7

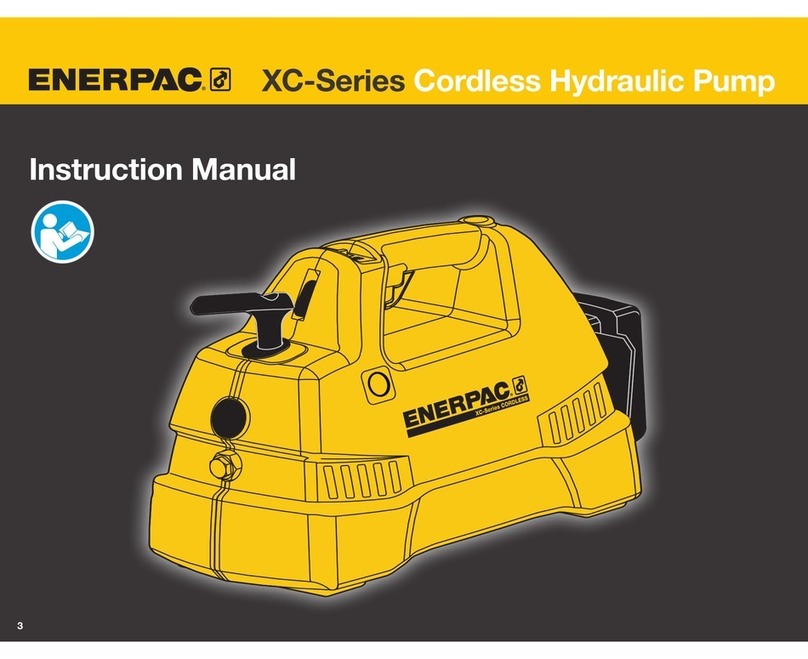

VIEW OF THE PANEL AND CONTROL VALVE BLOCK

THE VALVE BLOCK is the seat af all components that controls the hydraulic circuit, the part is

obtained working a laminated aluminium block

1. OIL INLET HOLE – oil enters in pressure in the valve from this hole

2. ROTATING JOINT is an adjustable joint where the quick couplers are installed. It permits to fold the

quick coupler after the use protecting it against shocks. It also allows the flexible hose to have a

natural bend avoiding sharp bends.

3. FILTER CARTRIDGE is the hydraulic oil filter. It can easily substituted but it cannot be maintained

4. MALE QUICK COUPLER is the quick coupler which the oil comes out under pressure through from

“P” power pack. The male quick coupler should always be installed in this position for guaranteeing the

right circulation of the oil.

5. ON/OFF FLOW LEVER is the lever which the oil is sent to flexible hoses and hydraulic tool through. It

is OFF placed rightwards, it is ON placed leftwards.

The lever should always be in OFF position at the end of operations or when the engine is started and

when the Manta power pack is used as a generator. The illustration shows the lever as installed on

the model SCORPION ( pointed to the center of the pack ), on the RAPTOR D the lever is installed

on the front part ( pointed to the exterior ) but the sense of the ON OFF position is the same , the

RAPTOR D imagine of the flow is on the illustration at page 11

6. OIL OUT LET HOLE On the model RAPTOR D this hole is plugged as the oil baypasses to tank from

an internal passage.

7. PRESSURE RELIEF VALVE is the valve adjusting the maximum value of the hydraulic pressure of the

power pack. It is adjusted originally at a value of 140 BAR. It can be adjusted at different values of

pressure

8. ROTATING JOINT is an adjustable joint where the quick couplers are installed. It permits to fold the

quick coupler after the use protecting it against shocks. It also allows the flexible hose to have a

natural bend avoiding sharp bends..

9. FEMALE QUICK COUPLER is the quick coupler which the oil returns to tank “T” The female couplers

is in communication with tank and should always be installed in this position for guaranteeing the right

circulation of the oil.