Spring Air Systems DN REV-LOW Operating and maintenance manual

DN REV-LOW

Maintenance and

Operating Manual

___________________________

Spring Air Systems Inc., Oakville, Ontario

www.springairsystems.com

DN REV-LOW Maintenance and Operating

Manual

Table of Contents

Introduction 1

Spring Air Systems Hood Model Number Designations 2

Principle of Operation 2

VARIFLOW Baffles 3

Baffle Settings 4

REV-LOW Maintenance Instructions 4

Cleaning the Exterior 6

REV-LOW Maintenance Schedule 6

Trouble Shooting 6

Measuring the Exhaust Airflow 7

Installing the Terminator Baffle 8

REV-LOW-Startup Report 9

DN-Rev-LOW Maintenance and Operating Manual 1

DN REV-LOW Maintenance and Operating Manual

ULC/UL Listed Exhaust Hood without Exhaust Fire Damper

INTRODUCTION

Thank you for selecting a SPRING AIR SYSTEMS INC. Commercial kitchen exhaust Rev-Low

dry extractor. Your system consists of a dry extractor, exhaust fan and on/off switch. Others may

have supplied the exhaust fan and on/off operator.

Your SPRING AIR SYSTEMS INC. Dry extractor model was selected to best meet the design

requirements of your commercial kitchen application.

The DN series dry ventilator is a UL/ULC listed “Exhaust Hood without Exhaust Fire Damper”.

Typical SPRING AIR SYSTEMS Dry Rev-Low Ventilator Installation

Figure 1

An ON/OFF selector switch located in the kitchen area or mounted on the exhaust fan starter coil

electrical enclosure normally controls the exhaust fan.

DN-Rev-LOW Maintenance and Operating Manual 2

SPRING AIR SYSTEMS HOOD MODEL NUMBER DESIGNATIONS

There are numerous types and styles of SPRING AIR SYSTEM Rev-Low ventilator available.

Refer to the UL/ULC label for the complete model number and exhaust flow requirement for your

dry ventilator. The UL/ULC label is located on the underside of the grease through on the right

hand side of the dry ventilator.

SPRING AIR SYSTEMS HOOD MODEL NUMBER DESIGNATIONS

D N B-F MP 10 4

D Dry Grease Extractor

N No exhaust fire damper

D Fusible link, dead weight fire damper

B-F Box type rev-low hood

MG Make up air through front grilles

MP Make up air through perforated panels

MC Make up air down discharge through perforated

MR Make up air through rear wall plenum

10 The length of the ventilator in feet

4 The width of the ventilator in feet

Model Number Designation - Ventilators

Chart No1

PRINCIPLE OF OPERATION

A commercial kitchen cooking line consists of many different appliances depending on the type of

restaurant or institution. In every commercial kitchen the cooking vapors that comprise of grease,

smoke, and products of combustion rise

off the cooking surface. Natural

convection forces drive the cooking

vapors up towards the back wall as

shown in figure 2. The kitchen dilution

air is entrained into the cooking vapors

and the air mixture generally follows the

profile of the back and top of the hood.

The mixture of grease, smoke, products

of combustion, lint, dirt and kitchen

dilution air proceed along the roof of the

hood and follow a path down towards

the core extractor slot (the core

extractor slot extends along the length

of the hood). Most of the air mixture

enters the slot and a small amount rolls

back into the hood canopy to meet the

main air stream again.

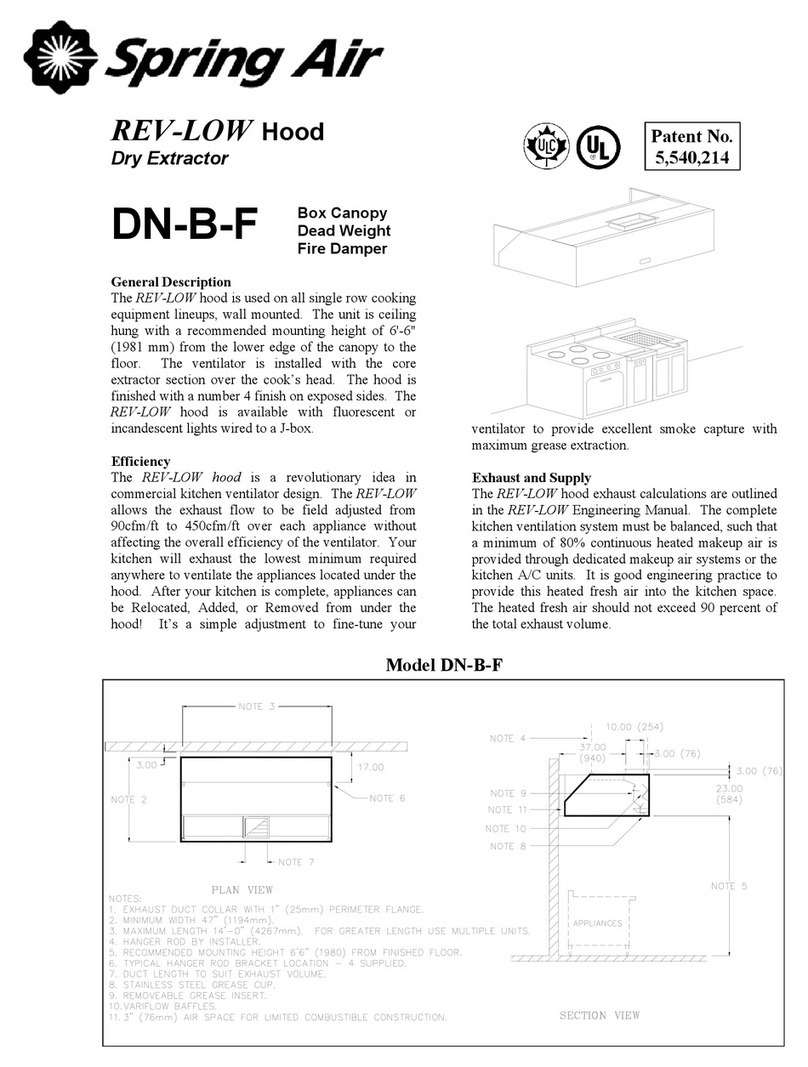

TheREV LOW Hood Model DN-B-F

Figure2

Optimizing the amount of air mixture that enters the core extractor slot is the key to the REV LOW

system. The REV LOW hood must incrementally maximize the amount of the air mixture that

enters the slot and minimize the amount of roll back into the canopy as the total amount of the air

mixture deviates along the length of the cooking lineup.

Back wall of hood

Optional 3" aiir space

Roof of hood

Core Extractor

Exhaust Air

Vapours from appliances

APPLIANCES

Front of hood

Kitchen dilution air

Variflow baffle

DN-Rev-LOW Maintenance and Operating Manual 3

VARIFLOW Baffles

Section View of Core Extractor for DN-B-F REV LOW Hood

Figure 3

The REV LOW accomplishes this complicated process with a unique core extractor profile that

contains a series of specially designed VARI-FLOW baffles located along length of the core

extractor. See Figure 3 above. The VARI-FLOW baffles are adjusted prior to shipment to allow

the optimum amount of the air mixture to enter the core extractor slot and thereby minimize roll

back into the hood canopy. For instance the VARI-FLOW baffles located above a Charbroiler are

opened to the maximum 450 CFM/ft position and the VARI-FLOW baffles located above ovens or

steamers are closed to the minimum 90 CFM/ft position. This variable adjustment along the

length of each hood provides an exhaust system that truly minimizes the amount of exhaust air to

properly ventilate any kitchen line up.

Section View of REV LOW Extractor with Detail of Vari-flow Baffle

Figure 4

End mullion

Removable Inserts

Core extractor slot

Core extractor slot

Shown in full open position

Exhaust duct collar

Top of core extractor

Variflow Baffle

Front of core extractor

Grease trough

Drain connection

Exhaust duct collar

Baffle Partially Closed

Roof of hood

Baffle Closed

Back of hood

Baffle Opened

Front of hood

Variflow Baffle

Core extractor

Back Wall

DN-Rev-LOW Maintenance and Operating Manual 4

BAFFLE SETTINGS

Vary-flow Baffle labeling

Figure 5

Each baffle is factory set base on the type of appliance under the hood.

REV-LOW MAINTENANCE INSTRUTIONS

Hood with Spring Air Systems RPD Controller

At the start of the day

1. Rotate the occupied/Unoccupied switch to the occupied position to start the exhaust system.

The exhaust fan(s) will turn on and after a minute time delay the supply unit(s) will turn on.

2. Check each hood for air movement in the slot. Put your hand up to the entrance of the slot

and feel if there is air movement. The air movement should feel the strongest over the heavy

appliances. (broilers)

Check Air Flow in slot Wiping Interior of Hood

3. If there is no air movement check if the green fan light on the Spring Air remote panel is on (If

not check the breaker panel or fuse), check if the motor starters have pulled in (Press the red

reset button), and finally check fan belts in exhaust fan(s) on the roof. Then call a

serviceman.

4. Go to the makeup air diffusers and check for air movement from the supply unit. If no air

movement check, motor starter (push red reset button), check fan belts on unit on roof, call a

serviceman.

5. Check that all the grease inserts are in the hoods and installed properly.

DN-Rev-LOW Maintenance and Operating Manual 5

At the end of the day

1. After the cooking equipment has been turned off rotate the occupied/Unoccupied switch to

the unoccupied position to shut off the exhaust system. The exhaust and supply fan(s) will

shut down.

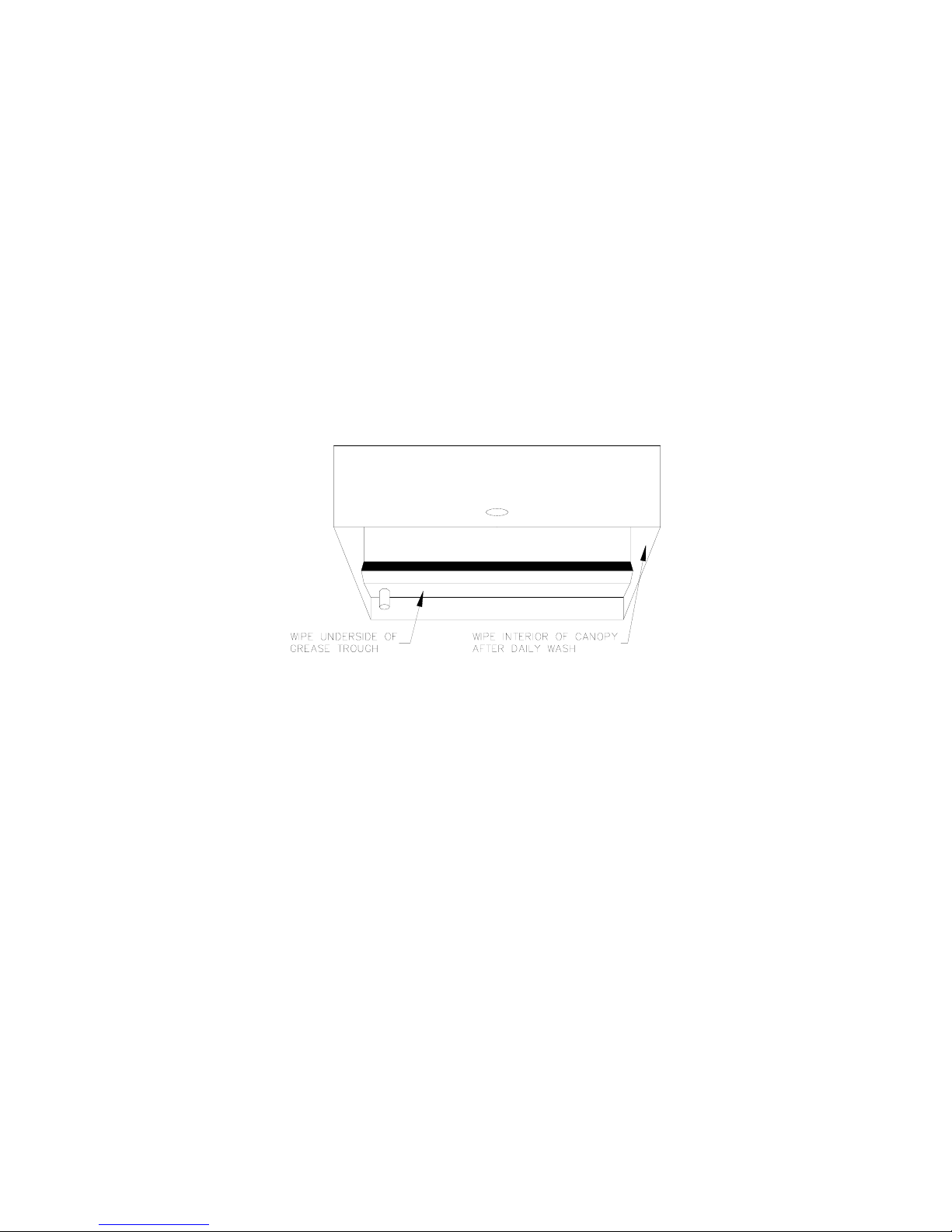

2. The REV-LOW hood will deposit particulate on both the hood backwall and roof. Wipe down

the stainless steel backwall above the appliances and the interior of the hood, including the

back and roof. Use a recognized hood degreaser. Wipe down the underside of the grease

trough. This is located directly above the cooks’ head.

Empty Grease Cup Steam Clean Interior

At the end of every other cooking day

1. Empty the grease cups located under the grease trough.

2. Remove the grease inserts and wash in a dishwasher or pot sink. . Use a recognized hood

degreaser and clean to bare metal.

3. Replace the insert in the hood.

At the end of the cooking day every six months

1. After removing the grease inserts for cleaning check the position of the Variflow Baffles in the

hood. The Variflow Baffles should be open over the heavy equipment and closed over the

lighter equipment. (Baffles should be wide open over charbroilers and closed over ovens.

2. Steam clean the interior of the grease extractor

Inspect Baffle Positions Check Baffle Setting

3. Go to the roof and check the condition of the exhaust fan and makeup air fan belts. Tighten

or replace as necessary.

4. Replace the makeup air filters. (Filter replacement times will vary with location of the

restaurant)

DN-Rev-LOW Maintenance and Operating Manual 6

CLEANING THE EXTERIOR

Normal soil can be removed with a mild detergent and water mixture applied to a cloth. To

remove baked on grease, apply a cleanser to a damp cloth or sponge and rub on the metal in the

direction of the polishing lines. DO NOT RUB IN A CIRCULAR MOTION.

Burnt deposits, which do not respond, can usually be removed by rubbing the surface with a

SCOTCH-BRITE scouring pad of STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

WOOL. Heat tint can be removed by a vigorous scouring in the direction of the polish lines using

a SCOTCH BRITE of STAINLESS scouring pad in conjunction with a powdered cleanser.

REV-LOW MAINTENANCE SCHEDULE

DAILY:

1.At the end of the cooking day wipe off the interior and exterior of the dry ventilator canopy

and the underside of the grease trough with damp clothe.

WEEKLY:

1.Remove the grease inserts and wash in a mild detergent and water mixture.

2.Cleaning the Hood Exterior

Cleaning the Hood Exterior

Figure 7

Wipe off the interior of the dry ventilator plenum behind the grease extractor inserts and the

interior and exterior of the grease trough. Remove the grease cup and clean if necessary.

SIX MONTHS

1.Check the exhaust fan belts for alignment, tighten, and wear. Adjust an/or replace.

2.Inspect the fusible link fire damper. Clean and/or replace the fusible link if necessary.

TROUBLE SHOOTING

Low air (i) Improper exhaust fan rotation.

(ii) Broken or slipping belt.

(iii) Exhaust ductwork inspection door open.

(iv) Obstruction in the ductwork.

(iv) Flow-flow baffle must be adjusted

No Air (i) Broken belt.

(ii) Exhaust fan overload tripped.

(iii) Exhaust fan disconnect open.

(iv) Exhaust fan motor fuse blown.

(v) Fire damper closed.

(v) Check if baffles are upside down in extractor.

DN-Rev-LOW Maintenance and Operating Manual 7

MEASURING THE EXHAUST AIRFLOW

The exhaust air is measured along the inlet slot of the ventilator. To ensure accurate results take a reading every foot

along the length of the ventilator is recommended.

VANAXIAL VELOMETER

Hold the

instrument

perpendicular to

the VORTEX

BAFFLE and

parallel to the

throat (inlet slot) of

the ventilator.

Velometer should

not exceed three

inches in

diameter.

Measuring Exhaust Air

Figure 8

PITOT TUBE OR ANEMOMETER

Hold the instrument

perpendicular to

the VORTEX

BAFFLE and

parallel to the

throat (inlet slot) of

the ventilator. Take

three readings

across the throat

and average the

results.

Measuring Exhaust Air

Figure 9

Calculating the Exhaust Air

Calculate the average velocity across the inlet slot and refer to the chart below for the

corresponding CFM/ft (l/s/m).

Ventilator Type Velocity Exhaust Air Volume

Fpm m/s CFM/ft l/s/m

DN-B-F/DN-DI 450 2.3 100 140

DN-B-F/DN-DI 675 3.4 150 210

DN-B-F/DN-DI 900 4.6 200 275

DN-B-F/DN-DI 1125 5.7 250 340

DN-B-F/DN-DI 1350 6.9 300 410

DN-B-F/DN-DI 1575 8.0 350 480

DN-B-F/DN-DI 1800 9.2 400 550

DN-B-F/DN-DI 2000 10.2 450 620

DN-B-F/DN-DI 2250 11.5 500 690

DN-B-F/DN-DI 2450 12.5 550 755

Chart 1

HANDLE IS UP AND OUT

CORRECT UP SIDE DOWN

REMOVEABLE INSERT INSTALLATION

Dry Extractor Maintenance and Operating Manual

8

INSTALLING THE TERMINATOR BAFFLE

The TBDD Terminator baffle is available in various lengths to suit adverse site

conditions. This will provide additional exhaust air over heavy appliances that

are being effected by the surrounding environment.

Installation:

Remove the TBDD from the packing material. Take off all of the Removable Access Doors “A” from the hood. You

should be able to clearly see all the adjustable baffles “B” and their settings. Ensure that the adjustable baffle(s) “B” over

the heavy appliance is set at 5. The TBDD baffles “C” are going to be installed on the adjustable baffles “B” over the light

appliances. To install the TBDD baffle “C” onto the adjustable baffle “B” simply line up the gap on the TBDD baffle “C”

with the lower end of baffle “B”. Tap the TBBD along the length until it is snug on baffle “B”. If the fit is loose remove the

TBBD baffle “C” and gently tap the gap with a hammer in the middle and at each end. Re-attach to baffle “B”.

Install these baffles on the two adjustable baffles “B” located on the right or left side of

the charbroiler (when looking from the front of the hood).

3.0"

TERMINATOR BAFFLE FOR DD-B-F BAFFLE

MODEL TBDD-3

CROSS SECTION OF DD-B-F HOOD

ADJUSTABLE BAFFLE "B" 0.625"

TERMINATOR BAFFLE "C"

REMOVEABLE ACCESS "A"

GAP

INSTALLER CAN FLATTEN WITH HAMMER

BAFFLE ONTO THE ADJUSTABLE BAFFLE

LEAVE GAP LOOSE ENOUGH TO SLIP

TO TIGHEN FIT ON SITE.

Dry Extractor Maintenance and Operating Manual

9

REV-LOW- STARTUP

REPORT

General Information

Job Name

Date

Customer

Location

Spring Air Service

Exhaust Fan Model No.

Manufacturer

Up blast Discharge yes no

Exhaust Fan HP

Exhaust Air Design (CFM)

Supply Air Design (CFM)

Ventilator mounting Height

from finished floor to front of hood

Make Up Air Systems Good Fair Poor None

Hood Item

Model Length

Width No. of Baffles

Baffle Size *Design CFM

Baffle No.

Left to Right

Baffle Setting Velocity Reading

(fpm)

Calculated Exhaust Volume

per Baffle (CFM) **

1

2

3

4

5

6

Total Exhaust Measured CFM

Design Exhaust CFM

Hood Item

Model Length

Width No. of Baffles

Baffle Size *Design CFM

Baffle No.

Left to Right

Baffle Setting Velocity Reading

(fpm)

Calculated Exhaust Volume

per Baffle (CFM) **

1

2

3

4

5

6

Total Exhaust Measured CFM

Design Exhaust CFM

Dry Extractor Maintenance and Operating Manual

10

Hood Item

Model Length

Width No. of Baffles

Baffle Size *Design CFM

Baffle No.

Left to Right

Baffle Setting Velocity Reading

(fpm)

Calculated Exhaust Volume

per Baffle (CFM) **

1

2

3

4

5

6

Total Exhaust Measured CFM

Design Exhaust CFM

Hood Item

Model Length

Width No. of Baffles

Baffle Size *Design CFM

Baffle No.

Left to Right

Baffle Setting Velocity Reading

(fpm)

Calculated Exhaust Volume

per Baffle (CFM) **

1

2

3

4

5

6

Total Exhaust Measured CFM

Design Exhaust CFM

Hood Item

Model Length

Width No. of Baffles

Baffle Size *Design CFM

Baffle No.

Left to Right

Baffle Setting Velocity Reading

(fpm)

Calculated Exhaust Volume

per Baffle (CFM) **

1

2

3

4

5

6

Total Exhaust Measured CFM

Design Exhaust CFM

Other Fine Products From

SPRING AIR SYSTEMS...

• Water Wash Ventilators

♦ Hot Water Wash

♦ Cold Water Spray/Hot Water Wash

♦ Water Wash Control Panels

• Dry Extractor Hoods

• REV-LOW Hoods

• Cartridge Hoods

• Filter Hoods

• Surface Fire Suppression

• Commercial Kitchen Exhaust Fans

• Kitchen Enviro Systems

♦ KES - 100% Exhaust

• Commercial Kitchen Supply Units

• Compensating Hoods

• Exhaust Fans

• Supply Fans

• Commercial Kitchen Control Panels

• Variable Speed Exhaust/Supply Systems

Phone: 905-338-2999, FAX: 905-338-1079, e-mail [email protected]

www.springairsystems.com

Table of contents

Other Spring Air Systems Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Miele

Miele DA 6698 W Operating and installation instructions

Sirius Satellite Radio

Sirius Satellite Radio SLTC EM 97 900 installation instructions

AEG

AEG 140 D Installation and operating instructions

Whirlpool

Whirlpool WHVF 63F LT K Instructions for use

Cookology

Cookology HICYL351BK instruction manual

Jocel

Jocel JCEID60-007520 manual

FALMEC

FALMEC Burano 50 Instruction booklet

Whirlpool

Whirlpool UXT5230AY Installation Instructions and Use & Care Guide

Electrolux

Electrolux LFP216S user manual

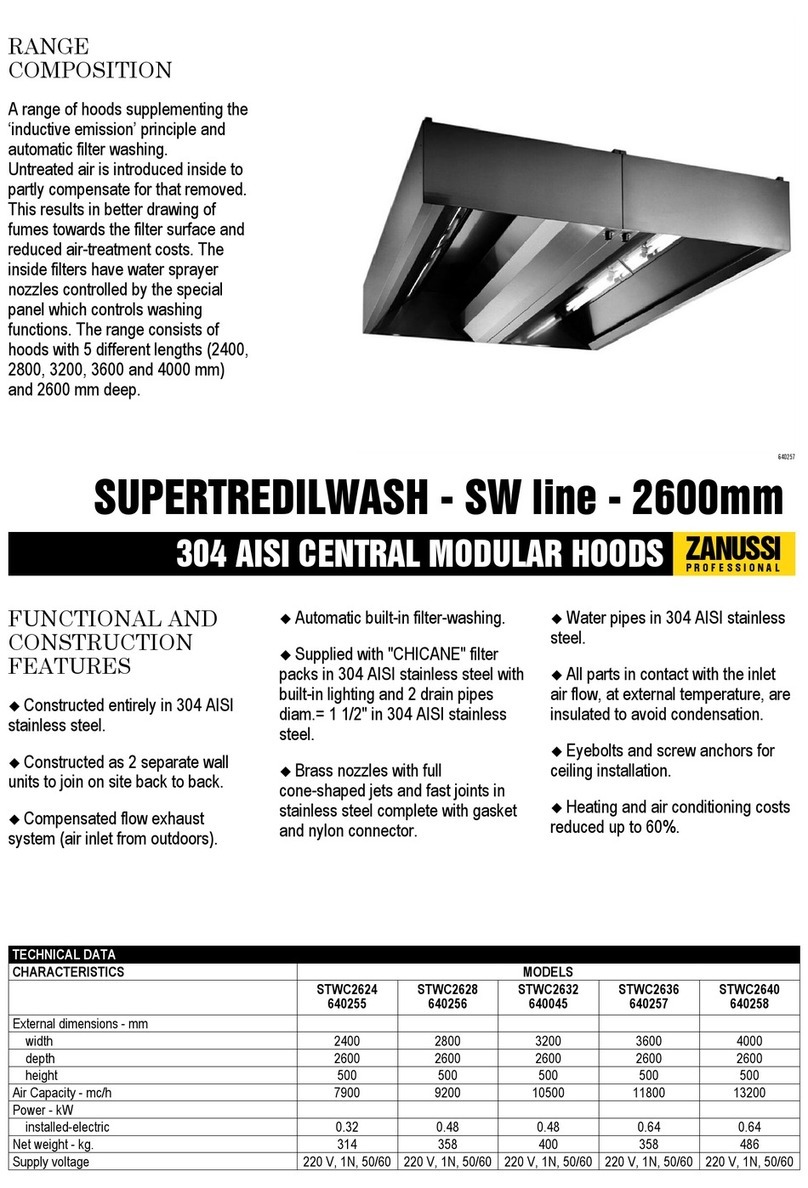

Zanussi

Zanussi Supertredilwash 640045 Brochure & specs

Ariston

Ariston ISLT 65 AS X Instructions for use

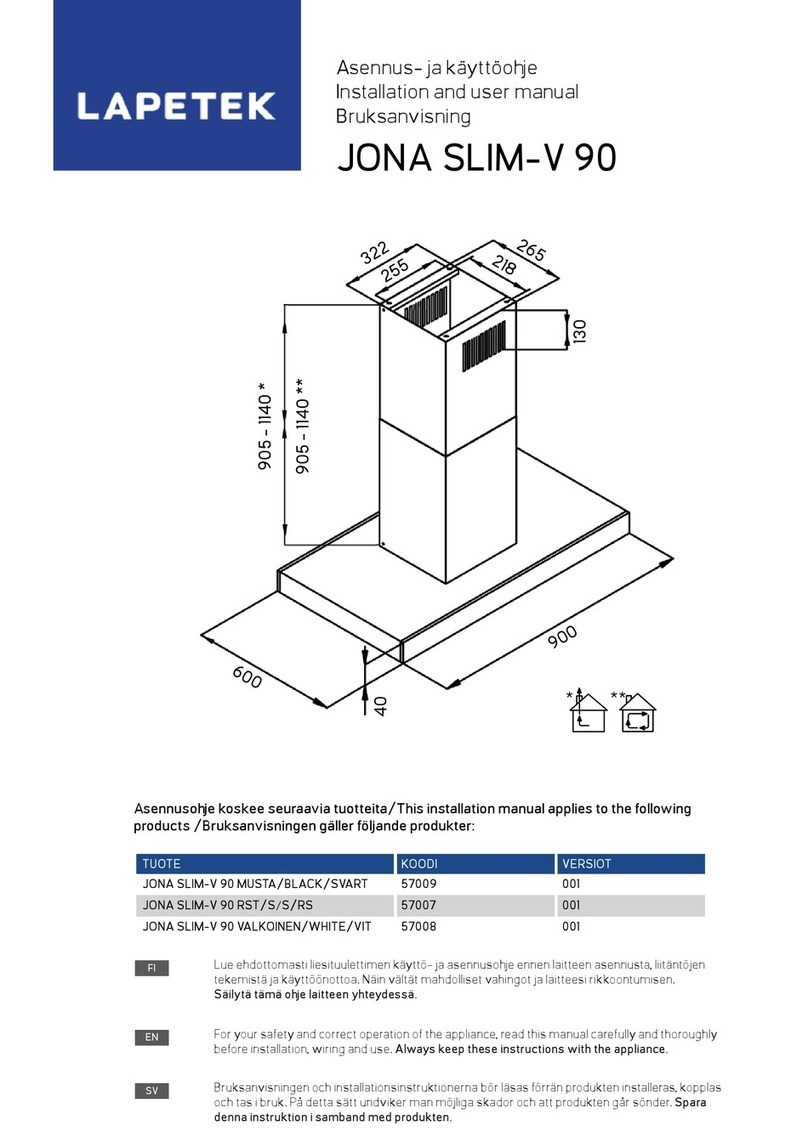

Lapetek

Lapetek JONA SLIM-V 90 Installation and user manual