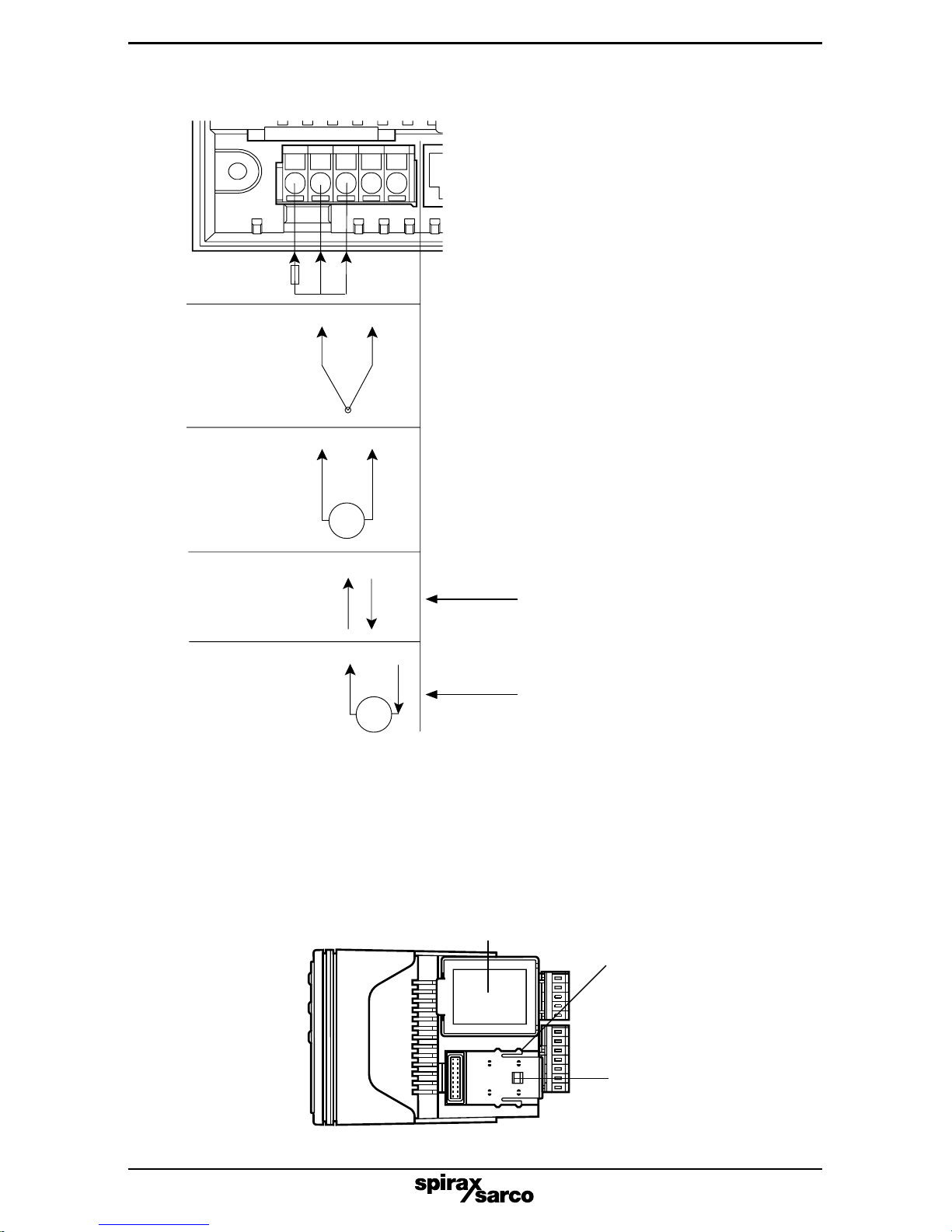

IM-P332-07 MI Issue 2 5

The power supply rating will be indicated on the top of the instrument. Ensure it is correct for

the application.

Cables are retained by screws. Ensure that the exposed section of the cable is fully

inserted and that no loose strands are exposed. 600 Vrms cable 0.5 mm² (0.02"²) to

1.5 mm² (0.06"²) core should be used.

Signal Input/Outputs - All signal input, output and communication terminals and associated

internalcircuitry are intendedforoperation at voltagesless than 40 Vdc.These circuits, which

may become accessible during normal operation, must only be connected to signals

complying with the requirements for Safety Extra Low Voltage (SELV) circuits.

Sensor connections - All sensor connections are made via the five way 'fast wiring' socket

at the rear of the unit (wire size 0.5 mm² (0.02"²) to 1.5 mm² (0.06"²)).

Note: Screened cable is recommended for thermocouple, RTD and voltage input wiring runs

over 10 metres (32.3 ft) long.

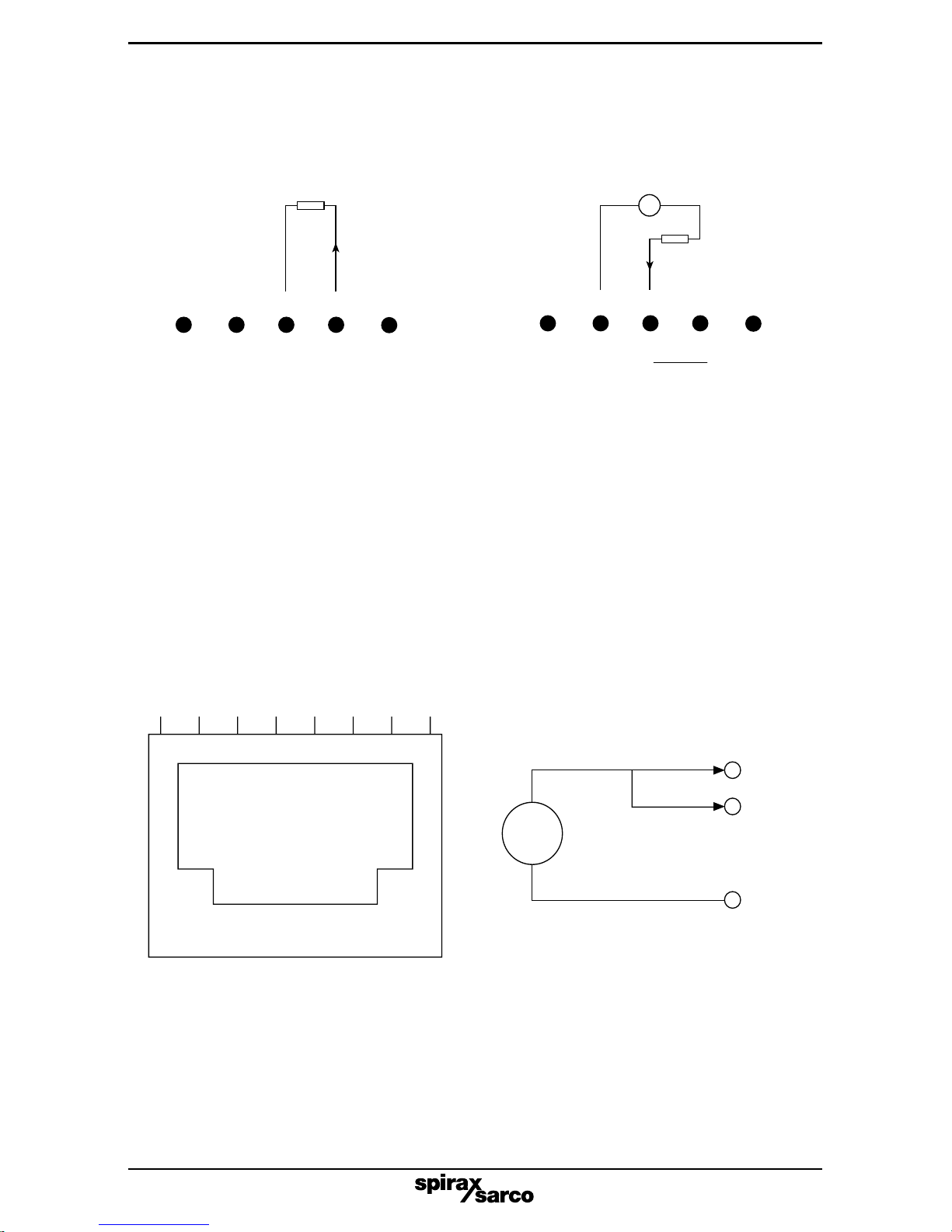

To make a connection: insert a small screwdriver blade into the tension clamp orifice,

(1, Figure 4), push and twist to deflect clamp into the open position. Do not lever the

screwdriverasthismayforcetheconnectorbodysideways.Insertthestrippedwiresufficiently

into (2) then remove the screwdriver. Ensure no loose wire strands protrude.

To avoid connector blocks' being plugged into the wrong connector a polarisation kit is

included. This should be used to ensure that the sensor connector block can only be plugged

into the sensor connections and the Pod connector blocks can only be plugged into their

appropriate connectors.

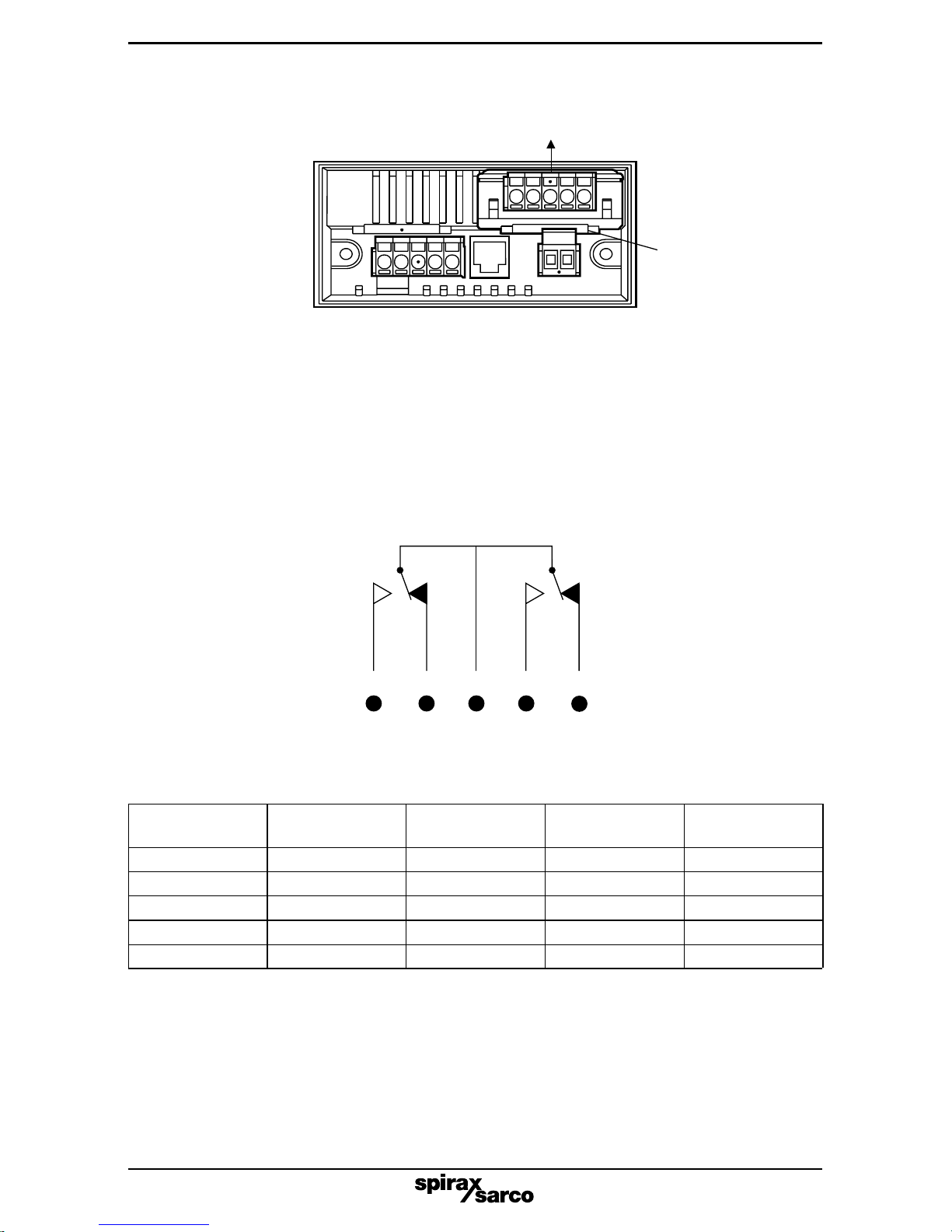

(+)L (-)N

E ternal

1 amp

fuse

Fig. 3

3.2 Electrical installation

All connections are made to sockets, which are removable for ease of maintenance and

wiring. Cable size should be between 0.5 mm² (0.02"²) and 1.5 mm² (0.06"²).

Supply-Thesupplyterminalsandassociatedinternalcircuitryareisolatedfromallotherparts

of the equipment in accordance with BS EN 61010-1, for connection to an Installation over-

voltage Category II supply, (pollution degree 2). The supply voltage and frequency must

remain within the limits stated on the product label.

The mains supply to the unit must be protected by an external 1 amp fuse

(see Figure 3) and a suitable switch or circuit breaker must be located close to the

equipment, in order to isolate the supply.

1

2

Fig. 4