Sprague SM-3 User manual

Operation and

Maintenance Man u al

MODEL SM-3

AIR-OPERATED LIQUID MINIPUMP

10195 Brecksville Road

Brecksville, OH 44141 USA

Telephone: 440-838-7690 • Fax: 440-838-7513

www.cwfc.com

ISSUED MARCH 2004

Sprague Products

Division of Cur

tiss-

Wr

ight Flow Control Corporation

Sprague Products

®

Sprague Products

TABLE OF CONTENTS

Page

Method of Operation

...............................................................

...............................................................

..............................

2

Safety

...............................................................

...............................................................

.......................................................

3

Installation

...............................................................

...............................................................

...............................................

3

Operation

...............................................................

...............................................................

.................................................

4

Maintenance

...............................................................

...............................................................

.............................................

4

Dimensional Data

...............................................................

...............................................................

.....................................

5

Troubleshooting

...............................................................

...............................................................

.......................................

6

User Con gured Operation Modes

...............................................................

...............................................................

...........

7

Disassembly Procedure

...............................................................

...............................................................

.....................

8-11

Reassembly Procedure

...............................................................

...............................................................

....................

12-14

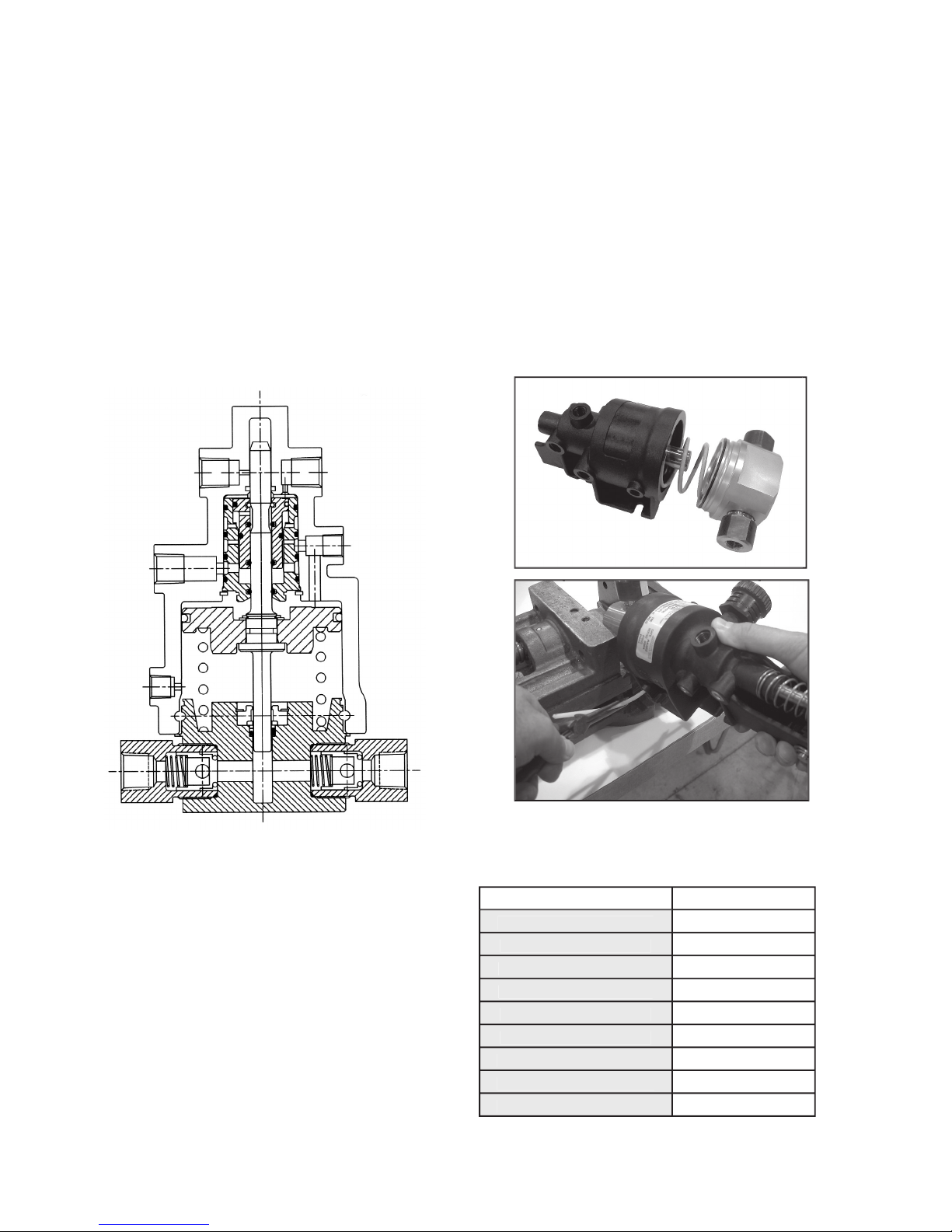

Assembly Drawings, Parts Lists Including Service Kits

...............................................................

..................................

15-18

METHOD OF OPERATION

2

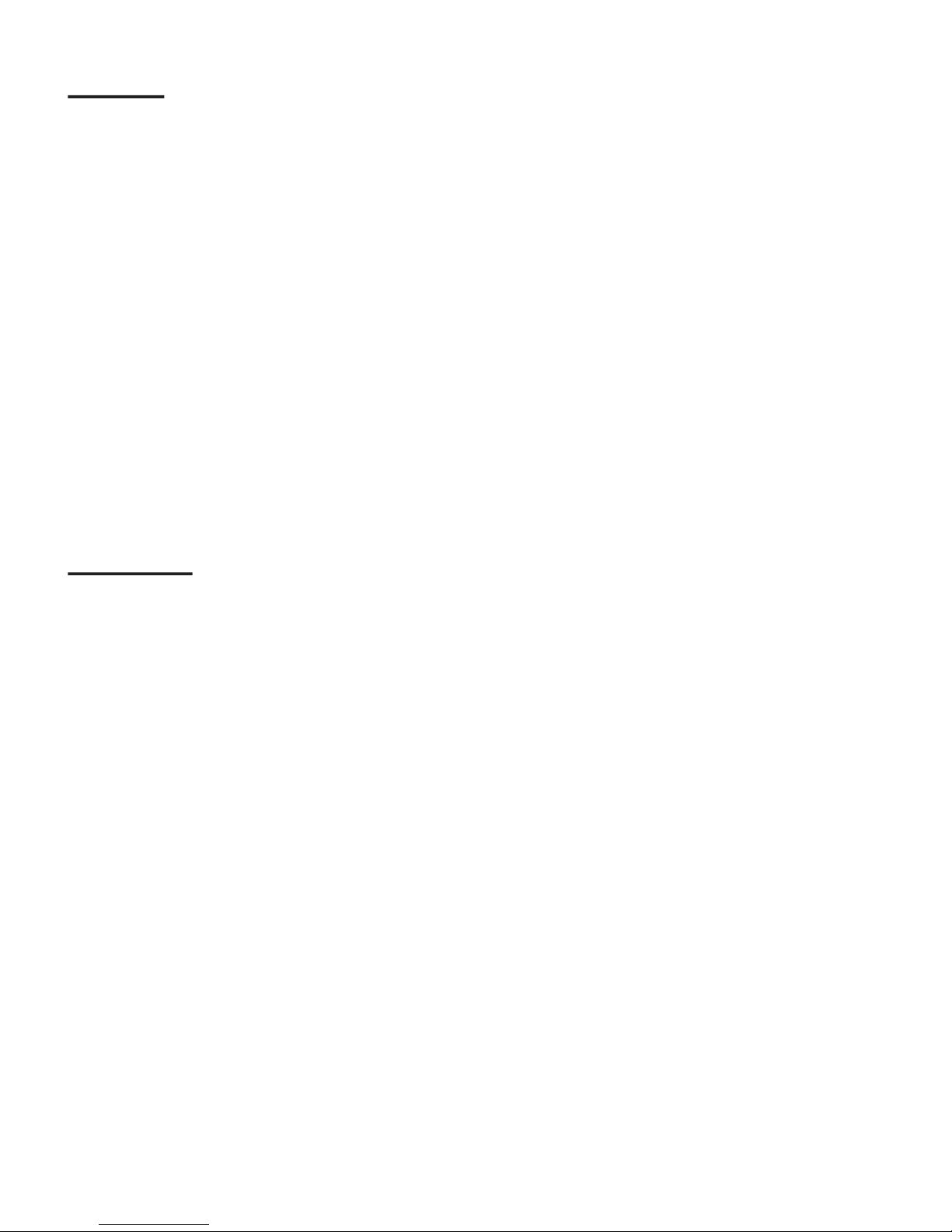

Pump Ratio Selections Chart

For the following pump models: SM-3A, SM-3S

100 psi Driving Air Supply

Nominal

Ratio

Max.

Output

Pressure

Disp. Per

Stroke

Cu. In.

LIQUID DISCHARGE PRESSURE – PSI

0

100

200

350

500

1000

1500

2M

4M

6M

8M

10M

12M

15M

20M

CAPACITIES – CUBIC INCHES PER MINUTE APPROXIMATE

5:1

575

1.050

550

330

275

180

10:1

1150

0.527

476

350

200

180

150

10

20:1

2300

0.263

305

280

210

160

110

75

60

15

35:1

4030

0.150

158

140

120

100

90

60

50

40

60:1

6900

0.085

98

90

80

70

60

31

25

22

17

100:1

11500

0.053

58

55

53

50

48

40

30

21

16

14

10

150:1

17300

0.035

39

38

37

36

35

28

25

20

12

11

9

7

6

225:1

25900

0.023

24

23

22

21

20

18

17

16

9

8

7

6

5

4

3

Nominal Performance (Based on Operating Air Supply of max 15 scfm @ 100 PSI)

Example:

SM-3A-010 pump has an nominal ratio of 10 to

1 or 10 psi liquid pressure for each 1 psi of operating air

pressure.

In operation a SM-3A-010 pump using 100 psi of input air

will actually produce a maximum liquid output pressure of

1150 psi; 80 psi air will produce an output pressure of 920

psi air; 60 psi air will produce an output pressure of 690 psi

output; and 40 psi air will produce an output pressure of

460 psi output.

The Sprague pump develops high output

pressure by applying the principle of dif-

ferential areas.

The pump has a large area air piston,

air-driven at low pressures. This air piston

drives a small area liquid piston that in turn

pumps liquids at high pressures.

The liquid output pressure is determined

by the ratio between the area of the air

driven piston, the area of the liquid driven

piston, and the applied operating air pressure.

The area relationship of the air piston to the liquid piston is

referred to as the pump ratio. A nominal ratio is indicated

in the dash number, which follows the pump model basic

number.

Liquid

Pressure

Line to

Hydraulic

Cir

cuit

Bleed Line

to Reser

voi

r

Bleed V

alve

Restrictor

V

alve – Required for

Burst T

esting

Burst TestingBurst T

Filter – 10 Micron

Liquid Supply

Line from

Reser

voir

Air Filter

10 Micron

Compressed Air

Line Thru

Reducer into

Air Filter

(1/4

″

NPT Port)

″ NPT Port)″

Air Pressure

Regulator

Air

Pressure

Gauge

Air

Shut-Off

V

alve

SM-3 Pump

Manifold

Liquid

Pressure

Gauge

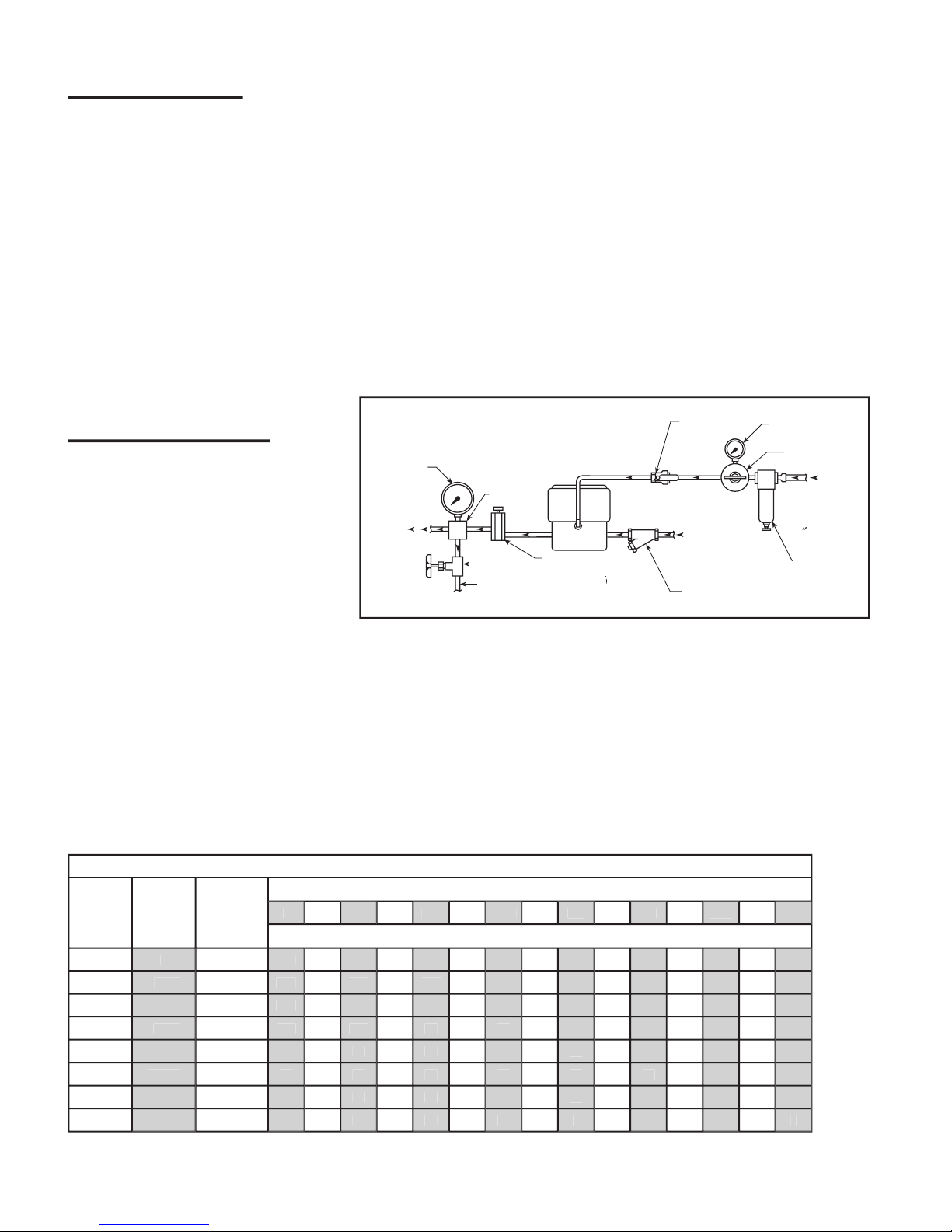

PUMP AND ACCESSORIES - TYPICAL ARRANGEMENT

FIGURE 1 Pump installed in a typical circuit with recommended accessories which are available

from Sprague Products

3

SAFETY

SM-3 minipumps are designed to provide high levels of safety, provided basic safety guidelines are followed.

AIR MODULE

Make sure that all air connections are made up properly.

If NPT connections have been speci ed, the NPT t-

ting should be wrapped with two turns of PFTE tape and

screwed into the plastic plate nger tight. Tape within one

or two threads of the end.

DO NOT OVERTIGHTEN THESE FITTINGS.

MAXIMUM TORQUE 25 IN-LBS.

Inspect ttings regularly to make sure they have not loos-

ened in service.

All air side components must be correctly tted when ser-

vicing the pump – please refer to the maintenance section

for guidance.

There are no external moving parts. However, make sure

that air is disconnected when working on pumps to avoid

injury. Maximum Drive Air Pressure 125 PSI

INSTALLATION

LOCATION

Minipumps should be mounted on a at surface which

maybe at any angle.

Location is preferably clean and dry and free from solvents

or aggressive chemicals coming into contact with the

minipump.

MOUNTING

4 slots are provided in the minipump main body for mount-

ing. Details of bolt hole positions are shown in Figure 2

SM-3 Dimensional Data section page 5. Minipumps should

be securely mounted to a rm surface to avoid damage to

connections when the pump is operating.

DO NOT OVER-TORQUE MOUNTING BOLTS.

MAXIMUM TORQUE IS 40 IN-LBS.

Pipework should not be used to support the minipump,

plumbing should be arranged that easy removal of the mi-

nipump from the location is possible. Avoid over tight pipe

runs to minipump that require pipes to be bent to disen-

gage uid and air connections.

AIR SUPPLY

Air should be clean and dry. SM-3 pumps will be suscep-

tible to freezing due to the water vapor condensing as the

air exhausts. Filter air to 10 micron.

“AIR MUST BE DRY OR ICING WILL OCCUR.”

No air lubrication is required and is to be avoided.

EXHAUST & SEPARATION PORT

Do not block or restrict the exhaust or separation port.

Pump performance can be reduced or pump may cease to

operate.

LIQUID SUPPLY

A clean liquid supply is essential. Inlet liquid should be l-

tered to 25 micron absolute prior to entering the minipump

high-pressure body. Should dirty liquid be used, the high

pressure seals and both check valves will wear excessively,

leading to shortened operation between maintenance.

LIQUID MODULE

SM-3 minipumps can generate very high liquid pressures

and great care should be taken in use and maintenance.

Make sure that the system pressure and any pressure

potentially trapped in the pump has been released prior to

disassembly.

Connections are either NPT, or for ratios of 100 and higher,

coned and threaded H.P. tube tting on the outlets.

NPT liquid connections should be wrapped with two turns

of PTFE tape and screwed nger tight into the connection,

then turned with a wrench a further 1 to 2 full turns.

Note:

If the tting is found not to be pressure tight, make

Note: If the tting is found not to be pressure tight, make Note:

sure that pressure is bled to zero prior to further tightening.

Coned and threaded ttings should be made up in accor-

dance with the supplier's recommendations – see Nova

Swiss cataloge, available from Sprague.

DO NOT RUN ALUMINUM BODY PUMPS ON WATER OR

WATER WITH ADDITIVES.

OPERATION

STARTING

SM-3 minipumps are supplied in standard operating mode,

which means they are ready to run with a single air connec-

tion and the liquid inlet and outlet connected.

In this mode all that is required is a clean air supply con-

nected to the main air inlet. See assembly drawings for port

clari cation.

An Air Filter / Regulator is required for standard opera-

tion. The air supply should be regulated to a maximum of

125psi. An air shut off valve should also be installed.

TO START MINIPUMP, OPEN AIR SUPPLY LINE SLOWLY.

Should minipump not operate, see trouble shooting section.

NOTE

: Pump Ratios 60: 1 and above may

require positive pressure at liquid inlet to prime, or to be

lled manually as follows:

depress inlet check valve poppet and pour clean liquid to ll

pumping chamber. Reconnect plumbing and start pump.

STOPPING

Minipump may stall with air supply still connected.

MINIPUMP CAN BE STOPPED AT ANY TIME WHEN RUN-

NING, BY SIMPLY SHUTTING OFF THE AIR SUPPLY.

Note: If other operating modes have been selected, the

minipump stop-start characteristics are different – see user

con gured operating mode section.

4

MAINTENANCE

TOOLS

The following is a list of essential and useful tools required

to maintain the SM-3 minipumps:

Long nosed pliers

Medium at blade screwdriver

Soft Nylon Hammer

Selection of wrenches

Bench mounted vice

Torque wrench with open-ended adapters

Water soluble cleaning uid and small brush

Accrolube Te on

®

grease or equivalent o-ring lubricant

Anti-seize lubricant

DISASSEMBLY

Minipump disassembly is in two parts – air module then

liquid module.

See disassembly sequence on following pages.

CLEANING AND INSPECTION

Once all the components have been carefully laid out, they

should be washed in an aqueous oil degreaser. Parts should

be rinsed in clean tap water and dried, laid out for inspection.

All parts should be inspected for signs of wear.

Things to look for:

Score marks on piston shafts, bodies, and back-up rings.

Seal damage.

Excessive wear on check valve seat surfaces.

Make sure all worn parts are replaced. Service kits, as

shown at the end of this manual, contain wear replacement

parts recommended by Sprague. Kits contain sealing and

small components only, individual machined components

can be ordered separately using part numbers shown on

parts lists.

REASSEMBLY

Make sure all parts are clean and that all seals are lubricated

at assembly. Minipump reassembly is the reverse to dis-

assembly, taking note of torques as shown on following

pages.

Te on is a registered trademark of the DuPont Company

5

Model

Fluid Inlet Port

Fluid Outlet Port B

Air Inlet Remote and Single Port

SM-3X-005

3/8

″

NPT

″ NPT″

3/8

″

NPT

″ NPT″

1/4

″

NPT

″ NPT″

SM-3X-010

3/8

″

NPT

″ NPT″

3/8

″

NPT

″ NPT″

1/4

″

NPT

″ NPT″

SM-3X-020

3/8

″

NPT

″ NPT″

3/8

″

NPT

″ NPT″

1/4

″

NPT

″ NPT″

SM-3X-035

3/8

″

NPT

″ NPT″

3/8

″

NPT

″ NPT″

1/4

″

NPT

″ NPT″

SM-3X-060

3/8

″

NPT

″ NPT″

3/8

″

NPT

″ NPT″

1/4

″

NPT

″ NPT″

SM-3X-100

1/4

″

NPT

″ NPT″

9/16

″

-18 NBS (1/4

″

HP)

″ HP)″

1/4

″

NPT

″ NPT″

SM-3X-150

1/4

″

NPT

″ NPT″

9/16

″

-18 NBS (1/4

″

HP)

″ HP)″

1/4

″

NPT

″ NPT″

SM-3X-225

1/4

″

NPT

″ NPT″

9/16

″

-18 NBS (1/4

″

HP)

″ HP)″

1/4

″

NPT

″ NPT″

Porting

– Standard Pumps

Mounting bolts

– 1/4

″

or M6

″ or M6″

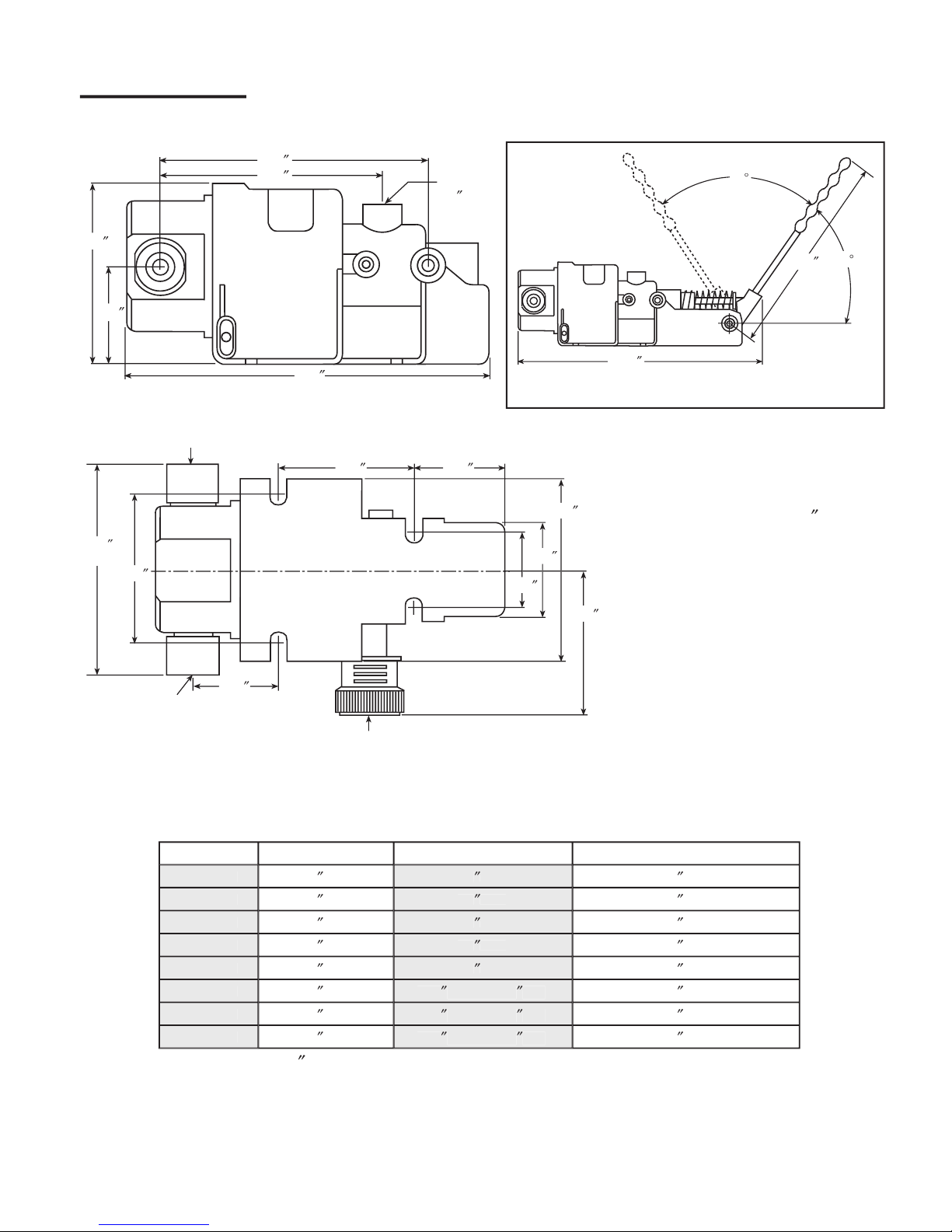

DIMENSIONAL DATA

5.62

″

4.75

″

3.93

″

2.06

″

″

7.80

″

″

Air Inlet

1/4

″

NPT

″ NPT″

60

°

60

°

12.0

″

11.25

″

2.93

″

2.12

″

3.95

″

1.92

″

1.65

″

3.25

″

1.90

″

3.20

″

5.00

″

max

Fluid

Outlet

Fluid

Inlet

Air Exhaust

Bolt Mounting Slots use1/4

″

(6mm) Fasteners

Weight:

STD. ALUM. BODY

4.5 LBS

STD. ST. STL. BODY

6.75 LBS.

HAND ALUM. BODY

5.75 LBS.

HAND ST. STL. BODY

8.00 LBS.

Hand Pump Option

Figure 2

6

TROUBLESHOOTING

TROUBLE

CORRECTION

Pump does not operate

Make sure clean air supply has correct ow and pressure. (Min. 20 PSI & 3 SCFM)

Check if pump has not stalled due to hydraulic pressure at outlet of

check valve.

Check that pilot air, if remote pilot mode selected, is at correct pressure and available

to pump.

Check that air exhaust is not blocked with ice or dirt.

Check that separation vent port is not blocked.

Leakage past air valve o-ring.

Leakage past air piston seal.

Pump operates intermittently

Check that the correct air pressure and ow is available.

against low output pressure

Pump may be icing.

Minipump appears to “cough”.

Leakage in air valve.

If checked and found OK, it is likely that a fault is inside the air control valve. Remove air control valve from minipump

and service.

Minipump does not generate

Outlet check valve: - run the pump and close the valve on the high pressure outlet.

required pressure

Shut off the drive air and if the outlet pressure drops, the outlet check valve is

contaminated or worn.

Inlet check valve: - run the pump and close the valve on the high pressure

outlet. If the pump continues to cycle, the problem is the inlet check valve.

High pressure seal: Replace the high pressure seal if liquid mists out of the

drain port

If everything checks out it is likely that the high-pressure seals have worn and require replacement. Dissassemble the uid

section of minipump and replace seals. Inspect the check valves for wear.

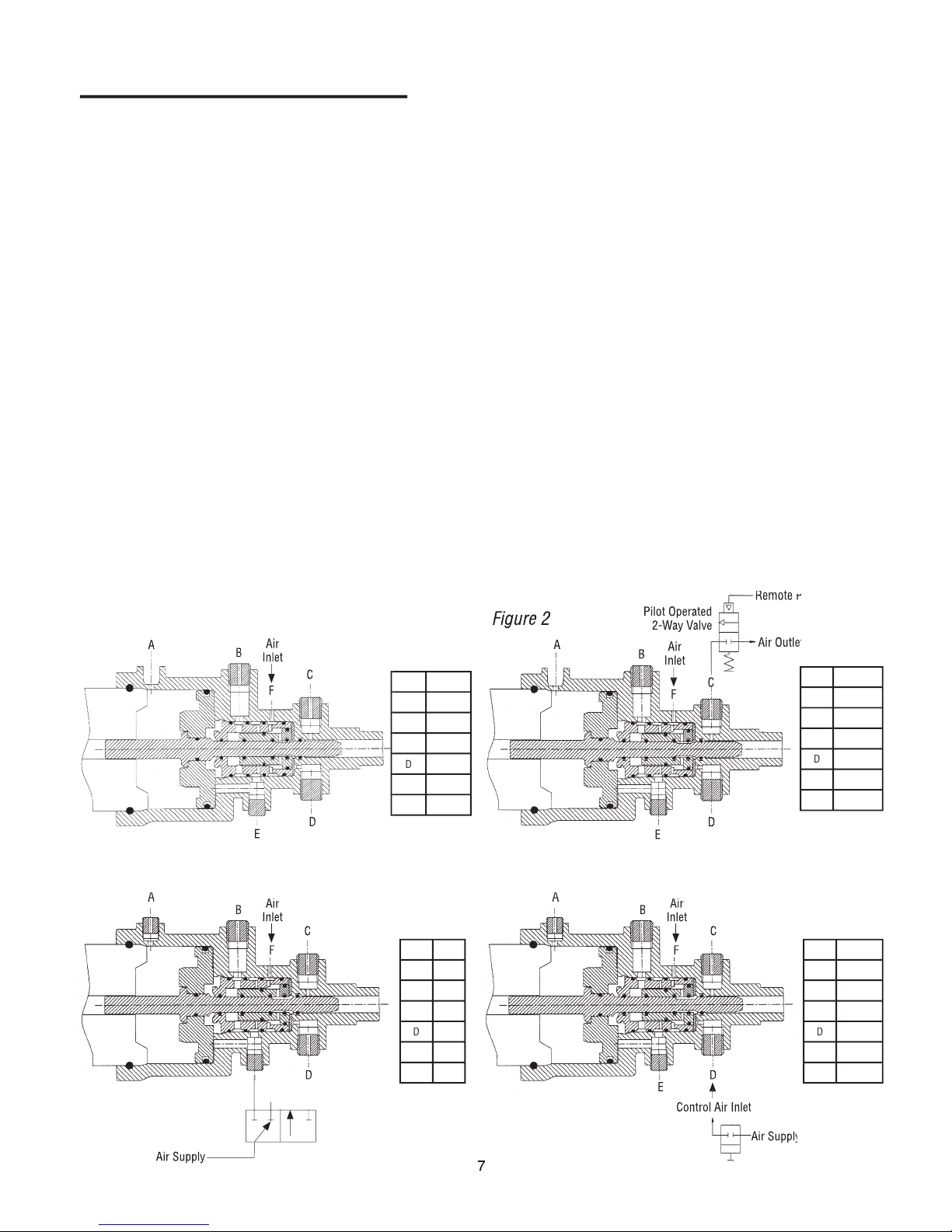

USER CONFIGURED OPERATING MODES

SM-3 minipumps have the capacity to allow the user to simply and quickly alter the way the pump operates. Minipumps

are delivered in the standard operating mode condition. For all operating modes the pilot exhaust port is tted with a vent

plug.

STANDARD OPERATING MODE

This mode of operation is shown in Figure 1. In this mode,

a single air supply is used as motive power for the air drive.

Within the air valve, a small quantity of air is bled off to act

as pilot air for the spool valve. This air is exhausted after

use through the pilot exhaust port. When air is supplied

to the minipump, the minipump operates until the balance

pressure is reached or until the air supply is switched off. In

this mode, the single stroke port is plugged off.

REMOTE OPERATION MODE

This mode of operation is shown in Figure 2. In this mode

a pilot operated 2-way valve is tted between the air supply

and the air inlet port. Pilot air is then connected to the sens-

ing port of the 2-way valve. This mode allows the pump

to be started and stopped remotely by applying air to the

2-way sensing port. In this mode, the single stroke port is

blanked off.

SINGLE CYCLE OPERATION MODE

There are two different single cycle operating con gurations shown in Figures 3A and 3B.

Figure 3A shows the schematic for direct acting single stroke control that can be eld con gured. Plug all ports

except E, which is connected to a Nornally Closed three way valve.

In order to single cycle the pump using an external generated air pulse, (each pulse powering one complete

Mini-Pump cycle) this con guration can only be Factory supplied as a SM-3X-XXX-XX-S, and should be

plumbed as shown in Figure 3B. (To run this con guration continuously provide a constant air supply at D)

A

B

F

C

E

D

Air

Air

Inlet

A

A

B

F

C

D

Air

Air

Inlet

A

B

F

C

E

D

Air

Inlet

Air Outlet

Air Outlet

Remote Pilot

Remote Pilot

Pilot Operated

2-Way Valve

Port

Plug

A

Vent

B

Muf er

C

Pilot

D

Plug

E

Plug

F

Inlet

Port

Plug

A

Vent

B

Plug

C

Vent

D

Plug

E

Plug

F

Plug

Port

Plug

A

Vent

B

Muf er

C

Vent

D

Plug

E

Plug

F

Inlet

Figure 1

Figure 2

Figure 3A

Air Supply

A

A

B

F

C

E

D

Air

Air

Inlet

Control Air Inlet

Port

Plug

A

Vent

B

Muf er

C

Vent

D

Inlet

E

Plug

F

Inlet

Figure 3B

Air Supply

Air Supply

7

8

DISASSEMBLY

1.

SM-03 minipump as delivered. (Hand pump option

shown) Handle rod is simply inserted as shown on

page 18.

2.

Remove Spirol Pin with a 3/32 pin punch. Locate

retainer rod in slot at top of low pressure body, lever-

ing out with small screwdriver and gripping with pliers.

Remove retainer as shown.

3.

Secure H.P. Body in vice as shown. Secure end of re-

tainer rod with needle nose pliers and pull. Rotate lower

pressure housing counterclockwise to facilitate extrac-

tion of retainer.

Remove high pressure end and piston assembly from

low pressure body. Piston spring is compressed.

Be careful during disassembly.

4.

5.

Remove piston assembly from air body and spring from

high pressure end.

6.

Remove external retaining ring from piston. Be care-

ful, do not over expand retaining ring.

MANUAL OPERATION

On request, manual operation minipumps can be supplied. As with standard minipumps, they are supplied in the standard

operating mode. These minipumps can also be recon gured to remote operating or single stroke modes. The hand opera-

tion uses a hand lever, where one complete movement of the lever equates to one cycle of the minipump. The hand lever is

easily removed for convenience.

7.

Slide washer and piston off piston shaft.

8.

Remove retaining ring from high pressure body.

(Use eye protection safety glasses.)

9

9.

Remove back-up ring from high pressure body.

10.

Remove high pressure seal assembly from recess

within high-pressure body. Seal orientation under

back-up ring is as shown. See Figure 10a & 10b.

11.

Holding high pressure body in vise, remove inlet check

valve body as shown. Watch for inlet check valve parts

inside and o-ring on body.

Retaining Ring

Retaining Ring

Bearing Washer

Bearing Washer

Bearing

Bearing

Back-Up Ring

Back-Up Ring

Lip Seal

Lip Seal

O-Ring

O-Ring

Retaining Ring

Retaining Ring

Bearing Washer

Bearing Washer

Bearing

Bearing

Back-Up Ring

Back-Up Ring

Lip Seal

Lip Seal

O-Ring

O-Ring

Bearing Carrier

Bearing Carrier

Seal Detail (5:1 thru 35:1)

Seal Detail (5:1 thru 35:1)

Seal Detail (60:1 thru 225:1)

Fig. 10a

Fig. 10b

10

12.

Holding high pressure body in vice, remove intlet

check valve as shown. Watch for inlet check valve

parts inside and o-ring on gland.

12 a) =

5, 10, 20, 35 & 60:10 Ratios

12 b) =

100, 150 & 225 Ratios

13.

Holding high pressure body in vise, remove outlet

check valve body as shown. Watch for outlet check

valve parts inside and o-ring in body.

14.

Fig. a

Fig. b

Fig. c

Fig. d

Remove outlet check valve assembly from outlet check

valve body.

14 a) = 5,10, 20, 35 & 60 ratios

14 b) = 100, 150,& 225 ratios

15.

Remove retaining ring from low pressure body.

11

16.

Remove spool and sleeve by gradually applying air

pressure to main air inlet port shown while holding

piston shaft fully into sleeve (block off single cycle

port and remove protector from main exhaust port as

shown.) Do not use pliers to extract sleeve, as this will

damage sealing surfaces.

17.

Remove spool from air body.

18.

Remove spool from sleeve.

19.

Remove retaining clip and plain washer to hinge

pin.

20.

Push out hinge pin. Care to be taken as compres-

sion spring will forcibly eject handle and handle

return Spigot from low pressure body.

The following instructions, 19 to 21, apply only to

the manual operation option, (H).

21.

Handle components laid out.

12

REASSEMBLY

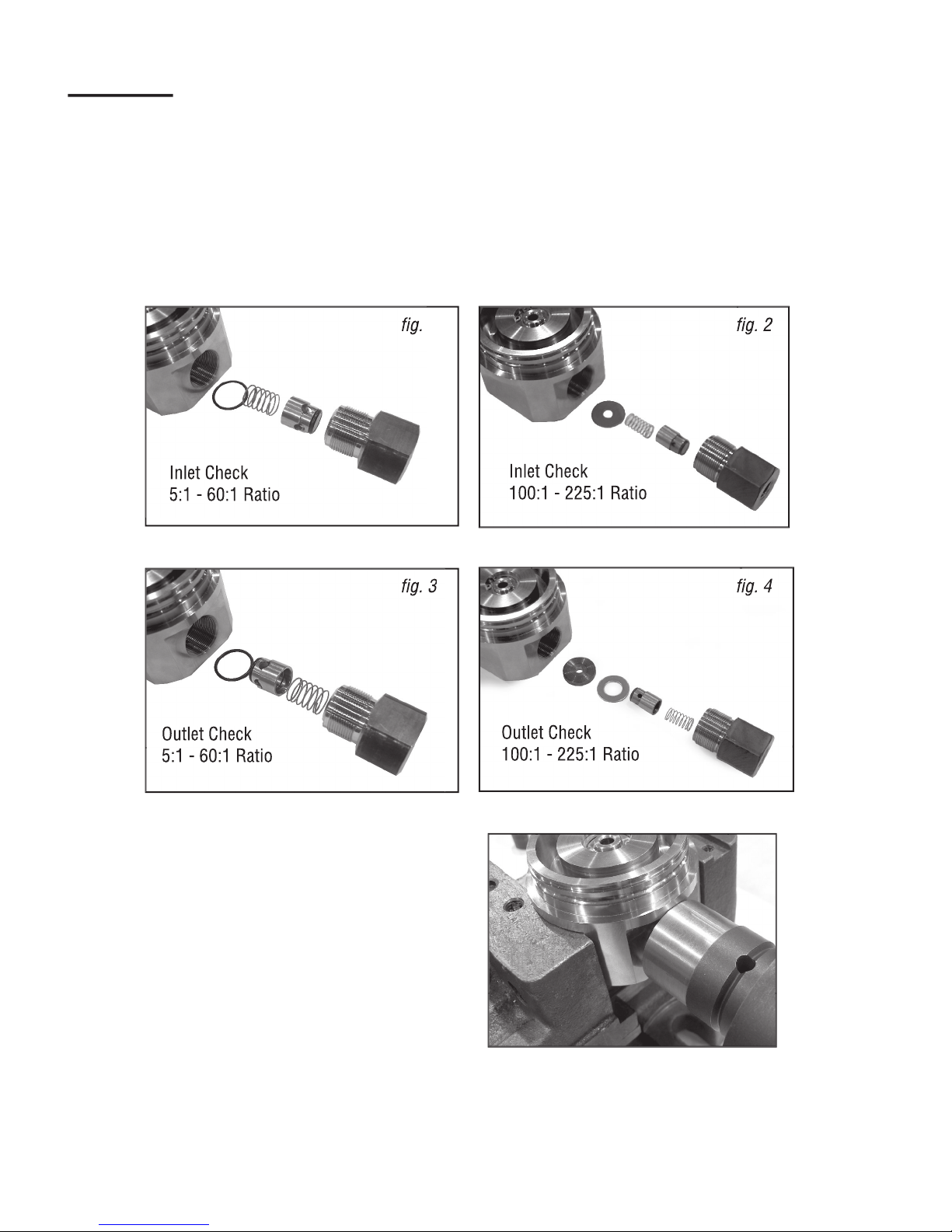

INLET & OUTLET CHECK VALVES

Before reassembling pump, wash metalic parts thoroughly

in water solution (“Simple Green”), rinse and dry. Lubri-

cate o-rings with “Accrolube” te on grease or equivalent.

Use lubricants compatible with seal compounds. Lubricate

external threads with loctite nickel anti-seize or equivalent.

Reassemble in the reverse order to disassembly, noting the

following points.

Refer to assembly drawings for part numbers and con gu-

ration.

Reassemble and install inlet and outlet check valves into

uid body. See Figure 1 - 4. NOTE: order of assembly and

position of poppets. NOTE: torque instructions. DO NOT

over-torque valve bodies and be careful to avoid crossing

threads when installing check valve bodies.

Tighten the inlet and outlet check valve bodies to the follow-

ing torques:

ALUMINUM BODY

(5-100:1 RATIO)

115-125 FT. LBS.

STAINLESS STEEL BODY

(5-60:1 RATIO)

115-125 FT. LBS.

(100-225:1 RATIO)

230-240 FT. LBS.

Inlet Check

5:1 - 60:1 Ratio

Inlet Check

100:1 - 225:1 Ratio

Outlet Check

5:1 - 60:1 Ratio

Outlet Check

100:1 - 225:1 Ratio

g. 1

g. 1

g. 2

g. 3

g. 4

Lubricate the 91417-231-29 o-ring and assemble on the air

piston. See gure below.

SPOOL/SLEEVE ASSEMBLY – Lubricate the o-rings with

“Accrolube” Te on grease or equivalent. Use lubricants

compatible with seal compounds. Assemble the external

o-rings on the sleeve, 91417-025. Assemble the external

o-rings on the spool, 91417-020 and 91417-017-29 in ap-

propriate grooves. Assemble internal o-rings in the spool

and sleeve, p/n 91417-012-41. The use of a soft o-ring pick

or plastic probe will aid in this assembly. Use care – DO

NOT scratch the o-ring or spool/sleeve. Assemble the spool

into the sleeve per assembly drawing.

13

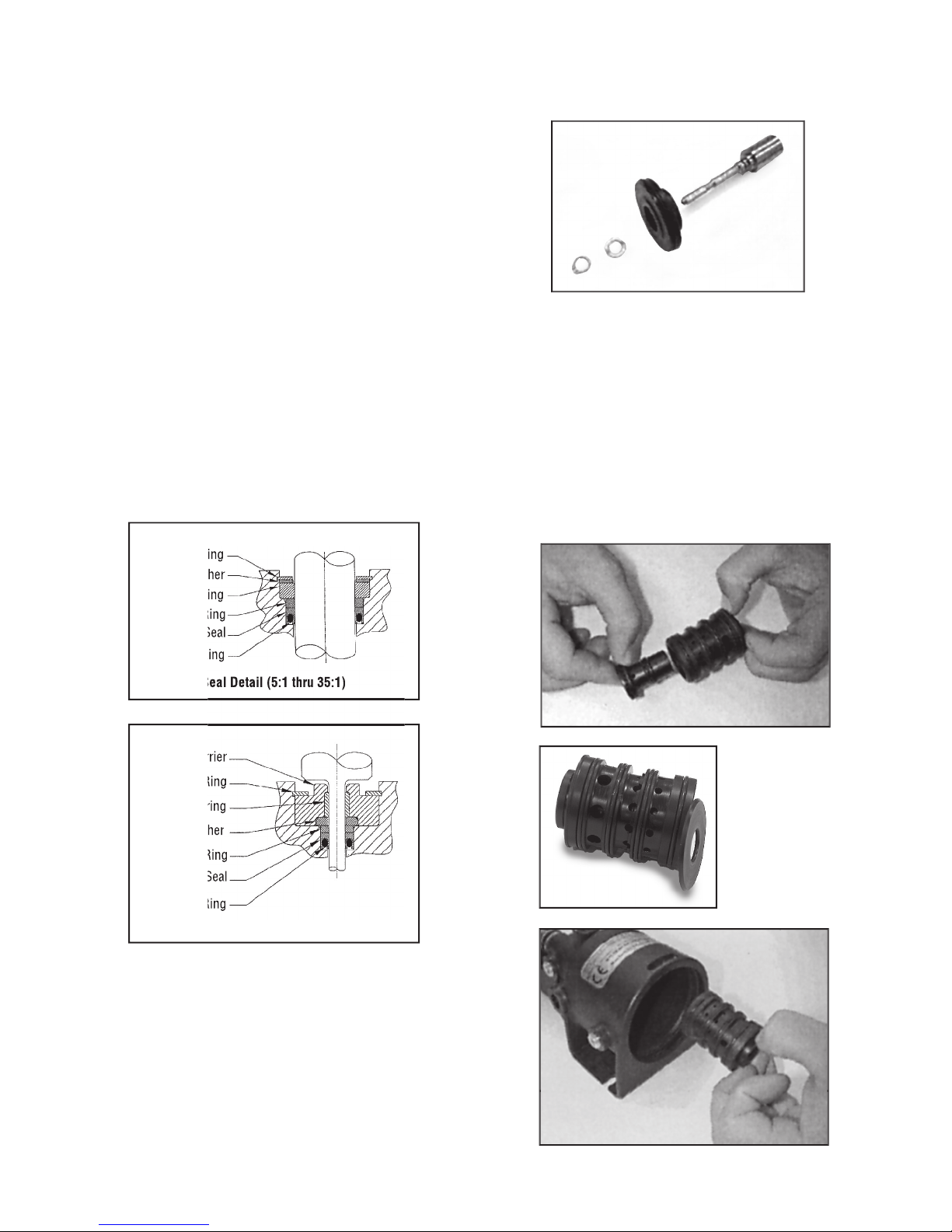

HIGH PRESSURE SEAL

See assembly drawings for part numbers and con gura-

tion. Lubricate o-ring and assemble into the lip seal. Use

care, do not scratch or mark the o-ring or lip seal. As-

semble lip seal into high pressure body. Orientation of the

seal is CRITICAL. The open end of the lip seal is facing

the bottom. See seal detail below. Push the lip seal to the

closed end of the counterbore with an appropriately sized

plug. Next, assemble the back-up ring, these parts should

be seated at the bottom of the counterbore. Depending on

the ratio, the construction varies.

For the 5:1 thru 35:1 ratio’s, assemble the bearing, washer

and retaining ring. For the remaining ratio’s, 60:1 thru

225:1, assemble the bearing into the bearing carrier.

Assemble the bearing washer into the bearing carrier.

The chamfer on one side of the bearing washer faces the

bearing carrier. Assemble these components into the high

pressure body and install the retaining ring with the sharp

edge facing out.

The retaining ring must be completely seated into the

groove. Safety note: USE EYE PROTECTION.

LOW PRESSURE BODY – [AIR MOTOR]

AIR PISTON ASSEMBLY – Replace the 91417-013 o-ring

on the piston shaft. Lubricate the o-ring with “Accrolube”

Te on grease or equivalent. Use lubricants compatible with

seal compounds. Assemble air piston onto the piston shaft,

see orientation on assembly drawing. Assemble washer and

retaining ring sharp edge out (away from the seal). Make

sure the retaining ring is properly seated in the groove.

Retaining Ring

Retaining Ring

Bearing Washer

Bearing Washer

Bearing

Bearing

Back-Up Ring

Back-Up Ring

Lip Seal

Lip Seal

O-Ring

O-Ring

Retaining Ring

Retaining Ring

Bearing Washer

Bearing Washer

Bearing

Bearing

Back-Up Ring

Back-Up Ring

Lip Seal

Lip Seal

O-Ring

O-Ring

Bearing Carrier

Bearing Carrier

Seal Detail (5:1 thru 35:1)

Seal Detail (5:1 thru 35:1)

Seal Detail (60:1 thru 225:1)

NOTE: Orientation

of spool washer.

14

LOW PRESSURE AIR BODY – Lubricate the o-ring with

“Accrolube” Te on grease or equivalent. Use lubricants

compatible with seal compounds. Install the 91417-012-1

o-ring in the low pressure body internal o-ring groove. Use

a soft o-ring pick or plastic probe to aid in this assembly.

See assembly drawing for detail SM3-LP. Lubricate the

middle bore of the air body. Install the spool washer, p/n

100799, into the middle bore of the air body. The chamfer

on the spool washer must face the bottom of the air body

bore. Assemble the spool and sleeve into the air body

middle bore. The assembly must be fully seated. Install the

retaining ring, p/n 100441. Lubricate the piston shaft and

assemble into the air body, per assembly drawing.

MINIPUMP ASSEMBLY

Lubricate the o-ring with “Accrolube” Te on grease or

equivalent. Use lubricants compatible with seal com-

pounds. Install the 91417-039 o-ring on the high pressure

body external o-ring groove. Fixture high pressure body in

a vise. Place spring, p/n 100776 in low pressure body, as-

semble low pressure body on the high pressure body. Use

care, the high pressure piston must enter the high pressure

seal. Also, the o-ring on the high pressure body engages

the low pressure body, do not cut the o-ring. Install the

retainer p/n 100173 in the entry hole on the forward part of

the low pressure body. Rotate low pressure body clock-

wise as you feed, (push) the retainer in. Install spirol pin,

100402, per assembly drawing.

The following kits are available to refurbish the low pres-

sure air module and high pressure modules as follows:

ASSEMBLY NUMBER

SERVICE KIT NUMBER

3A3S (Low pressure module)

3A3S-SK

3X – 005 (5:1 H.P. module)

3X-005-SK

3X – 010 (10: 1 H.P. module)

3X-010-SK

3X – 020 (20:1 H.P. Module)

3X-020-SK

3X – 035 (35:1 H.P. module)

3X-035-SK

3X – 060 (60:1 H.P. module)

3X-060-SK

3X – 100 (100:1 H.P. module)

3X-100-SK

3X – 150 (150:1 H.P. module)

3X-150-SK

3X – 225 (225:1 H.P. module)

3X-225-SK

15

Item

No.

Description

Part No.

Quantity

Quantities the Same as STD. Unit

3A-005

3S-005

3A-010

3S-010

3A-020

3S-020

3A-035

3S-035

-02 (NEO)

-03 (VIT)

-04 (EPR)

1

Body, H.P., -005, ALUM.

100700-005A

1

Body, H.P., -005, SST.

100700-005S

1

Body, H.P., -010, ALUM.

100704-010A

1

Body, H.P., -010, SST.

100704-010S

1

Body, H.P., -020, ALUM.

100704-020A

1

Body, H.P., -020, SST.

100704-020S

1

Body, H.P., -035, ALUM.

100704-035A

1

Body, H.P., -035, SST

100704-035S

1

2

Piston Shaft, -005

100746

1

Piston Shaft, -010

100747

1

Piston Shaft, -020

100750-020

1

Piston Shaft, -035

100750-035

1

3

Bearing, -005

100738

1

Bearing, -010

100739

1

Bearing, -020

100740

1

Bearing, -035

100741

1

4

Backup Ring, -005

100738-1

1

Backup Ring, -010

100739-1

1

Backup Ring, -020

100740-1

1

Backup Ring, -035

100741-1

1

5

Washer Bearing, -005

100738-2

1

Washer Bearing, -010

100739-2

1

Washer Bearing, -020

100740-2

1

Washer Bearing, -035

100741-2

1

6

Ring, Retaining, -005

100442

1

Ring, Retaining, -010

100443

1

Ratio

Ring, Retaining, -020

100444

1

Ring, Retaining, -035

100445

1

7

Seal, Lip, UHMWPE, -005

100376

1

100664 PTFE

005

Seal, Lip, UHMWPE, -010

100377

1

100665 PTFE

010

Seal, Lip, UHMWPE, -020

100378

1

100666 PTFE

020

Seal, Lip, UHMWPE, -035

100379

1

100667 PTFE

035

8

O-Ring, NIT., 70 SH., -005

91417-123

1

91417-123-11

91417-123-17

91417-123-26

005

O-Ring, NIT., 70 SH., -010

91417-118

1

91417-118-11

91417-118-17

91417-118-26

010

O-Ring, NIT., 70 SH., -020

91417-114

1

91417-114-11

91417-114-17

91417-114-26

020

O-Ring, NIT., 70 SH., -035

100821

1

100821-11

100821-17

100821-26

035

9

O-Ring, NIT., 90 SH.

91417-019-1

2

91417-019-24

91417-019-18

91417-019-28

10

Body, C.V., 3/8 NPT.

88906

11

Poppet, 3/8 NPT.

79420-1

12

O-Ring, NIT., 90 SH.

79550-8-1

79550-9-24

79550-8-18

79550-28

13

Spring, C.V.

S-216-23

Assembly Drawings and Parts Lists

SM3 HP (005-035)

RATIOS 5, 10, 20, & 35

RATIOS 5, 10, 20, & 35

Seal Detail

Outlet

Inlet

16

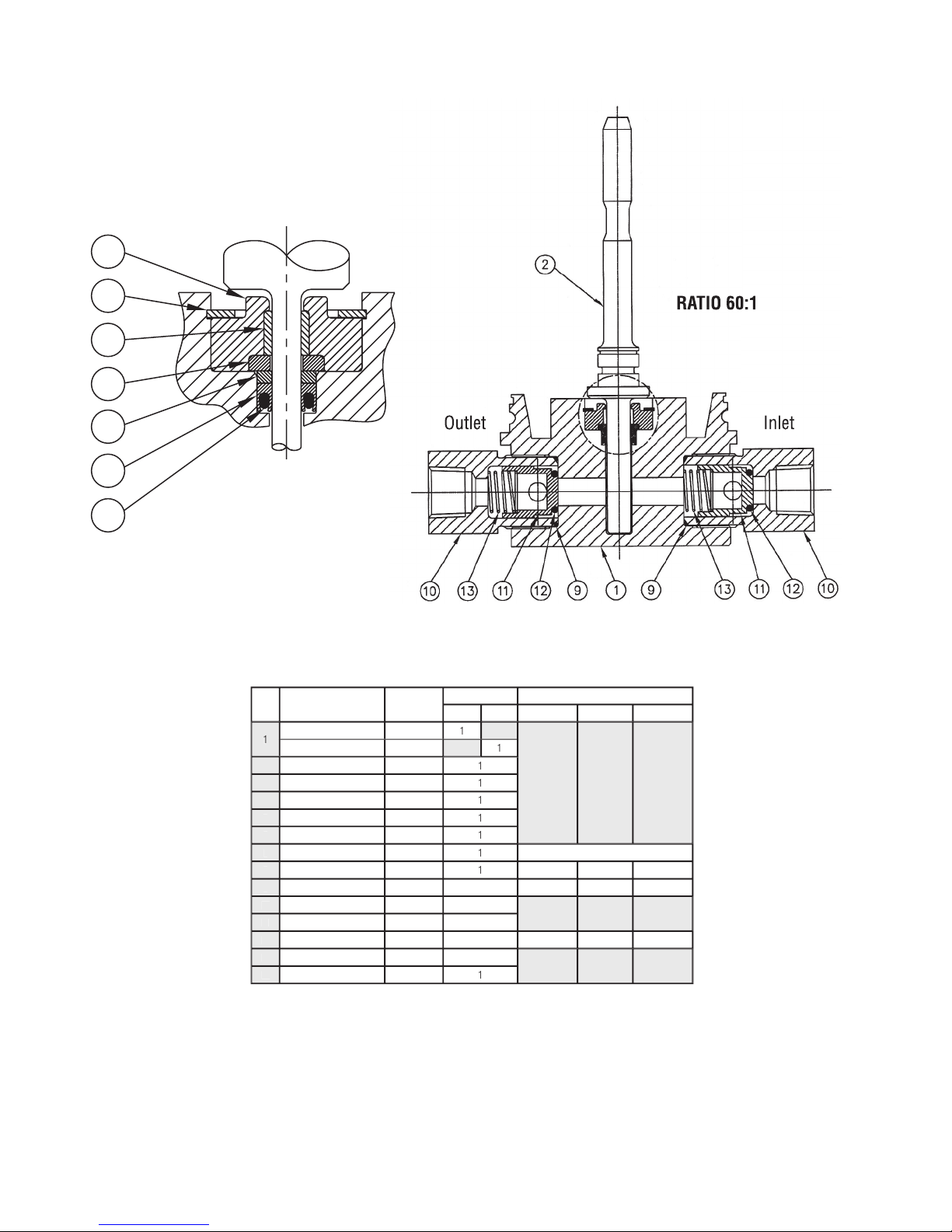

Item

No.

Description

Part No.

Quantity

Quantities Same as STD. Unit

3A-060

3S-060

-02 (NEO)

-03 (VIT)

-04 (EPR)

1

Body, H.P., -060, ALUM.

100704-060A

1

Body, H.P., -060, SST.

100704-060S

1

2

Piston Shaft, -060

100750-060

1

3

Bearing

100742

1

4

Backup Ring

100742-1

1

5

Washer Bearing

100742-2

1

6

Ring, Retaining

100446

1

7

Seal, Lip, UHMWPE

100660

1

100668 (PTFE)

8

O-Ring, NIT., 70 SH.

100820

1

100820-11

100820-17

100820-26

9

O-Ring, NIT., 90 SH.

91417-019-1

2

91417-019-24

9147-019-18

91417-019-28

10

Body, C.V., 3/8 NPT.

94056

2

11

Poppet, 3/8 NPT.

89297

2

12

O-Ring, NIT., 90 SH.

79550-15-1

2

79550-8-24

79550-8-18

91417-110-28

13

Spring, C.V.

S-216-63

2

14

Carrier, Bearing

100742-3

1

SM3 HP (060)

RATIO 60:1

Seal Detail

Outlet

Inlet

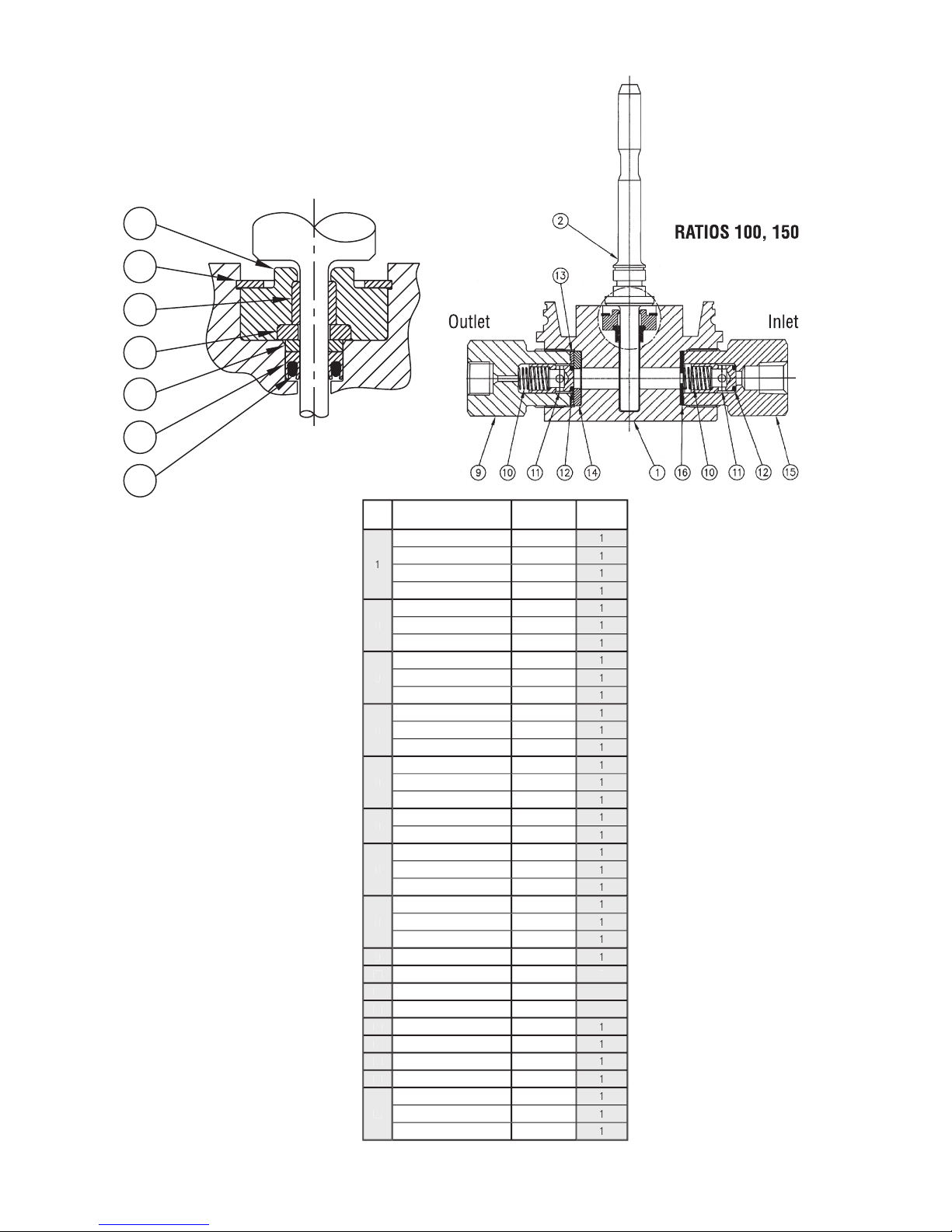

SM3 HP (100-225)

Item

No.

Description

Part No.

Quantity

1

Body, H.P., -100, ALUM.

100704-100A

1

Body, H.P., -100, SST.

100704-100S

1

Body, H.P., -150, SST.

100713-150

1

Body, H.P., -225, SST.

100713-225

1

2

Piston Shaft, -100

100750-100

1

Piston Shaft, -150

100750-150

1

Piston Shaft, -225

100750-225

1

3

Bearing, -100

100743-1

1

Bearing, -150

100744

1

Bearing, -225

100745

1

4

Backup Ring, -100

100743

1

Backup Ring, -150

100744-1

1

Backup Ring, -225

100745-1

1

5

Washer Bearing, -100

100743-3

1

Washer Bearing, -150

100744-2

1

Washer Bearing, -225

100745-2

1

6

Ring, Retaining, -100

100447

1

Ring, Retaining, -150, -225

100446

1

7

Seal, Lip, UHMWPE, -100

100661

1

Seal, Lip, UHMWPE,-150

100662

1

Seal, Lip, UHMWPE, -225

100663

1

8

O-Ring, NIT., 70 SH., -100

100325

1

O-Ring, NIT., 70 SH., -150

100324

1

O-Ring, NIT., 70 SH., -225

100323

1

9

Body, C.V., 9/16-18 UNF

89298-1

1

10

Spring, C.V.

S-216-63

2

11

Poppet, H.P., .400 ID/.495 OD.

89297

2

12

O-Ring, NIT., 90 SH.

79550-5-1

2

13

Gasket, CV, SS, .500 I.D.

S-216-28-8

1

14

Seat, CHK. VLV. for 82648

S-216-27-4

1

15

Body, C.V., H.P., 1/4 NPT

89298

1

16

Gasket, CV, SS, .250 I.D.

S-216-28-10

1

17

Carrier, Bearing

100743-2

1

Carrier, Bearing

100744-3

1

Carrier, Bearing

100745-3

1

RATIOS 100, 150, & 225

RATIOS 100, 150, & 225

Seal Detail

17

Outlet

Inlet

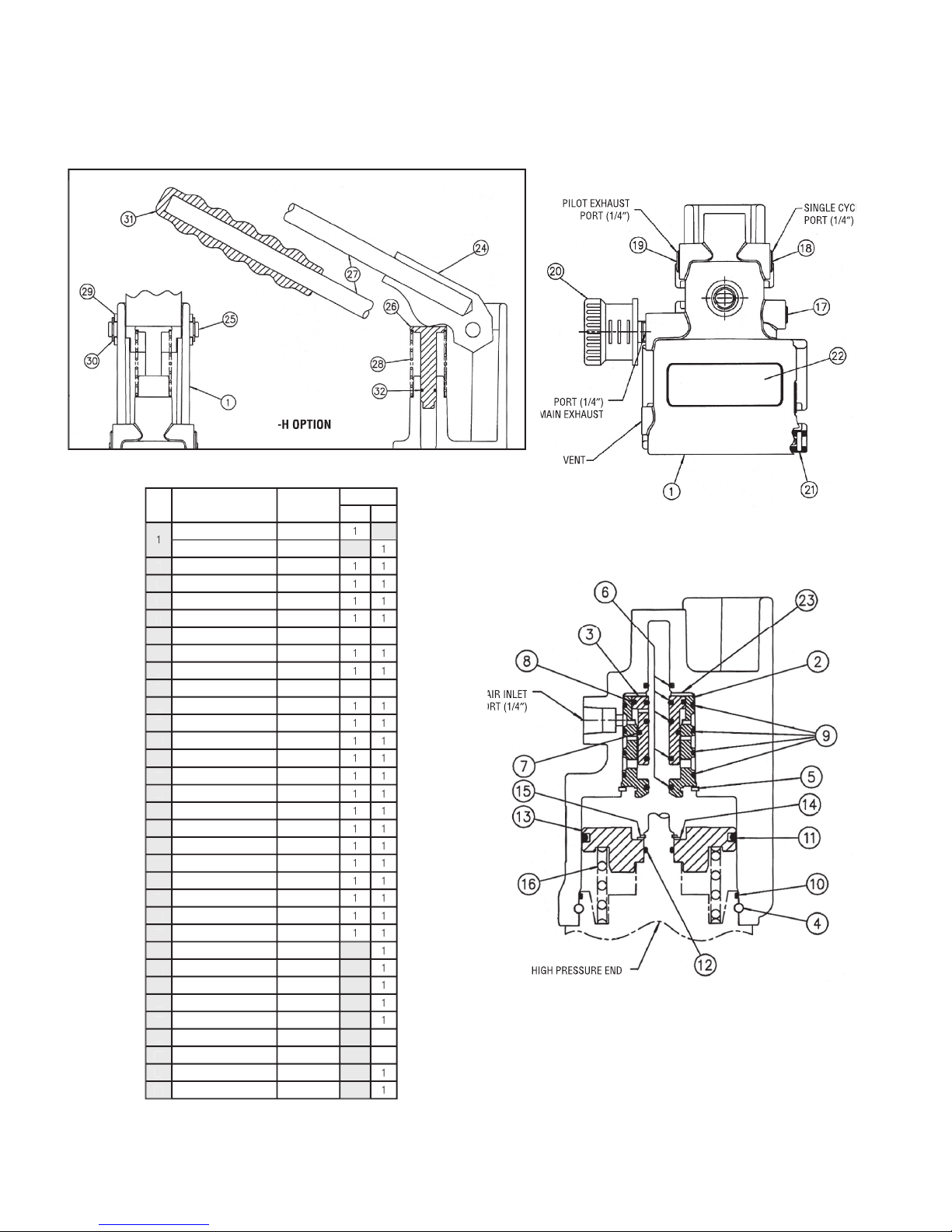

SM3 LP : Low Pressure Body Assembly

Item

No.

Description

Part No.

Quantity

3A3S

-H

1

Body, L.P., Air Motor, Std.

100777

1

Body, L.P., Air Motor, Hand

100778

1

2

Sleeve, Spool

100763

1

1

3

Spool

100764

1

1

4

Retainer

100173

1

1

5

Ring, Retaining

100441

1

1

6

O-Ring, 90 SH

91417-012-41

5

5

7

O-Ring, 80/90 SH

91417-017-29

1

1

8

O-Ring, 70/75 SH

91417-020

1

1

9

O-Ring, 70/75 SH

91417-025

3

3

10

O-Ring, 70 SH

91417-039

1

1

11

O-Ring, 80/90 SH

91417-231-29

1

1

12

O-Ring, 70 SH

91417-013

1

1

13

Piston, L.P.

100765

1

1

14

Washer

100754

1

1

15

Ring, Retaining

100880

1

1

16

Spring

100776

1

1

17

Plug, Pipe, 1/8 NPT.

93971-1

1

1

18

Plug, Pipe, 1/4 NPT.

93971-2

1

1

19

Plug, Vent, 1/4 NPT.

100186

1

1

20

Muf er

101021

1

1

21

Pin, Coiled, Spirol

100402

1

1

22

O-Ring 70/75 SH

80063-2

1

1

23

Washer, Spool

100799

1

1

24

Handle, Lever, Bracket

100771

1

25

Pin, Hinge

100757

1

26

Spigot, Handle, Return

100756

1

27

Rod, Handle

100758

1

28

Spring

100508

1

29

Washer

100482

2

30

Ring, Retaining

100900

2

31

Grip, Handle

100920

1

32

O-Ring, 80/90 SH

100810

1

18

-H OPTION

MAIN AIR INLET

MAIN AIR INLET

PORT (1/4

PORT (1/4

″

)

HIGH PRESSURE END

VENT

PORT (1/4

″

)

MAIN EXHAUST

MAIN EXHAUST

PILOT EXHAUST

PORT (1/4

″

)

SINGLE CYCLE

SINGLE CYCLE

PORT (1/4

″

)

STANDARD SUPPLY

© Sprague Products 2004

SM3 5M 304

Sprague Products

Division of Cur

tiss-

Wr

ight Flow Control Corporation

10195 Brecksville Road

10195 Brecksville Road

Brecksville, OH 44141 USA

Telephone: 440-838-7690 • Fax: 440-838-7513

www.cwfc.com

Sprague Products U.K.

Sprague Products U.K.

202 St. Andrews Road

Bridport, Dorset DT6 3B6

Table of contents