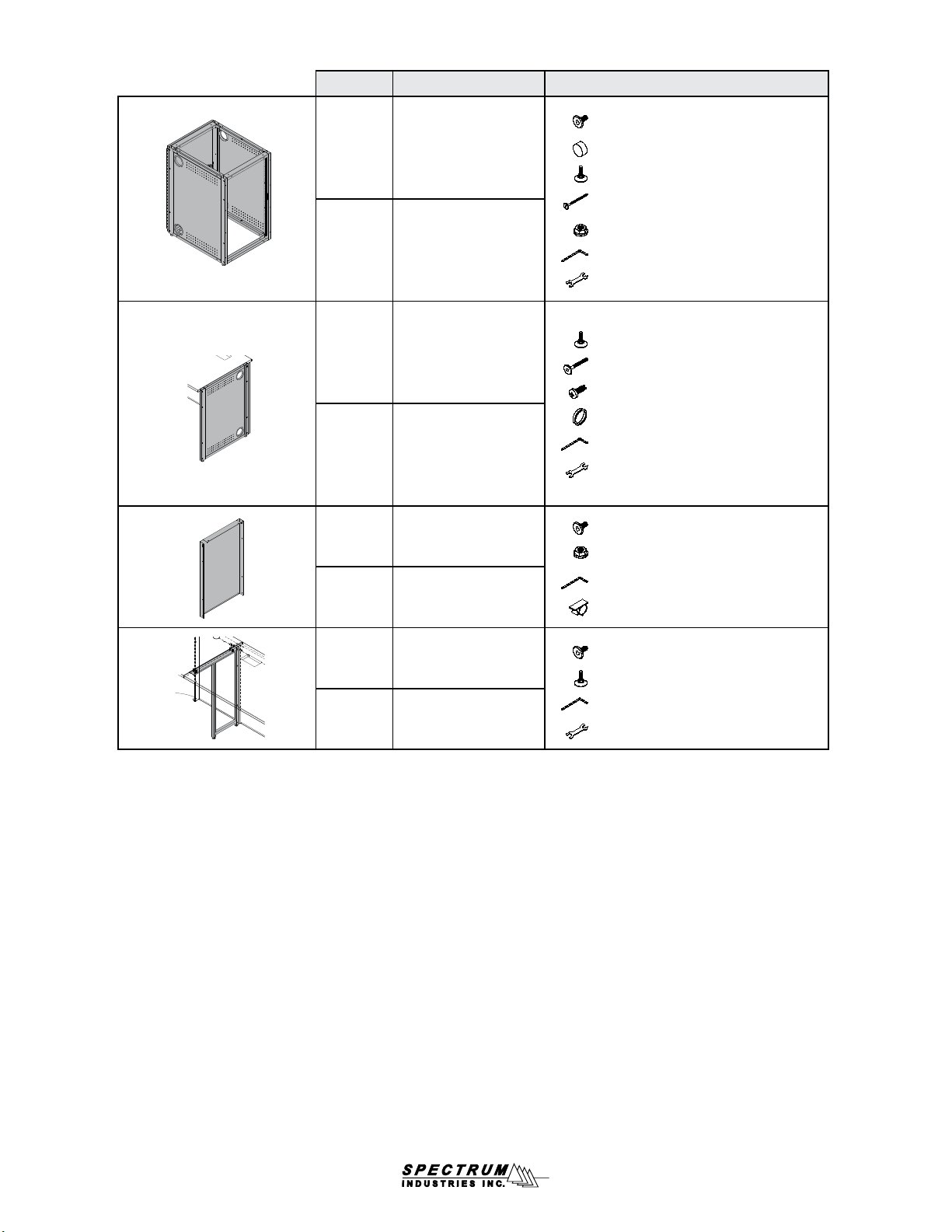

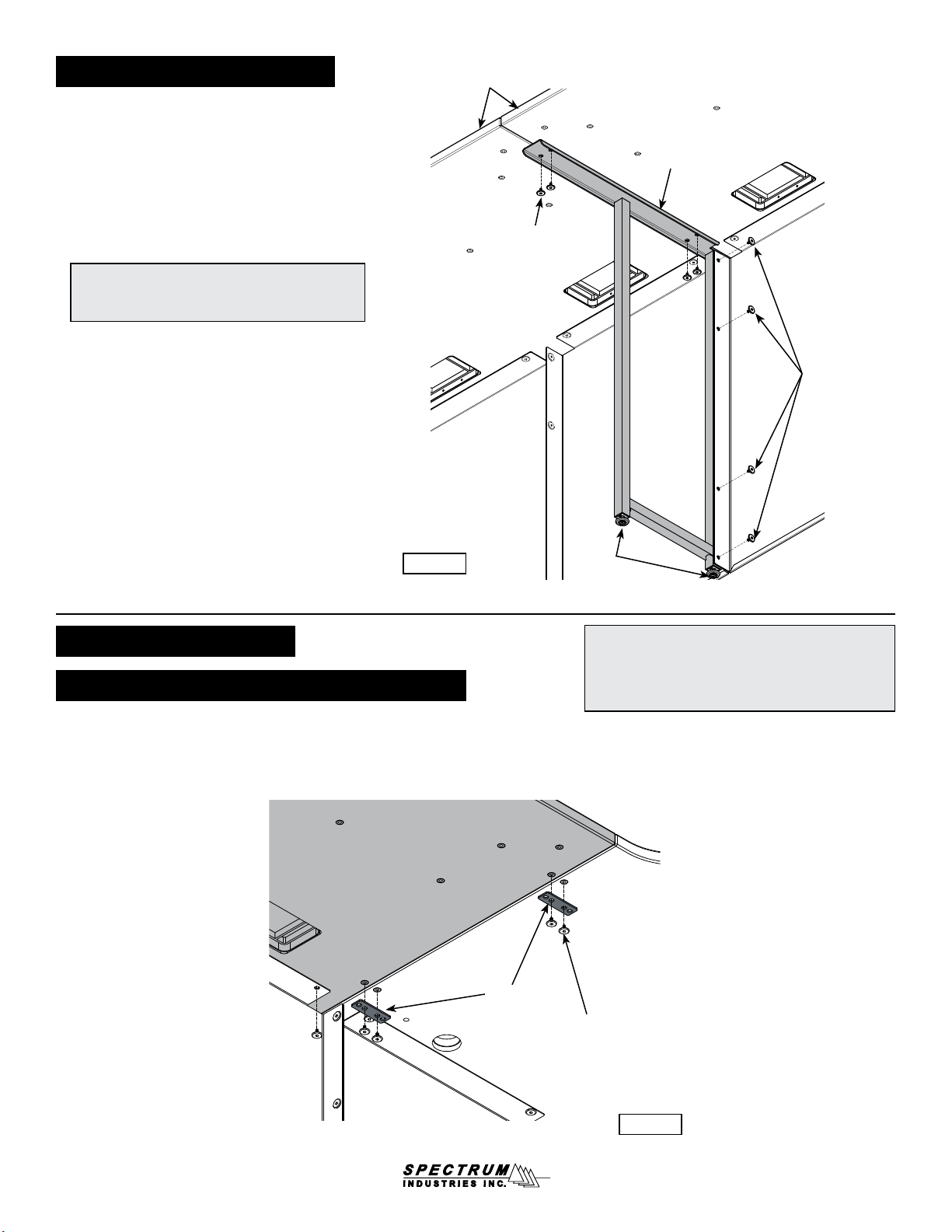

Worksurface-to-top of Equipment Rack:

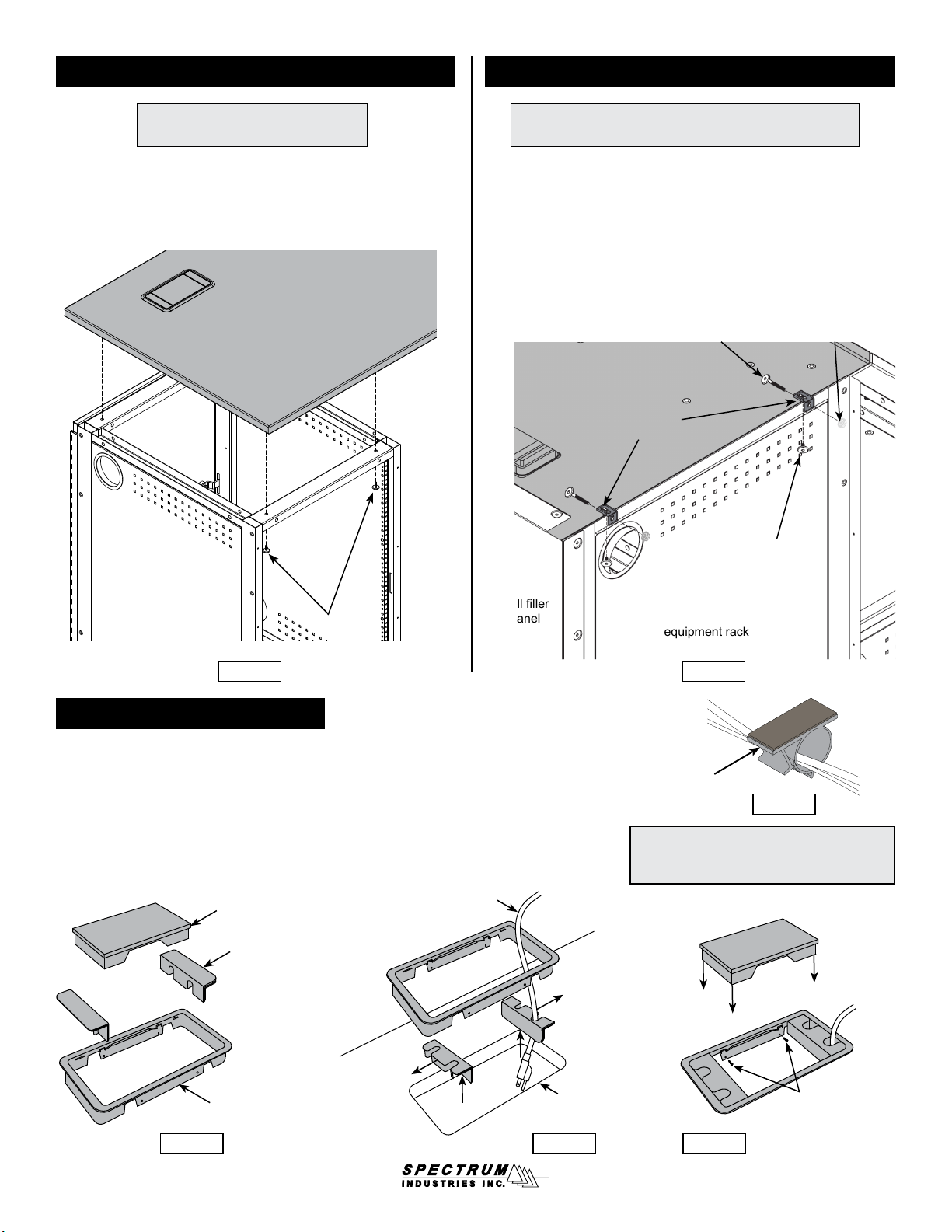

1. Set the worksurface onto the equipment rack and any adjacent

assembled wall ller panels (if applicable). Figure 7B.

2. Align the worksurface and equipment rack mounting holes.

3. Attach worksurface with (4) 1/4-20 x 15mm JC bolts.

1. Attach each worksurface bracket to the equipment rack with (1)

1/4-20 x 50mm JC bolt and (1) 1/4-20 serrated anged locknut

(attached from inside eq rack). (The slotted side of the bracket will

attach to the worksurface.) Do not tighten completely. Figure 7C.

2. Set the worksurface onto the assembled wall ller panel(s) and

worksurface brackets and align the mounting holes.

3. Attach worksurface with 1/4-20 x 15mm JC bolts.

4. Align the tops of the worksurfaces and tighten all screws securely.

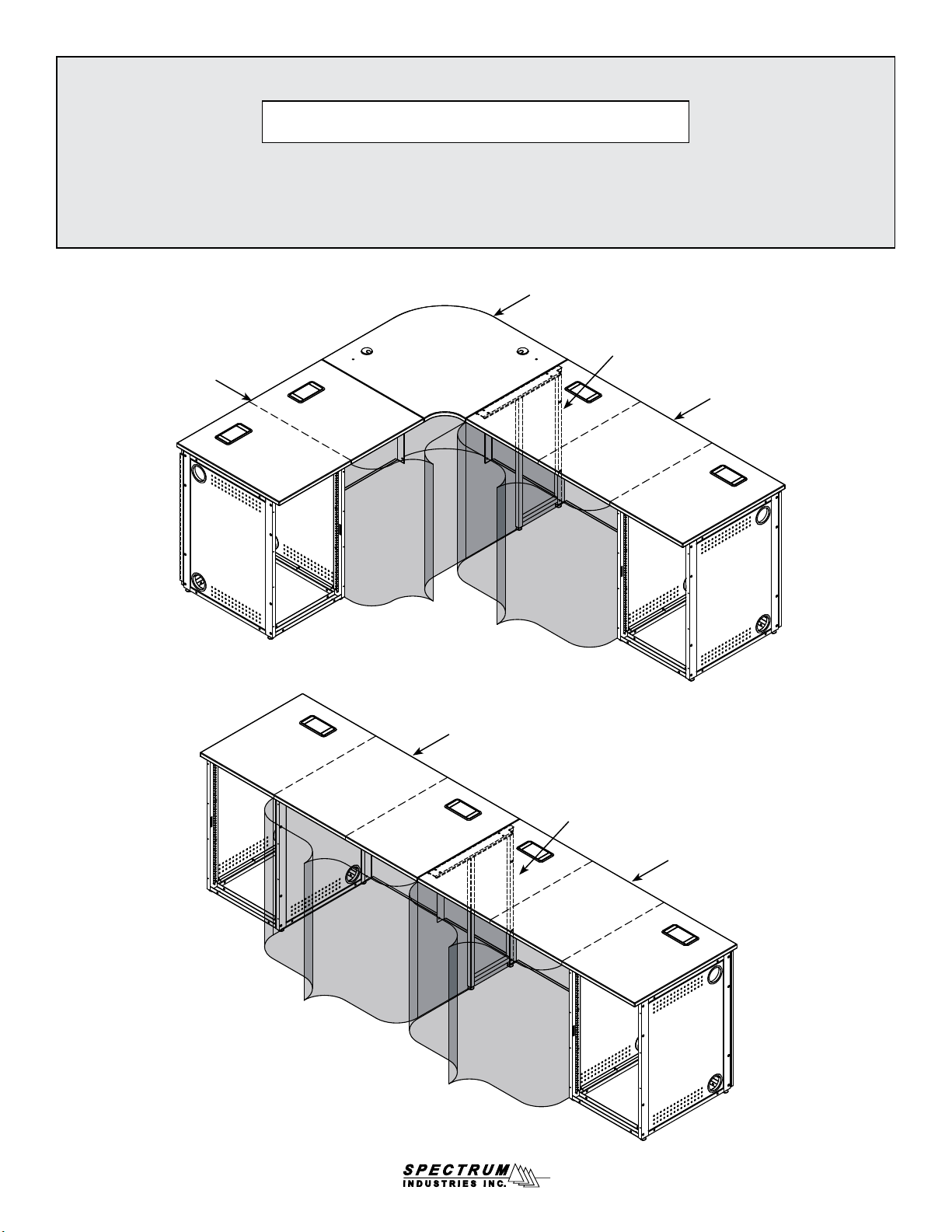

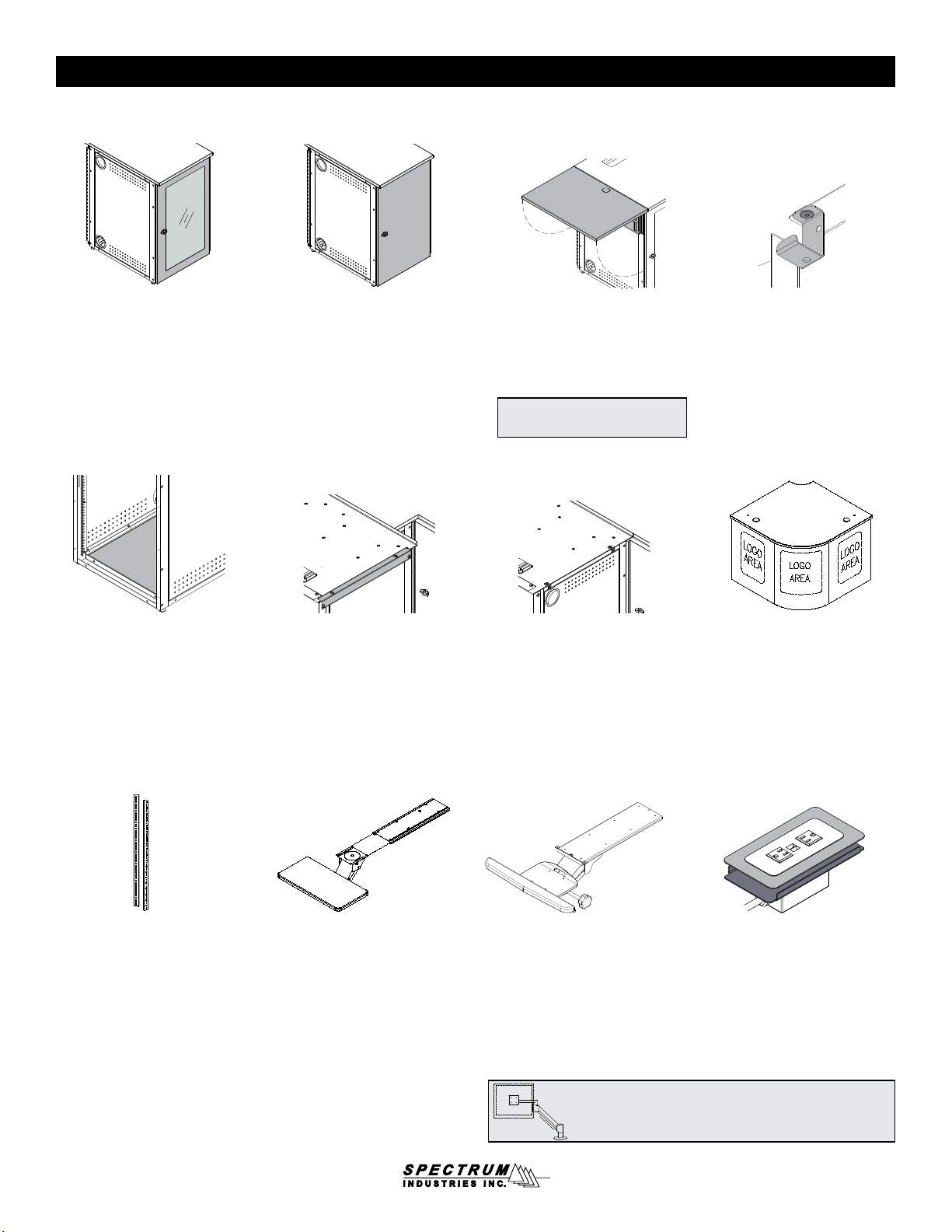

Grommets and Cord Clips

1. Remove the entire grommet assembly from the worksurface.

2. Remove the center cover and slide out the cord receptacles. Figure 8A.

3. Turn the receptacles around to access the cord pass-through holes and slide back into

the grommet frame around the cord(s). Figure 8B.

4. Re-install the grommet assembly into the worksurface cutout and replace the center

cover. Figure 8C. Optional: Install (2) #6 x 5/8” PHSM screws through the side of the

grommet frame to secure grommet to the worksurface.

5. Apply cord clips to underside of worksurface where needed to route cords. Figure 8D.

(Clips only included with radius corner and wall ller panels.)

Worksurface-to-Worksurface with Equipment Rack:

Figure 7C

Note: This is the connection between a worksurface of equal

height to another worksurface above an equipment rack.

Note: This is the attachment of a work-

surface to the top of an equipment rack.

wall ller

panel

equipment rack

Note: The grommets and cord clips provide cord

management when cords and wires are to be

routed to the worksurface from under the console.

Figure 8D

cord clip

0108630R7 Page 8 of 11

underside of

worksurface

1/4-20 x 15mm

JC bolt

(1 per bracket)

worksurface

brackets

1/4-20 x 50mm JC bolt

(1 per bracket)

1/4-20 anged locknut

(1 per bracket-attach

from inside eq rack)

Figure 7B

worksurface

1/4-20 x 15mm

JC bolt

(4 required)

equipment rack

center cover

cord receptacle

grommet frame

Figure 8A Figure 8B Figure 8C

cord

worksurface

cutout (2) #6 x 5/8” PHSM

screws (secure to

worksurface-optional)