the respiratory system. Dust comes into the human’s body mainly

through the respiratory tract. This way, to get into the body system, is used by very small particles

that pose the greatest threat to humans. A common feature of all industrial dusts is irritating effect

on upper respiratory tract of mucous membranes, e.g. iron oxides.

The effects of the above may be:

eye and skin irritation

nausea

metallic fever

headaches and dizziness

respiratory disorders

As a means of protection against gases and smoke you should:

ventilate the room in which the machine works

extract fumes and gases that were produced during the process

set the water level so that water comes into contact with the cutting material (applies to water

tables and plasma cutting)

control and do not exceed the max pollution values in the room where machine works

comply with all regulations regarding the operation of gas cylinders and gas cutting torches

3.8.4. RISK OF INFRARED, UV PROTECTION AND VISIBLE RADIATION

During plasma or gas cutting, there is a high radiation due to the burning of gases and the formation

of an electric arc.

The effects of radiation can be:

redness, damage to the scarfskin

faster ageing process

change of skin colour

allergies

burns

cancerous changes

damage, burns to the cornea, lens, retina, eye swelling, cataracts

loss of vision (when there is too much exposure to radiation)

stroke or heat exhaustion

As a means of protection against radiation:

protect the operator's eyes by using special protective glasses with a darkness level of at least 6 DIN

protect the operator's face by using a welding protective mask

use protective clothing that protects the operator against exposure to radiation

avoid looking directly at the burner flame

3.8.5. EXPLOSION HAZARD DURING CUTTING WITH A GAS BURNER

There is a risk of explosion when using a CNC machine with a gas burner and technical gases.

The explosion can be caused by:

oiled oxygen cylinders or welding equipment

overheated technical gas cylinder

oiled gas regulator during changing of cylinders

smoking in places where it is prohibited

using open fire in places where it is prohibited.

Hazards to the operator and bystanders due to the explosion:

heat burns

respiratory tract burns, respiratory problems

eye irritation

fainting

asphyxiation

injuries, injuries to limbs and head

limb amputation

death

Protection measures against explosion include:

strictly comply with applicable regulations regarding the use and storage of gas cylinders and the

installation of technical gases

cylinders must be placed vertically and secured from falling

in the event of damage to the installation, cylinders, regulators, hoses or other parts of the

installation it is absolutely necessary to terminate the work and inform the maintenance department

or the manager

use hoses, gas regulators and nozzles only for their intended purpose

do not use oil, grease in gas installations. All system components must be free of oil and grease

use explosion protection (e.g. fuses used on the burner and regulators)

carry out all work on the gas installation in accordance with applicable standards and by persons

having appropriate qualifications

shut off the gas supply after finishing work

If the machine is equipped in a plasma cutting device, detailed information on the rules of operation

and hazards during plasma cutting can be found in the operating instructions provided by the

manufacturer of the plasma source.

3.8.6. NOISE RISK

The equivalent sound pressure level at the workplace, corrected by the A characteristic, exceeds 70

dB (A) and is 83 dB (A). The final noise level during operation depends on many factors, including the

dimensions and grade of the material.

The equivalent sound pressure level at the workplace, corrected by the characteristics of A, does not

exceed 85 dB (A).

Hazards to the operator and bystanders due to noise:

Noise Level

Body reaction

to 70dB

Negative changes in the body

Over 70dB

Diseases

- hypertension

- stomach disorder

- increase of adrenaline in the body

to 90dB

Hearing impairment and hearing loss over time

Over 120dB

Possible mechanical damage to the hearing

130dB

Pain limit

To protect your hearing, use:

protective earphones

anti-noise plugs

3.9. SAFETY DEVICES AND ELECTRIC SHOCK PROTECTION

In the event of danger, the machine can be turned off using the EMERGENCY STOP button. This

button is located on the control panel

Electrical controls are placed in an electrical cabinet

The plasma burner is protected by sensors limiting the work area in the X-, X+, Y-, Y+ axes,

respectively. Modifications, alterations or damages to elements limiting the work area may result in

damage to the device. That is also a hazard of life or health loss for people standing nearby.

CNC table scheme

1. Working machine head

2. Top-up valve (opens and closes the reservoir tank after switching on or off respectively)

3. Coolant drain valve (for retention tank)

4. Plasma torch

5. Pump

6. Retention tank

7. Plotter bar Y axis

8. Adjustable bases for leveling the machine

9. Control panel with a computer

10. Start/Power switch

11. 230V AC socket supplying the computer

12. Main switch

13. Emergency stop switch

14. Y- limit switch

15. X+ limit switch (X- switch at the other end of the running rail)

16. Z+/Z- limit switch

17. Y + limit switch

3.10. ELECTRICAL SAFETY DURING STANDARD OPERATION

When operating the machine, follow the rules and guidelines below:

before starting work, the operator should check the technical condition of the machine by visual

inspection, in particular, the condition of guards, fastening elements and general condition of the

electrical installation

if the operator finds out that the machine is out of order, he should immediately secure it from

starting it up and notify maintenance department or manager

there must not be unnecessary items or tools on the numerically controlled table and control

cabinet

only use original consumable parts for work

spare parts must only be installed and removed with the safety switch off

load and work only with material dimensions specified in the TECHNICAL DATA chapter

all adjustment activities should be carried out after disconnection of the main switch. Such

activities must be supervised by a second person who could help if necessary

it is not allowed to manually or mechanically remove waste materials while plasma burner is

performing a cutting process. Clean the machine after switching off the power supply

while the machine is working, only the operator controlling the burner may be at the operating

position

inspections and repairs are the responsibility of the maintenance team. The operator cannot

perform such activities

Responsibilities of the machine operator are:

compliance with safe working methods given in the manual and provided by the manager or

foreman as a part of the instruction

ensuring good technical condition of the burner and its full efficiency

cleaning the table and linear guides after finishing work

ensuring the disconnection from the power supply after work

protection against starting up by unauthorized persons

3.11. DANGER OF ELECTRIC SHOCK

The burner should be connected to a power supply equipped with a switch that protects against

electric shock. The table structure should be connected to the grounding installation of the building

by PE wire (minimum 16 mm2). Work on the electrical installation may only be carried out by an

authorized and qualified electrician with qualifications for the use of electrical equipment and

installations of up to 1 kV. It is not allowed to change the settings of electrical devices. If electrical

work requires voltage to be turned on, a second person must help to turn on and off the power if

necessary. During repairs, adjustments or maintenance operations, the machine must be absolutely

stopped and secured in such a way that it cannot be accidentally started. At least once a year the

burner should be brought under electrical tests for electric shock protection. Once all tests are

completed, the relevant approval report has to be issued. The plasma burner must be definitely

connected to the grounding installation of the object in which it was installed via a protective

conductor. In the case of a "water" table, the burner must absolutely work above the surface of the

liquid. In case of burner having contact with water, this can result in electric shock and injuries to the

operator.

3.12. PROTECTION OF ELECTRICAL INSTALATION AGAINST HIGH VOLTAGE

It is the user's responsibility to protect the electrical installation system, to which the machine is

connected, from accidental over-voltages that may damage the machine's control parts. Damages to

the machine's control units caused by temporary surges and over-voltages will not be repaired under

the warranty. In such a case, the warranty will be voided by the manufacturer. The plasma burner as

a computer-controlled numerical device should be protected by an uninterruptible power supply

(UPS) with a minimum power of 1000W.

3.13. ELECTROMAGNETIC FIELDS (EMF)

Electric current flowing through any conductor creates locally electric and magnetic fields (EMF -

electromagnetic field). To reduce the danger associated with the EMF fields:

never wrap the body with torch wires

do not stand between burner wires

keep both hoses on one side of your body.

the return hose should be connected as close as possible to the place where the cutting process is

carried out

do not work, sit or lean on the plasma generator while it is operating

DANGER: The electromagnetic field (EMF) generated during plasma cutting can interfere with the

functioning of medical implants, e.g. a cardiac stimulator or hearing aid. People with medical

implants, e.g. a pacemaker, are required to consult a doctor before starting work, and take special

care. It is forbidden to stay near the place where the plasma cutting process is carried out without

consultation with an expert.

4. TRANSPORT AND STORAGE

During transport, the machine can be partially dismantled into:

CNC table

control cabinet

cutter bar

During the road transport, the machine must be secured (e.g. with wedges, belts) so that it does not

move. When handling the machine, anybody must not be under a lifted load. The forks of the forklift

must be set to the max position when unloading. The crossbar should be set in a position close to the

middle and secured against possible displacement. Pay special attention to avoid damaging the tank

and hydraulic hoses inside the device when using the forklift.

4.1. EXTERNAL DIMENSIONS AND WEIGHT

SPARTUS Pro CUT HD 2050

length x width x height: 2550 x 2000 x 130 mm

weight: ~ 700 - 800 kg

SPARTUS Pro CUT HD 2550

length x width x height: 3050 x 2200 x 130 mm

weight: ~ 900 - 1,000 kg

SPARTUS Pro CUT HD 3050

length x width x height: 3550 x 2400 x 130 mm

weight: ~ 1,200 - 1,350 kg

4.2. PACKAGE

The device is not wrapped up. It is not protected against rain. Means of transport and storage must

protect machine against weather conditions.

4.3. INSPECTION ON RECEPTION

In the event of deficiencies in delivery, the recipient must fill up a relevant document stating these

deficiencies and provide to the seller.

4.4. STORAGE

The machine is preserved and can be stored in a dry room for 3 months. It can stand without

restrictions in a heated room.

5. SETTING UP, INSTALLATION, STARTING

5.1. INSTALLATION AND SETTING UP THE MACHINE

The machine should be placed on a horizontal foundation or floor. It must be levelled. There are

leveling screws at the ends of the legs for height adjustment. When inserting and screwing, the

raised loads must be firmly supported. Connecting cables must not be a tripping hazard. Electrical

cables (including control cables disconnected for transport) are connected in a junction box in

accordance with relevant numbering.

Location of regulatory and leveling feet

5.2. CLEANING

The metallic table surfaces are coated with an anti-corrosion agent. Before startup, wipe them dry.

5.3. CONNECTION OF ELECTRICITY

This work can only be carried out by an authorized electrician in the field of operating electrical

equipment and installations up to 1 kV. Connection parameters are described in the TECHNICAL

DATA chapter. Before connecting machine to the network, it is recommended to check the insulation

resistance, which should not exceed 1 MV. When the machine has stood for more than 15 days in an

unheated room, a check is necessary. A machine with damp insulation should be dried and the

insulation resistance checked again.

5.4. CONNECTION OF VENTILATION (applies to sectional table)

The ventilation duct is located at the back-right part of the CNC table. The filtering device must

provide a capacity of approx. 3000 m3/h. It is forbidden to use a filter fan when machining aluminum

alloys, the resulting magnesium dust may be accumulated in the filter cartridges and that may cause

an explosion hazard.

5.5. WATER TABLE

The use of a water table makes it possible to significantly reduce the deformation of cut materials,

especially with small thicknesses such as 0.5 - 3 mm. It also reduces noise generated during the

cutting process as well as smoke and radiation. Remember that the used coolant has to be

utilised/recycled. The manufacturer recommends using a corrosion inhibitor solution liquid to

protect the metal parts of the machine against corrosion.

6. WORKING PROCESS

6.1. START-UP, WORKING CYCLE

When the machine is adjusted, the order of startup is as follows:

1. Turn on the main switch.

2. Turn on the power of the plasma cutter with the switch on the control panel.

3. Turn on the power to the plasma generator.

4. Start the CNC control program.

Work in a cycle always starts with putting a metal sheet on the table.

6.2. MACHINE RECONFIGURATION

Replacing the torch to cut a material with different thickness:

1. Turn the machine off with the main switch.

2. Turn off the power to the plasma generator.

3. Remove the plasma / gas torch.

4. Install the plasma / gas torch.

6.3. SHUTDOWN DURING TYPICAL OPERATION AND EMERGENCY

6.3.1. STANDARD SHUTDOWN

At the end of the cycle or during operation, it is possible to stop the machine with the "STOP" button

on the control panel or the "STOP" virtual key in the computer program.

6.3.2. EMERGENCY STOP

In an emergency, you can stop the machine at any time with the EMERGENCY STOP switch located on

the control panel.

6.4. CONTINUATION OF WORK AFTER EMERGENCY STOP OR FAULT

If, in an emergency, the machine was stopped by an emergency switch, first you need to remove the

cause of the hazard. To unlock the EMERGENCY STOP button turn it to the right.

Resetting the cutting program stops the machine. After restarting the program and confirming it on

the operator panel, the machine continues the cycle.

6.5. INTERFERENCE AT WORK, FAULTS

The cycle may stop, e.g. when the torch support is too close to the extreme positions of the CNC

table. It also stops due to torch contact with the metal sheet detected by the collision system (arc

breaking during the cutting process or for other reasons not described). Interference affecting the

operation of the CNC table may arise when the device is connected to a plasma source in which

ignition occurred by using high frequency (HF). This frequency strongly affects the electronic

components of the CNC table and in extreme cases may cause their damage. To eliminate the effects

of high frequency:

ground the machine structure with a PE wire min. 16mm2 with the electrical grounding point no

further than 6m from the device

ground the plasma source with a PE cable min. 16mm2 with the electrical grounding point not

further than 6m from the device

ground the head support in which the plasma source burner is located

apply the so-called EMC braid over the entire length of the plasma torch, connecting it to the

grounding of the electrical system

The procedures and methods presented above may not be effective whenever RFI / EMI interference

suppression is required. The final way to implement these solutions may depend on the plasma

source being installed. However, they should be used consistently for all models of the selected

group.

In the event of high levels of interference, it is recommended that the torch lead should be at a

minimum distance of 150 mm from other electrical cables.

7. MAINTENANCE

Failure to follow the lubrication and maintenance regulations for the plasma CNC may cause

equipment failure. If the users are found out that they do not comply with the guidelines included in

the documentation, the manufacturer reserves the right to make a paid repair excluding the

warranty conditions.

7.1 PERIODIC GREASING

toothed bar

Z axis ball screw

- Every day before starting and after finishing work - wipe the linear guides of X and Y axis with a dry

cloth, clean the table surface from waste materials remaining after the device's work. Lack of

systematic wiping off linear guides will result in premature corrosion of drive components and

damage to linear trolleys of the device. In practice, properly maintained elements mentioned above

will help the machine to reach a lifetime service of 12-18 months during the production process

whereas improper maintenance or lack of service will decrease that to 5-6 months.

- Maintenance once a week - the linear guides should be greased once a week with machine oil or

other oil specified by the manufacturer. For this purpose, the guides should be wiped dry with a

clean cloth, greased with an appropriate agent. Then make a few complete rides from the beginning

to the end of each axis. Usually three or four passes are sufficient. After these operations, wipe off

excess of oil from the guides. The lack of systematic maintenance of the X-axis and the Y-axis linear

guides may result in premature corrosion. The bar and gears should be cleaned with a wire brush or

compressed air at least once in every 7 days. After cleaning, a small amount of grease should be

applied to the bar and gear. Excess of grease should be removed with a cloth.

All maintenance operations must be carried out with the main switch turned off.

7.2 REMOVAL AND DISPOSAL

During scraping, aluminum scrap (pneumatic components) must be separated from steel scrap.

Pneumatic hoses made of polypropylene are utilized as plastics. The wiring and engine coils are

considered as copper scrap.

7.3 SERVICE

The manufacturer provides a 12-month warranty. Minor post-warranty repairs may be carried out by

the user only after consulting the manufacturer. If necessary, the manufacturer send spare parts

which were ordered. Major post-warranty repairs should be performed by the manufacturer or an

authorized service center.

8. LIST OF SPARE PARTS

8.1. LIST OF SPARE PARTS THAT WEAR OUT QUICKLY

Torch components such as electrode nozzles, caps, shields

8.2. DAILY SERVICE LIST OF ACTIONS BEFORE STARTING WORK

inspect the technical condition of the machine, check that all the components are ready for work

visually inspect the condition of electrical wiring, gas and air lines

in the event of any faults, they must be rectified before putting the machine into operation

wipe the linear guides of the X and Y axis with a dry cloth

These activities must be carried out with the device powered off

8.3. DAILY MAINTENANCE LIST OF ACTIONS AFTER ENDING WORK

clean spatters and dust off the burner with a dry cloth

use the compressed air to blow out dust and spatters from the X- and Y-axis gears

check and clean the burner consumables, replace them if necessary.

9. PERIODIC SERVICE

Tank and table cleaning, depending on the intensity of use.

Greasing of the ball screw of Z axis in every 20 hours of operation.

IT IS FORBIDDEN TO CARRIED OUT A WELDING PROCESS OR GRINDING WORKS "ON THE MACHINE"

OR NEARBY. THIS COULD DAMAGE THE CONTROLLER, FOR WHICH THE MANUFACTURER IS NOT

RESPONSIBLE. THE WARRANTY COULD BE VOID AS WELL.

Table of contents