SPT Plasmateknik AB SPLITFIRE User manual

INSTRUCTIONS FOR USE

SPLITFIRE

SPEEDFIRE

UPPERCUT

With PTA 121 hand torch

TO THE OPERATOR: PLEASE READ AND UNDERSTAND THIS MANUAL

BEFORE USING THE SPLITFIRE, SPEEDFIRE OR UPPERCUT. IT IS

ABSOLUTELY VITAL TO KNOW THE INFORMATION PRESENTED IN THIS

MANUAL IN ORDER TO USE THE MACHINES IN THE BEST WAY.

WITH THIS KNOWLEDGE AND A PROFESSIONAL APPROACH, YOU WILL BE

ABLE TO SOLVE MANY COMPLICATED CUTTING APPLICATIONS WITH THESE

SYSTEMS.

Rev. 4.2, 2012-11-01

STATE OF THE ARC PLASMA CUTTING TECHNOLOGY

Telephone

Email

SPT Plasmateknik AB

Transportvägen12

SE-241 38 Eslöv

Sweden

Internet

+46 10-172 73 50

www.spt.se

SPLITFIRE SPEEDFIRE UPPERCUT

2

CONTENTS

Page

1. TECHNICAL DATA 3

2. INSTALLATION 4

3. OPERATING INSTRUCTIONS 5

4. CHANGING CONSUMABLES 6

5. MAINTENANCE 8

6. TROUBLE SHOOTING 9

7. SAFETY INSTRUCTIONS 10

8. WARRANTY 14

9. RECYCLING 15

SPLITFIRE SPEEDFIRE UPPERCUT

3

1. TECHNICAL DATA

UPPERCUT

Power supply 400 V, 3~50 Hz

Mains fuse 32 A slow blow

Maximum power 17,6 kVA

Process power 120 V, 20-120 A

Duty cycle @ 40°C 30% @ 120 A

60% @ 100 A

100% @ 80 A

Power factor

Open circuit voltage

Protection class

Cooling

Temperature class

Dimensions LxWxH

Weight

0,95

240 VDC

IP 23

F

F

560x190x320

18kg

Maximum cutting capacity

Quality cut

Air pressure

45 mm

35 mm

5,5 bar

Air flow PTA 121 190 l/min

Standard torch length

SPLITFIRE

400 V, 3~50 Hz

16 A slow blow

10,4 kVA

120 V, 20-80 A

50% @ 80 A

60% @ 60 A

100 % @ 45 A

0,95

240 VDC

IP 23

F

F

560x190x320

17kg

25mm

20 mm

4,5 bar

160 l/min

6 m

SPEEDFIRE

400 V, 3~50 Hz

32 A slow blow

14,5 kVA

120 V, 20-100 A

40% @ 100 A

60% @ 80 A

100% @ 70 A

0,95

240 VDC

IP 23

F

F

560x190x320

17kg

35 mm

30 mm

5,5 bar

190 l/min

6 m 6 m

SPLITFIRE SPEEDFIRE UPPERCUT

4

2. INSTALLATION

Connect the torch to the power source. After connecting electric power and compressed

air, the machine is ready for use. Please read the enclosed instructions on how to use the

central connector.

Power supply

Connect the machine to 3-Phase, 50 Hz, 400 V only.

Use with generators

SPLITFIRE, SPEEDFIRE and UPPERCUT are equipped with filters for use with mobile

generators. The generator should be of at least 15 kVA for SPLITFIRE, 22 kVA for

SPEEDFIRE and 27 kVA available exclusively for the plasma cutting system.

Air supply

Connect dry, clean and oil free compressed air to the filter regulator on the rear of the

machine and adjust to 4,5 bar for SPLITFIRE and 5 bar for SPEEDFIRE/UPPERCUT. When

cutting at lower amperage than 70 A with SPEEDFIRE/UPPERCUT it may be necessary to

lower the air pressure to 4,5 bar in order to get the best cutting capability. Don’t forget to raise

the pressure again if returning to amperage above 70 A.

SPLITFIRE SPEEDFIRE UPPERCUT

5

3. OPERATING INSTRUCTIONS

Check that the machine has been properly connected to power supply and compressed air

according to chapter 2, INSTALLATION.

Check that the torch is fitted with appropriate consumables for the job at hand.

Connect the earth lead clamp directly at the work piece, ensuring that a good contact is

obtained. If necessary, clean the surface from paint, rust, dirt, etc.

Cutting

Switch the machine’s main power switch on. The READY lamp will light and the fan

will start working.

Choose process power, 20-80 for SPLITFIRE, 20-100 A for SPEEDFIRE or 20-120 A

for UPPERCUT.

Manouver the torch in position for cutting or gouging.

Press the START-switch on the torch handle.

Air will flow for one second before the pilot arc strikes. The pilot arc will burn for

about 3 seconds. If contact with the work piece is not obtanined within this time, the

pilot arc goes out. Then make a new try.

To end the process, release the START-switch. The plasma arc goes out

instantaneously. Air will continue to flow for about 30 seconds.

NOTE! When the machine is not in use or is only working at long intervals, switch off

the machine. It contains mechanical components that should not be exposed to unnecessary

wear. It also protects against unvoluntarily firing the pilot arc.

SPLITFIRE SPEEDFIRE UPPERCUT

6

4. CHANGING CONSUMABLES

SPLITFIRE SPEEDFIRE UPPERCUT

7

Consumables/torchparts for PTA 120/121

Part No. Description

899044 Torch head PTA 121

899003 Electrode standard PTA 120/121

899017 Electrode long PTA 120/121

899004 Swirl ring PTA 120/121 for 20-80 A

899023 Swirl ring PTA 120/121 for 80-120 A

899005 Nozzle 1,0 20-50 A PTA 120/121

899006 Nozzle 1,2 50-90 A PTA 120/121

899007 Nozzle 1,4 90-120 A PTA 120/121

899008 Nozzle 1,6 120 A PTA 120/121

899016 Nozzle 2,5 gouging PTA 120/121

899031 Nozzle 1,0 20-50 A long PTA 120/121

899032 Nozzle 1,2 50-90 A long PTA 120/121

899018 Nozzle 1,4 90-120 A long PTA 120/121

899033 Nozzle 2,5 gouging long PTA 120/121

899047 Protective cup PTA 120/121

899037 Spatter shield threaded PTA 120/121

899036 Contact cutting shield PTA 120/121

899010 Spatter shield PTA 120/121

899012 Distance cutting guide PTA 120/121

899013 Bevel cutting guide PTA 120/121

899038 Contact cutting shield long PTA 120/121

899014 Circle cutting guide PTA 120/121

899045 Handle PTA 121

899314 Button PTA 25/121

899049 Hose assembly PTA 121 6m

899050 Hose assembly PTA 121 15m

899015 Spanner PTA 120/121

899040 Torch PTA 121 6m complete

899041 Torch PTA 121 15m complete

N.B. Don’t use consumables for more than 80 A with the SPLITFIRE or 100 A

with the SPEEDFIRE. The result will be poor cutting capability.

SPLITFIRE SPEEDFIRE UPPERCUT

8

5. MAINTENANCE

DAILY

Inspect and, if necessary, change the torch consumable parts.

Inspect and, if necessary, empty the moisture trap on the filter regulator on the rear side of the

machine. The trap is emptied by pressing the bottom sealing while compressed air is

connected. If cleaning the trap is necessary, completely unscrew the glass cup after

disconnecting compressed air.

Carefully inspect the hose assembly and torch body with regard to any leak or damage.

Never use a damaged torch.

EVERY SIX MONTHS

Disconnect the machine from compressed air and electricity. Remove the cover. Clean

the machine with dry, clean and oil free compressed air. Inspect cable connections and gas

system.

In unusually dirty environments this procedure should be carried out every month.

SPLITFIRE SPEEDFIRE UPPERCUT

9

6. TROUBLE SHOOTING.

Thermal overload / Air supply failure

If the fan is working, but the green READY-lamp is not lit, the air supply is not

sufficient or the thermal overload protection is active. Check the compressed air supply. If the

machine is overheated, let it cool down while switched on until the lamp lights again. Then

the machine is in working order.

Malfunction

If the pilot arc does not strike:

•The safety switch of the torch is not closed. Check that the protective cup is

properly tightened.

•Check the air pressure on the filter regulator on the rear of the machine. The

pressure should be approx. 4,5/5,5 bar.

If the pilot arc is unstable:

•Check the air pressure on the filter regulator on the rear of the machine. The

pressure should be approx. 4,5/5,5 bar.

•The machine is working two phase. Check electrical supply.

Inferior cut quality or performance:

•Check the torch consumables. Replace if necessary.

•Inspect the torch body and hose assembly with regard to any damage or leak.

•Check the air pressure on the filter regulator on the rear of the machine. The

pressure should be approx. 4,5/5,5 bar.

•Check the earth lead connection. Place the earth lead clamp directly on the work

piece. If necessary, clean from paint, dirt, rust etc.

SPLITFIRE SPEEDFIRE UPPERCUT

10

7. SAFETY INSTRUCTIONS

All endangerments through plasma cutting are related with the process itself. Endangerments

may occur due to:

High contact voltage

HV ignition

Electromagnetic interferences

Heat and light radiation

Gases, fumes and smoke

Noise

Hot metal and spatter

Handling of pressure cylinders

The Plasma Cutting Machine has been developed in conformity with following standards:

EN 60974-1 safety requirements for installations for arc welding and welding power

sources

Endangerment due to high contact voltage

Warning!

Before opening the plasma rectifier generally the input power has to be disconnected

physically from the mains (unplug mains cable)! Only advised personnel are allowed to

carry out any repairs to the machine.

Attention! Connect the work piece cable and earth the workplace before starting the

machine!

The power source is equipped with a cooling unit and there is an electric potential between

the housing and work piece in case the work piece isn't earthed and the machine is switched

on. Because of the high resistance of more than 10 kOhm in the coolant the contact voltage is

absolute not dangerous but sensible.

Special hints:

Connect power source only to correctly earthed mains socket with proper connected

safety conductor

Wear insulating protective clothing (safety shoes, leather apron, gloves), place torch

on insulated holder,

Make sure that they cutting area and plasma machine components are dry and clean,

arrange regular inspections.

Never short safety circuits.

Working under elevated electrical endangerment

This plasma cutting machine in conformity with valid standards (EN 60974) can be used for

operation under elevated electrical endangerment

The power source and the plasma torches are forming a safety-proofed installation

which can be separated only by using tools.

The patented design of the torch prevents electrical danger when the torch

consumables are disassembled.

Therefore the power source is marked with the S-sign and operation under elevated electrical

endangerment is allowed.

Attention! Always follow the local safety rules!

SPLITFIRE SPEEDFIRE UPPERCUT

11

Endangerment through high voltage (HV)

A HV-igniter starts the pilot arc. The HV-supply is cut-off automatically after pilot arc has

struck.

Attention! Never touch nozzle or nozzle cap when power source is switched ON!

HV-ignition may establish electromagnetic fields and can influence:

heart pace-makers

electronic devices

Endangerment through electromagnetic interferences

The plasma cutting unit is in conformity with the conditions of the EN 50199

“Electromagnetic compatibility”. This standard is valid for arc welding and related processes

(plasma cutting) that come in use in commercial and private fields.

Warning!

Special precautions may be required if the plasma unit is used in private fields (for instance

screened cables etc.)

The user takes the full risk when installing and using the machine. He has to follow strictly

the instructions of the supplier. If electromagnetic interferences are noticed the user is to

contact the producer to solve the problem.

Recommendations to classify the environment (EN 50199):

Before the installation takes place the user has to value the environment for electromagnetic

problems and to take into consideration:

Other mains supplies, control cables, signal and telecommunication lines along, above,

below or beside the installation

Broadcasting or television installations

Computers or other controls

Safety devices, protection circuits

The health of people in the area (heart pace makers, hearing aids etc.)

Devices for measuring and calibrating

The noise immunity of equipment around the installation, so that they are compatible

with electromagnetic interferences. Special measures may be required.

The time of day that plasma cutting is performed

Recommendations to minimise interferences:

If interferences take place, the following should be done:

Apply filter for mains connection

Screening of mains cable of the plasma installation (safe contact between screen and

housing required)

Constant maintenance

SPLITFIRE SPEEDFIRE UPPERCUT

12

Always keep cover plates and doors of the plasma machines closed

Avoid excessive length of cutting cables

Arrange potential equalisation between metallic parts around the installation (the

operator has to be electrically isolated from those parts)

Earthing of the work piece

Selective screening of other cables and installations

Endangerment through heat and light radiation

The plasma arc produces intense ultraviolet and infrared radiation that can hurt the eyes and

skin. Therefore the following precautions have to be arranged:

Wearing of flame-retardant welding clothes (helmet, apron, gloves, safety shoes)

Hand or head shield with protective glasses of medium shade for watching the cutting

process

Preparing the cutting area so that reflection and transmission of ultraviolet light is

reduced:

painting of walls in dark colour

use of protective walls and screens

Endangerment through fumes and smoke

Due to the plasma process itself hazardous substances may be produced. To avoid risks on

health the following has to be done:

Keep cutting place well ventilated

Remove fumes and smoke by exhaustion devices

Remove all chlorinated and other solvents from the cutting area. They could form

phosgene gas when exposed to ultraviolet radiation

Wear a breathing mask when cutting galvanised materials

Ensure that toxic limits are not exceeded

Endangerment through noise

Be aware that during plasma cutting a high noise level arises.

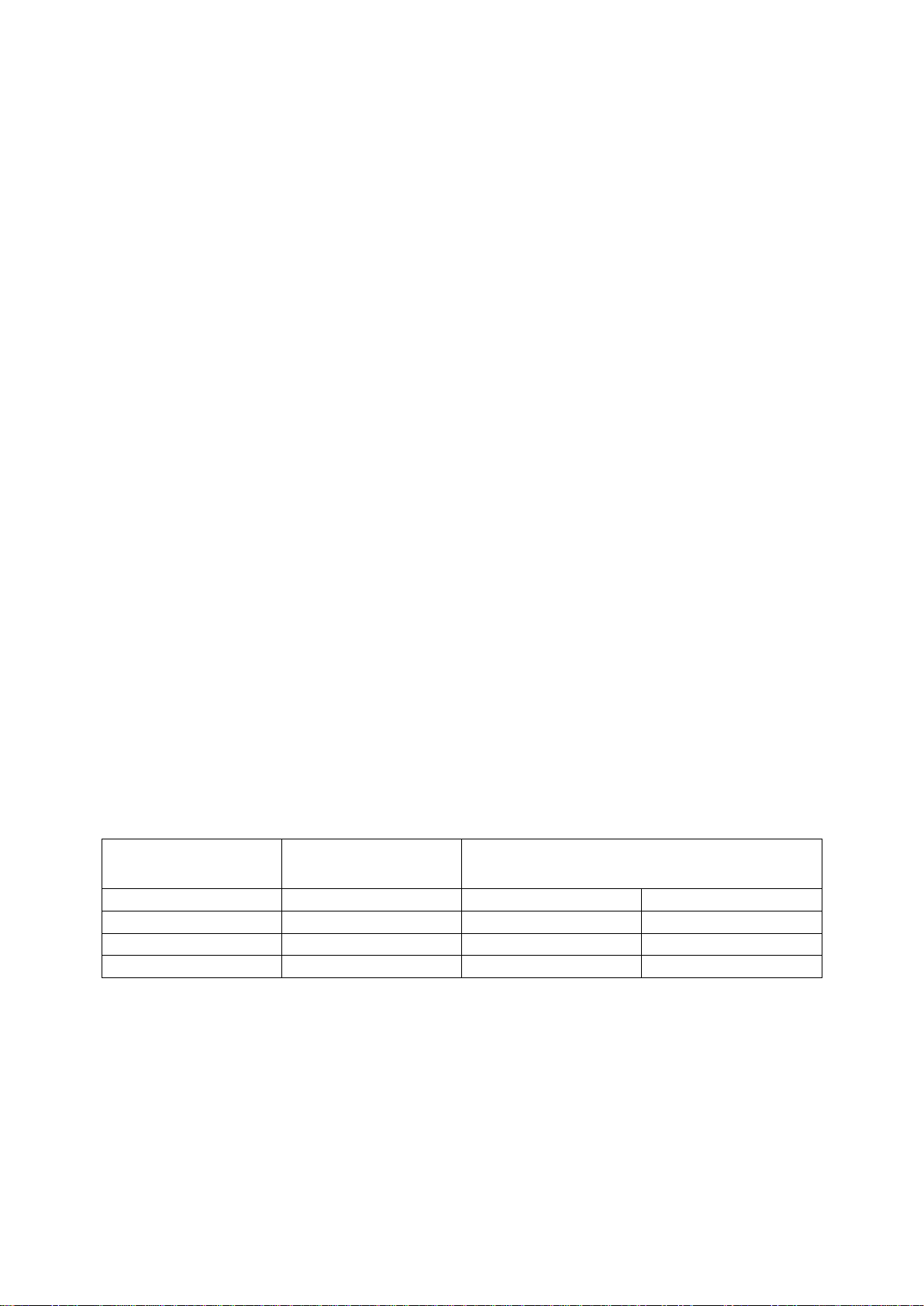

Cutting current

Thickness

Noise level in distance of

0,5 m

1,0 m

No load

56dB(A)

80A

4mm

82 dB(A)

79 dB(A)

160A

l6mm

86 dB(A)

83 dB(A)

240A

l6mm

96 dB(A)

92 dB(A)

Above levels are general. Variations may occur.

Therefore wear proper ear protection.

Endangerment through spatter

During plasma cutting sparks, slag and hot metal are produced. The risk of burns and fire

exists! To avoid these endangerments the following has to be advised:

Remove all potential flammable materials from cutting area, at least in a 10 m

distance.

SPLITFIRE SPEEDFIRE UPPERCUT

13

Allow cut material to cool down before handling.

Make fire extinguisher available in the cutting area.

Handling of pressure cylinders

In some cases compressed gases are required for the plasma cutting process. To avoid

endangerments the following has to advised:

Place cylinders upright in secured position.

Never use damaged cylinders, pressure reducers and armatures.

Use pressure reducers only for the gas it is determined.

Never lubricate pressure reducers with grease or oil.

All parts coming in contact with oxygen must be free from oil and grease.

When using oxygen and/or flammable gases the pressure reducer must be equipped

with an explosive-proofed device (backfire-device)

Regularly check the gas hoses and other equipment for leaks etc.

Always follow local regulation regarding gas equipment.

SPLITFIRE SPEEDFIRE UPPERCUT

14

8. WARRANTY

SPT Plasmateknik AB grants a 24 month warranty for its products.

Validity

The warranty applies to power sources manufactured by SPT Plasmateknik AB

(SPT). The warranty period is 24 months from date of delivery to end user, but not

more than 30 months from delivery from factory. If the product is used more than

normal 1-shift work, the warranty period is shortened accordingly.

Any warranty claim should be accompanied by proof of purchase.

Coverage

SPT will take responsibility to repair a machine to the state it was in before the fault

occurred.

The warranty covers spare parts and reimbursement for work carried out by an

authorised service point. Labor costs are limited to a fixed rate for each action carried

out.

Upon replacement of parts, SPT reserves the right to invoice parts. The invoices will

be credited upon the return of faulty parts to SPT.

When a warranty claim occurs, the customer should immediately turn to an

authorised service point, or SPT directly. SPT requires detailed information about the

conditions under which the machine was in use when the fault occurred, such as

location (indoor/outdoor), ambient temperature, power supply (generator/normal

power supply –if generator, information is needed about the rating and type of

generator).

When a machine is taken in for warranty repair it is required that the torch also is

brought in with the consumables mounted that were there when the fault occurred.

The serial number must be clearly visible.

The user is responsible for limiting the damage by immediately stopping using the

machine if a problem is suspected.

Warranty repair may only be carried out by authorised service points. SPT reserves

the right to deny warranty claims where work has been carried out by non-authorised

service personnel.

Should SPT find that the product has been used inappropriately and it is likely that

such inappropriate use may continue, SPT reserves the right to refuse warranty

repair and refund the customer, with a deduction for the use the customer has had of

the product. SPT also reserves the right to restore the product to working order on

the customer’s expense.

Limitations

The following is not covered by warranty:

Defects caused by natural wear.

Defects caused by non-compliance of use and maintenance recommendations.

Improper gas pressure settings.

Improper electrical power supply.

Overload.

Damage caused by transport, handling and improper storage.

Fire

Damage caused by natural causes such as lightning, flooding etc.

SPLITFIRE SPEEDFIRE UPPERCUT

15

Further, the warranty does not cover:

Fault finding, direct or indirect travel costs, transport costs, travel costs, allowances,

accommodation and such.

SPT bears no responsibility whatsoever for consequential damages caused by fault

in its products, such as, but not limited to, loss of revenue, damages to 3rd party,

production delays, penalties etc.

The warranty is not valid if modifications of any kind has been made to the product,

without the written approval from SPT. Repairs made by non-authorised service

personnel renders the warranty void.

A modified product will be restored to the original state at the expense of the

customer prior to any repair, as SPT can not be responsible for the function of its

products otherwise.

Warranty on replaced parts

A replaced part will be covered by the original warranty. If less than 6 months

remains from the warranty period, a replaced part will be covered for maximum

months.

Disputes

Disputes will be handled according to the general terms in Orgalime S 2000.

9. RECYCLING

Do not throw electrical equipment in the regular rubbish! According

to EU-directive 2002/96/EG regarding waste that contains electric or

electronic parts (WEEE) and its implementation with national laws

products must be collected separately and brought to approved

recycling facilities after their useful life. As the owner of the product

you should find out the location of an approved recycling facility from

your local dealer.

This manual suits for next models

2

Table of contents

Other SPT Plasmateknik AB Welding System manuals