Erbauer ERB709BTE User manual

ERB709BTE Original Instructions

ERBAUER 315MM THICKNESSER ERB709BTE

SAFETY AND OPERATING MANUAL

WARRANTY

YEARS

ERBAUER 315MM THICKNESSER ERB709BTE

ERBAUER 315MM THICKNESSER ERB709BTE

GUARANTEE

This product carries a guarantee of 24 months. If your product develops

a fault within this period, you should in the first instance contact the retailer where

the item was purchased.

This guarantee specifically excludes losses caused due to:

- Fair wear and tear

- Misuse or abuse

- Lack of routine maintenance

- Failure of consumable items (such as batteries)

- Accidental damage

- Cosmetic damage

- Failure to follow manufacturer’s guidelines

- Loss of use of the goods

This guarantee does not affect your statutory rights. This guarantee is only valid

in the UK.

For further technical advice, spare parts or repair service (outside of guarantee)

please contact your retailer quoting your Erbauer model number

Congratulations on your purchase of a quality power tool from Erbauer (UK)

Ltd. This product should give you reliable service but for your peace of mind

this power tool does carries a 24-month guarantee, the terms of

which are detailed below.

If this product develops a fault within the guarantee period contact your

retailer.

Please retain this handbook in case you need to refer to safety, care

or guarantee information in the future.

GENERAL SAFETY INSTRUCTIONS

WARNING! To ensure safe operation when using your Belt & Disc Sander, make

sure you follow basic safety principles to reduce risk of personal injury, electric

shock and fire. Please read the following instructions prior to operating this product

and keep for future use.

SAVE THESE INSTRUCTIONS

1. Keep the work area clean.

- Cluttered and dark areas invite accidents.

2. Consider work area environment.

- Do not expose power tools to rain. Do not use power tools in damp or

wet locations. Keep the work area well lit. Do not use tools in the presence of

flammable liquids or gases.

3. Guard against electric shock.

- Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators,

ranges, refrigerators).

4. Keep children away.

- Do not let persons, especially children, not involved in the work touch the tool

or the extension cord and keep them away from the work area.

5. Store idle tools.

- When not in use, tools should be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool.

- It will do the job better and safer at the rate for which it was intended.

7. Use the right tool.

- Do not force small tools to do the job of a heavy-duty tool. Do not use tools for

purposes not intended, for example, do not use circular saws to cut tree limbs

or logs.

8. Dress properly.

- Do not wear loose clothing or jewellery, they can be caught in moving parts.

Non-skid footwear are recommended when working outdoors. Wear protective

hair covering to contain long hair.

9. Use protective equipment.

- Use safety glasses. Use face or dust mask if working operations create dust.

10. Connect dust extraction equipment.

- If the tool is provided for the connection of dust extraction and collecting

equipment, ensure these are connected and properly used.

11. Do not abuse the cord.

- Never yank the tool to disconnect it from the socket. Keep the cord away from

heat, oil and sharp edges.

ERBAUER 315MM THICKNESSER ERB709BTE

ERBAUER 315MM THICKNESSER ERB709BTE

12. Secure work.

- Where possible use clamps or a vice to hold the work. It is safer than using your

hand.

13. Do not overreach.

- Keep proper footing and balance at all times.

14. Maintain tool with care.

- Keep cutting tools sharp and clean for better and safer performance. Follow

instructions for lubrication and changing accessories. Inspect tool cord periodically

and if damaged have them replaced by an authorised service facility. Inspect

extension cords periodically and replace if damaged. Keep handles dry, clean and

free of oil or grease.

15. Disconnect tools.

- When not in use, before servicing and when changing accessories such as blades,

bits and cutters, disconnect tools from the power supply.

16. Remove adjusting keys and wrenches.

- From the habit of checking to see that keys and adjusting wrenches are removed

from the tool before turning it on.

17. Avoid unintentional starting.

- Ensure switch is in the “off” when plugging in.

18. Use outdoor extension leads.

- When tool is used outdoors, use only extension cords intended for outdoor use

and so marked.

19. Stay alert.

- Watch what you are doing. Use common sense. Do not operate tool when you are

tired.

20. Check damaged parts.

- Before further use of the tool, it should be carefully checked to determine that it

will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorised service centre unless

otherwise indicated in this instruction manual. Have defective switches replaced

by an authorised service facility. Do not use the tool if the switch dose not turn it

on and off.

21. Warning.

- The using of any accessory or attachment other than those recommended in this

instruction manual may present a risk of personal injury.

22. Have your tools repaired by qualified person.

- This electrical tool complies with the relevant safety requirements. Repairs should

only be carried out by qualified persons using original spare parts, otherwise this

may result in considerable danger to the user.

ERBAUER 315MM THICKNESSER ERB709BTE

HEALTH ADVICE

WARNING! When drilling, sanding, sawing or grinding, dust particles will be

produced. In some instances, depending on the materials you are working with,

this dust can be particularly harmful to you (e.g. lead from old gloss paint).

You are advised to consider the risks associated with the materials you are working

with and to reduce the risk of exposure. You should:

- Work in a well-ventilated area.

- Work with approved safety equipment, such as those dust masks that are specially

designed to filter microscopic particles.

ADDITIONAL SAFETY INSTRUCTIONS FOR YOUR TOOLS

- Always wear eye protection when operating any machine.

- Before starting up, check to make sure all holding screws are tight.

- Always stop motor and disconnect from power source before making any adjustments.

- Be sure all guards are in place before operating equipment.

- Read operator’s manual thoroughly and familiarize yourself with machine before

attempting to operate.

- Do not force work through the machine. Allow the planer to apply the proper feed

rate.

- Check feed rollers occasionally to be sure chips and sawdust are not lodged between

any components. If rollers are not seated firmly, the feed rolls will not hold stock firmly

against the bed, allowing kickback.

- Only plane wood boards.

- Use sound timber, with no loose knots and as few tight knots as possible.

- Never stand directly in line with either the infeed or outfeed sides. Always stand off

to one side of the machine.

- Make sure the workpiece is free of from nails, screws stones and other foreign objects

which could damage the blades.

- Make sure the blades are attached correctly as described in the instructions.

- Use caution when handling the blades and cutterhead assembly. The blades are sharp

and can easily cut your hand.

- Allow the cutterhead to reach full speed before using.

- Never use machine without correctly mounted and adjusted protective covers.

- Never use blunt planing irons as this increases risk of kickback.

- The parts of the cutting steel not in use should be covered.

- When planing shorter pieces a pusher should be used.

- When planing narrow pieces further precautions need to be taken to insure safe work,

such as appliances for pushing the work piece from above and spring loaded

protection.

- Planes may not be used for folding, milling, making marks or pegs.

ERBAUER 315MM THICKNESSER ERB709BTE

SYMBOLS

On the product, the rating label and within these instructions you will find among

others the following symbols and abbreviations.

Familiarise yourself with them to reduce hazards like personal injuries and damage to

property.

V~

W

m/min

min-1

yyWxx

Volt

Input power

Metres per minute

Per minute

Manufacturing date code; year of manufacturing (20yy) and week of

manufacturing (Wxx);

Hz

kg

dB (A)

Hertz

Kilogram

Decibel (A-rated)

Caution / Warning.

Read the instruction manual.

Wear gloves.

Keep hands away from

cutter head.

Wear hearing protection.

Wear eye protection.

Wear respiratory protection.

The product complies with the applicable European directives and an evaluation

method of conformity for these directives was done.

Switch the product off and disconnect it from the power supply before assembly,

cleaning, adjustments, maintenance, storage and transportation.

WEEE symbol. Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check with your Local

Authority or local store for recycling advice.

ERBAUER 315MM THICKNESSER ERB709BTE

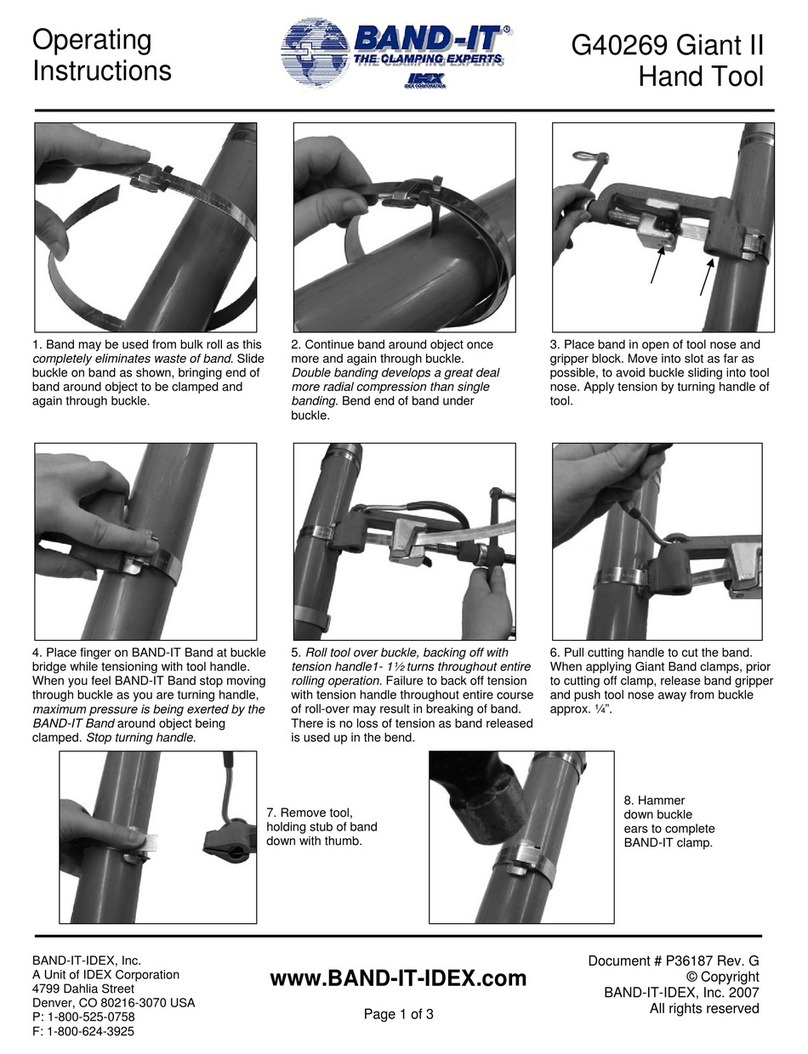

1. Support infeed roller

2. In-feed extension table

3. Table

4. Depth scale

5. Carbon brush cap

6. Cutter head adjustment handle

7. Storage compartment

8. Overload switch

9. ON/OFF switch

10. Roller knob

11. Dust port

12. Out-feed extension table

13. Support outfeed roller

14. Mounting hole

15. Dust extraction adapter

16. Carrying handle

7

11

16

8

10

9

12

13

6

4

5

3

2

1

15

14

ERBAUER 315MM THICKNESSER ERB709BTE

Input voltage

Power input

Min. cutting length

Max. cutting width

Max. cutting depth

Range of cutting depth

Feeding speed

Blade speed

Weight

230-240V~50Hz

1500W

127mm

315mm

2.5mm

5-153mm

8m/min

10000min-1

33kg

CARACTERISTIQUES TECHNIQUES

99.6dB(A)

112.6dB(A)

3dB(A)

A weighted sound pressure LpA

A weighted sound pressure LWA

Uncertainty

The sound intensity level for the operator may exceed 85dB(A) and sound protection

measures are necessary.

IMPORTANT NOTE

Remove the mains plug from socket before carrying out any adjustment or servicing.

Ensure your mains supply voltage is the same as your tool rating plate voltage.

NOISE

ERBAUER 315MM THICKNESSER ERB709BTE

YOU WILL NEED

(items not supplied)

14mm Open-end wrench

or adjustment wrench

Phillips screwdriver

(items supplied)

4mm, 5mm and 6mm Hex key (3pcs)

Knife alignment gauge (1pc)

8mm Open-end wrench (1pc)

UNPACKING

- Unpack all parts and lay them on a flat, stable surface.

- Remove all packing materials and shipping devices if applicable. Carefully lift the

machine from the the carton by the carry handles (16) on each side of the side cover

and place it on a level work surface.

WARNING! This tool is heavy.To avoid back injury, lift it while bending your legs,

not your back, and ask for assistance when need. The in-feed and out-feed

extension tables (2, 12) are attached to the thicknesser. Shipped in a folded, “upright”

position, the extension table must be in the “down” position before planing can begin.

- Make sure the delivery contents are complete and free of any damage. If you find that

parts are missing or show damage do not use the product but contact your dealer.

Using an incomplete or damaged product represents a hazard to people and property.

- Ensure that you have all the accessories and tools needed for assembly and operation.

This also includes suitable personal protective equipment.

The thicknesser is supplied with following accessories:

Thicknesser assembly

[17] x 01

Hexagon bolt

M6 x 20

[19] x 01

Hexagon bolt

M8 x 45

[21] x 04

Spring washer 6

[20] x 01

6mm Hex key

[22] x 01

5mm Hex key

[23] x 01

4mm Hex key

[24] x 01 Knife alignment gauge

[25] x 01

8mm Open-end wrench

[26] x 01

Cutter head

adjustment handle

[6] x 01

Dust port

[11] x 01

Dust extraction adapter

[15] x 01

Rubber foot

[18] x 04

ASSEMBLY INSTRUCTION

ERBAUER 315MM THICKNESSER ERB709BTE

WARNING! Do not connect to power supply

until assembly is complete. Failure to comply

could result in accidental starting and possible

serious injury.

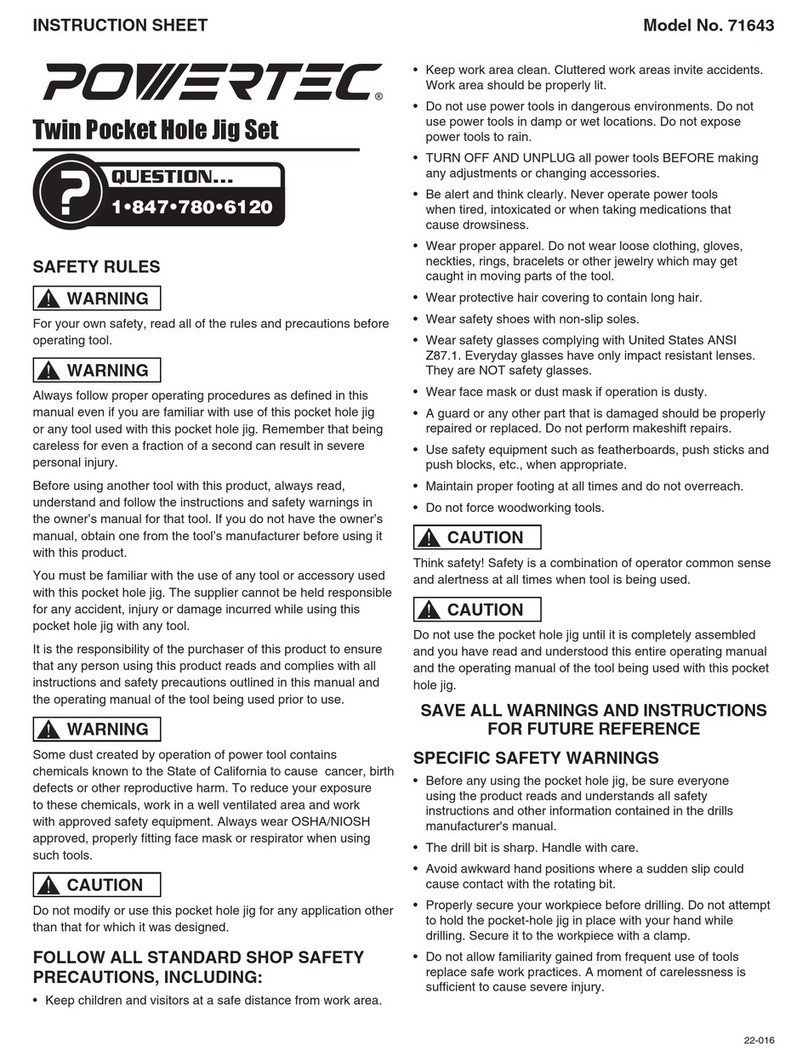

SECURE TOOL TO WORKBENCH (Fig. 1)

The thicknesser features pre-drilled mounting holes

(14) on the base that allow mounting the tool to

the workbench.

If you choose to permanently mount your planer

to the workbench, use the four pre-drilled mounting

holes on the base.

- Drill four holes all the way through the workbench.

- Lift the thicknesser base and attach a rubber foot

(18) to each corner of the thicknesser assembly

(17). Align the hole in each foot with the mounting

hole (14) on the thicknesser assembly.

- Carefully place the thicknesser assembly on the

top of the workbench and align mounting holes

on the base with the holes on the workbench.

- Insert one hexagon M8 x 45 (21) in each of four

holes and fasten with flat washers (27) (not included),

spring washers (28) (not included) and nuts (29)

(not included).

- Tighten the hexagon bolts with a 14mm open-end

wrench or adjustment wrenche (not included) and

6mm hex key (22).

You can also mount the thicknesser directly to the

workbench using the lag screws (not included).

INSTALLING THE CUTTER HEAD ADJUSTMENT

HANDLE (Fig. 2)

- Attach the cutter head adjustment handle (6) to

the thicknesser and fasten with a hexagon bolt

M6 x 20 (19) and a spring washer 6 (20).

- Tighten the hexagon bolt using 5mm hex key (23).

Fig. 1

18

21

14

27

29

28

19

20

6

17

Fig. 2

ERBAUER 315MM THICKNESSER ERB709BTE

INTALLING THE DUST EXTRACTION ADAPTER

AND DUST PORT (Fig. 3-5)

- Using the 4mm hex key (24), loosen three hexagon

bolts M5 x 12 (29) located at the rear of the cutter

head assembly and move the flat washers 5 (30)

away from the surface so that they are next to the

head of the bolts.

- Align three holes (31) on the top of dust extraction

adapter (15) with the tabs (32) on the top of rear

of the cutter head assembly. And at the same

time align the three notches (33) on the dust

extraction adapter with the three hexagon bolts.

- Push the extraction adapter down until the tabs

in place.

-Tighten three hexagone bolts that secure the dust

extraction to the rear of the cutter head assembly.

- Attach the dust port (11) to the dust extraction

adapter (15).

To prevent sawdust bulidup, for best result, attach

a vacuum hose (not included) to the dust port. Do

NOT operate the saw with hose in place unless the

vacuum is turned on.

WARNING! Dust extraction adapter must

be fitted and the thicknesser must regularly

check for dust build up and cleaned frequently,

otherwise there is a risk of heat built up and

potential fire.

Fig. 3

29 30

32

Fig. 4

30

31

29

33

Fig. 5

11

15

ERBAUER 315MM THICKNESSER ERB709BTE

GETTING STARTED

- With the ON/OFF switch in the OFF position, lower

the cutter head to about 25.4 mm from the table.

Set the ON/OFF switch to the ON position. Allow

the thicknesser to reach its full speed.

Fig. 6

OPERATION INSTRUCTION

BEFORE YOUR START

This thicknesser finishes rough-cut lumber to size

and planes soft and hardwoods up to 153 mm thick

and 315 mm wide.

Any piece of wood will have a natural tendency to

bow and warp, even if it was initially milled perfectly

straight. This planer features a powerful 1500W

motor with overload protection and high carbon

steel knives to handle such tough cutting jobs.

Intended for use by the Do-It-Yourself enthusiast,

for wood working projects at home and in the

workshop.

THIS TOOL IS INTENDED FOR

- Surface planing (smoothing a rough lumber)

-Thickness planing (reducing the thickness of a

board)

SWITCH ON/OFF (Fig. 6)

- Open the switch guard (34) of the ON/OFF switch.

- To start the machine, press the ON/OFF switch (9)

to ON position (“I”).

- To stop, press the switch to OFF position (“O”).

- Close the switch guard.

CIRCUIT OVERLOAD SWITCH (Fig. 6)

This tool is equipped with an overload circuit

protection (35). If an overload occurs, the circuit

overload switch (35) cuts the power supply and

pops out. Should this occur:

- Set the On/Off switch to the Off position.

- Unplug the power cord from the power source

and wait several minutes until the tool cools

down.

- Remove the workpiece, if present.

- Plug in the power cord again.

- Press the circuit overload switch (35) and resume

operation.

34

35

9

ERBAUER 315MM THICKNESSER ERB709BTE

- If any excessive vibration is detected, switch the

thicknesser off and unplug it from the power

source. Check for any loose parts.Tighten or make

adjustments if necessary. Do not operate the

thicknesser until it is running smoothly and

without any vibrations.

CAUTION! Before starting, check for loose

fasteners or hardware. Make sure the cutter

head knife guard is securely mounted and the cutter

head rotates freely.

STOCK

Thickness

Width

Length

Depth of cut

MINIMUM

5mm

19mm

203mm

MAXIMUM

153mm

315mm

Unlimited

2.5mm

PLANING SPECIFICATIONS

- Do not plane lumber or wood that is contaminated

with metal, paint, dirt, water, or moisture from

tree sap, or wood that is severely bowed, warped

or twisted.

CAUTION! Plane selected lumber or wood

that has a minimum number of tight knots.

Wood with too many knots or loose knots has a

tendency to cause premature wear on the cutter

head knife, and increases the risk of unsafe

operation.

- Practise on a piece of scrap material first in order

to become familiar with the type of wood you are

planing. Take into consideration the hardness,

grain pattern, dryness and straightness of the

lumber or wood.

WORKPIECE LIMITATIONS

PLANING TIPS

-The thicknesser automatically feeds the workpiece

into and out of the cutter head. Do not force the

thicknesser to work faster than the designated

cutting speed. Damage to the workpiece and

thicknesser can result.

-The thicknesser works best if at least one side of

the workpiece is flat. If both sides are rough, the

ERBAUER 315MM THICKNESSER ERB709BTE

Fig. 7

thicknesser should be used to create one flat side

first. Plane the opposite side after one side is flat

and smooth.

- Planing should be carried out in steps in order to

achieve the final planing thickness. If the thickness

is to be reduced by 6 mm, then 3 mm should be

removed from each side. This also allows the

planed workpiece to dry and cure uniformly.

- Measure the thickest part of the workpiece that is

being planed. Make light cuts on both sides.

- Do not attempt to make a deep cut or a cut that

is deeper than 2.5 mm. Make several passes until

the desired thickness is achieved. Light cuts create

a finer finish.

- Avoid snipe or depressions made by the cutter

head knives at the beginning or end of the

workpiece by supporting both ends evenly. Keep

the board level during the entire planing operation.

-The knives on the thicknesser will not wear evenly

if the wood is fed through the same spot on the

table every time. Feed the wood through the

thicknesser at different spots on the table when

possible to help eliminate uneven wear of the

knives.

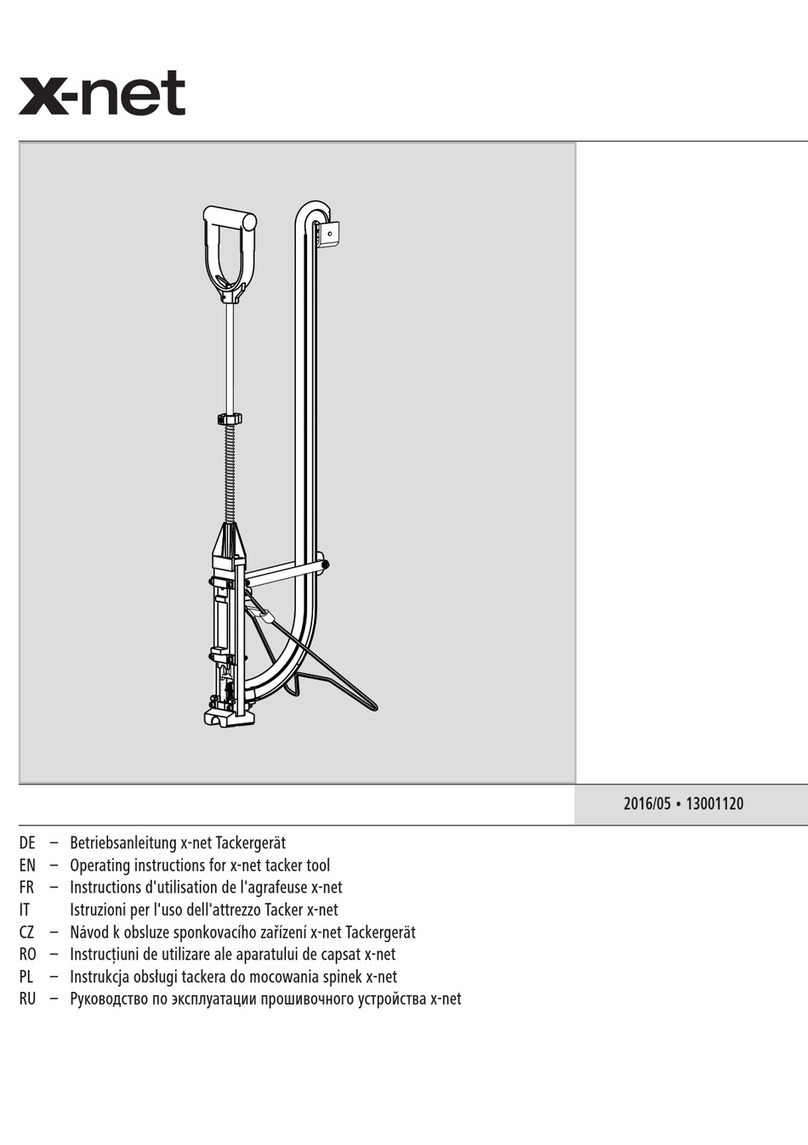

FEEDING THE WORKPIECE (Fig. 7)

- Always feed the workpiece with the grain, if

possible. If the workpiece must be fed against the

grain, make very light cuts.

- Hold the workpiece down firmly along the

workpiece guides and allow the thicknesser to

automatically feed the workpiece into the cutter

head.

WORKPIECE SUPPORT (Fig. 8)

Proper workpiece support prevents sagging or snipe

in the workpiece during planing. Make sure the

workpiece is supported along its entire length. If

necessary, extend the length of the in-feed/out-feed

extension tables (2, 12) in order to support the

workpiece:

- Loosen the in-feed/out-feed roller knobs (10).

- Pull the support infeed roller (1)/support outfeed

roller (13) out to the desired length.

Cutting direction

Planing against the grain

Planing with the grain

7

6

5

4

3

2

1

00

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

in/po mm

UP

DOWN

3/64

1.2

1/16

1.6

1/64

0.4

1/32

0.8

in

mm

0

ERBAUER 315MM THICKNESSER ERB709BTE

-Tighten the roller knobs (10) to secure the in-feed/

out-feed table extensions.

IMPORTANT! If an additional support is

needed for the workpiece, place supports on

both ends of the thicknesser, or install the thicknesser

at a depth where the planing surface is level with

the workbench. The supports must be at the same

height as the in-feed/out-feed extension tables

(2, 12), or the depth of installation must be such

that the workbench is at the same height as the

thicknesser.

SETTING THE PLANING DEPTH (Fig. 9)

Measure the workpiece at its thickest point. Use the

depth scale (4) at the in-feed side of the planer to

approximate the starting point of the first pass.The

first attempt at planing is intended to brush the

surface.

It is good practice to measure the workpiece after

every planing operation.

- Set the On/Off switch to the On position.

- Slowly guide the workpiece (36) along the

workpiece guides into the planer. After the cutter

head contacts the workpiece, pull the workpiece

out and raise the cutter head using the cutter

head adjustment handle (6).

- Repeat step 2 in 3 mm of a turn or less in order

to lower the cutter head until it just brushes the

surface of the workpiece. This establishes the

starting point for the next cutting pass.

- Use the adjustment scale to fine-tune the depth

of planing. One revolution of the cutter head

adjustment handle (6) moves the cutter head up

or down 1.6 mm.

IMPORTANT! Planing should be done in

steps in order to achieve the final planing

thickness. If the thickness is to be reduced by

6 mm, then 3 mm should be removed from each

side. Measure the workpiece after every planing

operation.

Fig. 9

Adjustment scale

Fig. 8

4

6

1

2

13

10

12

36

ERBAUER 315MM THICKNESSER ERB709BTE

WARNING! To ensure safety and reliability,

all repairs should be performed by a qualified.

service technician.

WARNING! When servicing, use only

identical replacement parts. The use of any

other parts may create a hazard or cause damage

to the tool.

WARNING! TO AVOID INJURY FROM

UNEXPECTED STARTING OR ELECTRIC

SHOCK unplug the tool from the power supply

before cleaning or performing any maintenance.

GENERAL MAINTENANCE

Periodic maintenance allows for long life and

trouble-free operation. Cleaning, lubrication and

maintenance schedules should be maintained. As

a common preventative maintenance practice,

follow the recommended steps below:

- Clean the tool to allow smooth functioning after

each use.The tool may be cleaned most effectively

with compressed dry air. Always wear safety

goggles when cleaning tools with compressed air.

- Ventilation openings must be kept clean and free

of foreign matter. Do not attempt to clean by

inserting pointed objects through openings.

- Check all electrical wires and connections for

damage.

- Keep motor air openings free of oil, grease and

sawdust or wood-chips.

- Check if all moving parts are well lubricated with

silicone or a light oil spray, especially after lengthy

exposure to damp and/or dirty conditions.

- Check for loose screws, alignment of moving parts

or binding of moving parts, breakage of parts,

mounting or any other condition that my affect

the operation.

- Inspect the feed rollers after each use. Resin and

tar may build up. Use clean cloth to clean the

rollers.

- Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from

various types of commercial solvents and may be

damaged by their use. Use clean cloth to remove

dirt, carbon dust, etc.

MAINTENANCE

Cutter head side view

ERBAUER 315MM THICKNESSER ERB709BTE

WARNING! If the knives are to be removed

for sharpening or replacement, extreme care

should be taken, as the knives are very sharp.

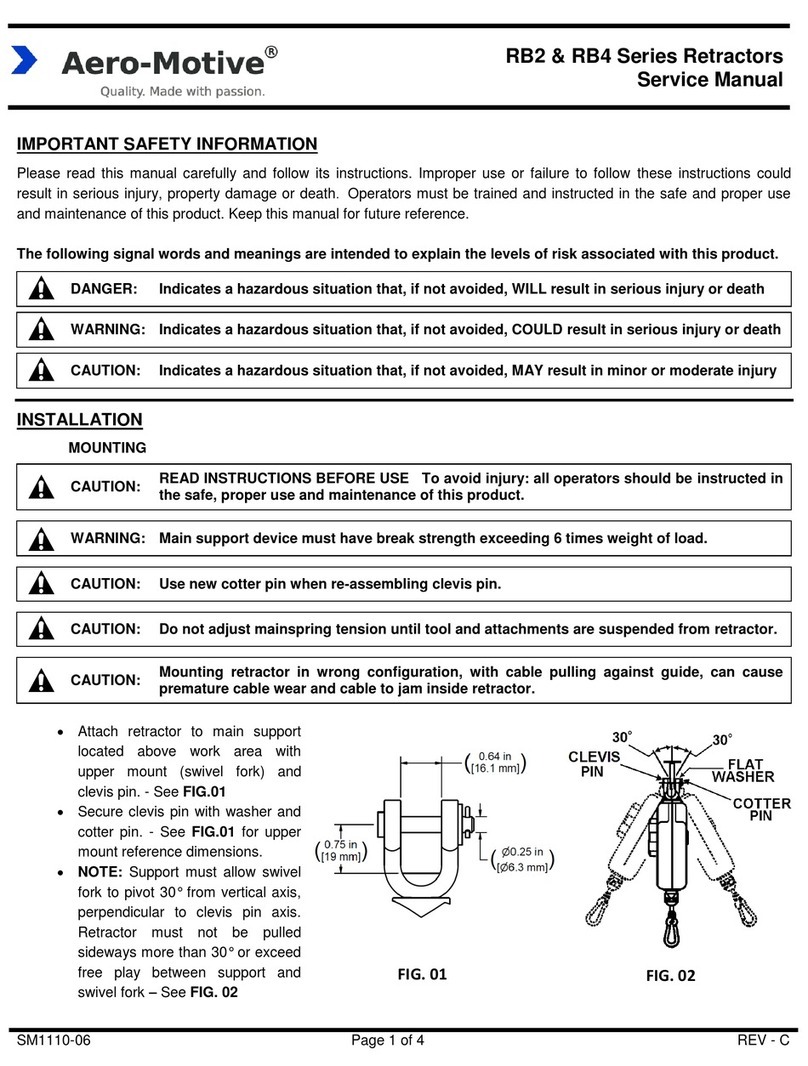

REPLACING CUTTER HEAD KNIVES AND

CLEANING (Fig. 10-15)

This tool only use the knife size: 319 x 18.2 x 3.2mm.

CUTTER HEAD GUARD (Fig. 10-11)

- Raise the cutter head to the highest position using

the cutter head adjustment handle (6).

- Remove the cutter head adjustment handle (6) by

using 5mm hex key (23) to loosen the hexagon

bolt M6 x 20 (19) and the spring washer 6 (20).

- Loosen the four hexagon bolts (39) using the 6mm

hex key (22). Remove the top cover (37) and side

covers (38).

- Remove the dust extraction adapter (15) in reverse

order from what is described in the section

“INSTALLINGTHE DUST EXTRACTION ADAPTER

AND DUST PORT”.

- Use a clean cloth to wipe away any build-up of

debris from underneath the cover and the guard.

- Use penetrating oil (not included) to clean all

moving parts and the depth adjustment screws.

Apply a light coat of medium weight oil after

clean-up. Apply a light coat of paste wax to the

table, in-feed and out-feed extension table surfaces.

Do not use too much wax; it can hinder the

planing and stain the workpiece.

KNIFE REMOVAL (Fig. 12-13)

- Rotate the cutter head at the pulley so that one

knife is facing up.

- Loosen the knife anchor screws by turning them

in a clockwise direction.

- Carefully remove the knife.

Fig. 12

Knife anchor

screw

Knife anchor

screw

Knife

anchor

Knife

Fig. 13

Fig. 10

39

620

37

38

19

Fig. 11

15

ERBAUER 315MM THICKNESSER ERB709BTE

KNIFE INSTALLATION (Fig. 14)

IMPORTANT: Clean the knives regularly.

Gum and pitch collects on knives, and causes

excess friction during operation.The knives may

overheat and wear. Remove the knives to clean and

use a gum/pitch remover available in specialized

retail shops.

- Carefully place the knife back in the cutter head.

Make sure that the spring is in place.

- Place the knife alignment gauge (25) on the cutter

head, with the lobe making contact with the edge

of the knife.

- Apply light pressure on the knife alignment gauge

and make sure the knife and knife anchor are

centered in the cutter head.

IMPORTANT: If the knives and anchors are

not centred in the cutter head, they will rub

against the cutter head carrier and the planer may

get damaged.

- While applying light pressure to the knife alignment

gauge, tighten the anchor screws by turning them

in a counter-clockwise direction, alternating from

one side to the other, starting from the outside

and working toward the inside.

- Reinstall the top and side covers, and make sure

the depth scale (on one of the side covers) is facing

the front.

- Clean the exterior of the planer with a clean, dry

cloth. Apply a light coat of paste wax in order to

ease cleaning and reduce dust build-up.

SHARPENING KNIVES (Fig. 15)

The knives can be sharpened individually with a

whetstone. Make sure the whetstone is not worn

in the centre - it must be flat. Make sure to remove

any burrs on the flat side. If the knives are nicked,

they must be replaced or reground. Knives can be

reground several times, until they become 14mm

wide. Have your knives reground by an experienced

person.

Fig. 14

Knife

Knife

anchor

screw

Knife

anchor

Spring

Fig. 15

25

Green &Yellow E(Earht)

Blue

(neutral)

N

13amp fuse

approved to

BS1362

Brown

(live)

L

Cable grip

Outer sleeve

13amp

ERBAUER 315MM THICKNESSER ERB709BTE

CARBON BRUSH REPLACEMENT (Fig. 16)

IMPORTANT! To maintain peak efficiency

of the motor, we recommend checking the

brushes after each 50 hours of use. Replace both

carbon brushes when either has less than 2mm

of carbon remaining, or if the spring or wire

is damaged or burned. Make sure to replace both

brushes at the same time even if only one is

damaged.

To inspect or replace the carbon brushes:

- Remove the brush cap (5) on the motor using a

wide, Phillips screwdriver (not included).

- Carefully pull out the spring-loaded brush

assemblies (40). Repeat for the opposite side of

the motor (behind the dust extraction adapter).

- Insert new brush assemblies into guide channels,

with the carbon part going in first. Make sure to

fit the two metal “ears” into their slots in the

channel.

- Remember to replace both end caps after inspecting

or the servicing brushes.Tighten the brush cap

but do not over tighten.

Fig. 17

Brush opening

Fig. 16

PLUG REPLACEMENT (Fig. 17)

If you need to replace the fitted plug then follow

the instructions below.

IMPORTANT: The wires in the mains lead

are coloured in accordance with the following

code:

Blue – Neutral

Brown – Live

Green/Yellow – Earth

As the colours of the wires in the mains lead

of this appliance may not correspond with the

coloured markings identifying the terminals in

your plug, proceed as follows.The wire, which is

coloured blue, must be connected to the terminal

which is marked with an N or coloured black.The

wire, which is coloured brown, must be connected

to the terminal which is marked with an L or

coloured red.The wire, which is coloured green/

yellow, must be connected to the remaining

terminal which is marked with an E or .

WARNING: Never connect live or neutral

wires to the earth terminal of the plug. Only

5

5

40

Table of contents

Other Erbauer Tools manuals

Popular Tools manuals by other brands

Blue Diamond

Blue Diamond EXTREME DUTY Series Operator's manual

Thomas&Betts

Thomas&Betts Stakon COMFORT CRIMP ERG4005 Instructions for use

FLORABEST

FLORABEST 280270 instructions

x-net

x-net C12 operating instructions

Aero-motive

Aero-motive RB2 Series Service manual

OEM Tools

OEM Tools 27407 Operating instructions and parts manual