Speedwolf SP-FS18 User manual

SPEEDWOLF

SP-FS18

User’s Manual

Shenzhen SPEEDWOLF Technology CO.,LTD.

Version 2.00(201801)

Optical Fiber Fusion Splicer

Warning: Ignore the warning, non-proper use of fusion splicer could lead to fatal

and serious injury.

1. The input voltage of this model of machine is definite; please do not use the voltage

outside the scope. Please use the correct AC and DC power supply.

2. When the fusion splicer comes across the following failures, please immediately

remove the AC power cord from the power supply input and turn off the fusion

splicer, otherwise will lead to the incapable of the repairing and even will cause

personal injury, death and fire.

★Smoke, smell, noise or heat anomaly

★Broken or damaged machines

★Liquid or foreign matter enters the interior of the machine

3. This model of fusion splicer does not have the need to maintain internal

components, dismantling of fusion splicer and power modules is prohibited; any

mistake in maintenance will lead to the machine beyond repair even causing bodily

harm.

4. The machine has strictly limitation to the power supply module used.

5. The fusion splicer is prohibited to be used under the environment with the

inflammable liquid or flammable gas; otherwise will lead to fire, explosion and

other serious consequences.

●Disclaimer Clause

The Company does not assume any liability for all damage caused by the use

of non original battery.

●To avoid possible wrong operation or insecurity, a valid ground three-hole

socket must be used when AC/DC adaptor access to AC 220V 50HZ power.

Content

1. Brief Introduction............................................................................................1

1.1 Specifications..............................................................................................................1

1.2 Configuration of fusion splicer...................................................................................2

1.3 Parts Name of fusion splicer.......................................................................................3

1. 4 Descriptions of the Keyboard ....................................................................................4

2. Basic operation...................................................................................................5

2.1 Descriptions of the power modules .........................................................................5

2.2 AC operation.........................................................................................................5

2.3 Battery supply operation.......................................................................................6

2.4 Turn on and turn off....................................................................................................9

2.5 Display brightness control ........................................................................................10

2.6 Cover fiber protection sleeve.................................................................................10

2.7 Preparation of fiber end-face ....................................................................................11

2.8 Place fiber .................................................................................................................13

3

.

Check and Maintenance.........................................................................13

3.1 Cleaning V-grooves...................................................................................................14

3.2 Cleaning Fiber Clamp Chips.....................................................................................14

3.3 Cleaning Wind Protector Mirrors .............................................................................15

3.4 Cleaning Objective Lenses .......................................................................................15

3.5 Replace Electrodes....................................................................................................16

3.6 Set Calendar..............................................................................................................17

4. Change the spare lithium battery pack............................................18

5

.

Power Supply.....................................................................................................19

Addenda A: Summary of quick operating..........................................20

Addenda B: Guarantee period and limits...........................................22

Addenda C: Contact..............................................................

错误

!

未定义书签。

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

1

1. Brief Introduction

Shenzhen SPEEDWOLF Technology CO.,LTD. specializing in the production of optical fiber

fusion splicer, optical fiber cleaver, OTDR, light source, optical power meter, and optical fiber

fixture, and other optical communication instrument high-tech enterprises. Company production of

OP-FS16,SP-FS18fiber splicing machine is not only widely used in China Telecom, China Mobile,

Unicom, radio and television major domestic telecommunications operators, but also exported to

South America, Europe, Russia, Southeast Asia andAfrica and other parts of the world.

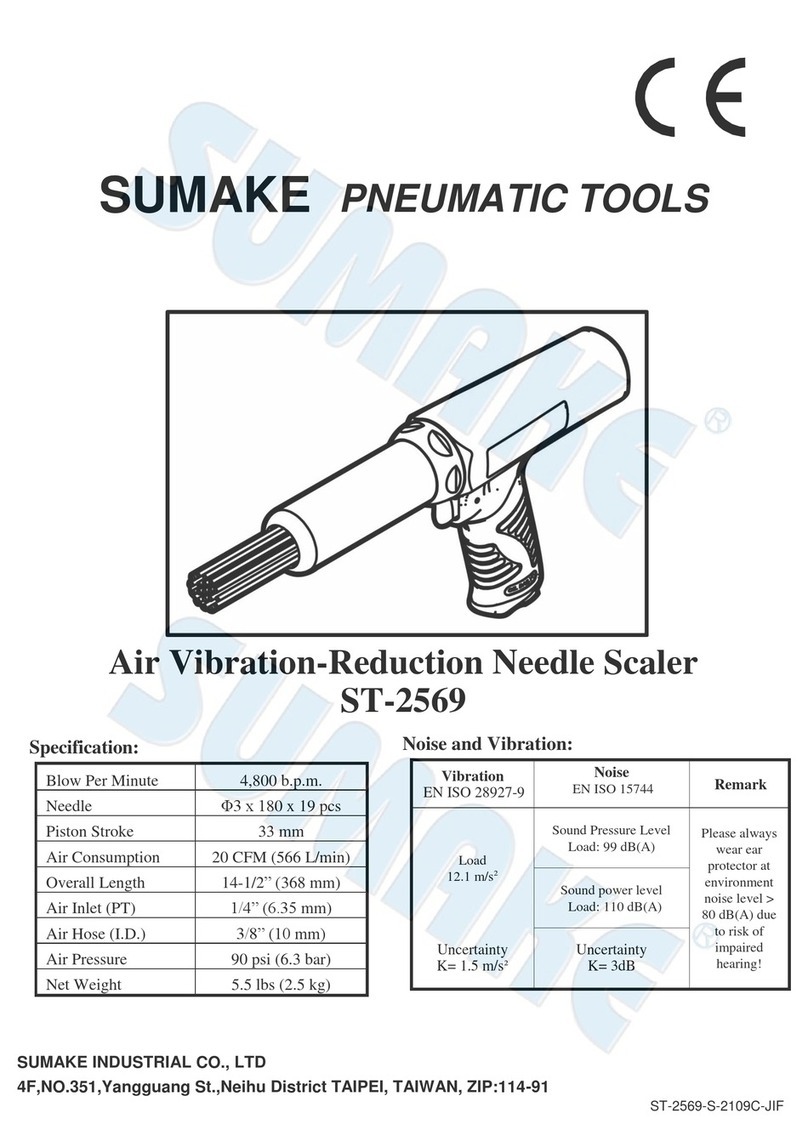

1.1 Specifications

SP-FS18 FTTH Fusion Splicer

Splicing Type

SM, MM, DS, NZDS

Splicing Loss

0.02dB(SM),0.01dB(MM),0.04dB(DS),

Return Loss

>60dB

Splicing Mode

Manual, Half Auto, Auto

Fiber Alignment

Core to Core Alignment by PAS technology

Applicable Fiber

Cable indoor and 0.25mm,0.9mm fiber, SC

connector(option)

Splicing Time

≤9s

Heat Time

≤30s

Cleaved Length

8~16mm

Fiber Image/ Magnification

300/200 times

View Display

5 inch digital high-quality LCD screen

Tension Test

Standard 2N (option)

Heat Shrinkable Sleeve

60mm, 40mm and serials heat Shrinkable Sleeve

Battery Capacity

200 cycles splicing and heating, 3 hours charging time

( splicing and charging at same time)

Battery Life

Cycling charge 300-500 times, easy to replace battery

Electrodes Life

3000, easy to replace electrodes

Power Source

≤20W

Interface

USB Convenient data download and software update

Construction Lighting

Built in high brightness, wide range of lights, easy to

operate at night

Power supply

Built in lithium battery 5200mAh 11.1V; external

adapter, input: AC100-240V, output: DC13.5V/4.5A

Operating Condition

0-5000m above sea level, Temperature: -10-60℃,

Humidity:0~95%RH (No dew)

Weight (including battery)

1.98 KG (including battery)

Dimension (LxWxH)

135mm(L)×158mm(W)×155mm(H)

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

2

1.2 Configuration of fusion splicer

Following is the standard configurations of fusion splicer:

No.

Name

Quantity

1

SP-FS18 Fusion Splicer

1 set

2

Carrying Case

1 set

3

AC Adaptor

1 pc

4

Power cord

1 pc

5

Cooling tray

1 pc

6

Spare Electrodes

1 pair

7

User Manual CD

1 pc

8

Test Report

1 pc

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

3

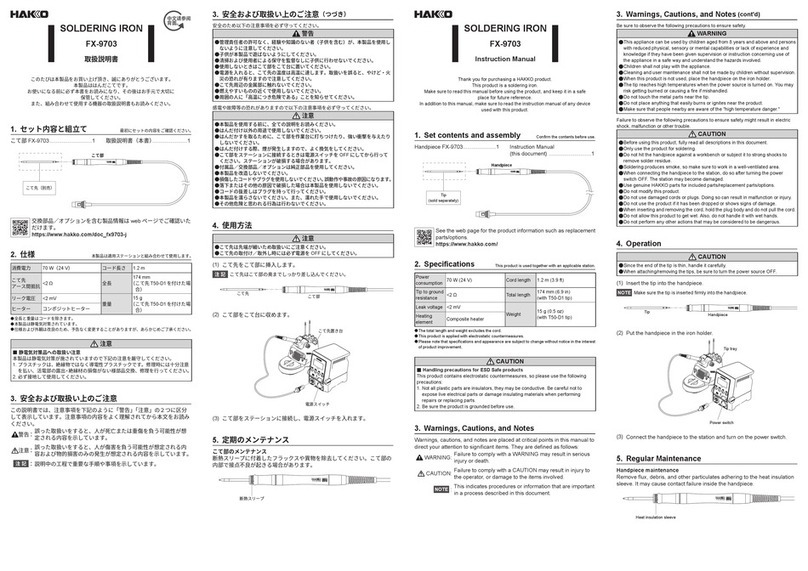

1.3 Parts Name of fusion splicer

Left Keyboard Right Keyboard

Power Module

Key board

Power switch

Windshield

cover

Heater

LCD

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

4

1. 4 Descriptions of the Keyboard

Membrane figure of left and right keyboards

Keyboard

Standby mode

Mode of manual

operation

Mode of automatic

operation

Mode of parameter menu

Power switch

Power switch

Power switch

Power switch

To increase the

brightness of the display

The optical fiber moves

upward

Invalid

Increase the parameter quantum or

move the cursor

To reduce the brightness

of the display

The optical fiber moves

downward

Invalid

Increase the parameter quantum or

move the cursor

Invalid

The optical fiber moves

left

Invalid

Increase the parameter quantum or

move the cursor

Turn on the help screen

The optical fiber moves

right

Invalid

Increase the parameter quantum or

move the cursor

To enter the menu

mode

To switch on the manual

driver at pausing state

Invalid

Select→edit the fusion(heating)

parameter files

To enter “select splice

parameter files” menu

To enter the “select

parameter files” menu

Invalid

To enter the next menu interface/

confirm the modifier

Invalid

Invalid

Invalid

Exit from the current menu screen

Heater switch

Heater switch

Heater switch

Heater switch

Reset of motor

Reset of motor

Reset of motor

Invalid

Start to fusion

Further propulsion/start

fusion

Invalid

Invalid

Discharging

Discharging

Invalid

Invalid

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

5

Switch X/Y display

screen

Switch X/Y display

screen

Switch X/Y display

screen

Invalid

2. Basic operation

SP-FS18 Fusion splicer is designed to splice

many types of fiber by using core

diameter aiming rationale, its shape is

compact, light weight, which is suitable for

field work. Operation is simple, fusion speed

is high, and fusion loss is small.

2.1 Descriptions of the power modules

SP-FS18 Fusion Splicer uses 2 in 1 power module design, during the work, the

Fusion Splicer can be supplied by the polymer lithium ion battery separately; or use

AC adapter for electricity supply; when adapter is used for electricity supply, the

polymer lithium ion battery is charged at the same time. The lithium battery to be

changed must be the model specified by the Company.

2.2 AC operation

2.2.1 When AC power supply is adopted, the AC/DC adapter supplied by the

company should be used. The basic parameters of the adapter are as follows:

INPUT: AC100-240V~1.8A 50/60HZ

OUTPUT: DC13.5V ∕5A

2.2.2 The AC/DC adapter will not be able to supple normal DC output if the input

AC voltage is lower than 100V or higher than 240V. At this situation, the

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

6

DC output line of the adapter must not be inserted into “POWER INPUT

“specified on the power module of the Fusion Splicer, otherwise it will

results in the damage of fusion splicer.

2.2.3 If lithium battery is arranged in the battery case, the battery pack will also be

charged when the adapter is supplying power. However, it is recommended

that the Fusion Splicer be shut when charged.

2.3 Battery supply operation

The user may choose to use the polymer lithium battery in the splicer to

separately supply for the Fusion Splicer.

2.3.1 Checking of battery capacity

When the power module is not in the charged state, press the "PUSH"

button on the flank of the power module. Then the four battery capacity

indicator (red) lights on the left side will be bright. The number of the lit light

represents the highness or lowness of the battery capacity. See the following

table.

When the power module is in the charged state, the four battery capacity

indicator (red) lights on the left side will be bright, which only represents the

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

7

highness of the current charge voltage, but the capacity of the battery.

2.3.2 Battery charging

<1> Whether the battery capacity is in adequacy, every time the AC power

adapter is inserted into “POWER INPUT “on the Fusion Splicer power

module, the power module will start a charging process.

<2> Display of charged state: During the charging, the charging indicator

(CHARGE) light is red; after the charging completion, the charging

indicator (CHARGE) will be green.

<3> When the splicer is shut down, the maximum charging time is three hours

40 minutes, and the shortest is 40 minutes. The length of the charging time is

dependent on the current battery capacity of the splicer.

<4> If the splicer is charged when it is active, the charging time should be longer.

The user is recommended to charge the battery when the splicer is shut down,

thus the charging time will be shortened.

2.3.3 Under Voltage Alarm

This model of fusion splicer has the function of “Under Voltage Alarm”. If

the capacity of the lithium battery is lower than the specified value (the default

value is around 10.3V), the splicer will automatically alarm and lock the

keyboard to disable input. The user should press until the Fusion Splicer

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

8

is shut down, and charge the lithium battery pack as soon as possible, or use the

adapter to supply power.

2.3.4 The other considerations

<1> For any fusion splicer not to be used for more than 1 month, it is suggested

to separate the lithium battery and machine for saving.

<2> The lithium battery should be charged in the environmental temperature

ranging between 0℃~+40℃.

<3> The battery, with certain service life, belongs to consumables. When the

fusion splicer can only work for a short time despite the battery level of

the lithium battery above 90%, please replace the battery. Please use the

battery of the model designated by the Company for replacement.

<4> Before the battery power supply for the fusion splicer, the battery level

must be checked. If the battery is low or the low voltage warning is given,

please recharge the lithium battery timely.

<5> Please do not charge or discharge the battery in a low temperature for a

long time to prevent the decrease of the battery life. Accidents may happen

if charging or discharging the battery or special battery charger and battery

in a high temperature.

<6>When charging the battery with the special battery charger, immediately

disconnect the charger when the battery is fully charged. Huge damage may

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

9

be incurred or accidents may occur on the lithium battery if the battery fully

charged is still under the charging state.

<7> The battery should be stored in a clean, dry and ventilated indoor

environment of temperature ranging –5℃~+35℃and humidity of 65±20%

RH.

<8> If the battery is stored for a long time, it should be charged with the special

charger provided by the Company once every 90 days. The life of the

battery may be extended if the battery is half fully charged in a long time.

<9> It is prohibited to remove the battery without explicit approval or put it

into fire, to prevent explosion of battery.

2.4 Turn on and turn off

Turn on

Press button on the operator panel until the LED indicator lights turn from

green to red, release the button . When all of the motors return to the initial

position, the screen shows the reset menu.

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

10

Turn off

Press button on the operator panel until the LED indicator turn from

red to green, release the button , now the machine is turned off.

2.5 Display brightness control

When the external environment is different, the user can adjust the display

brightness for the convenience of theFusion Splicer operation. Display brightness

control should be done in the “standby” operation interface.

<1> Press or in the “standby” operation interface to change the

brightness of the display.

<2> Press to confirm the brightness changes, and return to “standby”

operation interface.

●When the display brightness is moderate, the capacity loss can be reduced,

and the endurance of the battery can be prolonged.

2.6 Cover fiber protection sleeve

The installation of fiber protection sleeve

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

11

2.7 Preparation of fiber end-face

2.7.1 Open the big and small clips of the cutter; push the sliding plate

installed with blade from the end to the front.

2.7.2 Use fiber stripping pliers to strip fiber coating layer, the length of which is

30-40 mm. Use gauze dipping with alcohol or wadding soft enough to

wipe clean the fiber. Wiping with a clean cotton cloth once, and do not

clean it with the same cloth for the second time. (Notes: Please use the

alcohol with purity more than 99 %.)

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

12

Fiber stripping Clean

2.7.3 Aim the edge of the fiber coating layer at the “16”calibration of the

cutter yardstick and put the fiber into orientation pressure tank with

the left hand, and be sure that the bare fiber has been straightly put on

the right and left rubber pads.

2.7.4 Close the small clip, big clip by right hand and promote sliding plate

installed with blade to the other side, and then cut the fiber.

2.7.5 Hold the cutter by left hand and open the big clip by right hand and

remove the fiber chips to put them in fixed containers.

2.7.6 Pinch and hold the fiber with the left hand, and open the small clip with the

right hand at the same time, and carefully remove the fiber.

●Notes: The clean cross-section of fiber cannot touch other things.

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

13

2.8 Place fiber

2.8.1 Open shielding cover and left and right fiber clips.

2.8.2 Put the good fiber end face in the V-shaped groove; ensure the tip of the

fiber between the tip of the electrode and V-shaped groove’s edge.

●If the fiber is bending, bending part should be upward when placing the

fiber.

●To ensure the splice quality of the fiber, the clean cross-section of fiber

cannot touch other things.

2.8.3 Use fingers to pinch the fiber, and then close the left clip, and press the

fiber. Ensure the fiber is placed in the bottom of V-shape groovy. If the

fiber is placed incorrect, please replace the fiber. The fiber end face don’t

touch the V-shape groove when place the fiber.

2.8.4 Place another optical fiber according to the above steps.

2.8.5 Close shielding cover.

3.Check and Maintenance

Critical cleaning points and maintenance checks are described below.

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

14

3.1 Cleaning V-grooves

If contaminants are present in the V-grooves, proper clamping may not occur,

resulting in higher splice loss. The V-grooves should be frequently inspected and

periodically cleaned during normal operation. To clean the V-grooves do the

following:

<1> Open the wind protector.

<2> Clean the bottom of the V-groove With an alcohol-impregnated thin cotton swab.

Remove excess alcohol from the V-groove with a clean dry swab.

Be careful to not contact the electrode tips.

Do not use excessive force when cleaning the V-groove.

The V-groove arm may get damaged.

If the contaminants in the V-groove cannot be removed with an

alcohol-impregnated thin cotton swab, use a cleaved fiber end-face to dislodge

contaminants from the bottom of the V-groove. Repeat step 2 after this

procedure.

3.2 Cleaning Fiber Clamp Chips

<1> If contaminants are present on the clamp chips, proper clamping may not occur,

resulting in poor quality splices. The fiber clamp chips should be frequently

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

15

inspected and periodically cleaned during normal operation.

<2> To clean the clamp chips, do the following: Open the wind protector. Clean the

surface of the chip clamp with an alcohol-impregnated thin cotton swab.

Remove excess alcohol from the chip clamp with a clean dry swab.

3.3 Cleaning Wind Protector Mirrors

If the wind protector mirrors become dirty, the fiber core position may be

incorrect due to decreased optical path clarity, resulting in higher splice loss. To

clean the mirrors, do the following: Clean the mirror surface with an

alcohol-impregnated thin cotton swab. Remove excess alcohol from the mirror

surface with a clean dry swab. Mirror should look clean with no streaks or

smudges.

3.4 Cleaning Objective Lenses

If the objective lenses’ surface becomes dirty, normal observation of the core

position may be incorrect, resulting in higher splice loss or poor splicer operation.

Therefore, clean both of them at regular intervals. Otherwise, dirt may

accumulate and become impossible to remove. Cleaning Objective Lenses:

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

16

<1> Before cleaning the objective lenses, always turn off the splicer.

Do not hit or touch tip of electrode when cleaning it.

<2>Gently clean the surface of lenses (X-axis and Y-axis) with an

alcohol-impregnated thin cotton swab. Using the cotton swab, start at the

center of the lens and move the swab in a circular motion until you spiral out to

the edge of the lens surface. Remove excess alcohol from the mirror surface

with a clean dry swab. The lens surface should be clean and free of streaks or

smudges.

<3> Turn on the power and make sure no smudges or streaks are visible on the

monitor screen. Press X/Y to change the screen and check the state of the lens

surface on both the X- and Y-screens. Perform dust check.

3.5 Replace Electrodes

Electrodes wear with use and also must be cleaned periodically due to silica

oxide buildup. It is recommended that the electrodes should be replaced after 1,000

arc discharges. When the number of arc discharges reaches a count of 1,000, a

message prompting to replace the electrodes is displayed immediately after turning

on the power. Using the electrodes without a replacement will result in greater

splice loss and reduced splice strength.

Replace Electrodes

<1> Press button on the operator panel until the LED indicator turn from red to

green, release the button , now the machine is turned off.

<2> Remove the old electrodes and Method for tearing:

SPEEDWOLF

—SP-FS18 Fusion Splicer User’s Manual

Shenzhen Speedwolf Technology Co.,LTD

A-14,Haide Building, Nanxin Road Nanshan District,Shenzhen,P.R.China

If you have any question,please contact us directly for help,Email: speedwolf@speedwolf.net

17

a. Loosen screw located on electrode cover.

b. Take electrode out of electrode cover.

(Electrode is fixed in the electrode cover)

<3> Clean the new electrodes with alcohol-impregnated clean gauze or lint-free

tissue and install them in the splicer.

<4> Place the electrode cover and tighten screw

●Do not pull out night light wiring when replacing electrode.

●The tightening of the screw should not exceed the strength of fingers.

3.6 Set Calendar

This function sets the date and time in the calendar incorporated in the splicer.

<1> In the[Maintenance Men1]Menu, press or and move the cursor to

select the [ Calendar ]

Table of contents