Sporlan PSK201 User manual

PSK201

Digital Thermostats for Medium Temperature Refrigerating Units

INSTALLATION AND OPERATING INSTRUCTIONS

1 GETTING STARTED

1.1 Important

Read these instructions carefully before installing and operating

this controller and follow all addtional information for installation

and electrical connection. Keep this guide for future reference.

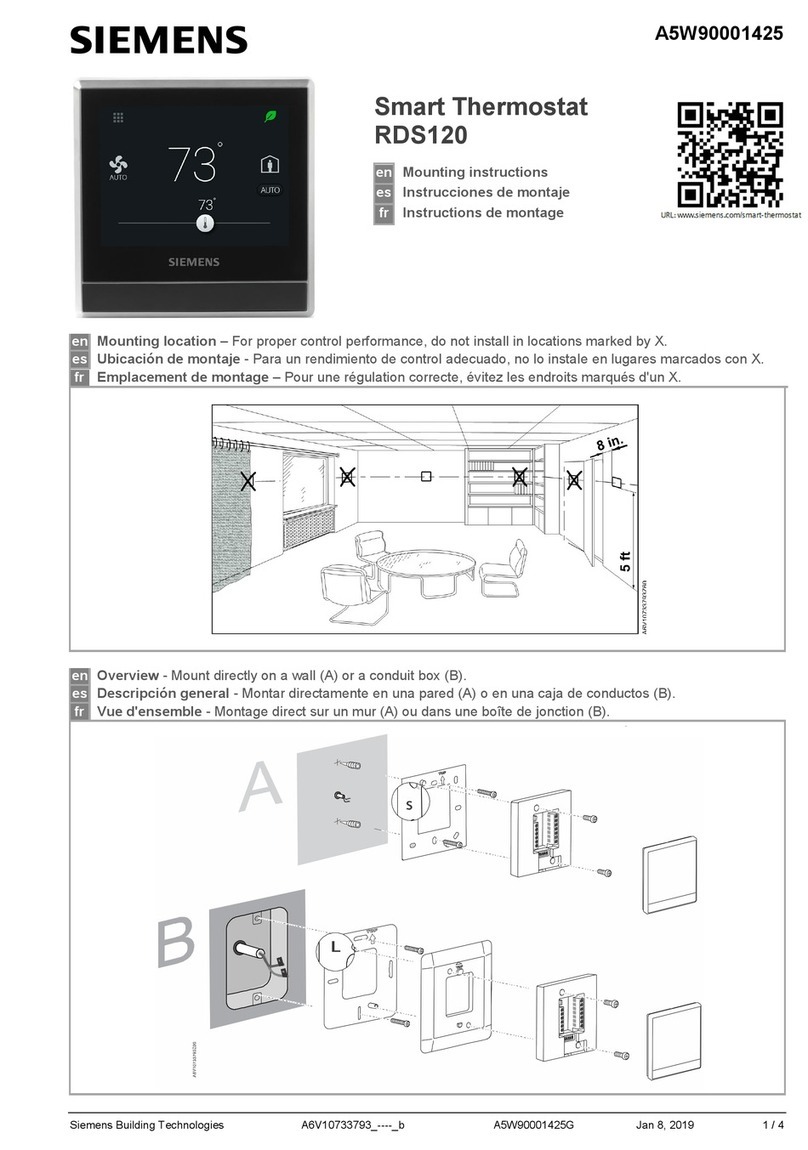

1.2 Installing the controller

Additional information for installation:

•59.0mm(2.322in)isthemaximumdepthwithscrewterminal

blocks

•83.0mm(3.267in)isthemaximumdepthwithextractableterminal

blocks

•thepanelthicknessmustnotbegreaterthan8.0mm(0.314in)

•workingconditions(workingtemperature,humidity,etc.)mustbe

between the limits indicated in the technical data

•donotinstallthecontrollerclosetoheatsources(heaters,hotair

ducts,etc.),devicescontaininglargemagnets,locationssubjectto

directsunlight,moisture,humidity,dust,mechanicalvibrations

or shocks

59.0 (2.322)

83.0 (3.267)

75.0 (2.952)

33.0

(1.299)

panel cut out

A

B

Size - mm (inches)

Installation - Panel mounting, with click brackets (supplied by the builder).

Dimension Minimum Typical Maximum

mm inches mm inches mm inches

A 71.0 2.79 71.0 2.79 71.8 2.82

B 29.0 1.14 29.0 1.14 29.8 1.17

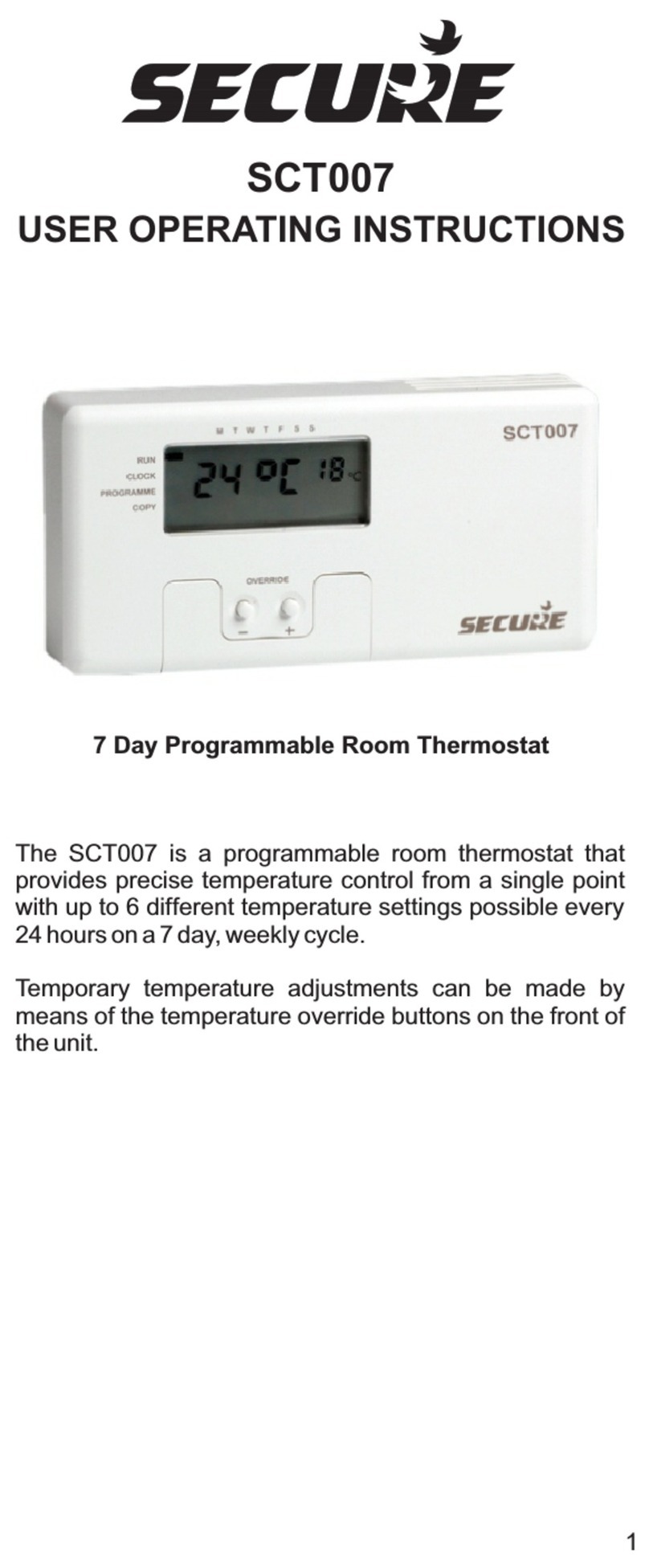

Electrical Connection

PSK201

•accordingtosafetyregulations,protectionagainstaccesstoelectrical

parts must be ensured by a correct installation of the controller; the

parts that ensure this protection must be installed so that they can not

beremovedwithouttheuseofatool.

1.3 Wiring diagram

Additional information for electrical connection:

•donotuseelectricorpneumaticscrewdrivers/wrenchesonthe

terminal block connections

•ifthecontrollerhasbeenmovedfromacoldlocationtoawarmone,

condensation can occur on the inside of the unit causing unsafe or

unreliable operation; wait at least one hour before attempting to

power up and use the controller

•makesurethatthesupplyvoltageandfrequencyarecorrectforthe

power supply of the controller

•alwaysdisconnectpowerfromthecontrollerbeforeservicingit

•thiscontrollerisnotintendedtobeusedasasafetycontroldevice

•forservicingorrepair,pleasecontactyourParkerSporlanSales

Engineer.

2 USER INTERFACE

2.1 Turning on/o the controller

eunitisturnedonwhenpowerissuppliedtoit,andlikewiseturns

owhenpowerisremoved.

2.2 e display

When the unit is turned on during normal operation the display will

show the cabinet temperature.

2.3 Activating the defrost by hand

•makesurenoprocedureisrunning

•pressandhold for4seconds.

electric

system

1234

51

011

K1

power

supply

comp.

cabinet

max. 10 A

PSK201

September 2012 / Bulletin 100-50-6.1

Page 2 – Bulletin 100-50-6.1

3 SETTINGS

3.1 Setting the working setpoint

•makesurenoprocedureisrunning

•press : LED will ash

•press or within15seconds;alsolookatparametersr1,r2andr3

•press ordonotpressanykeyfor15seconds.

YoualsocanmodifytheworkingsetpointthroughparameterSP.

3.2 Setting conguration parameters

To gain access to the procedure:

•makesurenoprocedureisrunning

•pressandhold and for4seconds:thedisplaywillshow“PA”

•press

•press or within15secondstosetdisplayto“-19”

•press ordonotpressanykeyfor15seconds

•pressandhold and for4seconds:thedisplaywillshow“SP”.

To select a parameter:

•press or

To modify a parameter:

•press

•press or within15seconds

•press ordonotpressanykeyfor15seconds.

Toquittheprocedure:

•pressandhold and for4secondsordonotpressanykeyfor

60seconds.

Switch off/on the power supply of the controller after the

modification of the parameters.

3.3 Restoring the default value of conguration parameters

•makesurenoprocedureisrunning

•pressandhold and for4seconds:thedisplaywillshow“PA”

•press

•press or within15secondstosetthedisplayto“743”

•press ordonotpressanykeyfor15seconds

•pressandhold and for4seconds:thedisplaywillshow“dEF”

•press

•press or within15secondstosetthedisplayto“149”

•press ordonotpressanykeyfor15seconds:thedisplaywill

show “dEF”ashing4seconds,afterwhichthecontrollerwillquit

the procedure

•switcho/onpowertothecontroller.

Make sure the default value of the parameters is correct, in

particular note if the probes are PTC probes.

4 SIGNALS

4.1 Signals

LED EXPLANATION

LED compressor

iflit,thecompressorwillbeturnedon

if ashing:

•themodiedworkingsetpointwillberunning

•acompressorprotectionwillberunning(parametersC0

andC2;thecompressordelaysincetheendofthecabinet

probeerroris2minutes)

LED defrost

iflit,thedefrostwillberunning

LED alarm

iflit,analarmwillberunning

°C °CLED

iflit,temperaturemeasurementswillbeindegrees

Celsius(parameterP2)

°F °F LED

iflit,temperaturemeasurementswillbeindegrees

Fahrenheit(parameterP2)

5 INTERNAL DIAGNOSTICS

5.1 Internal diagnostics

CODE EXPLANATION

Pr1 Cabinetprobeerror

Solution:

•lookatparameterP0

•checktheintegrityoftheprobe

•checktheconnectionbetweencontrollerandprobe

•checkthecabinettemperature

Eects:

•thecompressorwillbeturnedon

Whentheconditionsthattriggeredthealarmarenolongerpresent,the

controller will return to normal operation.

6 TECHNICAL DATA

6.1 Technical data

Frontal bezel protection:IP65.

Connections (use copper conductors only): screw terminal blocks

(powersupply,inputandoutput).

Working temperature:from0to55°C(32to131°F),10to90%

relativehumidity(withoutcondensation).

Power supply:115VAC/230VAC,50/60Hz,3VA(approximate).

Insulation class:2.

Measure inputs:1(cabinetprobe)forPTC/NTCprobes.

Working range:from-50.0to150.0°C(-50to300°F)forPTCprobe,

from-40.0to105.0°C(-40to220°F)forNTCprobe.

Resolution:0.1°C/1°C/1°F.

Digital outputs:1relay:

•compressorrelay:16res.A@250VAC(change-

overcontact);5FLA,30LRA.

The maximum current allowed on the load is 10 A.

Bulletin 100-50-6.1 – Page 3

7 WORKING SETPOINTS and CONFIGURATION PARAMETERS

7.1 Working setpoints

7.2 Conguration parameters

Minimum Maximum U.M. PSK201 Working Setpoints

r1 r2 °C/°F 0.0 working setpoints

Parameters Minimum Maximum U.M. PSK201 Working Setpoints

SP r1 r2 °C/°F 0.0 working setpoints

Parameters Minimum Maximum U.M. PSK201 Temperature Inputs

CA1 -25.0 25.0 °C/°F 0.0 cabinet probe offset

P0 0 1 — 1

kind of probe

0 = PTC

1 = NTC

P1 0 1 — 1 display decimal point value during normal operation (Celsius mode only)

1 = YES

P2 0 1 — 0

unit of measure, temperature

0 = °C

1 = °F

Parameters Minimum Maximum U.M. PSK201 Setpoints

r0 0.1 15.0 °C/°F 2.0 working setpoint differential

r1 -99.0 r2 °C/°F -50.0 minimum working setpoint

r2 r1 99.0 °C/°F 50.0 maximum working setpoint

Parameters Minimum Maximum U.M. PSK201 Compressor Protections

C0 0 240 min 0 compressor delay after turning on the controller

C2 0 240 min 3 minimum time the compressor remains turned off

Parameters Minimum Maximum U.M. PSK201 Defrost

d0 0 99 h 8 defrost interval

0 = the defrost at intervals will never be activated

d3 0 99 min 30 defrost duration

0 = the defrost will never be activated

d4 0 1 — 0 defrost when you turn on the controller

1 = YES

d5 0 99 min 0 defrost delay when you turn on the controller (only if d4 = 1)

d6 0 1 — 1

temperature shown during the defrost

0 = cabinet temperature

1 = if, upon the activation of defrost, the cabinet temperature is below

“working setpoint + r0”, at most “working setpoint + r0”; if, upon the

activation of defrost, the cabinet temperature is above “working setpoint

+ r0”, at most the cabinet temperature to the defrost activation

Parker Hannin Corporation

Sporlan Division

206 Lange Drive, Washington, MO 63090 USA

phone 636 239 1111

fax 636 239 9130

www.sporlan.com

Bulletin 100-50-6.1 / 92012© 2012 Parker Hannin Corporation.

⚠WARNING – USER RESPONSIBILITY

Failure or improper selection or improper use of the products described herein or related items can cause death, personal injury and property damage.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by

users having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance,

maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow

the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user,

the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or

systems.

For safety information see the Safety Guide at www.parker.com/safety or call 1-800-CParker.