Sponsler SP714-S2i User manual

Liquid ControLs Group An IDEX Fluid & Metering Business

Sponsler SP714-S2i

Pulse Amplier

Installation & Parts

Operation: EM700-10

INTRODUCTION

Safety Procedures.................................................... 3

General Information ................................................. 3

Dimensions .............................................................. 4

Specications ........................................................... 4

Regulatory Compliance Tag Markings...................... 6

TABLE OF CONTENTS

INSTALLATION

Installation Overview ................................................ 7

Wiring ....................................................................... 7

Settings ................................................................... 11

Diagnostics.............................................................. 11

Maintenance............................................................ 11

This manual provides warnings and procedures that are intended to inform the owner

and/or operator of the hazards present when using the Liquid Controls Meter on LP-

Gas and other products. The reading of these warnings and the avoidance of such

hazards is strictly in the hands of the owner-operators of the equipment. Neglect of

that responsibility is not within the control of the manufacturer.

NOTICE

The most current English versions of all Liquid Controls publications are available on our web site, www.lcmeter.com. It is the

responsibility of the local distributor to provide the most current version of LC manuals, instructions, and specication sheets in

the required language of the country, or the language of the end user to which the products are shipping. If there are questions

about the language of any LC manuals, instructions, or specication sheets, please contact your local distributor.

Publication Updates and Translations

2

SAFETY PROCEDURES AND GENERAL INFORMATION

!WARNING

North America - Installations must be in full accordance with the National Electrical Code (US) or the Canadian

Electrical Code respectively to maintain the hazardous location ratings on the product.

Outside of North America - Installations must be in full accordance with EN 60079-14 to maintain the hazardous

location ratings on the product. Use Ex d certied cable glands only. For ambient temperatures above 70ºC, use eld

wiring rated 20ºC above the maximum ambient temperature.

WARNING: Explosion Hazard -

Substitution of components may impair suitability for hazardous area applications.

WARNING: Explosion Hazard -

When in hazardous locations, turn power OFF before replacing or wiring modules.

WARNING: Explosion Hazard -

Do NOT disconnect equipment unless power has been switched OFF or the area is known to be Non-Hazardous.

Observe National and

Local Codes

!WARNING

Be Prepared

• Before using this product, read and understand the instructions.

• All work must be performed by qualied personnel trained in the proper application, installation, and maintenance of

equipment and/or systems in accordance with all applicable codes and ordinances.

• When handling electronic components and boards, always use proper Electrostatic Discharge (ESD) equipment and

follow the proper procedures

• Make sure that all necessary safety precautions have been taken.

• Provide for proper ventilation, temperature control, re prevention, evacuation, and re management.

• Provide easy access to the appropriate re extinguishers for your product.

• Consult with your local re department, state, and local codes to ensure adequate preparation.

• Read this manual as well as all the literature provided in your owner’s packet.

• Save these instructions for future reference.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury, or death

from re and/or explosion, or other hazards that may be associated with this type of equipment.

General Information

The SP714-S2i is a meter-mounted pulse amplier that amplies and conditions low amplitude signals, typically

produced by the magnetic pickup coil of a Sponsler turbine owmeter. The SP714-S2i transforms the low power input

signal from the pickup coil into square-wave output signals with enough energy to travel a greater distance and be

detected reliably by the electronic device, such as a ow computer or an electronic register.

The SP714-S2i includes an input signal sensitivity adjustment (R1) that permits the SP714-S2i to discriminate

between an input signal and noise by increasing or decreasing the input signal amplitude necessary to be processed

as a valid signal. This, in conjunction with being directly mounted onto the turbine ow meter, allows the SP714-S2i to

operate effectively in noisy environments.

The SP714-S2i also includes diagnostic tools. The diagnostic test oscillator (SW2) enables the operator to verify the

ampliers operation without a signal source. The green LED (D1)indicates the power supply status. The red LED (D2)

indicates the signal frequency status.

In order to maintain IECEx compliance, the SP714-S2i is connected to the turbine owmeter boss. The

turbine meter and SP714-S2i assembly is pressure tested at the factory, then shipped as an assembly.

SP714-S2i and Sponsler Turbine Flowmeter Shipped as Assembly

3

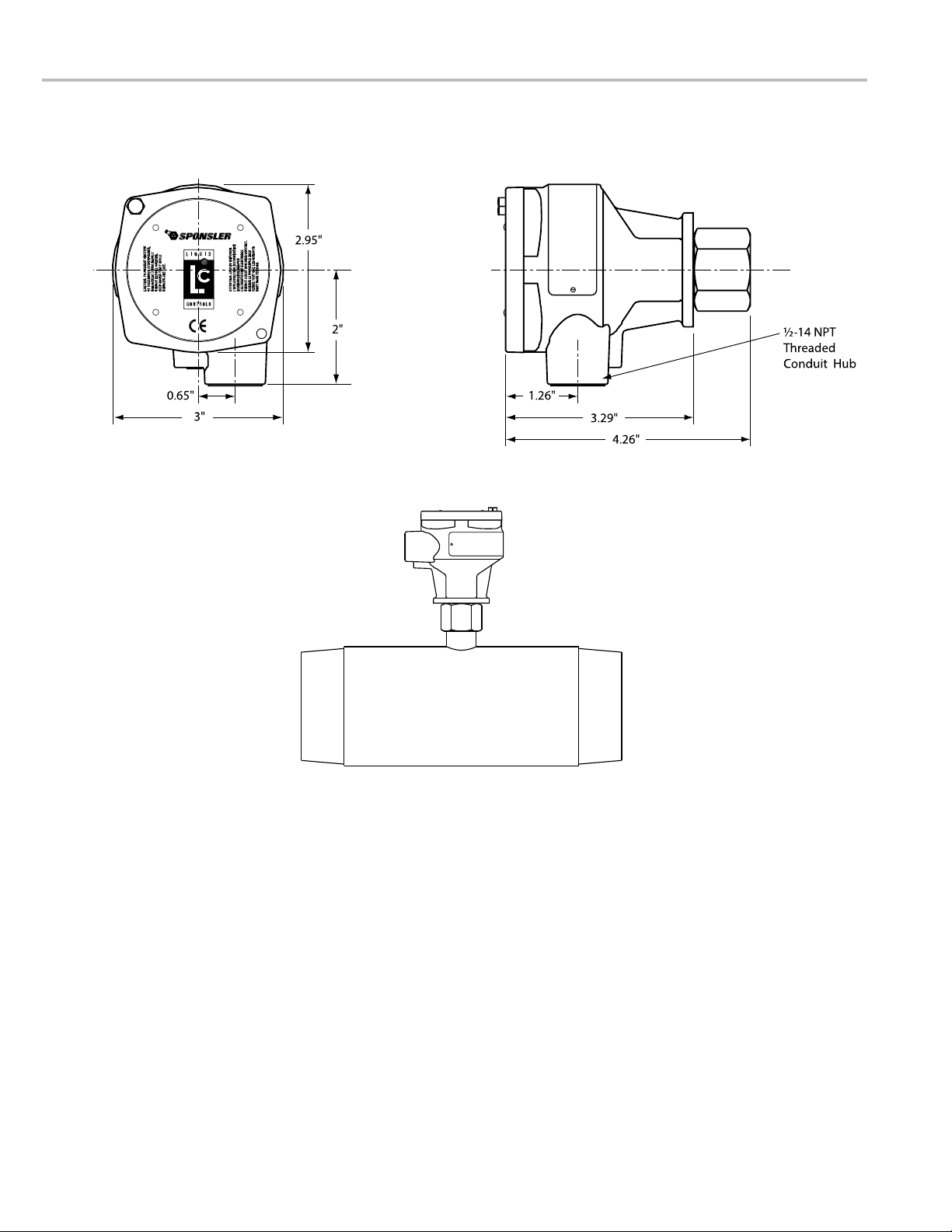

DIMENSIONS AND SPECIFICATIONS

Weight

• 1.2 lbs (0.54 kg)

Materials of Construction

Housing

• Aluminum Alloy ADC12

• Powder Coat: Corro-Coat PE 74-141 Polyester

Adapter (to turbine meter boss)

• Stainless Steel

Cable Entry

• ½"-14 NPT

Temperature Range

Operating

• -40 to 176 °F (-40 to 80 °C)

Storage

• -76 to 257 °F (-60 to 125 °C)

Input Voltage

• 6-28 VDC; 83 mA maximum @ 24 VDC

• Protected against polarity reversal

Signal Input

Frequency

• 2 kHz maximum over operating temperature in all modes

Amplitude

• 10 mV p-p minimum sine or square wave

Impedance

• 50 KΩ

Sensitivity Field

• Adjustable by potentiometer (R1)

Output Signal Characteristics

See following page.

FRONT SIDE

SP714-S2i

AND TURBINE

FLOWMETER

Dimensions

4

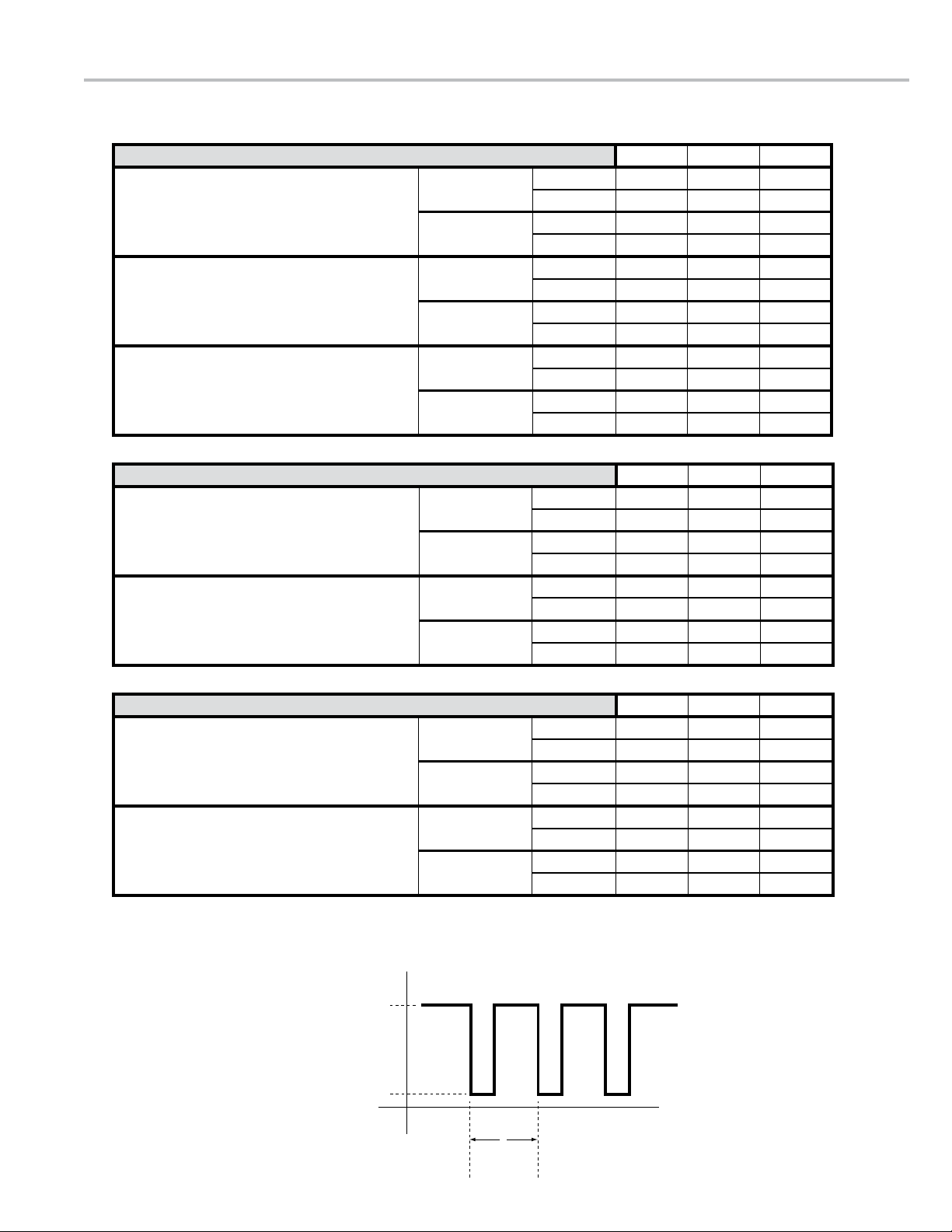

SPECIFICATIONS

MiniMuM MaxiMuM units

DC power supply voltage: 12 V

Total System Resistance: 130 Ω± 25 Ω

Output Voltage Logic HIGH 9 VDC

Logic LOW 5 VDC

Output Current Logic HIGH 12 mA DC

Logic LOW 83 mA DC

DC power supply voltage: 24 V

Total System Resistance: 250 to 400 Ω

Output Voltage Logic HIGH 18 VDC

Logic LOW 5 VDC

Output Current Logic HIGH 15 mA DC

Logic LOW 83 mA DC

DC power supply voltage: 28 V

Total System Resistance: 360 Ω± 60 Ω

Output Voltage Logic HIGH 21 VDC

Logic LOW 5 VDC

Output Current Logic HIGH 15 mA DC

Logic LOW 83 mA DC

*Depends on power supply voltage and total system resistance (Load impedance + signal cable resistance)

MiniMuM MaxiMuM units

DC power supply voltage: Vcc: 4 – 28 VDC

Total System Resistance: 500 Ωminimum @ 28 VDC

Output Voltage Logic HIGH Vcc – 1* VDC

Logic LOW 0.25 VDC

Output Current Logic HIGH ~8 to 60 mA DC

Logic LOW 8 mA DC

DC power supply voltage: Vcc: 4 – 28 VDC

Total System Resistance: 10 kΩ(Example)

Output Voltage Logic HIGH Vcc – 0.60* VDC

Logic LOW 0.25 VDC

Output Current Logic HIGH ~8 to 11 mA DC

Logic LOW 8 mA DC

*Depends on DC power supply voltage value

MiniMuM MaxiMuM units

DC power supply voltage: Vcc: 4 – 28 VDC

Total System Resistance: 500 Ωminimum @ 28 VDC

Output Voltage Logic HIGH Vcc – 0.5* VDC

Logic LOW 0.5 VDC

Output Current Logic HIGH 7 mA DC

Logic LOW 8 to 60 mA DC

DC power supply voltage: Vcc: 4 – 28 VDC

Total System Resistance: 10 kΩ(Example)

Output Voltage Logic HIGH Vcc – 1* VDC

Logic LOW 0.5 VDC

Output Current Logic HIGH 7 mA DC

Logic LOW 8 to 11 mA DC

*Depends on external DC power supply voltage value

TYPICAL

SIGNAL

OUTPUT

WAVEFORM

Maximum

Voltage

Time

Minimum

One

Cycle

0

5

REGULATORY COMPLIANCE TAG

Explosive Atmospheres symbol

IECEX DNV 11.0012X

This equipment has been found to comply with the Certication Scheme for Explosive Atmospheres of INTERNATIONAL

ELECTROTECHNICAL COMMISSION (IECEx). Evaluation was made in 2013 by Det Norske Veritas (DNV) to IECEx scheme

with a certicate number IECEx DNV 11.0012X, where X represents the following Special Conditions for Safe Use: 1) Only Ex

d certied cable glands are to be used; and 2) For ambient temperatures above 70 °C, use eld wiring suitable for 20°C above

maximum ambient temperature.

II

Suitable for use in surface (not mine) installations.

2 G

High level of protection is provided against ammable gases, vapors, or liquids, which may exist during normal operation.

Ex d

Explosion protection is provided by a ameproof enclosure.

IIB

Gas group, which includes ethylene, propane, and methane.

T6:

Temperature class for surface temperature limitations. T6 is ≤ 85ºC

Gb

Equipment group per IEC 60079-0:2007.

amb

Safe limits of ambient temperature.

IP66

Ingress protection: dust tight and protected against powerful water jetting.

Consult factory for current compliance status.

6

INSTALLATION OVERVIEW

In order to maintain IECEx compliance, the SP714-S2i is shipped as part of an assembly with a Sponsler turbine

owmeter. A complete installation of the owmeter and pulse amplier assembly includes the physical installation of

the owmeter and the electrical installation of the SP714-S2i. Guidelines for the physical installation of the owmeter

can be found in the Sponsler turbine owmeter manual. Instructions for the electronic installation of the SP714-S2i are

included in this manual.

1. Install Sponsler turbine owmeter (with SP714-S2i) into system piping. Sponsler Turbine Flowmeter Installation Manual

2. Wire the SP714-S2i to a pulse acquisition device and set the S1 switches to the preferred output signal characteristics. Page 7

3. Perform eld test and adjust the input signal sensitivity (if necessary). Page 11

Use the proper cable glands, conduit connectors, cables,

conduit, and installation procedures when wiring the SP714-S2i.

Installations must be in full accordance with national and local

codes to maintain the hazardous location ratings on the product.

Observe National and Local Codes

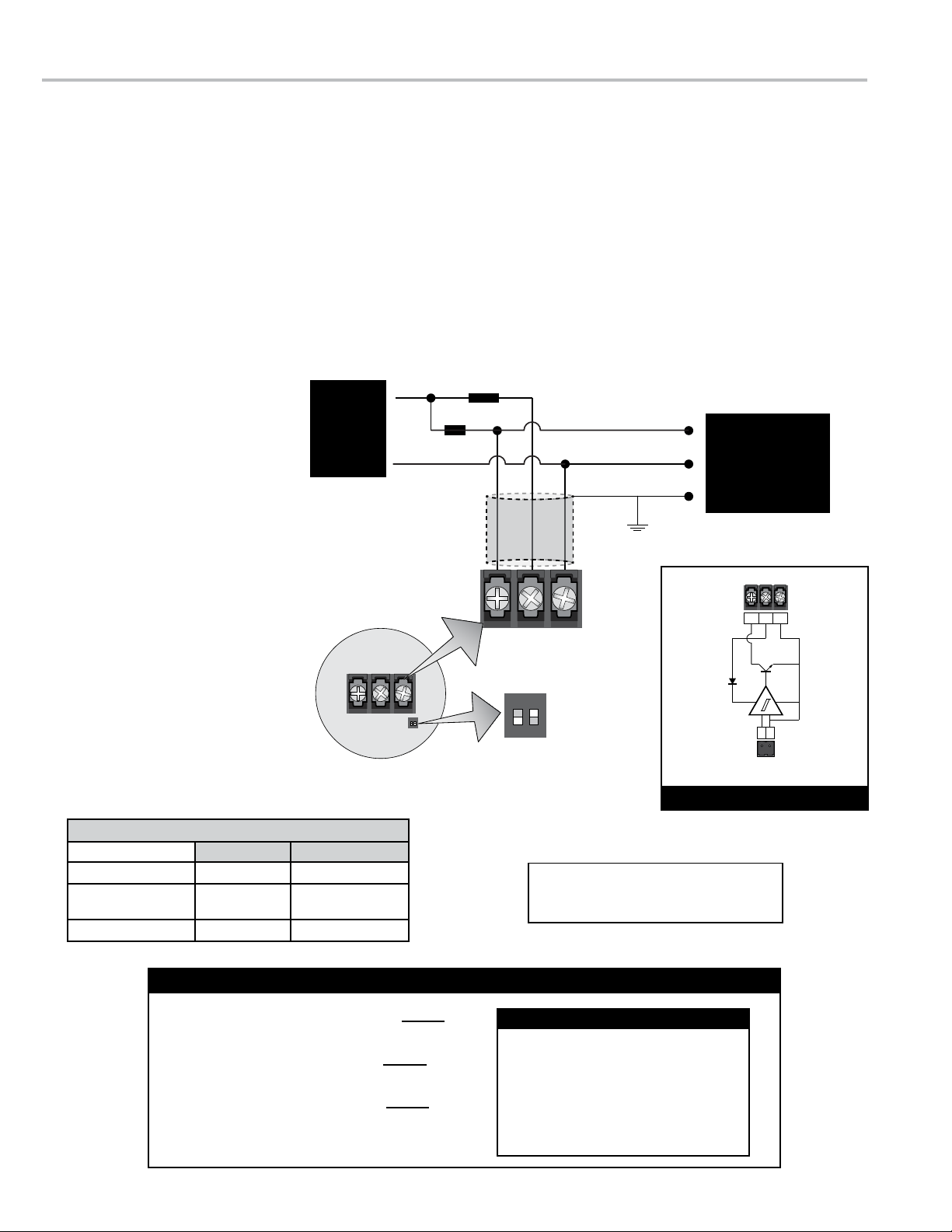

WIRING THE OUTPUT SIGNAL CONFIGURATIONS

The SP714-S2i can be set to one of three congurations: 2-wire Standard, 3-wire TTL Sourcing, and 3-wire Open

Collector. The 2-wire Standard conguration translates the output signal from the turbine owmeter’s pickup coil into

a current value. 2-wire connections are effective transmitting the signal over long distances. The 3-wire TTL Sourcing

conguration translates the output signal from the turbine owmeter’s pickup coil into a voltage value. The output

of the 3-wire TTL Sourcing conguration is driven either positive or negative internally. The 3-wire Open Collector

conguration translates the output signal from the turbine owmeter’s pickup coil into a voltage value. The output is

driven by an “Open Collector” transistor.

Each conguration requires a specic positioning of the two S1 switches, specic

wiring connections (to the power supply and the pulse acquistition device), and a

resistor(s) spliced into the +V leg from the power supply (optional for the 3-wire TTL

Sourcing conguration).

The best conguration for your application is determined by the specications of the

pulse acquistion device (typically a ow computer or electronic register) receiving

the SP714-S2i signal and the electrical characteristics of the application.

SW1

S1

JU4

D1 D2

GND

TB2

S2

R1

TB1

ONON

12

GND

1

S1 Switches

• 18 AWG stranded wire in shielded cable, UL Listed For

ambient temperatures above 70°C, use eld wiring suitable for 20°C

above maximum ambient temperature.

• ½-14 NPT cable glands Use Ex d certied cable glands only.

• Connectors for pulse acquisition device or DC power supply

See “Observe National and Local Codes” on this page.

• PTFE tape or pipe sealant

7

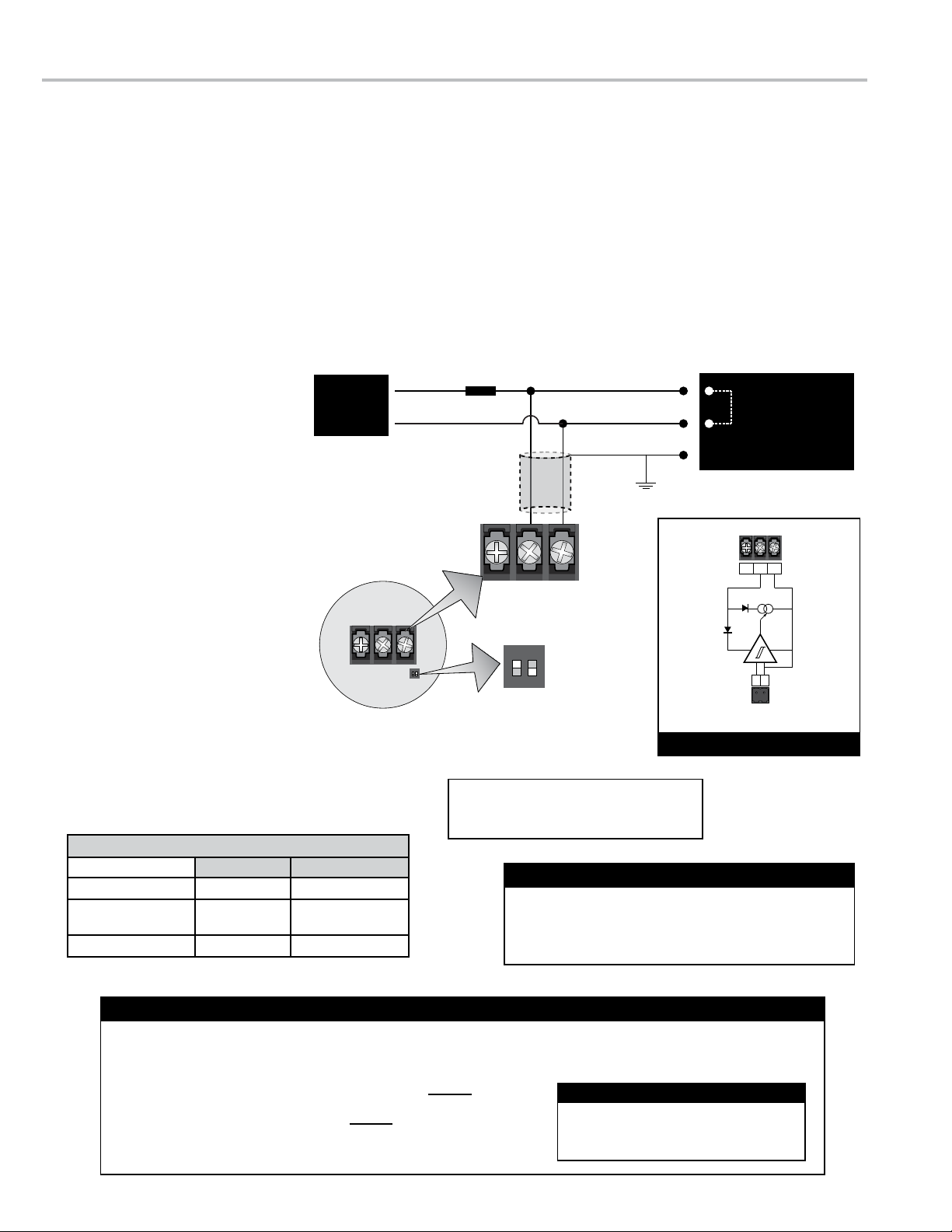

2-WIRE STANDARD

The 2-wire Standard conguration translates the output signal from the turbine owmeter’s pickup coil into a current

value. The 2-wire Standard conguration produces an output signal using a resistor to convert the electrical current

variations into voltages. In this conguration, the power supply travels on the signal wire. 2-wire connections are

effective transmitting the signal over long distances.

1. Remove the SP714-S2i housing cover.

2. Pull the SP714-S2i board from the housing for access to the TB1 terminal block and the S1 switches.

3. Attach proper cable glands and/or conduit connectors to the SP714-S2i, the pulse acquisition device, and DC power supply.

4. Run the wires (through proper conduit) between the SP714-S2i, the pulse acquisition device, and DC power supply.

5. Set the rst S1 switch to the

ON position and the second S1

switch to the OFF position.

6. Splice the resistor onto the +V

leg from the DC power supply.

The value of the resistor can be

determined using the information below.

7. Wire the SP714-S2i to the pulse

acquisition device and DC

power supply as indicated in the

schematic.

8. If necessary, adjust the input

signal sensitivity (R1), activate

the diagnostic test oscsillator

(SW2), and/or check the

diagnostic operational LEDs (D1

& D2). See page 11.

9. Coil the wires underneath the

CPU board and place the board

inside the housing, ensuring

the wires are not pinched, and

replace the housing cover.

2-WIRE STANDARD WIRING

S1

ONON

12

GND

1

Signal+V

0V Signal Ground

Cable Shield

Resistor (RP)

Two

Conductor

Shielded

Cable

Position 1 - ON

Position 2 - OFF

ONON

12

Electronic Register

or

Flow Computer

Zinput resistance

DC Power

Supply

Chassis GND

S1

TB1

INTERNAL OPERATING PRINCIPLE

3 2 1

2 1

TB2

Pickup Coil Signal

TB1

3 2 1

Connect Chassis GNDs at pulse acquisition device only

If the total system resistance in a 2-wire standard

conguration exceeds the recommended value, the

preamplier may function irregularly as a result of

insufcient supply voltage to the terminals.

!CAUTION !

SP714-S2i Connections

Pulse Acquisition Device

Sponsler IT 400 TB2 (1) TB2 (2)

LectroCount

LCR-II/LCR 600 J8 (33) J8 (37)

Toptech MultiLoad TB2B (V+ any) TB2B (V COM any)

Maximum Cable Length: 380 m (1200’)

Minimum Wire Gauge: 0.75 mm2(18 AWG)

Maximum cable wire resistance must be less than 30 Ω Rcable = Rw1+ Rw2 (both wires in cable)

Total system resistance with +24 VDC power supply must be between 250 and 400 Ω Rsystem = Rcable + RP

Maximum System Current Imax = 90 mA Imax =

Resistor (RP) Power Dissipation PRd =

Resistor Value - 2-wire Standard

(Vdc)2

Rp

Vdc

Rsystem

24 VDC Power Supply: Rp = 330 Ω, 2 W

12 VDC Power Supply: Rp = 150 Ω, 2 W

Recommended Resistor Value (Rp)

8

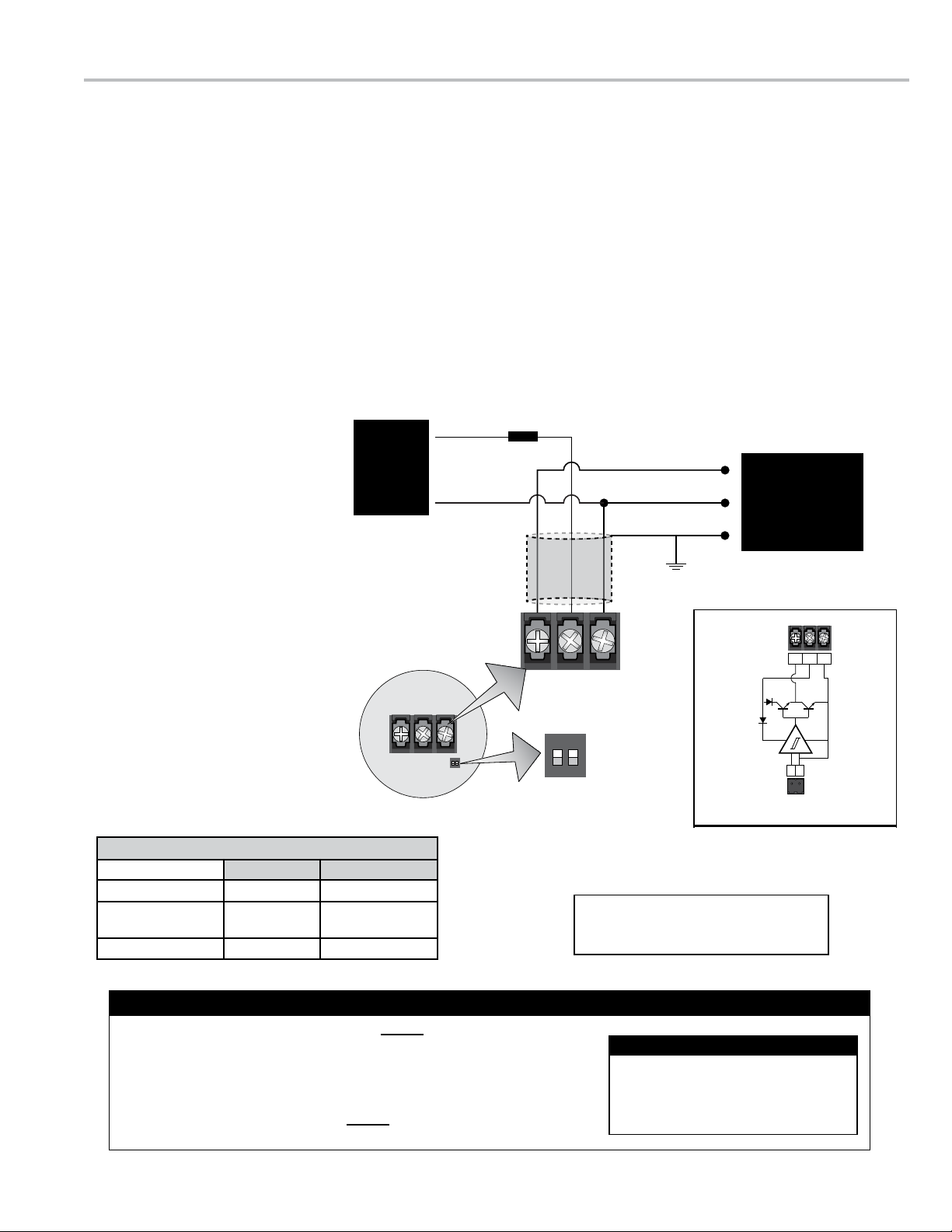

The 3-wire TTL Sourcing conguration translates the output signal from the turbine owmeter’s pickup coil into a

voltage value. The output of the 3-wire TTL Sourcing conguration is driven either positive or negative internally. Note

that the name “TTL” is misleading because the output switches from 0V to +Vs, not 0V to +5V as the TTL standard

indicates. In the SP714-S2i, “TTL” indicates that the output is driven in both the positive and zero volt cases. A pull-

up or pull-down resistor is optional in the 3-wire TTL Sourcing conguration; however, a resistor can be installed to

prevent damage from faults.

1. Remove the SP714-S2i housing cover.

2. Pull the SP714-S2i board from the housing for access to the TB1 terminal block and the S1 switches.

3. Attach proper cable glands and/or conduit connectors to the SP714-S2i, the pulse acquisition device, and DC power supply.

4. Run the wires (through proper conduit) between the SP714-S2i, the pulse acquisition device, and DC power supply.

5. Set the rst S1 switch to the ON position and the second S1 switch to the ON position.

6. Splice the resistor onto the +V

leg from the DC power supply.

This step is optional. The value of the

resistor can be determined using the

information below.

7. Wire the SP714-S2i to the pulse

acquisition device and DC

power supply as indicated in the

schematic.

8. If necessary, adjust the input

signal sensitivity (R1), activate the

diagnostic test oscsillator (SW2),

and/or check the diagnostic

operational LEDs (D1 & D2). See

page 11.

9. Coil the wires underneath the

CPU board and place the board

inside the housing, ensuring

the wires are not pinched, and

replace the housing cover.

S1

ONON

12

GND

1

3 2 1

Signal

+V

0V

S1

Signal Ground

Position 1 - ON

Position 2 - ON

ONON

12

DC Power

Supply

Resistor (RP)

Electronic Register

or

Flow Computer

Chassis GND

Cable Shield

3 2 1

2 1

TB2

Pickup Coil Signal

TB1

INTERNAL OPERATING PRINCIPLE

optional

Three

Conductor

Shielded

Cable Connect Chassis GNDs at pulse acquisition device only

SP714-S2i Connections

Pulse Acquisition Device

Sponsler IT 400 TB2 (1) TB2 (2)

LectroCount

LCR-II/LCR 600 J8 (33) J8 (37)

Toptech MultiLoad TB2B (V+ any) TB2B (V COM any)

Maximum Cable Length: 1000 m (3280’)

Minimum Wire Gauge: 0.75 mm2(18 AWG)

Limit total system current to 50 mA Imax =

For 24 VDC operation pulse acquisition device impedance must be at least 1200 Ω

For 5 VDC operation pulse acquisition device impedance must be at least 250 Ω

Resistor (RP)Power Dissipation P =

Resistor Value - 3-wire TTL Sourcing

24 VDC Power Supply: Rp = 680 Ω, 1 W

12 VDC Power Supply: Rp = 330 Ω, 1 W

5 VDC Power Supply: Rp = 12 Ω, 2.5 W

Recommended Resistor Value (Rp)

Vdc

RP

(V)2

RP

9

The 3-wire Open Collector conguration translates the output signal from the turbine owmeter’s pickup coil into a

voltage value. The output is driven by an “Open Collector” transistor. A resistor is required to “pull-up” the voltage

when the transistor is ‘off’.

1. Remove the SP714-S2i housing cover.

2. Pull the SP714-S2i board from the housing for access to the TB1 terminal block and the S1 switches.

3. Attach proper cable glands and/or conduit connectors to the SP714-S2i, the pulse acquisition device, and DC power supply.

4. Run the wires (through proper conduit) between the SP714-S2i, the pulse acquisition device, and DC power supply.

5. Set the rst S1 switch to the OFF position and the second S1 switch to the ON position.

6. Splice the resistors between

the +V leg from the DC power

supply and the signal input

leg to the pulse acquisition

device. The value of the resistor can

be determined using the information

below.

7. Wire the SP714-S2i to the

pulse acquisition device and

DC power supply as indicated

in the schematic.

8. If necessary, adjust the input

signal sensitivity (R1), activate

the diagnostic test oscsillator

(SW2), and/or check the

diagnostic operational LEDs

(D1 & D2). See page 11.

9. Coil the wires underneath the

CPU board and place the board

inside the housing, ensuring

the wires are not pinched, and

replace the housing cover.

S1

ONON

12

GND

1

3 2 1

Signal

+V

0V Signal Ground

Position 1 - OFF

Position 2 - ON

ONON

12

DC Power

Supply

Resistor (RP)

Resistor (RI)

Electronic Register

or

Flow Computer

Chassis GND

3 2 1

2 1

TB2

Pickup Coil Signal

TB1

INTERNAL OPERATING PRINCIPLE

Cable Shield

Three

Conductor

Shielded

Cable Connect Chassis GNDs at pulse acquisition device only

S1

Maximum Cable Length: 1000 m (3280’)

Minimum Wire Gauge: 0.75 mm2(18 AWG)

Limit total system current to 50 mA I=

Resistor (Ri)Power Dissipation P =

Resistor (RP)Power Dissipation P =

Resistor Value - 3-wire TTL Sourcing

Vdc

RP

(Vdc)2

RP

(Vdc)2

Ri

24 VDC Power Supply: Ri = 1200 Ω, 1 W

Rp = 680 Ω, 1 W

12 VDC Power Supply: Ri = 560 Ω, 0.5 W

Rp= 330 Ω, 1 W

5 VDC Power Supply: Ri = 270 Ω, 0.25 W

Rp = 25 Ω, 1 W

Recommended Resistor Value (Rp)

SP714-S2i Connections

Pulse Acquisition Device

Sponsler IT 400 TB2 (1) TB2 (2)

LectroCount

LCR-II/LCR 600 J8 (33) J8 (37)

Toptech MultiLoad TB2B (V+ any) TB2B (V COM any)

10

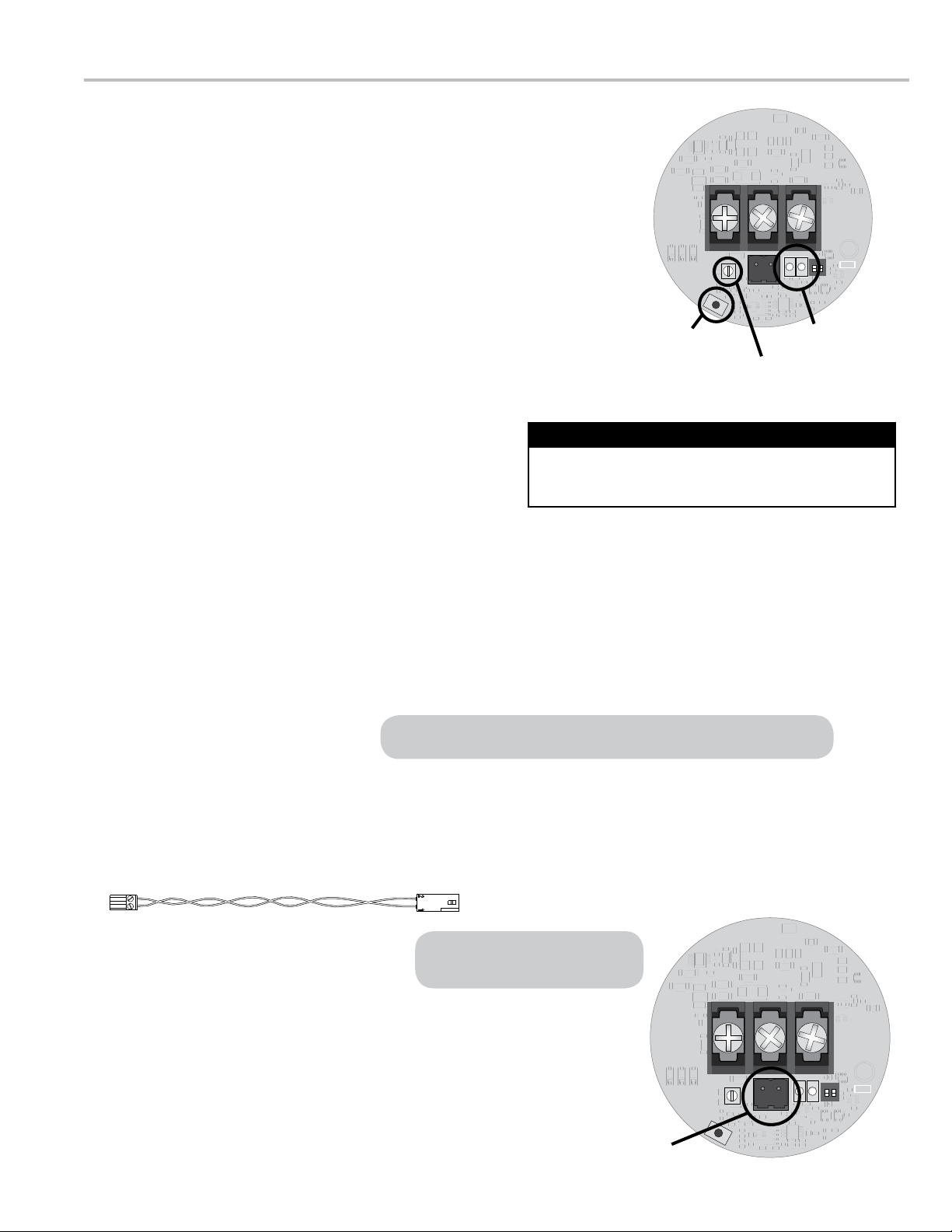

The R1 Input Signal Sensitivity Adjustment is a valuable tool that, in addition

to SP714-S2i being directly mounted to the turbine meter, allows effective

operation in noisy environments. The R1 is a potentiometer that sets the

amplitude of the input signal (from the pickup coil) that the SP714-S2i will

accept as a valid pulse.

Adjusting R1 allows the SP714-S2i to differentiate between the input signal

and any noise in the system. Turning the R1 clockwise decreases the

amplitude of the input signal required for a valid pulse, and turning the R1

counterclockwise increases the required amplitude.

The detection level of the R1 potentiometer is set at approximately 17 mV

rms at the factory. A red varnish is applied to the potentiometer screw to seal

the factory setting.

SETTINGS & DIAGNOSTICS

SW1

S1

JU4

D1 D2

GND

TB2

S2

R1

TB1

ONON

12

GND

1

R1

Input Sensitivity

Adjustment

sW2

Diagnostic Test

Oscillator

D1 & D2

Diagnostic LEDs

There are two Diagnostic Operational LEDs (D1 and D2) on the SP714-S2i PC board that indicate the current

operational status of the preamplier. The green LED (D1) indicates the power supply status. When the green LED is

on, the power supply is sufcient. When the LED is dim or ashing, the preamplier does not have sufcient power.

The red LED (D2) indicates the status of the signal traveling through the preamplier. The red LED ashes at the

same rate as the frequency as the signal passing through the SP714-S2i. If the LED is not ashing, no signal is

passing through the amplier. If the signal frequency is above 40 Hz, the light will ash very quickly and the LED will

appear to be constantly illuminated. If the input into the SP714-S2i stops on a positive portion of the signal pulse, the

LED will be illuminated constantly.

The SW2 Diagnostic Test Oscillator veries that the SP714-

S2i is operational. To activate the test, press the SW2 push

button. A 10 Hz signal will be introduced into the SP714-

S2i signal output pins (TB1). For best results, use the SW2

Diagnostic Test Oscillator without the presence of the pickup

coil signal.

If an input signal from the pickup coil is present, the 10 Hz

signal from the SW2 can disrupt the SP714-S2i output signal

and an error will be detected by the pulse acquisition device.

Do Not Use the SW2 During Operation

The D1 and D2 LEDs are inoperable in the 2-wire Standard conguration.

Polarity of the connector at the

pickup coil is not important.

Maintenance - CPU Board Replacement

The CPU board (PN 85025) is the only SP714-S2i part available for purchase. If you are replacing the 85025 CPU

board, the wiring harness, which connects the pickup coil and to the SP714-S2i CPU board, must be unplugged from

the old CPU board and plugged into the replacement board, then wired appropriately.

1. Remove the SP714-S2i housing cover.

2. Pull the CPU board from the housing, disconnect the

wires to the power supply and the pulse acquisition

device, and unplug the wiring harness.

3. Plug the wiring harness into the replacement CPU board,

wire the replacement CPU board to the power supply

and the pulse acquisition device, set the board into the

housing, and replace the housing cover. See pages 7-10 for

detailed instructions.

Wiring Harness

SW1

S1

JU4

D1 D2

GND

TB2

S2

R1

TB1

ONON

12

GND

1

Input signal

connector

11

© 2013 Liquid Controls

Pub. No. 500372

(8/2013)

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

TopTech SySTemS

1124 Florida Central Parkway

Longwood, FL 32750

(407) 332-1774

Nateus Business Park

Nieuwe Weg 1-Haven 1053

B-2070 Zwijndrecht (Antwerp), Belguim

+32 (0)3 250 60 60

Liquid conTroLS

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

SAmpi

Via Amerigo Vespucci 1

55011 Altopascio (Lucca), Italy

+39 0583 24751

ideX FLuid And meTering pvT. LTd.

Survey No. 256, Alindra

Savli GIDC, Manjusar

Dist. Vadodara 391 770

Gujarat, India

+91 2667 662001

Liquid conTroLS SponSLer

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

FAure hermAn

Route de Bonnetable

B.P. 20154

72406 La Ferté-Bernard Cedex, France

+33 (0)2 43 60 28 60

4702 North Sam Houston Parkway West, Suite 100

Houston, TX 77086

(713) 623-0808

corken

3805 Northwest 36th St.

Oklahoma City, OK 73112

(405) 946-5576

Table of contents

Other Sponsler Amplifier manuals