Spotnails XS6650 User guide

1100HicksRoad,RollingMeadows,IL60008USA

Phone:847‐259‐1620*800‐873‐2239Fax:847‐259‐9236*888‐369‐2588

www.spotnails.com

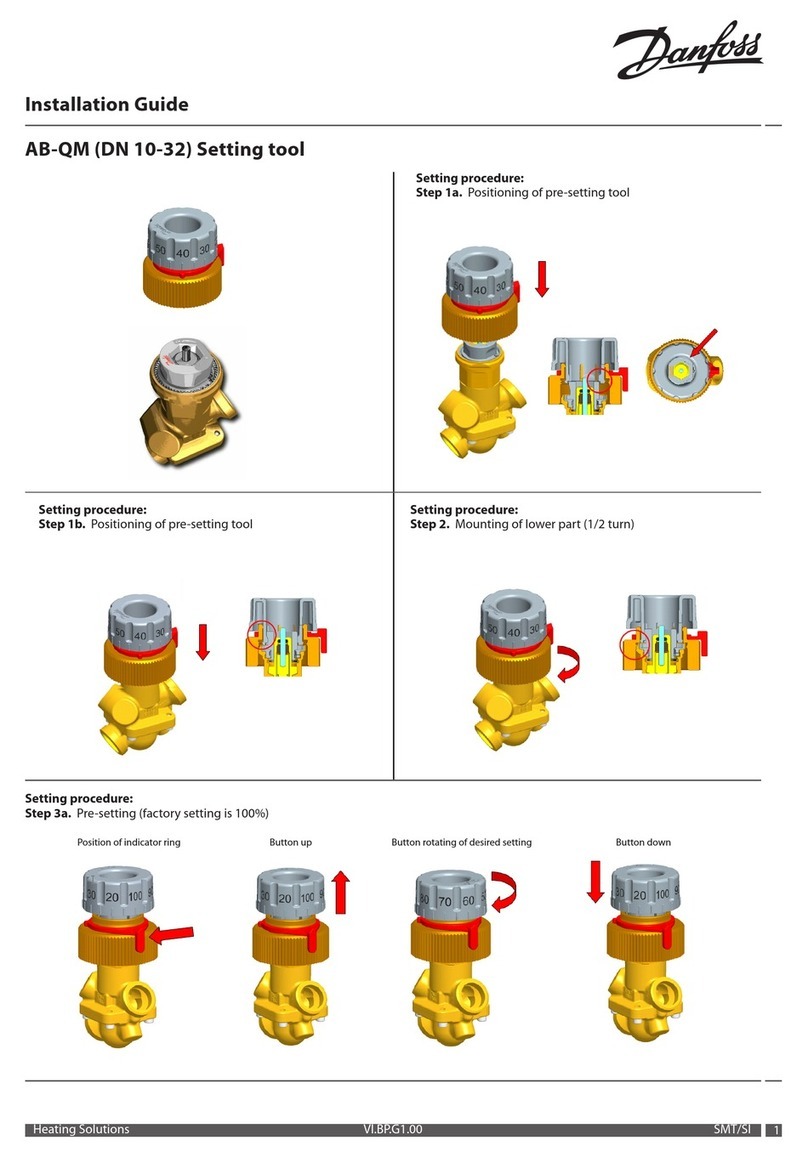

Takenocetotheschemacdiagramincludedinthismanual

Pleasecontactcustomerservicetoplaceanorderfor

replacementparts:

Operation, Maintenance

and Safety Manual

Pneumatic Tools

PLEASEREAD!Thismanualcontainsimportantinformationabout

productsafetyandshouldbereadbyalloperatorsofthistool.Contact

yourSpotnailsrepresentativeordistributorwithanyquestions

concerningthetoolanditsuse.

Spotnails

1100HicksRoad,RollingMeadows,Il60008

1‐800‐873‐2239

Distributed by: BEST MATERIALS ®

Ph: 800-474-7570, 602-272-8128 Fax: 602-272-8014

TABLEOFCONTENTS

Page

Safety Instructions ………………………………….. 3

Safety Warnings ……………………………………. 3

Employer Responsibility …………………………… 3

Operation …………………………………………… 4

Explosion Hazard ………………………………….. 5

Air Supply & Connections ………………………… 5

Loading ……………………………………………. 6

Tool Service/Maintenance ………………………… 7

Tool Troubleshooting Guideline …………………… 8

Warranty ……………………………………………. 11

NOTE: Spotnails tools are quality built and designed to provide

maximum performance when used with Spotnails fasteners.

Spotnails cannot assume responsibility for performance if our tools

are used with fasteners or accessories not meeting the same high

quality standard as Spotnails fasteners and accessories. Spotnails

cannot assume responsibility for performance of tool if tool has

been modified or repaired by non-authorized people.

Page2

WARRANTYITEMS

Warrantyforcapassembly’s,casngsandhousingcasngsisoneyear

Warrantyforbumpers,‘o’rings,driverbladesandpistonringsisnotapplicableas

theyarenormalwearingpartswhoselifeisdependentonapplicaon.

Warrantyforallotherpartsis90days.

WARRANTYCONDITIONS

Thebeginningdateinwhichthewarrantyisinforceisthedateofpurchase.

Thewarrantyisnottransferable.

Thewarrantyisvoidedbyanyofthefollowing:

A.Abuse,misuseordamagetothetool.

B.UseofpartsotherthangenuineSpotnailsparts.

C.Useoffastenersnotdesignatedforuseinthetool.

D.Modificaonstothetoolthataltertheoriginalfunconorintent

ofuseofthetoolbyanyoneotherthanSpotnails.

Spotnailsretainstherighttoreplaceorrepairanywarrantyitemsitdeemsnecessary.

Page11

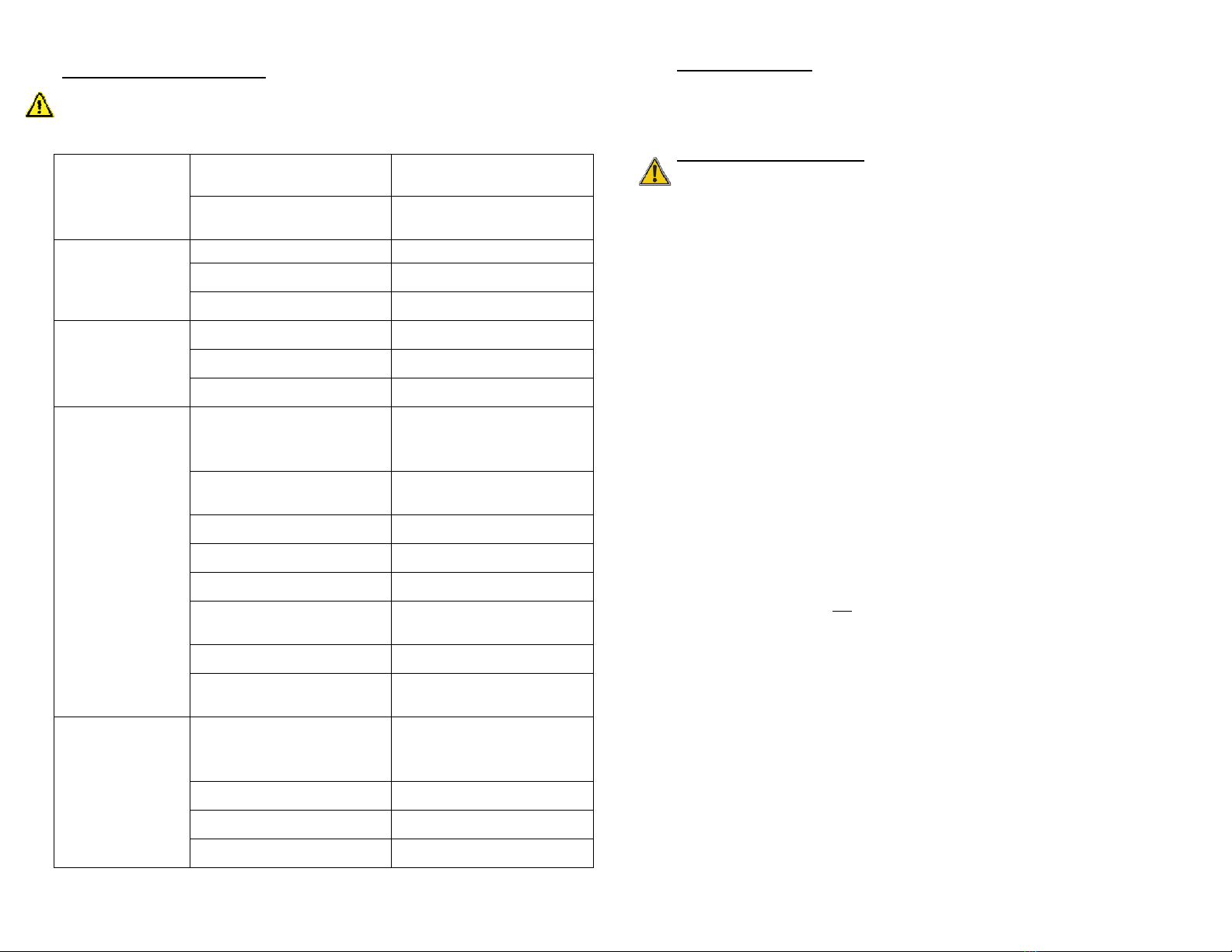

SYMPTOM CAUSEFIX

COILNAILERS

Skippingfasteners

1.Drypistonfeed1.Addoilintoairinletin

2.Feedpistono‐rings2.Replaceo‐rings

3.Checkfeedpawlto

ensurefreemovement

3.Inspectpawlandwipe

clean

4.Canisterboomhas

wrongfastenerseng

4.Adjustcanisterboom

forcorrectlengthofnails

5.Brokenwireweldnails

incanister

5.Removecoilofnailsand

replacewithnewcoil

Fastenersjamming

incanister/tool

1.Wrongfastenersbeing

used

1.Useonlyrecommended

fastenersfortool.

2.Brokenwireweldnails

incanister

2.Removecoilofnailsand

replacewithnewcoil

ALWAYSDISCONNECTTOOLFROMAIRSUPPLYANDREMOVEFASTENERS

FROMMAGAZINEPRIORTOPERFORMINGREPAIRSORCLEARINGJAMS

Page10

SAFETYINSTRUCTIONS

Beforeoperangthistool,alloperatorsshouldreadthismanualtounderstandand

followallsafetywarningsbeforeconnecng,disconnecng,loading,operang,

maintaining,changingaccessorieson,orworkingnearthetool.Failuretodosocanresult

inseriousbodilyinjuryorevendeath.

EyeProtecon

Theoperatorandallpersonnelinthegeneralareashouldweareyeproteconthat

conformstotherequirementsofANSIZ87.1.Eyewearmustprovideproteconagainst

flyingparclesbothfromthefrontandside.

HearingProtecon

Theoperatorandallpersonnelinthegeneralareashouldwearhearingproteconin

workingareawhereexposuretoloudnoiselevelmaycausehearingdamage.

HardHatProtecon

Insomeenvironments,itmaybenecessarytowearheadproteconthatconformstothe

requirementsofANSIZ789.1

SAFETYWARNINGS

Failuretofollowanyoftheinstruconsbelowcouldresultinsevere

injurytotooluserandbystandersorcausedamagetotoolandproperty.

Readandunderstandallinstruconspriortooperangtool.Stayalert,focusonyourwork

andusecommonsensewhenworkingwithtools.Donotusetoolwhilered,aerhaving

consumeddrugsoralcoholorwhileundertheinfluenceofmedicaon.Neverpointthe

tooltowardyourselforanyotherperson.

Keepbystandersandchildrenawaywhileoperangtool.Donotengageinhorseplaywhile

usingthetool.Respecttoolasaworkingimplement.Donotuseasahammerorawedge.

Donotli,pullorlowertoolbythehose.

EMPLOYERRESPONSIBILITY

Employer,toolownerandtooloperatorareresponsibleforthesafeuseofthetooland

ensuringthatthemanufacturersOPERATINGANDSAFETYINSTRUCTIONSareavailableto

operators.

Employerisresponsiblefortrainingtheoperatorinthesafeuseofthetoolandallowing

onlypersonswhohavereadandunderstandthetoolOPERATINGANDSAFETY

INSTRUCTIONStooperateand/orrepairthetool.Iftoolneedsrepair,employerisrespon‐

sibleforremovingthetoolandtaggingitforrepair.

Employerisresponsibleinselecngtheappropriatetoolactuaonsystemforthetool,

takingintoconsideraontheworkapplicaonsforwhichthetoolisused.

Employerisresponsibleforpersonalsafetywhenthetooloperatorandallotherpersonnel

intheworkareaarewearingappropriateeyeproteconequipmentandwhenrequired,

otherappropriatepersonalprotecveequipmentsuchashead,hearingandfootprotecon

equipment.

Page3

OPERATION

Donotusetoolwithmissingordamagedsafetywarninglabels

Inspectthetoolforproperoperaonpriortouse.Checkformisalignmentorbindingof

movingpartsandanyothercondionthatmayaffectthetoolsoperaon.Donot

overreach.Keepproperfoongandbalanceatallmes.

Alwaysassumethatthetoolcontainsfastenersandneverholdorcarrythetoolwitha

fingeronthetriggerorpointthetoolatyourselforanyoneelse.Keephandsandbody

awayfromfastenerdischargeareaoftool.Donotloadtoolwithfastenerswhenany

oneoftheoperangcontrolsareacvated.

Nevertamperwiththesafetydeviceorusethetoolifthesafetydeviceisnotfunconing

properly.

Donotactuatetoolunlesstoolitisplacedfirmlyagainsttheworkpiece.Drivefasteners

intoproperworksurfaceonlyandnotintootherfasteners.

DonotoperatetoolwithanypowersourceotherthanthatspecifiedintoolOPERATING

ANDSAFETYINSTRUCTIONS.Donotoperatetoolwithanyoperangpressureotherthan

thatspecifiedintoolOPERATINGANDSAFETYINSTRUCTIONS.

Alwaysselectanactuaonsystemthatisappropriatetothefastenerapplicaonandthe

trainingoftheoperator.

Useextracauonwhendrivingfastenersintoexisngwallsorotherblindareasto

preventcontactwithhiddenobjectsorpersonsonotherside(e.g.,wires,pipes,etc.)

Whenworkingclosetoanedgeofaworkpieceoratsteepangles,usecaretominimize

chipping,splingorsplinteringorfreeflightorricochetoffastenerswhichmaycause

injury.

Disconnectthetoolwhen:

Performingrepairsandclearingjams.

Elevang,loweringorotherwisemovingthetooltoanewlocaon

Toolisoutsideoftheoperator’ssupervisionorcontrol

Removingfastenersfromthemagazine

Aerdrivingafastener,toolmayspringback(recoil)causingittomoveawayfromthe

worksurface.Toreduceriskofinjuryalwaysmanagerecoilby:

Alwaysmaintaincontrolofthetool.

Allowrecoiltomovetoolawayfromworksurface.

Donotresistrecoilsuchthattoolwillbeforcedbackintotheworksurface.In

“contactactuaon”mode,ifworkpiececontactisallowedtore‐contactworksurface

beforethetriggerisreleased,anunintendeddischargeofafastenerwilloccur.

Alwayskeepfaceandbodypartsawayfromtool.

Page4

ALWAYSDISCONNECTTOOLFROMAIRSUPPLYANDREMOVEFASTENERS

FROMMAGAZINEPRIORTOPERFORMINGREPAIRSORCLEARINGJAMS

PLEASECONTACTCUSTOMERSERVICEFORTECHNICALSUPPORTIFYOU

HAVEANYOTHERPROBLEMS:800‐873‐2239

Page9

SYMPTOM CAUSEFIX

Skipping

fasteners

1.Feedpistoninneedof

lubricant

1.Lubricatefeedpiston

2.O‐ringoffeedpistonworn

out

2.Replaceo‐ring

3.Socketheadcapstuck3.Cleantheobstaclethat

blockthecap

4.Bumperwornout4.Replacebumperifworn

5.Nailsincorrectlysetin

magazine

5.Adjustthenailholderand

resetthenailsproperly

6.Driverbladeblockedor

bent

6.Cleantheobstaclethat

blockthedriverbladeor

replacethedriverblade

7.Airobstructedorair

pressureinsufficient

7.Cleantheobstacleand

adjustairunderproper

pressure

8.Pistono‐ringwornout8.Replaceo‐ring

9.Lackoflubricant9.Lubricateproperly

10.Feedspringwornout10.Replacefeedspring

11.Boltsonmagazineloose11.Tightenthebolts

12.Magazinebrokenordirty12.Replacemagazineif

worn,cleanifnecessary

13.Fastenerstooshort13.Useonlyrecommended

fasteners

Fastenerswill

notdrive

completely

intoworkpiece

1.Insufficientairpressure1.Increaseairpressure

DONOTEXCEED120PSI

2.Checkdepthadjustment

sengwhereapplicable

TROUBLESHOOTINGGUIDELINE

ALWAYSDISCONNECTTOOLFROMAIRSUPPLYANDREMOVEFASTENERSFROM

MAGAZINEPRIORTOPERFORMINGREPAIRSORCLEARINGJAMS

Page8

SYMPTOM CAUSEFIX

Triggervalve

housing/stem

leaksair

1.O‐ring/sealscutorworn1.ReplaceO‐ring/seals

2.Valvepackingwornout2.Replacetriggervalve

assembly

Caporexhaust

coverleaksair

1.Capsealwornout 1.Replacecapseal

2.Boltsoncaploose2.Tightenthebolts

3.Exhaustvalvewornout3.Replaceexhaustvalve

Noseleaksair1.Boltsonnoseloose1.Tightenthebolts

2.Bumperwornout2.Replacethebumper

3.Gasket/o‐ringcutorworn3.Replacegasket/o‐ring

Lackofpoweror

nofuncon

1.Airpressureinsufficient1.Adjustairpressure

properlybetween70‐120

PSI

2.Lackoflubricant2.Lubricatepistono‐ring,

cylinderorexhaustvalve

3.Cylinderspringbroken3.Replacecylinderspring

4.Wornheadvalveo‐rings4.Replaceo‐rings

5.Headvalvestuck5.Disassembleandlubricate

6.Blockedexhaust

6.Checkbumper,head

7.Triggerassemblyworn 7.Replacetriggerassembly

8.Drivernotfunconing

properly

8.Disassembledriverto

clean

Nailsjammed

1.Inwrongspecificaon

bentorpoorqualityofthe

nails

1.Applycorrect

specificaonandqualified

nails

2.Driverbladewornout2.Replacedriverblade

3.Boltsloose3.Tightenthebolts

4.Driverguidewornout4.Replacedriverguide

EXPLOSIONHAZARD

Donotoperatetoolinexplosiveatmospheres,suchasinthepresenceofflammableliquids,

gasesorcombusbledust.Sometoolswillcreatesparksthatcanbeanignionsourcefor

afireorexplosion.

AIRSUPPLY&CONNECTIONS

Donotuseairsupplypressuresthatexceed120PSI

(8.28baror8.4kg/mm’)

Useonlyclean,regulatedcompressedairasapowersourceforthistool.Donotusebole

gases,combusblegasesoroxygenasapowersourceforthetoolasthetoolmayexplode.

Recommendedoperangpressureis80to110p.s.i.(8.28baror8.4kg/mm’)Donotexceed

therecommendedmaximumoperangairpressureastoolwearwillbegreatlyincreased.

Theairsupplymustbecapableofmaintainingtheoperangairpressureofthetool.Pressure

dropsintheairsupplycanreducethetool’sdrivingpower.

Ifaregulatorfails,thepressuredeliveredtoatoolmustnotexceed1.5mesthemaximumair

pressureor200psig(13.8bar)whicheverisgreater.

Useapressureregulatortoallowvisualinspeconoftheairpressurebeingdeliveredtothe

tool.

AirHoses

Useairhosesthathaveratedpressuresofupto150%ofthemaximumpressurethatcanbe

generatedbythepowersource.Thesupplyhoseshouldcontainafingthatwillprovide

quickdisconnecngfromthemaleplugonthetool.

Fings

Installamalepneumacfingontotherearcapofthetool,ensuringthatthefingallows

thetooltoexhaustanyairinthetoolwhentheairhoseisdisconnected.

Donotusefingsthatwillnotallowthetooltoexhaustwhentheairsupplyisdisconnected.

Lubricaon

Useairlinelubricators.Iflubricatorsarenotavailable,orifhoselengthsexceed10feet,

add2dropsofnon‐detergent20weightoildailyintotheairinletofthetool.

Addtwodropsofnon‐detergent,20weightoilintothemalefing.

ColdWeatherStorage

Removeallfastenersfromthetool.

Neverstorethetoolincoldweatherenvironmentsforanyduraonofmeasanyfrost

oriceformaoninthetoolwillcausetoolfailures.

Forprolongedstorage,addtwodropsofoiltotheairinletofthetoolpriortodisconnuing

use.Alsocleantheexteriorofthetoolwithamildsolvent.

Page5

LOADING

Alwayshandletoolwithcare.

Visuallyinspectthetoolforwornordamagedpartspriortouse.

1.Disconnectfromairsupply

2.Installamale,pneumaticfittingintotherearcapofthetoolensuringthatthefitting

allowsthetooltoexhaustanyairinthetoolwhentheairhoseisdisconnected.

3.Addtwodropsofnon‐detergent,20‐weightoilintothemalefitting.

4.ConnecngtheAirHose

a.Useaquickconnectfingtothetoolandchecktheairpressurereadingonthe

regulatortoensureitdoesnotexceed120p.s.i.Checkthetoolforanyairleaks.

b.Placethetool,emptyoffasteners,inoperangposiononascrapworkpiece.

Fullydepressthesafetyandpullthetriggertoverifythatthetoolcycles.

5.Usingthefollowingcycleguidelines,cyclethetoolseveralmestocheckforproper

tooloperaon.

BEFOREUSINGVERIFYTHETRIGGERSETTINGTOENSUREITISSET

FORDESIREDTRIGGERACTUATION

RedTrigger–Single‐sequenalactuaon–RestricveInstalled

Thetoolwillnotcycleasecondmeunlessboththetriggerandsafetyyokeare

fullyreleasedandthendepressedagain.

Black–ContactActuaon–BumpFireIncluded

Thetoolwillnotcycleasecondmeunlessthetriggerand/orsafetyyokearefully

releasedandthendepressedagain.

Blue–SelecveActuaon‐InstantConversionBump/Restricve

Thistriggerallowsforoperatortoselecteithersingle‐sequenalactuaonor

contactactuaon.Seeaboveforexplanaonbeforeusing.

6.Openthemagazineorslidethepushertothelockedpositionandloadthe

fastenersapprovedfortheuseinthetool.

7.Cyclethetoolonascrappiecetoevaluatethedepthofthepenetrationbythe

fastenerintotheworkpiece.

8.AdjustableDepthControl

Toadjustthedepthofpenetration,disconnecttheairhose,adjustthedepthcontrol

knoborscrew,connecttheairhoseandcyclethetoolonascrapworkpieceto

evaluatetheadjustment.

Repeatasneededtosetthecorrectdepth,usingtheminimumamountofair

pressuretodrivethefastener.

Page6

TOOLSERVICE/MAINTENANCE

Cleanandinspectyourtooleverymeyouuseit

Toolserviceshallberepairedorequippedonlywithpartsoraccessoriesthatare

suppliedorrecommendedbyAuthorizedSpotnailsrepairpersonnel.Serviceorrepairsby

unqualifiedpersonnelmayresultinariskofinjury.

Pleaserefertotheschemacdrawingbeforestarnganyrepairs.

Toolshouldbeinspectedperiodicallyandreplaceanywornorbrokenpartstokeepthe

tooloperangsafelyandefficiently.

Tightenallscrews.Loosescrewscanresultinunsafeoperaonoftool.

Withtooldisconnectedfromtheairsupply,regularlyinspectthesafety,thetriggerand

thespringforfreeunhinderedmovement.Neveruseatoolthatrequiresservicing.

Wheneverrepairsorreplacementofpartsinsidethebodyoccur,checkthepiston‘o’ring

foradequategreaselubricaon.

Periodicallycleanthemagazineandnoseofthetoolwithamild,non‐flammablesolvent.

Disconnecttoolfrompowersourcewhennotinuse,loweringormovingtooltoanew

locaon,toolisoutsideoftheoperator’ssupervisionorcontrolandremovingfasteners

fromthemagazine.

Wrienapprovalofthetoolmanufacturermustbeobtainedpriortomakingany

modificaonstothetool.

Page7

Distributed by: BEST MATERIALS ®

Ph: 800-474-7570, 602-272-8128 Fax: 602-272-8014

Table of contents