SpeedEPart Agri-Fab 45-0356 User manual

PRINTED IN USA FORM NO. 48974 (REV. 1/04)

OWNER'S

MANUAL

Model No.

45-0356

3-POINT HITCH

DISC CULTIVATOR

• Safety

• A embly

• Operation

• Maintenance

• Part

CAUTION:

Read Rule for

Safe Operation

and In truction

Carefully

the fastest way to purchase part

www.speedepart.com

Agri-Fab¨

Digitally signed by WMV-Dresden

DN: cn=WMV-Dresden, c=DE,

o=WMV-Dresden,

Date: 2017.01.26 13:00:41 +01'00'

WMV-

Dresden

2

SAFETY RULES

Remember, any power equipment can cau e injury if operated improperly or if the u er doe not under tand how to

operate the equipment. Exerci e caution at all time when u ing power equipment.

1. Read thi owner' manual before u ing thi equip-

ment.

2. Do not allow children to operate the tow vehicle or

the di c cultivator.

3. Do not allow adult to operate the tow vehicle or the

di c cultivator without proper in truction.

4. Do not allow anyone to ride on the tow vehicle or the

di c cultivator.

5. Before lowering the di c cultivator, make ure no

one i near the area of operation.

6. Lower the di c cultivator when leaving the tow

vehicle unattended.

7. Wear appropriate footwear when u ing the di c

cultivator. The di c edge are harp!

8. Tow vehicle braking and tability may be affected

by the di c cultivator. Drive lowly with the di c

cultivator in the tran port po ition. Stay off steep

slopes.

9. Stop and in pect the equipment for damage after

triking an object. Repair any damage before con-

tinuing operation.

10. Keep all nut and bolt tight and be ure that the

equipment i in afe operating condition.

11. Before attaching or removing the di c cultivator,

park and lock the tow vehicle in a afe condition.

LOOK FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS. IT

MEANS – ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED.

CAUTION: VEHICLE BRAKING AND

STABILITY MAY BE AFFECTED BY THE

ADDITION OF AN ACCESSORY OR AN

ATTACHMENT. BE AWARE OF CHANG-

ING CONDITIONS ON SLOPES.

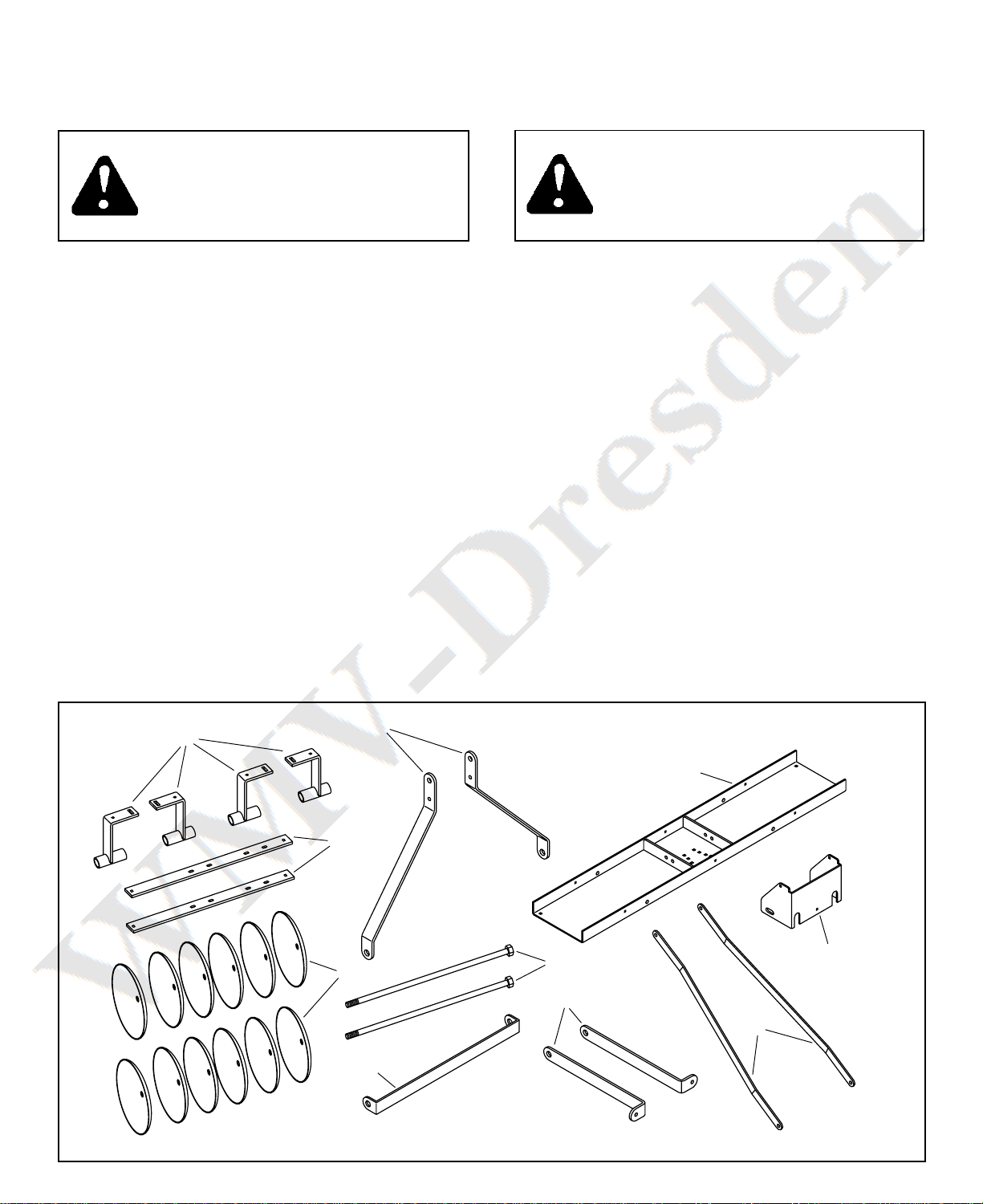

CARTON CONTENTS

1. Bearing Hanger Bracket (4)

2. Di c Anchor Strap (2)

3. Ma t Side (2)

4. Tray Frame

5. Di c Blade (12)

6. Cro Brace

7. Hex Bolt, 3/4" x 25" Lg. (2)

8. Ma t Exten ion Strap (2)

9. Ma t Lift Strap (2)

10.Weight Rack

11.Part Package ( ee page 3)

3

2

7

5

4

8

9

6

10

1

3

PARTS PACKAGE CONTENTS – PARTS SHOWN ACTUAL SIZE

S

KEY QTY. DESCRIPTION

A 1 Hex Bolt, 1/2" x 3-1/2"

B 2 Hex Bolt, 1/2" x 2-1/4"

C 4 Hex Bolt, 3/8" x 1-1/2"

D 8 Carriage Bolt, 3/8" x 1-1/4"

E 1 Hex Bolt, 3/8" x 1"

F 2 Hex Nut, 7/8"

G 1 Haircotter Pin

H 2 Hex Bolt, 1/2" x 1-1/4"

I 6 Spacer, 4.25" Lg.

J 4 Spacer, 4.50" Lg.

KEY QTY. DESCRIPTION

K 24 Flat Wa her, 2"

L 2 Lock Wa her, 7/8"

M 4 Flat Wa her, 1.25"

N 1 Spacer, 1.5" Lg.

O 2 Spacer, .75” Lg.

P 2 Hex Nut, Nylock, 3/4"

Q 13 Hex Nut, Nylock, 3/8"

R 5 Hex Nut, Nylock, 1/2"

S 2 Category 1 Pin

T 1 Pivot Pin

T

P

R

M

Q

L

K

G

F

J

I

E

D

H

C

B

A

N

O

Not to Size

4

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

(2) 9/16" Wrenche

(2) 3/4" Wrenche

(2) 1-1/8" Wrenche

(2) 1-5/16" Wrenche or 12" Adju table Wrenche

(1) Grea e Gun

Remove all loo e part and the hardware package from

the hipping carton. Then lay out and identify each part

and the common hardware a hown on page 2 and 3.

Be ure the carton i empty before it i di carded.

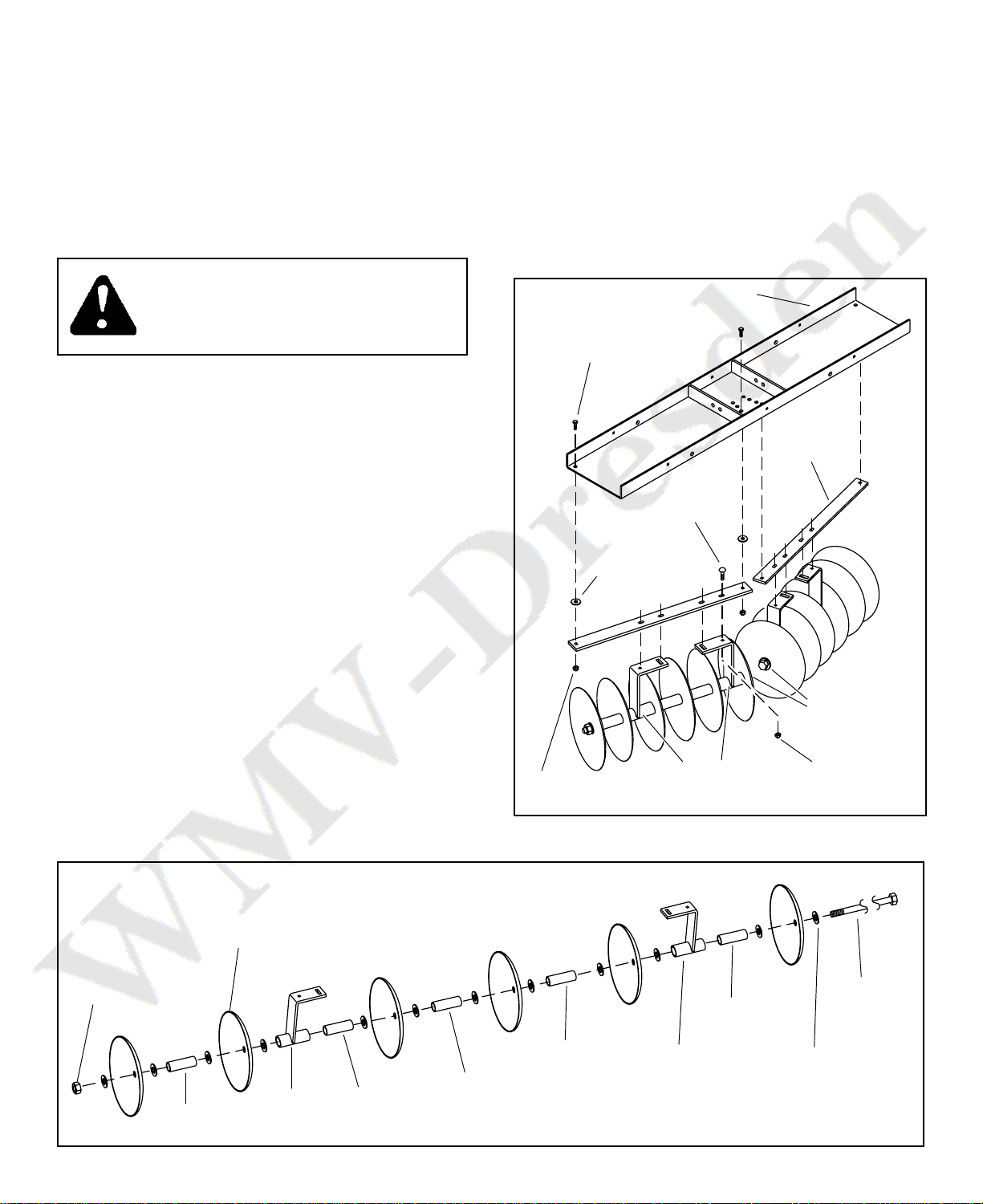

1. Refer to figure 1. A emble the following onto

each 3/4" x 25" hex bolt: ix di c blade , two

bearing hanger bracket , twelve 2" flat wa her ,

two 4.50" pacer , three 4.25" pacer and one

3/4" Nylock hex nut. The 4.50" pacer fit in ide

the bearing hanger bracket . Be ure all part are

a embled in the ame order a hown. Be ure

the bearing hanger bracket face toward each

other and that the di c blade all face the ame

direction. Tighten the Nylock hex nut.

IMPORTANT: U e only the 4.50" pacer (longe t)

in ide the bearing hanger bracket .

2. Add grea e to the bearing hanger bracket through

the grea e fitting until grea e i forced out the

end of the bracket .

CAUTION: DISC BLADES HAVE SHARP

EDGES. USE CARE IN HANDLING AND

ASSEMBLY. WEAR GLOVES FOR

EXTRA PROTECTION AGAINST CUTS.

3/8" NYLOCK

HEX NUT

3/8" NYLOCK

HEX NUT

BEARING

HANGER

BRACKET

DISC

ANCHOR

STRAP

3/8" x 1-1/2"

HEX BOLT

1.25" FLAT

WASHER

3/8" x 1-1/4"

CARRIAGE

BOLT

FACE HEAD

OF HEX BOLTS

TOWARD EACH

TRAY FRAME

FIGURE 2

3. A emble a di c anchor trap to a di c a embly

u ing four 3/8" x 1-1/4" carriage bolt and 3/8"

Nylock hex nut . Tighten. Repeat for other di c

a embly. See figure 2.

4. A emble the tray frame to the di c anchor trap

u ing four 3/8" x 1-1/2" hex bolt , four 1.25" flat

wa her , and four 3/8" Nylock hex nut . Fa ten to

the rear-mo t hole in the middle of the tray frame

for now. The di hed (concave) urface of the di c

blade hould face to the out ide with the head of

the 25" bolt on the in ide. Tighten. See figure 2.

FIGURE 1

3/4" x 25"

HEX BOLT

4.50"

SPACER

BEARING

HANGER

BRACKET

DISC

BLADE

4.50"

SPACER

4.25"

SPACER 2" FLAT

WASHER

3/4"

NYLOCK

HEX NUT

BEARING

HANGER

BRACKET

4.25"

SPACER

4.25"

SPACER

5

HAIRCOTTER PIN

MAST LIFT

STRAP

FIGURE 4

1-1/2 SPACER

1/2" NYLOCK

HEX NUT

PIVOT PIN

1/2" x 3-1/2"

HEX BOLT

MAST

SIDES

FIGURE 3

MAST EXTENSION

STRAP

CATEGORY

1 PIN

1/2" x 1-1/4"

HEX BOLT

1/2" NYLOCK

HEX NUT

MAST SIDE

7/8" HEX NUT

7/8" LOCK WASHER

TRAY FRAME

CROSS

BRACE

FIGURE 5

3/8" x 1"

HEX BOLT

WEIGHT RACK

3/8" NYLOCK

HEX NUT

1/2" x 2-1/4"

HEX BOLT

3/4" SPACER

1/2" NYLOCK

HEX NUT

END OF MAST

LIFT STRAP

TRAY

FRAME

7. In tall a pivot pin through the hole in the end of

the ma t ide and ecure the pin u ing the

haircotter pin. See figure 4.

8. Arrange the ma t lift trap a hown in figure 4.

A emble the trap and the 1-1/2" pacer be-

tween the ma t ide u ing a 1/2" x 3-1/2" hex bolt

and 1/2" Nylock hex nut. Do not tighten yet.

5. Attach two ma t exten ion trap to the front of

the frame tray o that the bent end of each trap

point outward. U e two 1/2" x 1-1/4" hex bolt

and two 1/2" Nylock hex nut . Do not tighten yet.

See figure 3.

6. At the other end of the ma t exten ion trap ,

attach the cro brace to the in ide and two ma t

ide to the out ide of the trap . U e the two

category 1 pin , two 7/8" lock wa her , and two

7/8" hex nut . Do not tighten yet. See figure 3.

9. Attach the weight rack to the back of the tray frame

u ing a 3/8" x 1" hex bolt and a 3/8" Nylock hex

nut. Do not tighten yet. See figure 5.

10. A emble the ma t lift trap on the out ide of the

frame tray brace u ing two 1/2" x 2-1/4" hex

bolt , 3/4" pacer and 1/2" nylock hex nut . Place

the pacer between the trap and the ide of the

weight rack. See figure 5. Refer al o to figure 6.

11. Tighten all loo e nut and bolt .

6

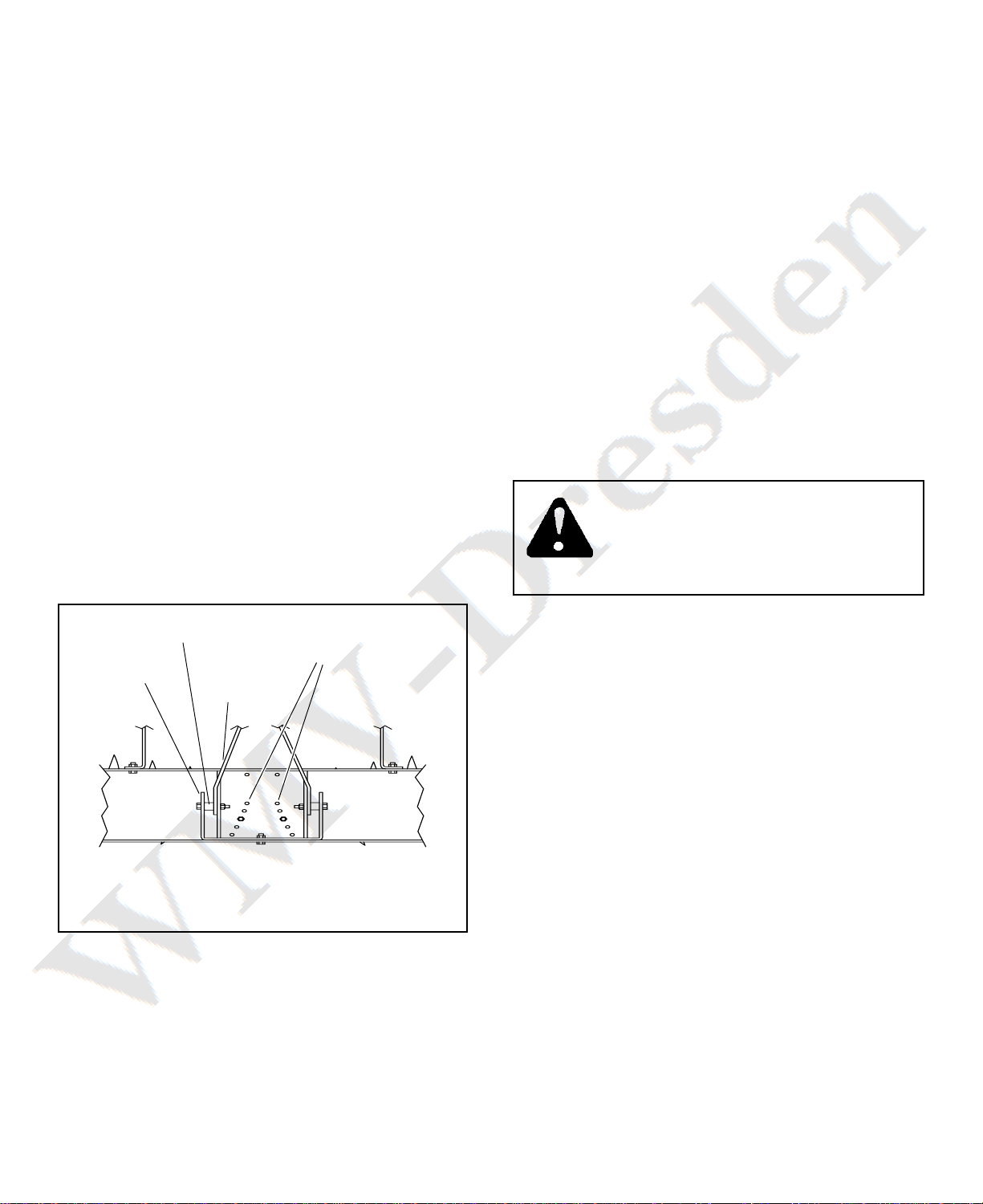

OPERATION

The di c cultivator i u ed to break up clod of dirt and

to uproot mall weed in plowed oil.

1. Before tarting, make ure the oil i dry enough by

queezing ome in your hand. If it form a ball that

doe n't crumble, the oil i too wet for di cing. Wet

oil will pack between the di c blade .

2. Adju t the di c to the de ired angle etting. The

di c cultivator ha five angle adju tment po ition .

The adju tment hole are located in the center of

the tray frame, in ide the weight rack. For more

aggre ive cultivating, move to the rear adju t-

ment po ition. For le aggre ive cultivating,

move to the front adju tment po ition.

To adju t the angle of a di c a embly, remove

the innermo t 3/8" x 1-1/2" hex bolt, 1.25" wa her,

and 3/8" Nylock hex nut that ecure the di c

anchor trap to the tray frame. Then move the di k

a embly o that the anchor trap i lined up with

the de ired adju tment hole. In tall the bolt and

wa her, then tighten the nut to lock in the etting.

Repeat thi procedure for the other di c a em-

bly. See figure 6.

CAUTION: DISC BLADES HAVE SHARP

EDGES. USE CARE WHEN WORKING

AROUND THE DISC CULTIVATOR. WEAR

GLOVES FOR EXTRA PROTECTION

AGAINST CUTS.

FIGURE 6

DISC ANGLE

ADJUSTMENT

HOLES

(TOP VIEW)

MAINTENANCE

1. Check for and tighten any loo e hardware before

each u e.

2. Clean the di c and lightly oil only bare metal after

each u e.

3. Lubricate all four bearing hanger bracket at grea e

fitting with grea e after each u e.

4. Remove all dirt and ru t. Touch up paint before

placing di c cultivator in torage.

5. Store di c cultivator in ide a dry area.

3. To break up dirt clod in plowed oil, tart di cing

lowly at fir t. A the clod are broken up, the

peed may be gradually increa ed. Di c the oil

u ing a cri cro pattern for be t re ult .

4. Up to 160 lb . of weight may be added to help

increa e penetration. 40 lb. uitca e weight can

be attached to the center weight rack, or concrete

block or other weight may be tied or trapped to

the cultivator tray. Before adding weight, the di c

cultivator hould be attached to the tow vehicle

with the cultivator lowered to the ground.

WEIGHT RACK

3/4" SPACER

MAST

LIFT

STRAP

7

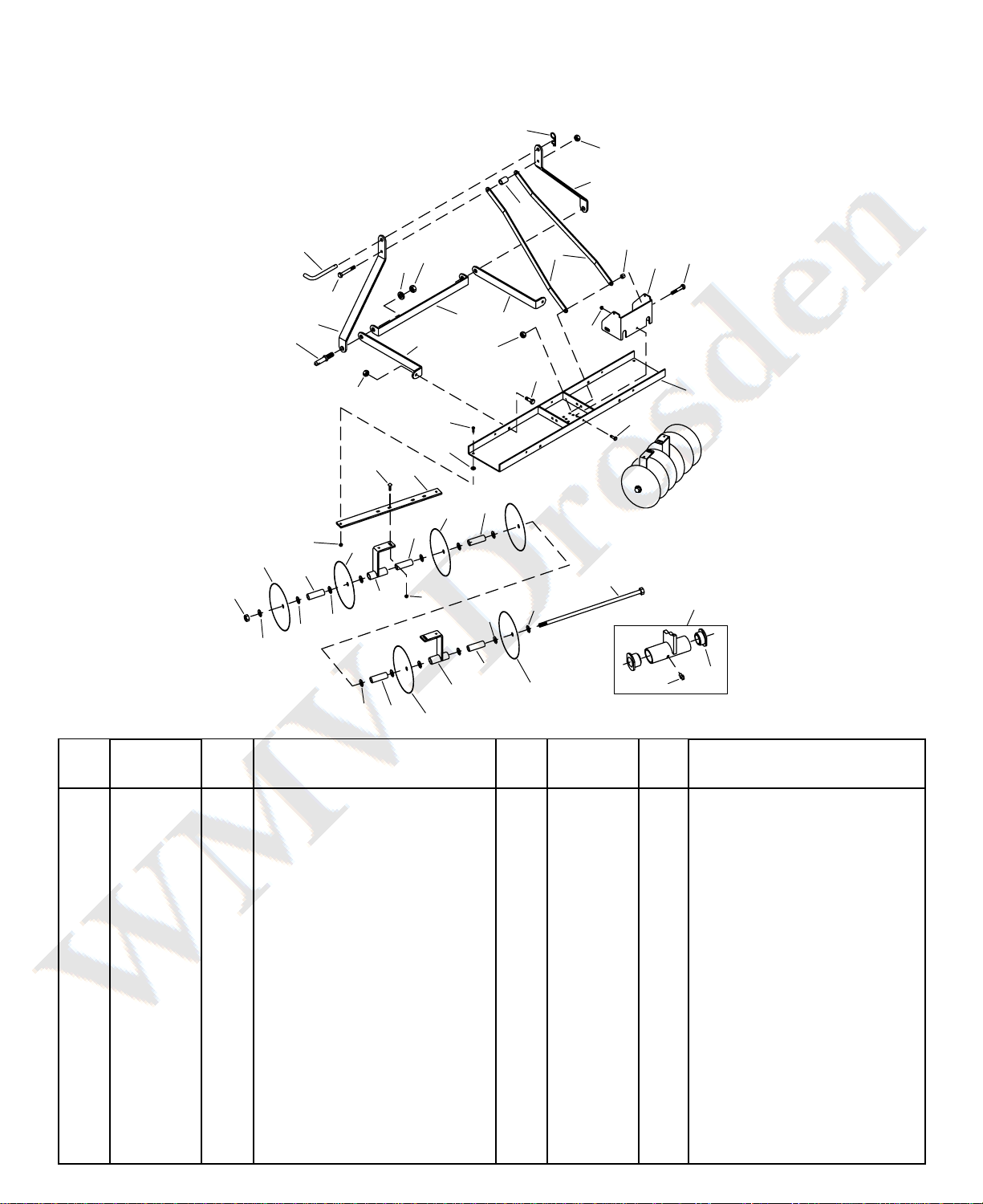

REPAIR PARTS FOR MODEL NO. 45-0356

3-POINT HITCH DISC CULTIVATOR

1 43343 1 Haircotter Pin, 1/8" x 2-3/8"

2 712-3083 5 Hex Nut, Nylock, 1/2"

3 25158 2 Ma t Side

4 25167 1 Spacer, .53" I.D. x .75" O.D.

x 1.5" Lg.

5 48978 1 Pivot Pin

6 48982 2 Lock Wa her, 7/8"

7 48970 2 Hex Nut, 7/8"

8 25180 2 Ma t Lift Strap

9 23368 2 Spacer, .76" I.D. x 1" O.D.

x .75" Lg.

10 25194 1 Weight Rack

11 HA180183 2 Hex Bolt, 1/2" x 2-1/4"

12 46526 1 Hex Bolt, 1/2" x 3-1/2"

13 48979 2 Category 1 Pin

14 25169 2 Ma t Exten ion Strap

15 25154 1 Cro Brace

16 43351 2 Hex Bolt, 1/2" x 1-1/4"

17 HA21362 13 Hex Nut, Nylock, 3/8"

REF. PART QTY. DESCRIPTION

NO. NO. REF. PART QTY. DESCRIPTION

NO. NO.

18 64781 1 Tray Frame

19 43001 1 Hex Bolt, 3/8" x 1"

20 710-0305 8 Carriage Bolt, 3/8" x 1-1/4"

21 25168 2 Di c Anchor Strap

22 736-0247 4 Wa her, .41" x 1.25" x .156"

23 43062 4 Hex Bolt, 3/8" x 1-1/2"

24 48911 2 Hex Nut, Nylock, 3/4"

25 46856 12 Di c Blade

26 46859 6 Spacer, .80" I.D. x 1" O.D.

x 4.25” Lg.

27 1540-162 24 Wa her, .77" x 2" x .1345"

28 63510 4 Bearing Hanger Bracket

29 24240 4 Spacer, .80" I.D. x 1" O.D.

x 4.50” Lg.

30 48966 2 Hex Bolt, 3/4" x 25" Lg.

31 44488 8 Bearing (included in 63510)

32 46858 4 Grea e Fitting (included in

63510)

48974 1 Owner Manual (not hown)

5

3

12

13

67

2

14

14

15

8

4

3

1

2

9

10

17

11

18

2

19

16

27

29

28

23

22

20 21

17

30

25

26

29

26

26

17

25

27

24 28

27 27

31

32

27

27

25 25

25

28

REPAIR PARTS

Agri-Fab, Inc.

303 We t Raymond

Sullivan, IL 61951

217-728-8388

www.agri-fab.com

the fastest way to purchase part

www.speedepart.com

© 2004 Agri-Fab, Inc.

Table of contents

Other SpeedEPart Tiller manuals