Speedaire 10D240 Instructions for use

Speedaire®3/8" Air

Composite Drill

Speedaire Air Composite Drill is used for maintenance, light

assembly or automotive repair. Comes with comfort grip, precise throttle control,

and durable motor and gears.

Figure 1

Unpacking

Specifications

When unpacking the unit, carefully

look for any damage that may have

occurred during transit. Check for

loose, missing or damaged parts.

General Safety Information

1. For Additional Safety

information Consult:

Your employer, union, and/or trade

association.

US Department of Labor (OSHA);

www.osha gov.

" Safety Code For Portable Air

Tools" (B186.1) available from:

www.ansi.org.

Projectile Hazards

Always wear impact-resistant eye

and face protection when involved

with or near the operation, repair

or maintenance of the tool or

changing accessories on the tool.

Be sure all others in the area are

wearing impact-resistant eye and

face protection.

Even small projectiles can injure

eyes and cause blindness.

Entanglement Hazards

Keep away from rotating bit and

chuck.

2.

3.

Bit Binding Hazards

Always use sharp bits.

Reduce downward pressure at

breakthrough.

ANSI recommends the use of a

support handle on drills with a

chuck capacity larger than 3/8 in. or

10mm.

Workplace Hazards

Slip/Trip/Fall is a major cause of

serious injury or death. Beware of

excess hose left on the walking or

work surface.

High sound levels can cause perma-

nent hearing loss. Use hearing

protection as recommended by your

employer or OSHA regulation (See)

29 CFR part 1910).

Maintain a balanced body position

and secure footing.

Repetitive work motions, awkward

positions and exposure to vibration

can be harmful to hands and arms.

If numbness, tingling, pain or

whitening of the skin occurs, stop

using tool and consult a physician.

Avoid inhaling dust or handling

debris from the work process which

can be harmful to your health. Use

dust extraction and wear respir-

atory protective equipment when

working with materials which

produce airborne particles.

Proceed with care in unfamiliar

surroundings. Hidden hazards may

exist, such as drilling into electric or

other utility lines.

4.

5.

Chuck Capacity

Free speed (No Load)

Length

Average air consumption

Air inlet

Maximum Air Pressure

Weight

Hose Size

...................................3/8"

............. 2000 RPM

.......................................... 8.26 in

........... 3.5 CFM

...................................... 1/4" NPT

.................. 90 PSI

....................................... 1.69 LBS

.................................... 3/8" I.D.

Includes:

1 - Air Drill

1 - Key

WARNING

To reduce risk of injury, everyone

using, installing, repairing,

maintaining, changing

accessories on, or working near

this tool must read and

understand these instructions

before performing any such task.

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the following symbols.

Safety Guidelines

Danger indicates an imminently

hazardous situation which, if not

The drill bit can suddenly

bind and cause the work

piece or tool to rotate, causing arm and shoulder

injuries.

able to handle the bulk, weight and power of this tool.

avoided, WILL result in death or serious injury.

Warning indicates a potentially

hazardous situation which, if

not avoided, COULD result in death or serious injury.

Caution indicates a potentially

hazardous situation which, if

Do not wear jewelry or

loose clothing.

not avoided, MAY result in minor or moderate injury.

Notice indicates important

information, that if not followed,

may cause damage to equipment

NOTICE

You can be cut or burned if you

come in contact with the drill bit,

chips or work surface.

Use intermittent drill pressure to

avoid long shaved chips.

Scalping can occur if hair is not

kept away from tool and

accessories. Choking can occur

if neck wear is not kept away

from tool and accessories.

Operators and maintenance

personnel must be physically

10D240

in Taiwan

5S6846

04634

STC100

06/11

#804

Speedaire®3/8" Air Composite Drill

10D240

Workplace Hazards (continued)

This tool is not intended for use in

explosive atmospheres and is not

insulated for contact with electric

power sources.

Some examples of these

chemicals are:

General Safety information

(continued)

Installation

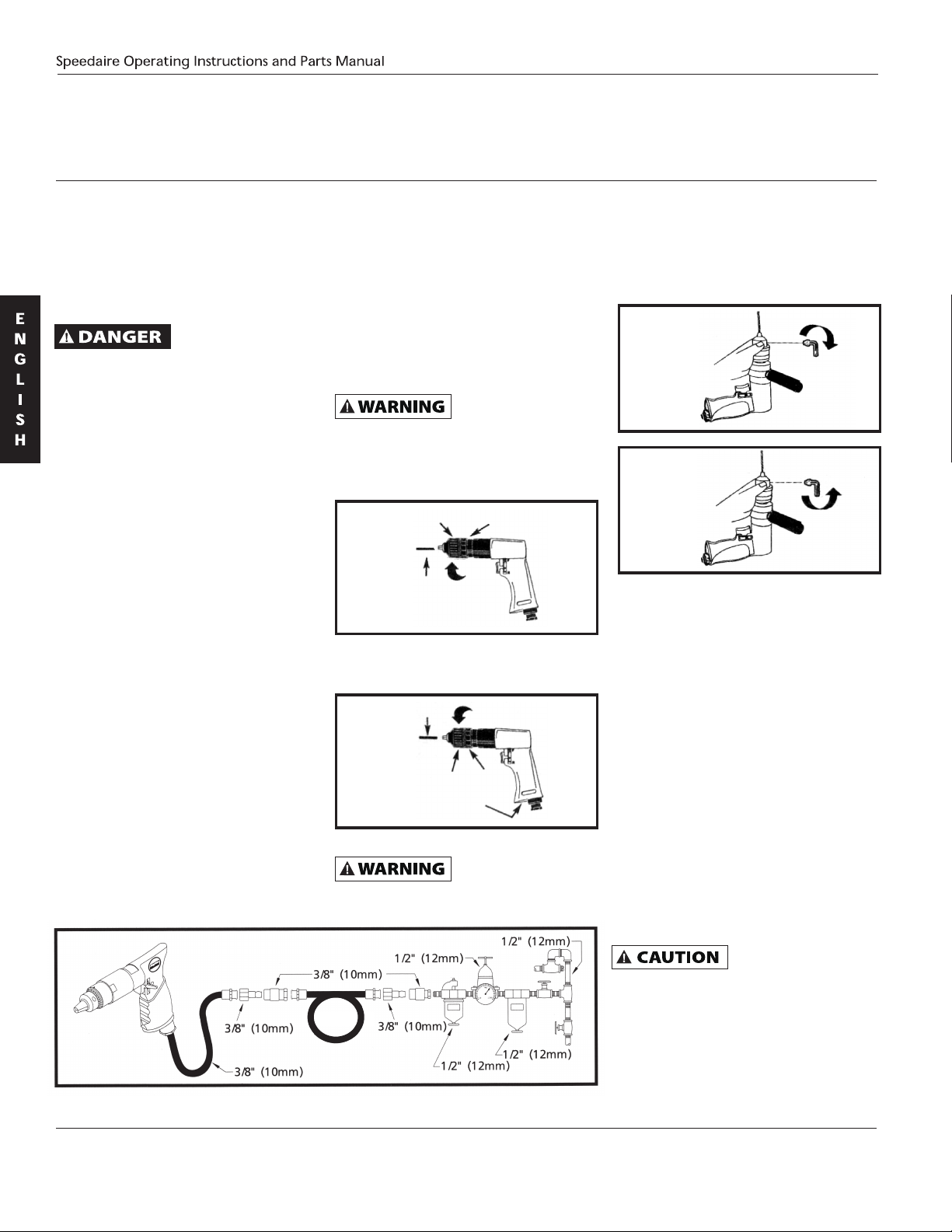

Figure 2 - Air Diagram

Figure 3

Designed to operate on 90 PSI, lower

pressure (below 90 PSI) will reduce

performance of the tool while higher

air pressure (over 90 PSI) raises the

performance of the tool beyond its

rated capacity and could cause serious

damage to tool and user.

Always use clean dry air. Excessive

moisture and dirt will greatly reduce

the life of any air motor. We

recommend the installation of an in-

line filter-regulator-lubricator as close

to the tool as possible.

Pre-Operation

Maintenance

Before the tool is connected to the air

supply, clean the air hose of

accumulated dust and moisture. Before

removing a tool for service or changing

accessories, make sure the air line is

shutoff and drained of air. This will

prevent the tool from operating if the

throttle is accidently engaged.

Operation

Your risk from these exposures

varies, depending on how often

you perform this type of work.

To reduce your exposure to these

chemicals:work in a well ventilated

area, and work with approved safety

equipment, such as dust masks that

are specially designed to filter out

microscopic particles.

For professional use only.

- Lead from lead based paints

- Crystalline silica bricks and

cement and other masonry

products

- And Arsenic and chromium

from chemically-treated rubber

5.

Supply tool with 90 PSI of

clean, dry air. Higher pressure

drastically reduces tool life. Connect

tool to air line using pipe, hose and

fitting sizes shown in Figure 2.

Air Supply and Connection

Hazards.

Air under pressure can cause severe

injury.

Always shut off air supply, drain

hose of air pressure and disconnect

tool from air supply when not in

use, before changing accessories or

when making repairs.

Never direct air at yourself or

anyone else.

Whipping hoses can cause serious

injury. Always check for damaged

or loose hoses and fittings.

Do not use quick disconnect

couplings at tool. See Figure 2

for correct set-up.

Whenever universal twist couplings

are used, lock pins must be

installed.

Lubrication

Use an air line lubricator with Mobll

Almo 525 air tool oil (model 4ZF22),

adjusted to two (2) drops per minute. If

an air line lubricator cannot be used,

add air motor oil to the inlet once a

day.

1.

2.

2

Some dust created by power

sanding, sawing, grinding,

drilling and other construction activities contains

chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

Do not exceed maximum

air pressure of 90 PSI

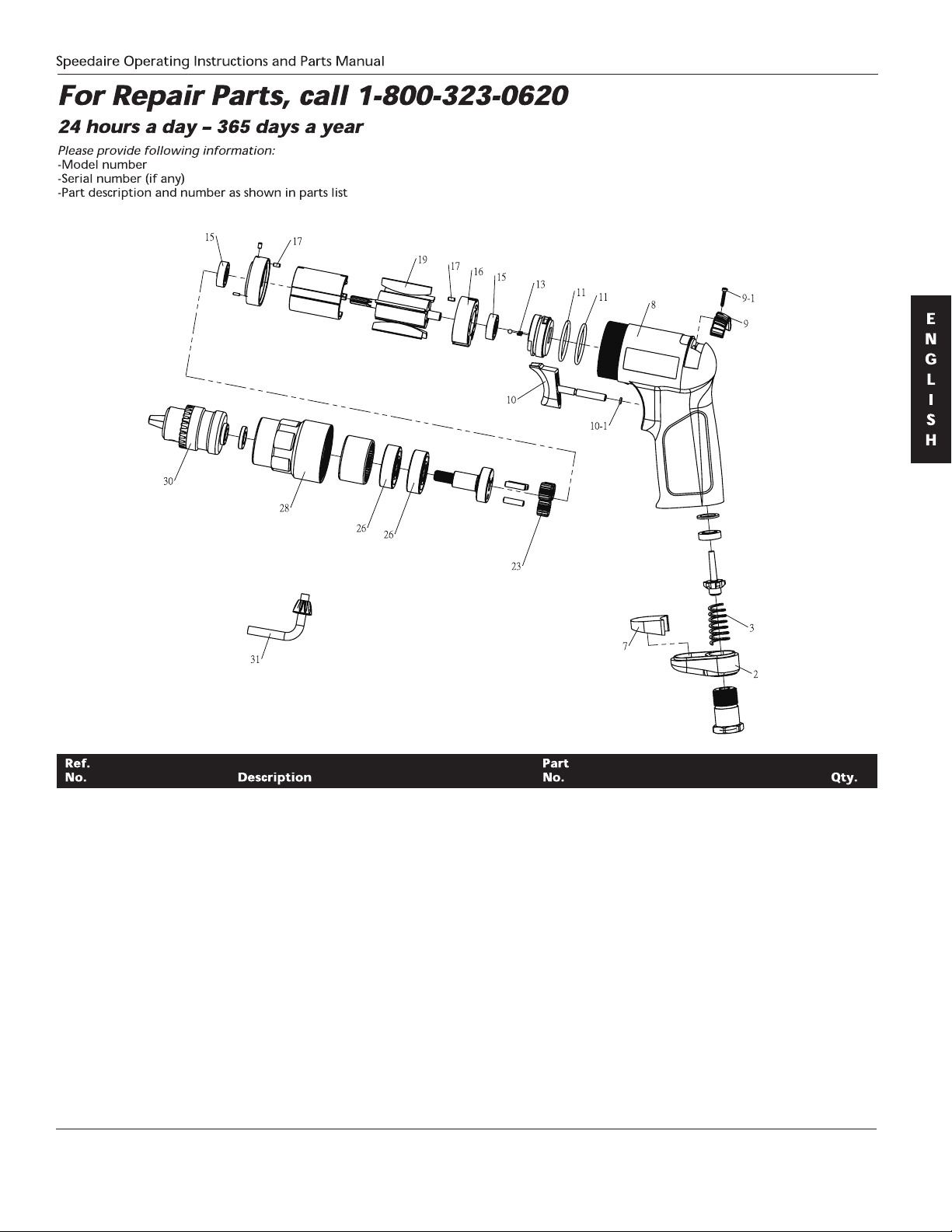

KEYLESS CHUCK DRILL OPERATION

TO INSTALL A DRILL BIT: Hold the ring

and turn the sleeve clockwise until drill

bit is secured tightly (See Figure 3).

bit. Tightening or loosening the drill bit with air

supply attached may cause injury

Disconnect the air line before

removing or installing a drill

bit. Tightening or loosening the drill bit with air

supply attached may cause injury

Disconnect the air line before

removing or installing a drill

Figure 4

TO REMOVE A DRILL BIT: hold the ring

and turn the sleeve counterclockwise

(See Figure4).

CHUCK KEY DRILL OPERATION

Figure 5

TO INSTALL A DRILL BIT: Insert chuck

key into one of the four chuck key holes.

Turn chuck key backwards to unlock

jaws of drill (See Figure 5). Turn chuck

counterclockwise to open jaws and

insert bit. Turn key forward to lock bit

into place (See Figure 6).

Figure 6

Sleeve

Backward

Forward

Turn Chuck Key

Backward To

Unlock Bit

Turn Chuck Key

Forward To Lock

Bit In Place

Sleeve

Ring

Ring

Exhaust

Bit

Bit

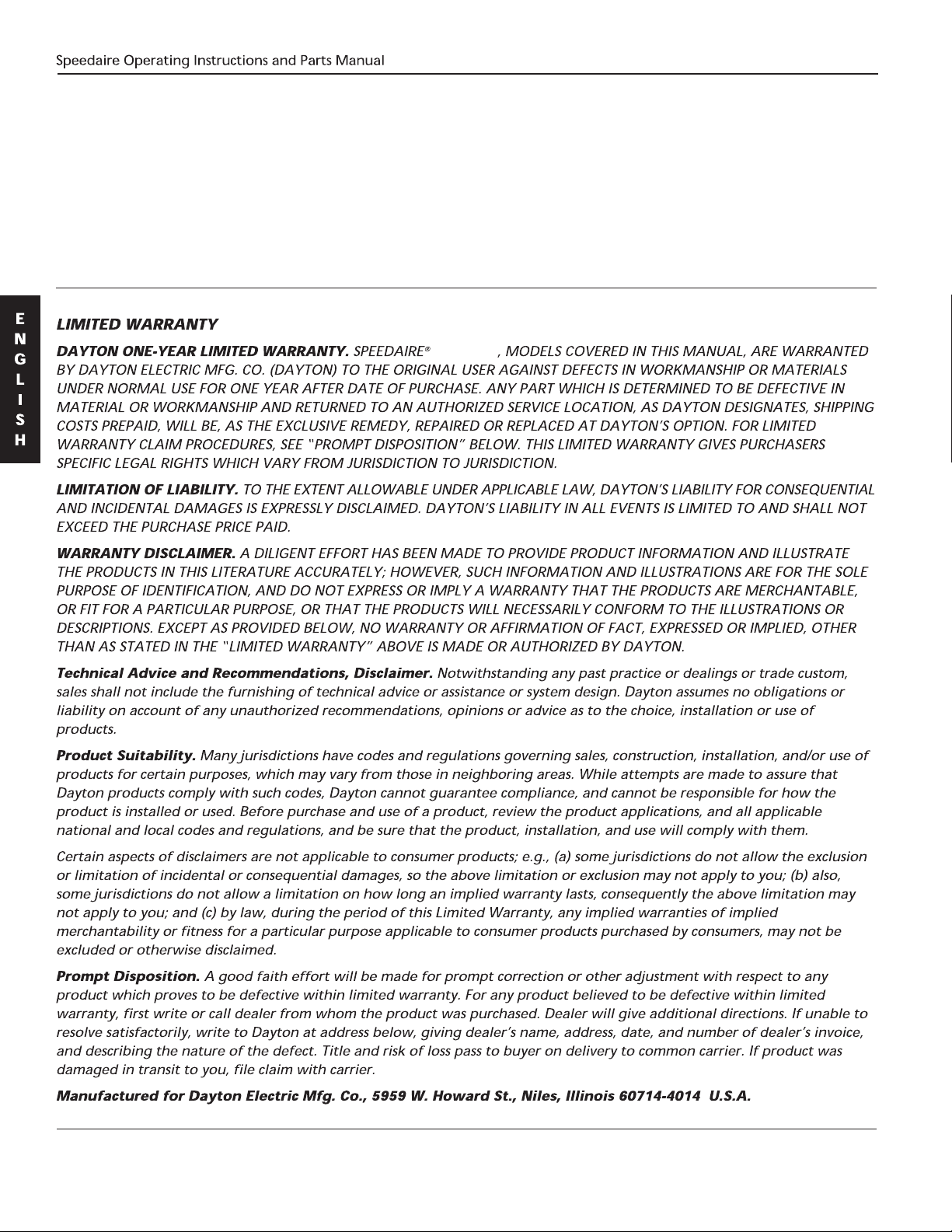

Repair Parts List

Figure 3 - Repair Parts lllustration for 3/8" Air Composite Drill

2

3

7

8

9

10

11

13

15

16

17

19

23

26

28

30

31

1

1

1

1

1

1

2

1

2

1

2

5

3

2

1

1

1

Deflector

Valve Spring

Silencer

Composite Housing

Reverse Valve Lever

Trigger

O-Ring (27x2)

Spring

Bearing (626)

Rear Plate

Spring Pin

Rotor Blade

Idle Gear

Ball Bearing (6201zz)

Front Housing

Drill Chuck (3/8")

Key

PN10D237002G

PN10D237003G

PN10D237007G

PN10D237008G

PN10D237009G

PN10D237010G

PN10D237011G

PN10D237013G

PN10D237015G

PN10D237016G

PN10D237017G

PN10D237019G

PN10D239023G

PN10D239026G

PN10D239028G

PN10D240030G

PN10D240031G

3

10D240

Speedaire®3/8" Air Composite Drill

4

10D240

10D240

Taladro Neumático de 3/8"

Speedaire

®

Descripción

Taladro reversible compacto y liviano Speedaire que se u tiliza para tareas de

mantenimiento, armado liviano o reparaciones automotrices. Equipado con una

empuñadura cómoda, control preciso de aceleración y un motor y engranajes

durables.

Incluye:

1 - Taladro

1 - Chaveta

Figura 1

Cuando desempaque la unidad, verifi-que

"Safety Code for Portable Air Tools"

Utilice siempre brocas bien afiladas.

Reduzca la presión en el momen to de

la perforación.

ANSi recomienda el uso de un mango

de soporte en las brocas con

Los resbalones, caídas y tropiezos son

uno de los principales motivos de

accidentes laborales graves y muertes.

Tenga mucho cuidado de no tender

superficie de trabajo o en lugares de

excesivas mangueras de aire en la

paso.

Mantenga una posición corporal

equilibrada y asiente firmemente los

pies en el suelo.

Los sonidos a gran volumen pueden

producír pérdidas permanentes de

capacidad auditiva. Utilica las

de sanidad laboral aplicables.

Los movimientos repetitivos, las

posturas forzadas y la exposición a

vibraciones pueden ser perjudiciales

para las manos y los brazos. En caso

de pérdida de sensibilidad,

hormigueo, dolores o palidez de la

piel, deje de utilizar la herramienta y

consulta con un médico.

Evite la inhalación de polvo o el

manejo de residuos producidos en el

trabajo, ya que pueden r esultar

perjudiciales para su salud. Utilice un

mecanismo de extracción de polvo y

cuando trabaje con materiales que

use equipo de protección respiratoria

su empresa o que dicten las normas

protecciones sonoras que recomiende

Riesgos En El Lugar De Trabajo

10 mm. 0 3/8".

capacidad de perforación superior a

puede provocar caídas.

La potencia de torsión generada

(B186.1) disponible en: www.ansi.org

Utilice siempre protección facial y

el cambio de accesorios.

cercanas a la herramienta llevan

protección facial y ocular resistente a

impactos.

Incluso los proyectiles de tamañ o

reducido pueden dañar el ojo y

No se acerque a la broca ni al

portabrocas mientras rotan.

Puede cortarse o quemarse si toca la

broca, el cincel del taladro, o la

superficie de trabajo.

Utilice presión de taladro

intermitente para evitar que salten

esquirlas cortantes.

No acerque el cabello a la

herramienta o sus accesorior, corre el

riesgo de perder un mechón o parte

del cuero cabelludo.

Mantenga cualquier tipo de collar

alejado de la herramienta, corre

riesgo de decapitación.

Riesgo De Bloqueos O Trabas

4.

producir ceguera.

Riesgo De Aprisionamiento

Asegúrese de que todas las personas

su reparación o mantenimien to o en

con la herramienta, cerca de ella, en

ocular resistente a impactos si trabaja

2.

3.

5.

Riesgos De Emisión De Proyectiles

cuidadosamen te si han ocurrido daños

duran te el envío. Revise si hay partes que

faltan, que están sueltas o que están

Capacidad del mandril......................... 3/8"

Velocidad en vacío(sin carga)... 2,000 Rpm

Longitud............................................. 8.26"

Consumo de aire promedio.............3.5 Cfm

Entrada de aire..................................... 1/4"

Presión de aire máxima.................... 90 Psi

Pesos............................................ 1.58 Lbs

Recomendado.......................................3/8”

dañadas.

Desempaque

Specifications

ADVERTENCIA

Con el fin de reducir el riesgo de

instale, repare, mantenga,

cambie accesoriosó trabaje cerca

de esta herramienta debe leer y

compreender estas instrucciones

antes de llevar a cabo cualquiera

de lastareas antes mencionadas.

lesión toda persona que utilice,

Información de Seguridad

General

Para más información de

seguridad, consulte:

A su empresa, sin dicato, asociación de

empleados, etc.

Con el Ministerio de trabajo de

EE.UU. (OSHA); www.osha.gov;

1.

10D240

No lleve joyas ni ropas

holgadas.

La broca puede quedarse

trabada de forma repentina,

y hacer rotar el material de trabajo ozla herramienta,

causando lesiones en brazos y hombros.

Los operadores y el personal

de mantenimiento deben estar

físicamente capacitados para soportar el volumen,

peso y potencia de esta herramienta.

Este manual Conliene informacion que es

muy importante que sepa y comprenda.

Esta information se la suministramos como

medida de SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Debe

reconocer los siguientes simboios.

Medidas de Seguridad

Esto is indlca que hay uns

situacion inmediara que le oce-

slonarfa la muerts o harfdes de gravedad.

Esto is indlca que hay una

sltuaclion que PODRIA ocesion-

arfa la muerte o heridas de gravedad.

arfa heridas no muy graves.

Esto is indlca que hay una

sltuaclion que PODRIA ocesion-

Esto le indlca una informa-

cion importante, que de no

segutrla, le podrla ocasionar daros al equlpo.

AVISO

in Taiwan

5S6846

04634

STC100

06/11

#804

Table of contents

Languages:

Other Speedaire Drill manuals