Specialised Welding Products MIG 160 User manual

INSTRUCTION MANUAL

MIG 160 / MIG 200 / MIG 300 / MIG 300S

CONTENTS

WARNING

INSTALLATION

OPERATION

WELDING PARAMETERS

TROUBLESHOOTING

WARRANTY

SPARE PARTS LIST

TORCH CONSUMABLE LIST

3

4

5

6

7

8

8

9-10

2

EC DECLARATION OF CONFORMITY

Trakis Nagykoros Kft declares that the following machines:

Classic MIG 160 / 200 / 300 / 300S

Blue Brand MIG 160 / 200 / 300 /300S

correspond to the following edicts and standards:

MSZ EN 60974-1:2006 - IEC 60974-1:2005

MSZ EN 60204-1:2001 - IEC 60204-1:1997

3

Fume

Welding vaporises metals, and anything that is resting on the surface. This gives rise to

fume, which is condensed find particulate material. The fume is mostly oxides of the metals,

including any alloying elements, but it also contains gases produced in the arc, such as

ozone or oxides of nitrogen, and decomposition products from any paints or coating which

was on the metal surface. The nature and quantity of this fume depends critically upon the

welding process, the materials and the welding parameters. Some is harmful to health, for

instance stainless steel fume contains chromium, and welding galvanised steel produces

zinc fume.

Effects can vary from a bout of ‘metal fume fever’ to longer term, more serious problems if

suitable fume removal is not carried out. There is guidance literature that may be consulted

regarding the safe levels for each constituent, and the employer needs to be aware that for

some fume constituents, there may be no safe level, and a statutory exposure limit may be

imposed. Nickel, cobalt and stainless steel welding fume are the subject of statutory limits

in the UK. Highly efficient exhaust apparatus is available. Some health surveillance may be

necessary.

Noise

Welding environments are frequently noisy as other operations such as grinding, etc. may

also be taking place. Some operations, such as de-slagging may take the noise up to such

a level where it will damage workers hearing. In such cases this would mean that hearing

protection is almost certainly required if the noise cannot be controlled by other means.

Some health surveillance may also be necessary. To protect UK workers new noise exposure

limits are due to become law during 2006 and will represent a significant lowering of

statutory noise action levels which are currently set at 85dB(A) and 90dB(A) respectively.

Optical Radiation

The Welding process produces a large quantity of visible light, ultraviolet and infrared.

Exposure to the radiation from an arc causes burns to the skin, and damage to the eyes. For

this reason, welders need to wear clothing to protect their bodies and arms, regardless of

the weather conditions. They also need efficient eye protection, which is usually supplied in

the form of a protective shield. The precise choice of the shade of glass filter in these shields

depends on the type of welding operation, since they vary in their light output.

Welders assistants also need protective clothing and eye protection. Passers-by should be

protected by placing opaque or properly filtered screens around the work area.

Burns and Mechanical Hazards

Welders need good quality gloves, preferably leather gauntlets, safety boots or shoes and

good quality cap and overalls. A leather apron may also be needed. Welding produces

quantities of molten droplets of metal which are scattered in all directions. It is essential

that the welder wears clothing which will not burn or melt, and which is stout enough to

provide adequate protection.

WARNING

4

INSTALLATION

Electrical Connection

The migs comprise of three models, all single phase. Always ensure the machine is connected

to the correct supply, with the correct size of fuses or circuit breakers as shown below. If

circuit breakers are used they must be type four otherwise tripping may occur although

there is no machine fault.

Model Supply Type Fuse

160 MIG 240 volt single phase 20 Amp

200 MIG 240 volt single phase 20 Amp

300 MIG 240 volt single phase 40 Amp

300S MIG 240 volt single phase 40 Amp

Electrical Safety

Clearly, the employer needs to establish the level of competence of the electrician who is

given the task of wiring the installation, and the type of maintenance which the installation

and the equipment will subsequently need. In the UK there is a requirement for periodic

electrical checks to be done on power sources. The design of welding power sources

themselves has gone through a number of changes, and for each, there are different

standards of safety. The employer must ensure that his installation is correctly matched to

the type he is using - for instance double insulated power sources should not be used with

a separate earth lead to the workpiece.

Earth Connection

A suitable earth lead is supplied with the machine. The earth clamp must be securely

attached to the workpiece as a poor connection will affect the quality of the weld.

The machine is covered by a twelve month warranty but the main transformer and choke

are covered by a three year warranty. The warranty does not cover the torch and its

consumable parts. Please note if you require a service call by an engineer under warranty

and the problem is identified as operator fault or torch fault then you will be liable for the

charge encountered by the engineer. Please be sure to retain your receipt as this will be

required in the event of a claim.

WARRANTY

5

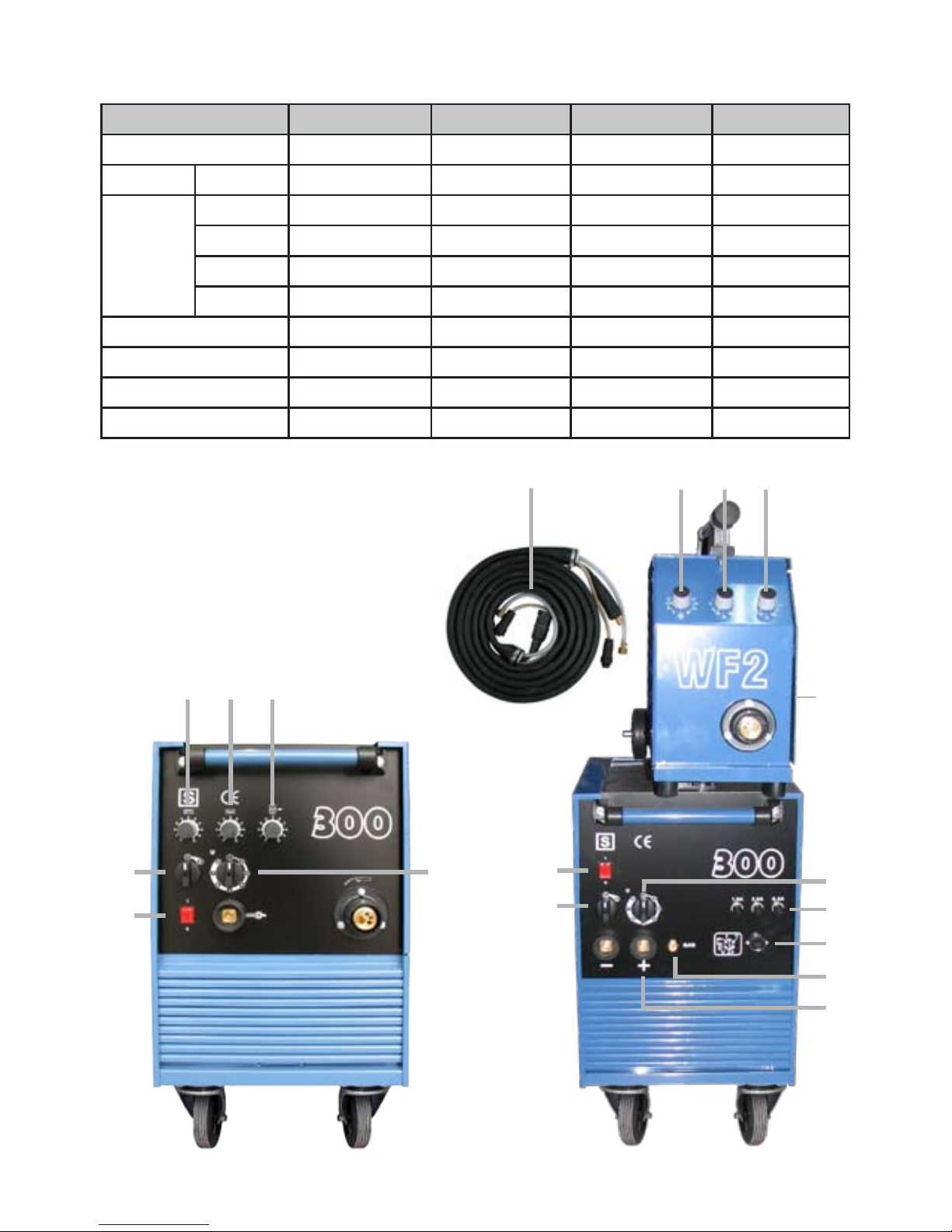

Controls

A On/Off Switch Is the illuminated rocker switch which lights up red when the

machine is switched on.

B Voltage Control 160 has six voltage settings 1 being the lowest.

Switch 200 has eight voltage settings 1 being the lowest.

C Voltage Control 300 / 300S the left-hand switch has two settings which alters

the

Switch voltage output in large steps, the right-hand switch has eight

settings which alters the voltage in small steps. Therefore 1-1 is

the lowest, 1-8 is intermediate and the maximum is 2-8 this

gives 16 voltage settings.

D Wire Speed Varies the wire speed between 2 and 20 metres per minute.

Control

E Weld Timer On models 200 and 300 only. This determines the amount of

welding time in the stitch and spot welding modes.

F Pause Timer On models 200 and 300 only. This determines the amount of no

weld time in the stitch welding mode.

G Fuses

H Wire Feed Connects to 300S by lead from WF2.

J Inter Connection 5m Standard, optional 10m.

Cable

OPERATION

A

B

DD

E F

A

B

6

Model MIG 160 MIG 200 MIG 300 / 300S WF2/ 4F2

Input 230v/50-60hz 230v/50-60hz 230v/50-60hz

Output Min 20A 22A 27A

Max 140A 200A 315A

35% 85A 150A 250A

60% 65A 120A 200A

100% 50A 92A 150A

Voltage Steps 6 8 16

Wire Size 0.6 - 0.8 mm 0.6-1.0 mm 0.6 - 1.2 mm 0.6 - 1.2 mm

Weight 65 kg 70 kg 92 kg 25 kg

Dimensions (LxWxH) 86 x 46 x 71 cm 85 x 46 x 71 cm 86 x 40 x 71 cm 56 x 22 x 40 cm

WELDING PARAMETERS

E F D

CC

A

E F

D

C

C

A

G

H

H

H

J

H

7

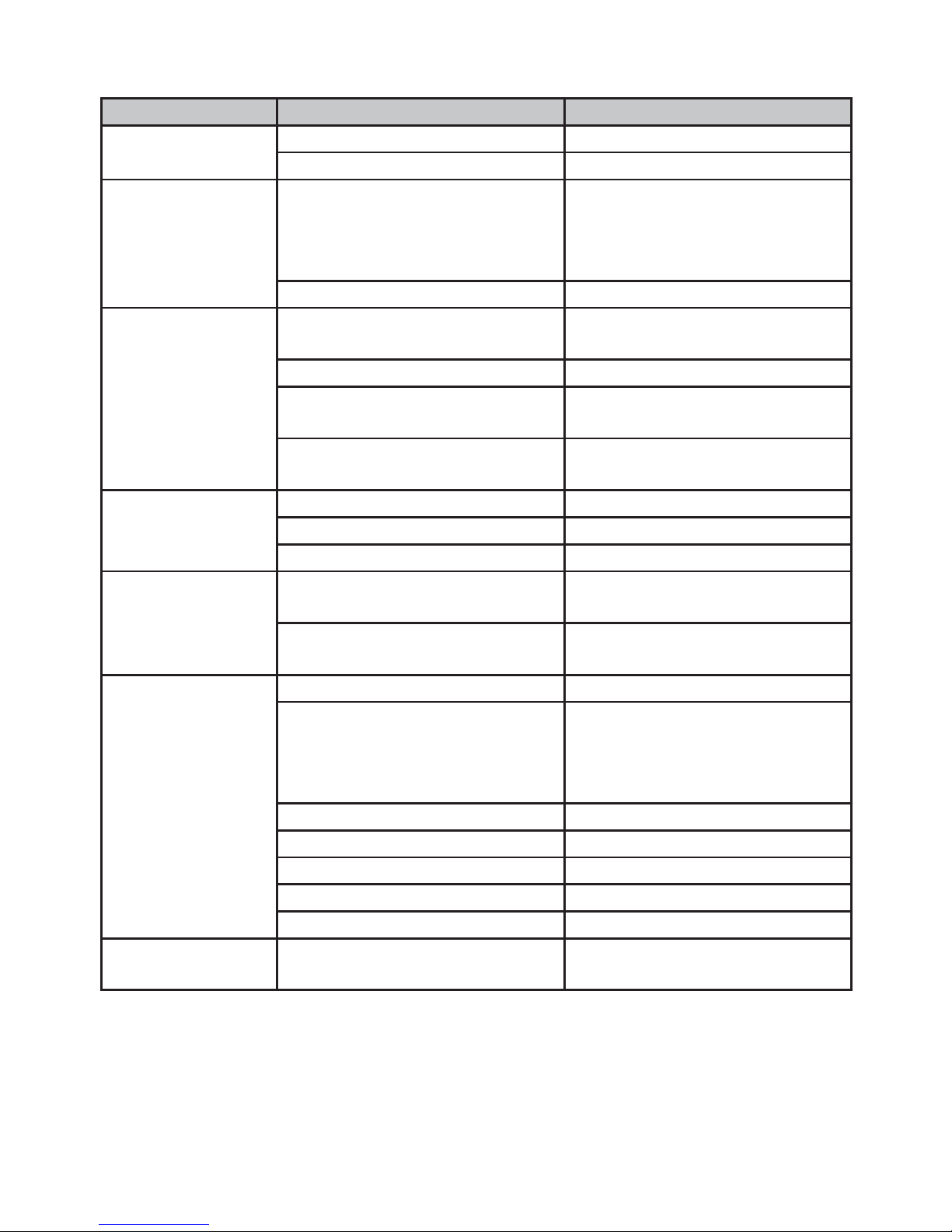

TROUBLESHOOTING

FAULT REASON REMEDY

Set is dead 1. On/Off switch is off Turn it on

2. Fuse in mains supply blown Replace fuse

Nothing happens when

torch trigger is pressed

1. Torch switch defective

2. Torch central connector pins not making

proper contact in the machine adaptor

Check for torch fault by shorting the

switch pin sockets on the central adaptor

and listening for the main contactor

coming in

3. Auxiliary circuit fuse blown Replace fuse

Wire is not conveyed

when feed roll is turning

1. The friction brake in the hub is

tightened too hard

Loosen

2. Insufficient pressure on drive roll Tighten

3. Wire is not running in the feed roll

grove

Re-align wire

4. Dirt in liner and/or contact tip Blow with compressed air, replace contact

tip

Wire feeding in jerks/

erratic

1. Contact tip worn/burnt Replace

2. Dirt in feed roll groove Clean and re-align wire

3. Groove of feed roll worn Replace

No arc 1. Bad contact between earth clamp and

workpiece

Tighten earth clamp and check connections

2. Short circuit between contact tip and

shroud

Clean replace tip/shroud as nececssary

Porous weld 1. Failure of Gas Shield Replace gas shroud check cylinder contents

2. Wrong distance and/or wrong

inclination of torch

The length of stick out wire from tip of

workpiece must be between 5-10mm

inclination not less than 60oin relation to

the workpiece

3. Too small qty. gas Increase gas flow

4. Draught Screen the weld area

5. Humid workpiece Dry workpiece

6. Heavily rusted workpiece Clean workpiece

7. Gas Solenoid defect Clean/Replace

Set suddenly stops 1. Machine overheated due to exceeding

duty cycle

Do not switch off, leave to cool down.

Machine will reset

Should any of these suggestions not remedy your fault contact your distributor in order to

facilitate service repair.

8

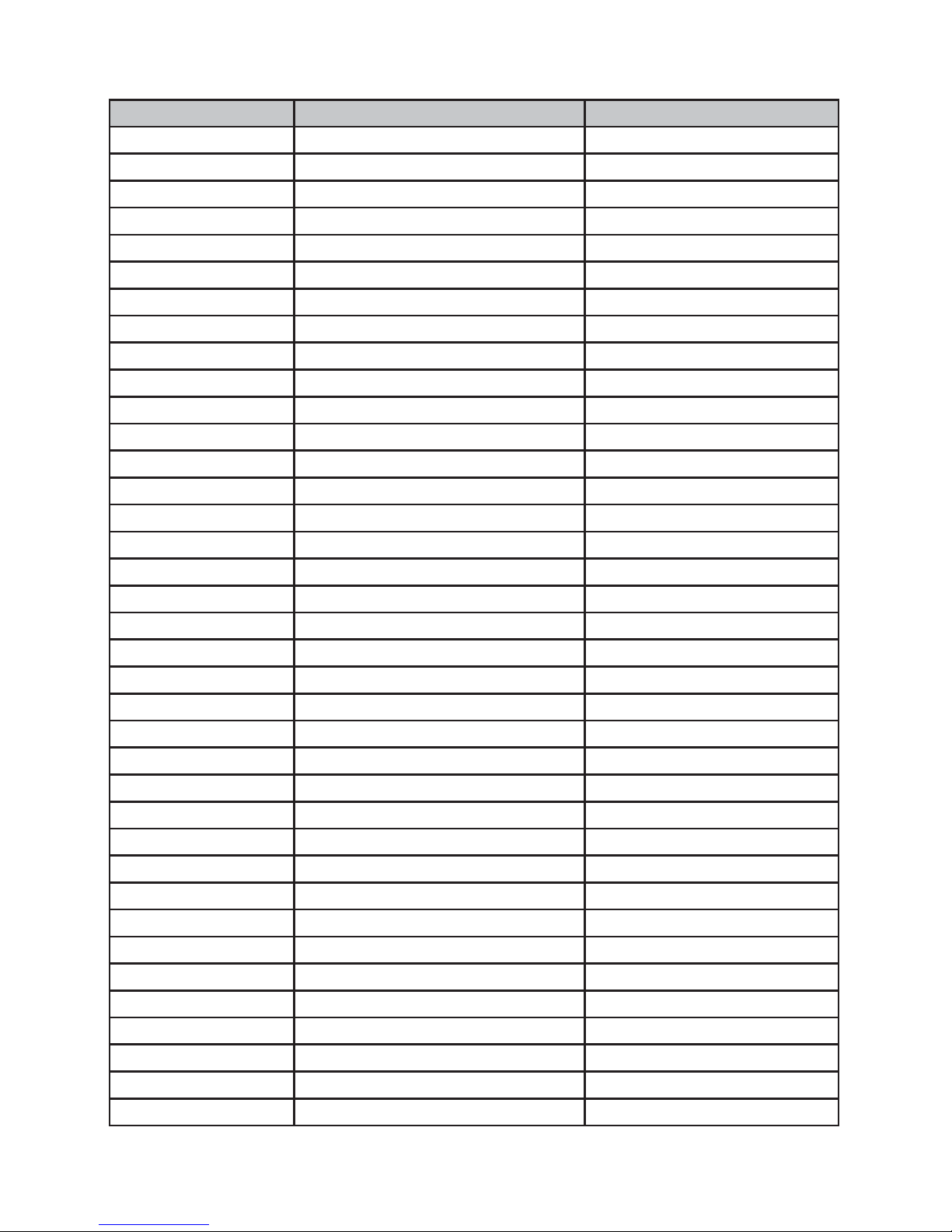

SPARE PARTS LIST

TRAKIS PART NUMBER DESCRIPTION MACHINE

W 9391 Potentiometer 10 KA 300 / 4F2

W 9392 Potentiometer 10 KB 160 / 200

W 9393 Potentiometer 470 KA 300 / 4F2

W 9394 ON/OFF switch 160 / 200 / 300 / 300S

W 9395 Reel Hub Assembly TRAKIS 160 / 200 / 300 / 4F2

W 9396 Hub Nut TRAKIS 160 / 200 / 300/ 4F2

W 9397 Gas Solenoid Valve 160 / 200 / 300 / 4F2

W 9398 Main Contactor DIL-K 410 160 / 200

W 9399 Main Contactor DIL-K 710 300 / 300S

W 9400 Wire Feeder Motor 24v 25w 160

W 9401 Wire Feeder Motor 24v 35w 200

W 9402 Wire Feeder Motor 24v 40w 300 / 4F2

W 9403 Printed Circuit Boards EB 102 160 / 200

W 9404 Printed Circuit Boards W-10 300 / 300S

W 9405 Feed Roll Ring 0.6-0.8 V 300

W 9406 Feed Rool Ring 1.0-1.2 V 300

W 9506 Feed Roll Ring 1.2-1.6 V 300

W 9507 Feed Roll Ring 0.6-0.8 V 160 / 200

W 9407 Feed Roll Ring 0.8-1.0 V 160 / 200

W 9408 Feed Roll Retainer Knob 160 / 200 / 300

W 9409 Capillary Tube 1.2 x 80 160 / 200

W 9410 Capillary Tube 2.0 x 97 300 / 4F2

W 9411 Combined Wire Feeder TRAKIS 160 / 200

W 9412 Fuse 5 x 20 1A 160

W 9413 Fuse 5 x 20 3.15A 160 / 200

W 9414 Fuse 5 x 20 6.3A 300 / 300S

W 9415 Fuse 6.3 x 32 1.6A 200 / 300 / 300S

W 9416 Cooling Fan 160 / 200

W 9417 Cooling Fan 300 / 300S

W 9418 Knob for Selector Switch 160 / 200 / 300 / 4F2

W 9419 Knob for Potentiometer 160 / 200 / 300 / 4F2

W 9505 Feed Roll Ring 0.6-0.8 V 4F2

W 9509 Feed Rool Ring 1.0-1.2 V 4F2

W 9510 Feed Roll Ring 1.2-1.6 V 4F2

W 9512 Feed Roll Retainer Knob 4F2

9381 Interconnecting Cable 5 mt. 4F2/ 300S

9382 Interconnecting Cable 10 mt. 4F2/ 300S

9

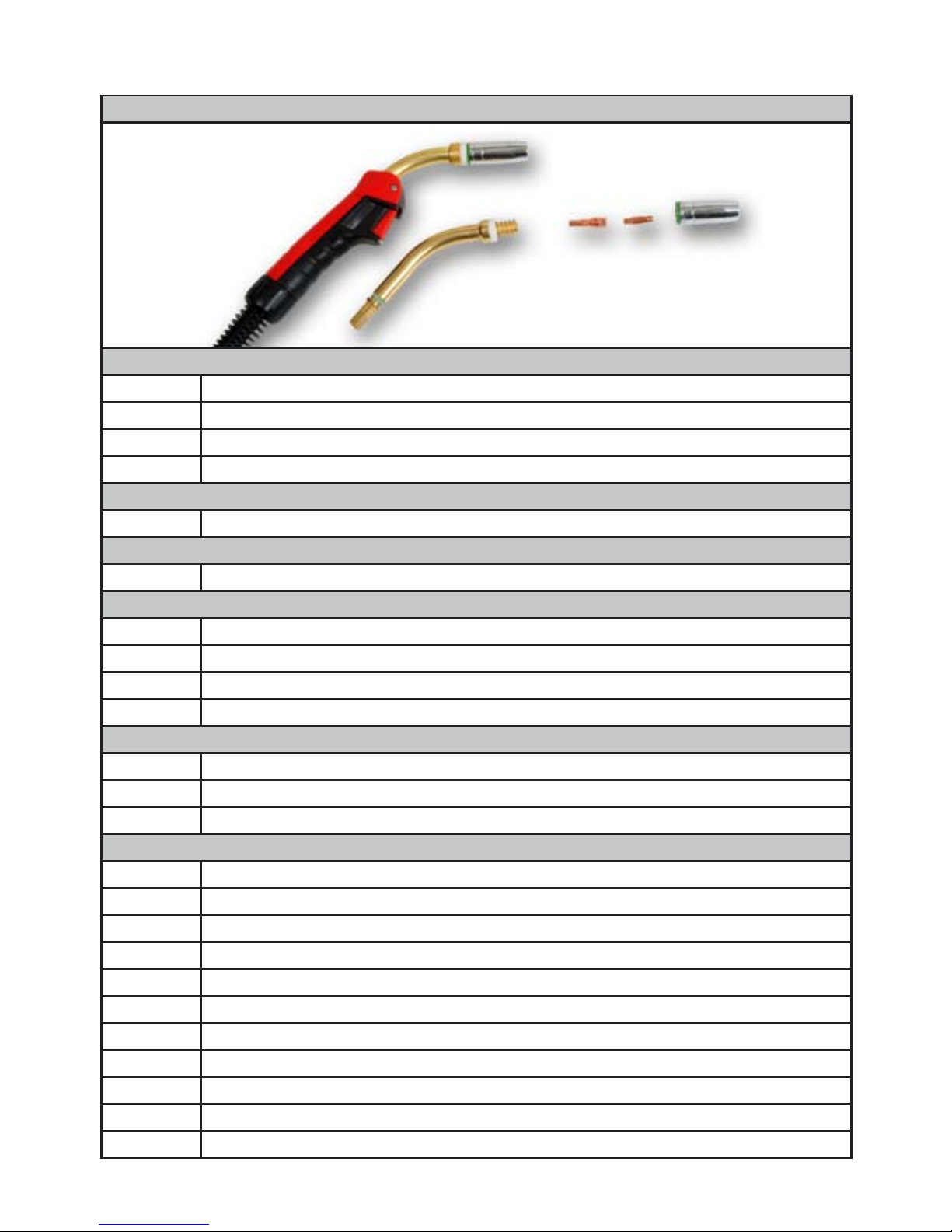

TORCH CONSUMABLE LIST

SWP 15 MIG TORCH & ACCESSORIES

SWP 15 MIG TORCH

CODE DESCRIPTION

6000 SWP 15 x 3 mtr Mig Torch - 002.0449

6001 SWP 15 x 4 mtr Mig Torch - 002.0450

SWAN NECKS

6033 Swan Neck - 002.0009

CONTACT TIPS

6567 0.6 mm Contact Tip - M6 Thread - 140.0008

6020 0.8 mm Contact Tip - M6 Thread - 140.0059

NOZZLES

6007 Conical Nozzle - 145.0075

6009 Tapered Nozzle - 145.0123

LINERS

6029 Steel Liner x 3 mtr 0.6 - 0.8 mm Wire - Blue - 124.0011

6030 Steel Liner x 4 mtr 0.6 - 0.8 mm Wire - Blue - 124.0012

6650 Teflon Liner x 3 mtr 0.6 - 0.8 mm - Blue - 124.0005

6651 Teflon Liner x 4 mtr 0.6 - 0.8 mm - Blue - 124.0008

6033

6567

6020

6007

6009

10

TORCH CONSUMABLE LIST (CONTINUED)

SWP 25 MIG TORCH & ACCESSORIES

SWP 25 MIG TORCH

CODE DESCRIPTION

6002 SWP 25 x 3 mtr Mig Torch - 004.0312

6003 SWP 25 x 4 mtr Mig Torch - 004.0313

6598 SWP 25 x 5 mtr Mig Torch - 004.0314

SWAN NECKS

6034 Swan Neck - 004.0012

TIP ADAPTORS

6023 Tip Adaptor for M6 Contact Tips - 142.0001

CONTACT TIPS

6568 0.6 mm Contact Tip - M6 Thread - 140.0005

6569 0.8 mm Contact Tip - M6 Thread - 140.0051

6021 1.0 mm Contact Tip - M6 Thread - 140.0242

6570 1.2 mm Contact Tip - M6 Thread - 140.0379

NOZZLES

6010 Conical Nozzle - 145.0076

6011 Cylindrical Nozzle - 145.0042

6012 Tapered Nozzle - 145.0124

LINERS

6029 Steel Liner x 3 mtr 0.6 - 0.8 mm Wire - Blue - 124.0011

6030 Steel Liner x 4 mtr 0.6 - 0.8 mm Wire - Blue - 124.0012

6657 Steel Liner x 5 mtr 0.6 - 0.8 mm Wire - Blue - 124.0015

6031 Steel Liner x 3 mtr 1.0 - 1.2 mm Wire - Red - 124.0026

6032 Steel Liner x 4 mtr 1.0 - 1.2 mm Wire - Red - 124.0031

6655 Steel Liner x 5 mtr 1.0 - 1.2 mm Wire - Red - 124.0035

6650 Teflon Liner x 3 mtr 0.6 - 0.8 mm Wire - Blue - 24A62

6651 Teflon Liner x 4 mtr 0.6 - 0.8 mm Wire - Blue - 126.008

6652 Teflon Liner x 3 mtr 1.0 - 1.2 mm Wire - Red - 126.0021

6653 Teflon Liner x 4 mtr 1.0 - 1.2 mm Wire - Red - 126.0026

6654 Teflon Liner x 5 mtr 1.0 - 1.2 mm Wire - Red - 126.0028

6034

6023 6568

6569

6021

6570

6010

6011

6012

Specialised Welding Products Ltd

14 Farringdon Industrial Centre

Farringdon, Nr Alton

Hampshire GU34 3DP

This manual suits for next models

3

Table of contents

Other Specialised Welding Products Welding System manuals

Popular Welding System manuals by other brands

Smoothcut

Smoothcut Plasma 100 operating manual

Telwin

Telwin INVERPULSE 320 MIG-TIG-MMA instruction manual

Ramsond

Ramsond CT Series instruction manual

Migatronic

Migatronic NAVIGATOR 2500 instruction manual

Lincoln Electric

Lincoln Electric INVERTEC V205-T AC/DC TIG Operator's manual

Lincoln Electric

Lincoln Electric OUTBACK SVM204-A Service manual