Srne HF4830S60-H User manual

SOLAR INVERTER CHARGER

Product Manual

Product Type

HF4830S60-H | HF4850S80-H

MF4830S60-H | MF4850S80-H

Solar Energy Storage Inverting & Control All-In-One Machine 1

Important Safety Instruction

Please maintain the manual for reference in the future

The manual comprises all safety, installation and operation instruction for HF/MF48-H Solar

Energy Storage and Inverting Control All-in-one Machine.

Before installation and use, please carefully read all instructions and notices in the manual.

There is unsafe voltage inside the all-in-one machine. In order to avoid personal injury, the user shall not

dismantle the machine by himself. To repair the machine, it is required to contact the company's professional

maintenance personnel.

Do not place the all-in-one machine in the reach of children.

The all-in-one machine has the protection grade of IP20, which belongs to indoor application

products. It is strictly prohibited to use outdoors,because there is no warranty for outdoor use damage.

Do not install the all-in-one machine in a humid, oily, inflammable, explosive or dusty environment.

Municipal power input and AC output are high voltage, please do not touch the wire.

The all-in-one machine in working is very hot, so please do not touch the machine.

Please don’t open the terminal protection cover of the all-in-one machine in working.

It is recommended to install appropriate fuse or circuit breaker outside the all-in-one machine.

Make sure to disconnect the fuse or circuit breaker close to the photovoltaic array, mains supply and

battery terminals before installing and adjusting the wiring of the integrated machine.

Check whether all wires are connected firmly after installation to avoid danger of heat accumulation due

to virtual connection.

The all-in-one machine is the off grid type. It is required to confirm that the all-in-one machine is the

unique power supply input device for the load device. It is forbidden to use the machine in parallel with other

input AC power to avoid damage.

Solar Energy Storage Inverting & Control All-In-One Machine 2

Table of Contents

1. Basic Information........................................................................................................................4

1.1 Product overview and characteristics .............................................................................................................................. 4

1.2 Basic system introduction.................................................................................................................................................... 5

1.3 Product characteristics .......................................................................................................................................................... 6

1.4Dimension drawing.................................................................................................................................................................. 7

2. Installation Instruction...............................................................................................................8

2.1 Installation notice.................................................................................................................................................................... 8

2.2 Wire specification and breaker type................................................................................................................................. 9

2.3 Installation and Wiring........................................................................................................................................................10

3.Operating Mode.........................................................................................................................15

3.1 Charge mode ..........................................................................................................................................................................15

3.2 Output mode..........................................................................................................................................................................16

4. Operation Instruction for LCD Screen....................................................................................17

4.1 Operation and display panel.............................................................................................................................................17

4.2 Introduction to operation keys.........................................................................................................................................17

4.3 Introduction to indicator light..........................................................................................................................................17

4.4 Introduction to LCD screen................................................................................................................................................18

4.5 Setting parameter .................................................................................................................................................................20

4.6 Battery type parameters .....................................................................................................................................................26

5.Other Function............................................................................................................................28

5.1 Dry node function.................................................................................................................................................................28

5.2 RS485 communication function.......................................................................................................................................28

5.3 USB communication function...........................................................................................................................................28

6.Protection....................................................................................................................................29

6.1 Protection function ...............................................................................................................................................................29

6.2 Meaning of fault code .........................................................................................................................................................30

6.3 Some fault troubleshooting ..............................................................................................................................................31

7.System Maintenance..................................................................................................................32

8. Technical Parameter..................................................................................................................33

Solar Energy Storage Inverting & Control All-In-One Machine 3

1. Basic Information

1.1 Product overview and characteristics

HF/MF48-H series is a new type of mixed solar energy storage inverting & control all-in-one machine

integrating solar energy storage & municipal power charge storage and AC sine wave output. It adopts DSP

control and advanced control algorithm to achieve characteristics of high response speed, high reliability and

high industrial standard. There are four charge modes namely only solar power, mains power priority, solar

power priority, mains power & solar power; and two optional output modes, namely inverting and mains power

to meet different application needs.

The solar charge module adopts the latest optimized MPPT tracking technology, which can quickly track

the maximum power point of the photovoltaic array in any environment to obtain the maximum energy of the

solar panel in real time with wide voltage range of MPPT.

AC-DC charge module adopts advanced control algorithm to realize full digital double closed-loop control

of voltage and current, with high control accuracy and small volume. Battery can be charged and protected

stably and reliably with wide AC voltage input range, full input/output protection function.

DC-AC inverter module based on full digital intelligent design adopts advanced SPWM technology, outputs

pure sine wave, converts DC into AC. It is suitable for AC loads such as household appliances, electric tools,

industrial device, electronic audiovisual, etc. The product adopts the segment LCD display design to display the

operation data and state of the system in real time. The comprehensive electronic protection function ensures

that safety and stability of the whole system.

Characteristics:

1. Adopt full digital voltage and current double closed-loop control and advanced SPWM technology to output

pure sine wave.

2. Two output modes, i.e. mains bypass and inverter output can achieve uninterrupted power supply function.

3. Four optional charge modes: only solar energy, mains priority, solar energy priority and mixed charge.

4. Advanced MPPT technology, with efficiency up to 99.9%.

5. Wide MPPT voltage range.

6. With function of activating lithium battery with solar energy and AC mains power, it supports connection of

lead-acid battery and lithium battery.

7. LCD screen design and 3 LED indicator lights dynamically display system data and operation states.

8.ON/OFF rocker switch can control AC output.

9.With power saving mode function, it can reduce no-load loss.

10.Intelligent adjustable speed fan is adopted for efficient heat dissipation and extended system life.

11.Possessing multiple protection functions and 360° comprehensive protection.

12.Possessing complete short circuit protection, overvoltage and undervoltage protection, overload protection,

back filling protection, etc.

Solar Energy Storage Inverting & Control All-In-One Machine 4

13.It has the function of mixed load: when the battery is not connected, photovoltaic and commercial power

can supply power to the load at the same time (if there is no battery, the commercial power must be

connected). When the battery is full, it can also enter the mixed load mode, which can make full use of the

photovoltaic energy.

1.2 Basic system introduction

The figure below shows the system application scenario of this product. A complete system includes the

following parts:

1. Photovoltaic module: convert the light energy into direct current energy and then charge the battery via the

all-in-one machine, or directly invert the light energy into alternating current to supply power to the load.

2. Mains or generator: connected at the AC input, it can supply power to the load and charge the battery at the

same time. If no mains power or generator is connected, the system can also operate normally. At this time,

the load power is supplied by the battery and photovoltaic modules.

3. Battery: the battery is to ensure the normal power consumption of the system load in case of no sufficient

solar energy or mains supply.

4. Household load: it can be connected to various household and office loads, including AC loads such as

refrigerators, lamps, televisions, fans, air conditioners, etc.

5. Inverting and control all-in-one machine: the energy conversion device of the whole system.

The specific system wiring mode is determined by the actual application scenario.

Solar Energy Storage Inverting & Control All-In-One Machine 5

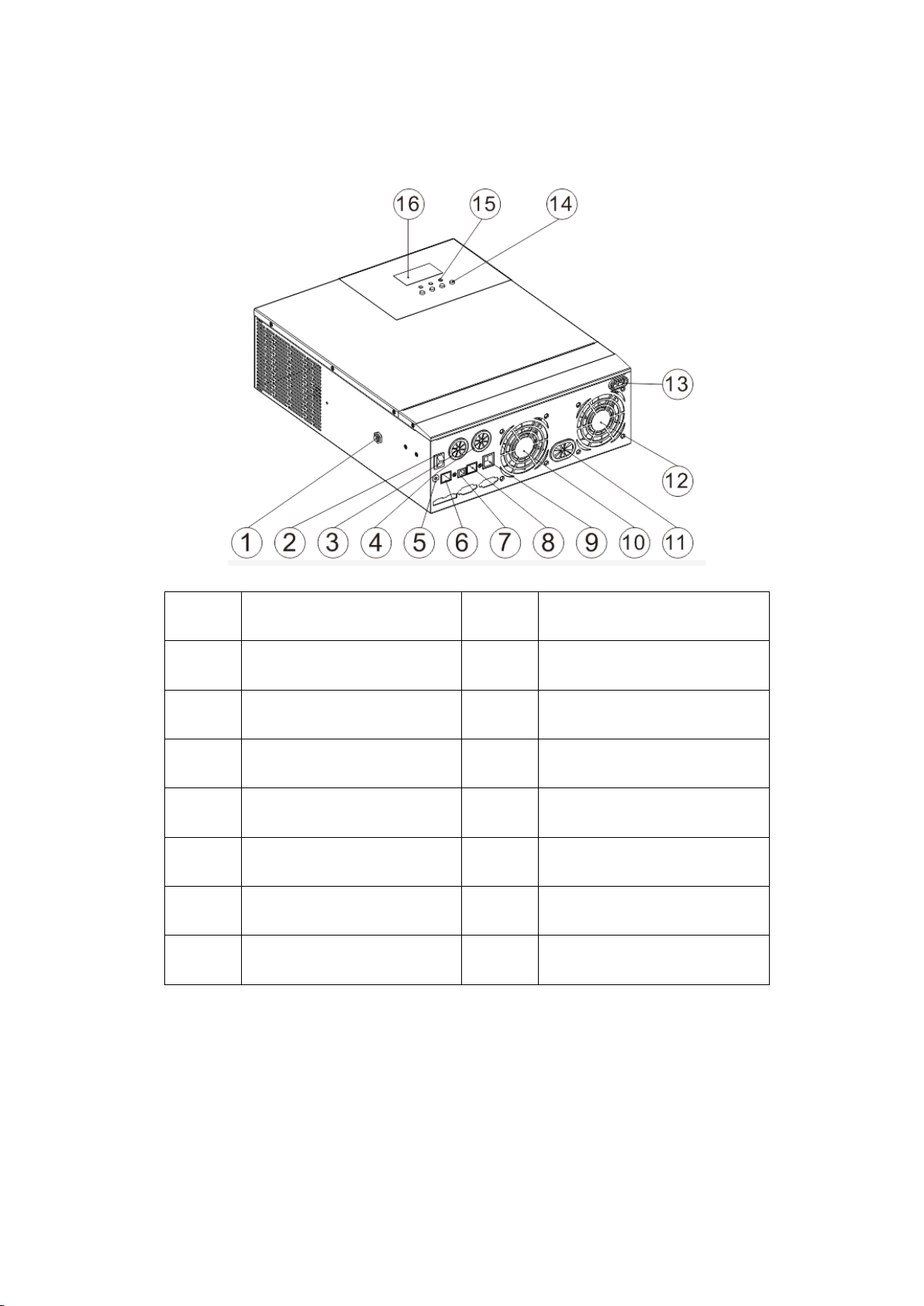

1.3 Product characteristics

Overload protector ⑨Dry contact port

②ON/OFF rocker switch ⑩Cooling fan

③ACi nput port ⑪Battery port

④AC output port ⑫Cooling fan

⑤Grounding screw hold ⑬PV port

⑥RS485-2 communication port ⑭Touch the key lightly

⑦USB communication port ⑮Indicator light

⑧RS485-1 communication port ⑯LCD screen

Solar Energy Storage Inverting & Control All-In-One Machine 6

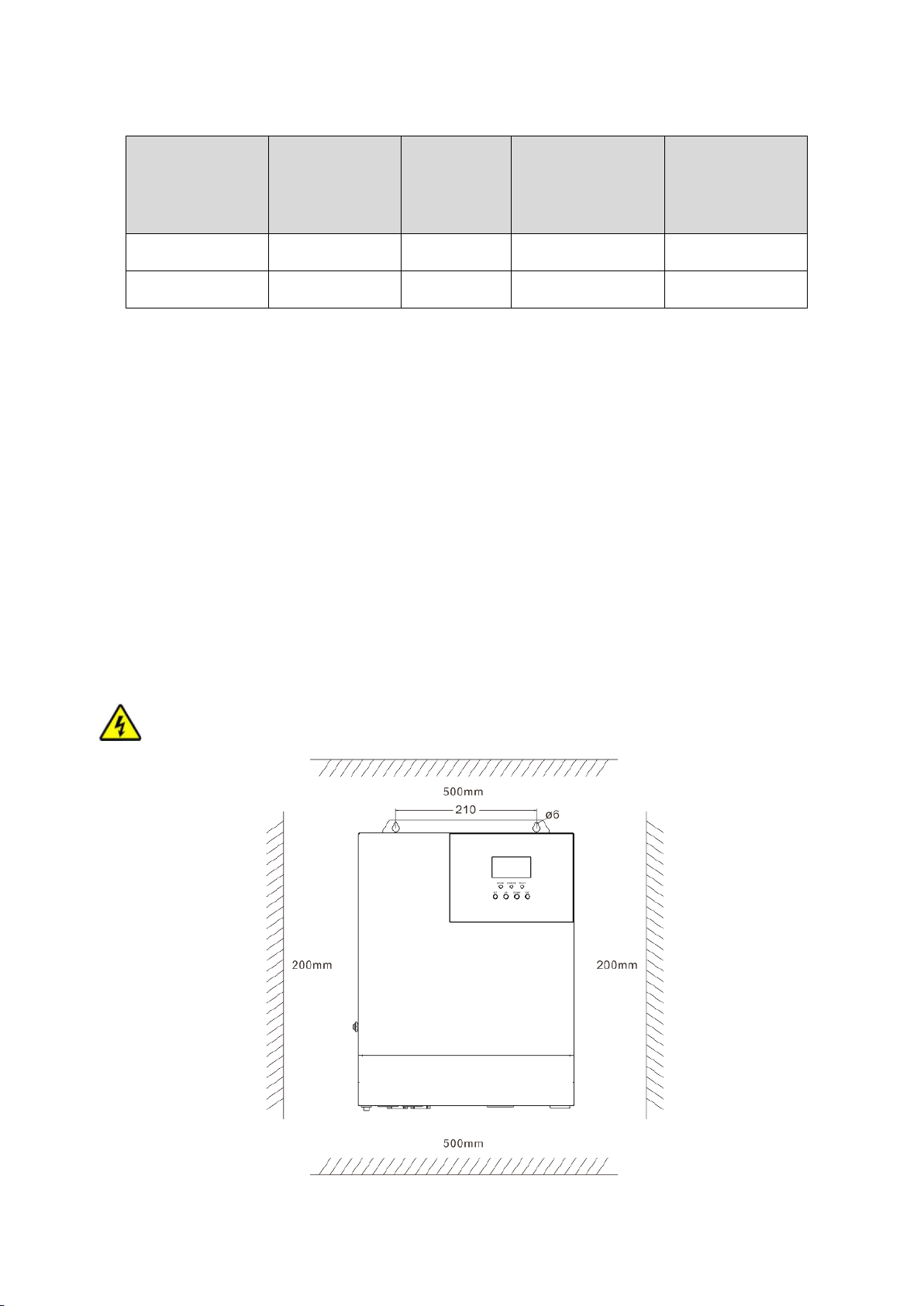

1.4Dimension drawing

Solar Energy Storage Inverting & Control All-In-One Machine 7

2. Installation Instruction

2.1 Installation notice

Before installation, please carefully read the manual and get familiar with the installation step.

Take care while installing the battery. When installing the lead-acid liquid battery, it is required to wear

goggles. Any body part contacting the battery acid must be washed with clear water in time.

Don ’t place any metal object beside the battery to prevent short circuit of the battery.

Acid gas may be generated during battery charge. Therefore, it is required to ensure good ventilation

around the environment.

During cabinet installation, sufficient space shall be reserved around the all-in-one machine for heat

dissipation; do not install the all-in-one machine and lead-acid liquid battery in the same cabinet to avoid

the corrosion of the all-in-one machine by acid gas generated during battery operation.

Only the battery with type consistent with the all-in-one machine can be charged.

Loose connection points and corroded wires may cause great heat, thereby melting the insulation layer of

wires, burning the surrounding materials, or even causing fire. Therefore, all connectors must be tightened,

and the wires must be fixed with ties, so as to avoid the looseness of connectors caused by wire shaking

during mobile application.

Tie conductors are selected based on no greater than 5A/mm2current density.

The machine installed outdoors shall be protected against direct sunlight and rain.

After the power switch is turned off, there is still high voltage inside the all-in-one machine. Please do not

open or touch the internal components, and carry out relevant operation after the capacitor is fully

discharged.

Please do not install the all-in-one machine in a humid, greasy, flammable, explosive or dusty or other

severe environments.

The polarity of the battery input end of this product shall not be reversed, otherwise the device may be

damaged easily or there may be some unpredictable dangers.

AC supply input and AC output are both high voltage, so please do not touch the wires.

Do not touch the fan in working to prevent injury.

It is required to confirm that the all-in-one machine is the unique power supply input device for the load

device. It is forbidden to use the machine in parallel with other input AC power to avoid damage.

Solar Energy Storage Inverting & Control All-In-One Machine 8

2.2 Wire specification and breaker type

For wiring and installation ways,it is required to observe national and local electrical specification

requirements.

Recommended wiring specification and breaker type for photovoltaic array: the output current of the

photovoltaic array is affected by the form, connection way and illumination angle of photovoltaic array, therefore

the minimum wire diameterof the photovoltaic array is calculated based on the short circuit currentof

photovoltaic array. Please refer to the short circuit current value in the specification of photovoltaic array (the

short circuit current keeps unchanged for the photovoltaic arrays in series connection; the short circuit current

of photovoltaic arrays in parallel connectioni s the sum of short circuit currentof all components connected in

parallel); the short circuit current of the array cannot exceed maximumi nput currentof PV.

Please refer to the table below for PV input wire diameter and switch:

Type Recommended wire

diameter

Maximum PV input

current

Recommended types

of air switchor breaker

HF/MF4830S60-H 6mm2/10AWG 18A 2P—25A

HF/MF4850S80-H 6mm2/10AWG 18A 2P—25A

Note: the voltage in parallel shall not exceed maximum PV input open-circuit voltage.

Please refer to the table below for recommended AC input wire diameter and switch:

Type Recommended wire

diameter

Maximum bypass

input current

Recommended types

of air switchor breaker

HF/MF4830S60-H 10mm2/7AWG 40A 2P—40A

HF/MF4850S80-H 10mm2/7AWG

40A 2P—40A

Note: there is already a corresponding breaker at input connection point of mains supply. Therefore, no

breaker may be equipped.

Recommended input wire diameter and switch type for battery

Type Recommended

wire diameter

Rated

battery

discharge

current

Maximum

charge current

Recommended

types

of air switch or

breaker

HF/MF4830S60-H 20mm2/4AWG 85A 60A 2P—120A

HF/MF4850S80-H 30mm2/2AWG 125A 80A 2P—200A

Solar Energy Storage Inverting & Control All-In-One Machine 9

Recommended wire specification and breaker type for AC output

Type Recommended

wire diameter

Rated

inverter AC

output

current

Maximum bypass

output current

Recommended

types of air switch

or breaker

HF/MF4830S60-H 10mm2/7AWG 13A 40A 2P—40A

HF/MF4850S80-H 10mm2/7AWG 22A 40A 2P—40A

Note: the wire diameter is only for reference. In case of long distance between photovoltaic array and all-in-

one machine or between all-in-one machine and battery, use thicker wire to reduce voltage drop and improve

system performance.

Note: above wire diameter and breaker are only for reference. Please select appropriate wire diameter and

breaker based on practical condition.

2.3 Installation and Wiring

Installation step:

Step 1: confirm the installation position and heat dissipation space, confirm the installation position of all-in-

one machine, such as wall surface; to install the all-in-one machine, guarantee there is sufficient air flowing

through the cooling fins of all-in-one machine. At least reserve 200mm space at the left and right air outlets of

the all-in-one machine to guarantee heat loss through natural convection. Refer to the overall installation

schematic above.

Warning: danger of explosion! Never install the all-in-one machine and lead-acid liquid battery into a

same sealed space or in a sealed place with probable accumulation of battery gas.

Solar Energy Storage Inverting & Control All-In-One Machine 10

Step 2: Remove the terminal protection cover

Step 3: wiring

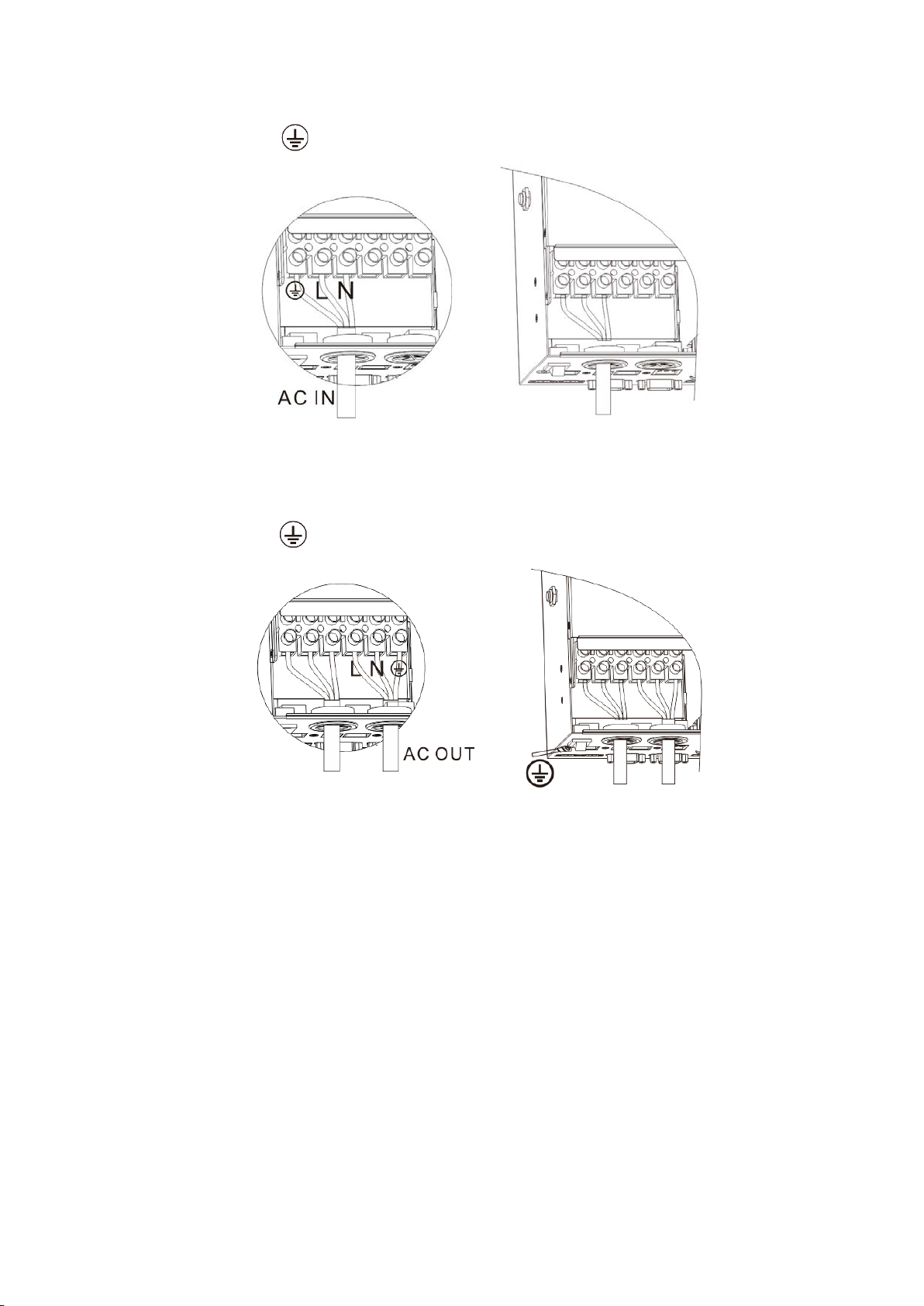

AC input/output wiring method:

①Before AC input/output wiring, disconnect the external breaker at first and then confirm whether the cable

used is thick enough. Please refer to chapter “2.2 Wiring Specification and Breaker type”;

②Correctly connect AC input wire in accordance with cable sequence and terminal position shown in the figure

below. Please connect ground lead at first, and then live wire and mull wire;

Solar Energy Storage Inverting & Control All-In-One Machine 11

:Ground L:Live N:Neutral

③Correctly connect AC output wire in accordance with cable sequence and terminal position shown in the

figure below. Please connect the ground wire at first, and then live wire and null wire. The ground wire is

connected to the ground screw hold through Oshaped terminal.

:Ground L:Live N:Neutral

Note: use thick ground cable as far as possible (with cable section not less than 4mm2), place the ground point

to be close to the all-in-one machine as far as possible and choose shorter ground wire to the greatest extent

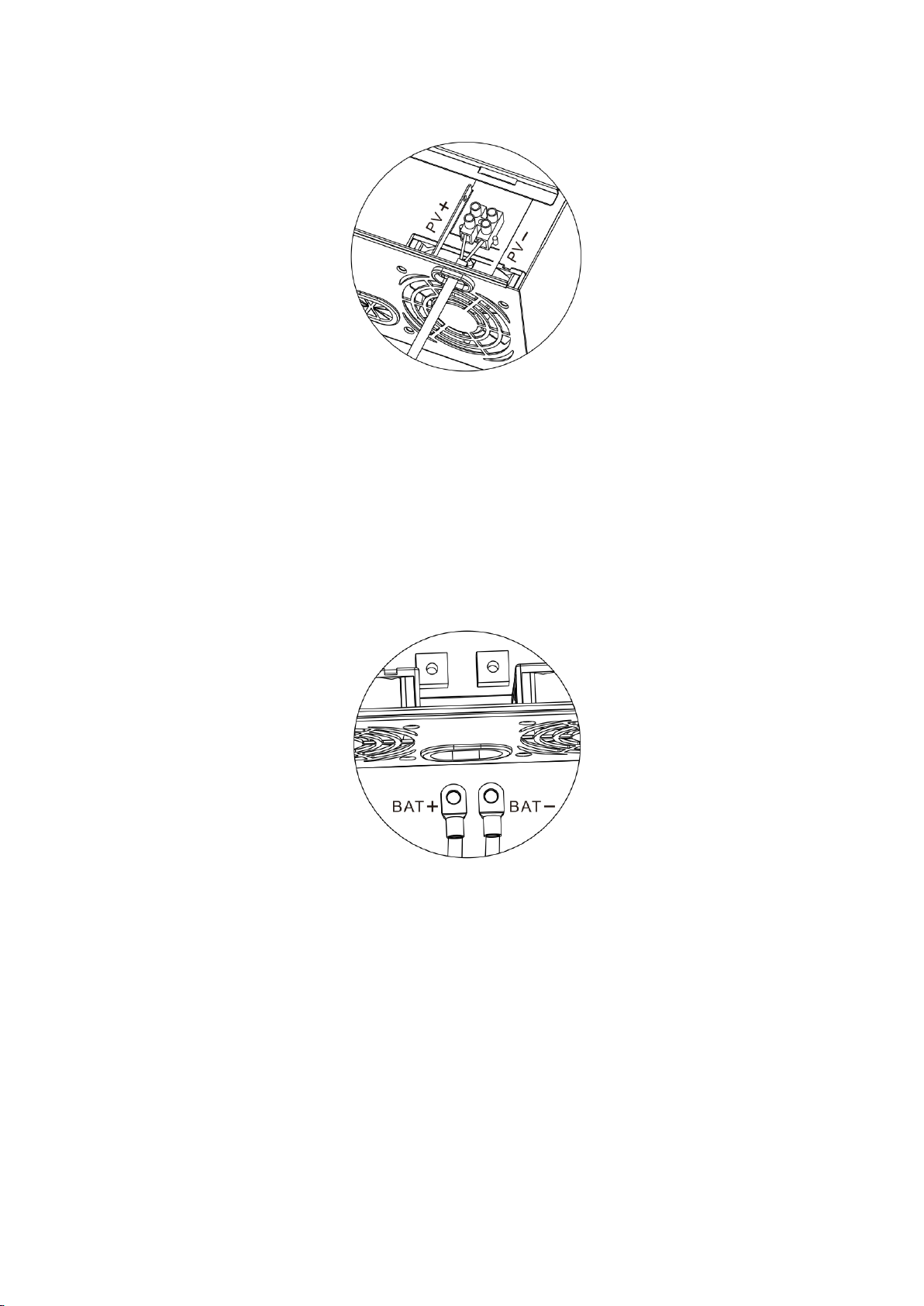

Wiring method of PV input:

Before wiring, disconnect external breaker at first, and confirm whether the used cable is thick enough.

Please refer to chapter “2.2 Wiring Specification and Breaker Type”;

②Correctly connect PV input wire in accordance with cable sequence and terminal position shown in the

figure below.

Solar Energy Storage Inverting & Control All-In-One Machine 12

PV+ positive input pole PV1- negative input pole

BAT wiring method:

①Before wiring, disconnect external breaker at first, and then confirm whether the used cable is thick enough.

Please refer to chapter “ 2.2 Wiring Specification and Breaker Type ” . BAT wire shall be connected with

the machine via O-shaped terminal. It is recommended to use the O-shaped terminal with 5mm inside

diameter. The O-shaped terminal must compress BAT wire firmly to prevent excessive heating caused by

great contact resistance;

②Correctly connect BAT wire in accordance with cable sequence and terminal position shown in the figure

below.

BAT+: positive battery pole BAT-: negative battery pole

Warning notice:

①Input from mains supply, AC output and photovoltaic array may generate high voltage. Before wiring, make

sure to break the breaker or fuse;

②During wiring process, make sure to pay attention to the safety; during the wiring process, please don’t

close the breaker or fuse. At the same time, guarantee that “+” and “-” poles of different parts are

correctly connected with wires; a breaker must be installed at the battery end and selected based on chapter

“2.2 Wiring Specification and Breaker Type”. Before wiring, make sure to break the breaker to prevent

strong electric spark generated during wiring. At the same time, avoid battery short circuit during the wiring

process; if the all-in-one machine is in the area with frequent thunder, it is suggested to install an external

arrester at PV input terminal.

Solar Energy Storage Inverting & Control All-In-One Machine 13

Step 4: inspect whether the wires are correctly and firmly connected, especially whether the positive and

negative input poles of the battery are correct, whether the positive and negative input poles of PV are correct,

whether AC input is inaccurately connected to AC output terminal.

Step 5: install protective cap of terminal

Step 6: Start all-in-one machine

At first close the breaker at the battery end, and then press the rocker switch at the lower left side of the machine

to “ ON ” state, “ AC/INV ” indicator light flashes, indicating normal operation of inverter. Afterwards,

close breakers of photovoltaic array and mains supply. In the end, after AC output is normal, turn on AC load

one by one to avoid protection action generated by great instant impact owing to simultaneous turnon of loads.

The all-in-one machine operates normally in accordance with set mode.

Note: if power is supplied to different AC loads, it is suggested to turn on the loads with great impact current,

and then turn on the load with little impact current after the load operates stably.

Note: in case of abnormal operation of all-in-one machine or abnormal display of LCD or indicator light, refer

to Chapter 6 for troubleshooting.

Solar Energy Storage Inverting & Control All-In-One Machine 14

3.Operating Mode

3.1 Charge mode

1. Photovoltaic priority: in photovoltaic priority charge mode, mains charge is started only when photovoltaics

is out of work. Make full use of solar energy for power generation in the daytime and transfer to the mains

supply for charge to maintain electric quantity of the battery. It is suitable for areas with relatively stable power

grid and relatively expensive electricity price.

2. Mains supply priority: mains supply is to charge the battery preferentially and the photovoltaic charge can

be started only when the mains supply is valid.

3. Mixed charge: with mixed charge through photovoltaics and mains supply, photovoltaic MPPT charge is

used preferentially. In case of insufficient photovoltaic energy, the mains supply is used for supplement. In case

of sufficient photovoltaic energy, mains supply stops charge. Electricity can be charged fastest with the way,

which is suitable for the area with unstable power grid, so as to supply sufficient backup power supply at any

time.

4.Only solar: only photovoltaic charge is used, no mains supply is started. This way can save the energy at most.

The electric energies of battery are all from solar energy. This way is suitable for areas with good light condition.

Solar Energy Storage Inverting & Control All-In-One Machine 15

3.2 Output mode

Photovoltaic priority mode: Photovoltaic and battery supply power to the load. With diversified charge

mode and optional output mode, when photovoltaic priority mode is selected, the green solar energy can

be used as far as possible so as to achieve energy conservation and emission reduction. It switches to mains

supply when the photovoltaics is invalid. With the mode, solar energy can be used maximally and electric

quantity can be maintained at the same time. Therefore, the mode is suitable for areas with stable power

grid.

Mains supply priority mode: it only switches to inverter for power supply when mains supply is invalid,

equivalent to a backup UPS. Therefore, the mode is applicable to area with unstable power grid.

Inverter priority mode: it only switches to mains supply in case of undervoltage of battery. With the mode,

DC electric energy is used maximally. Therefore, it is applied to the area with stable power grid.

Mixed functions mode: When the battery is not available or the battery is fully charged, the load is

provided by PV and commercial power, PV maximum output power output。( Only used for MF)

Solar Energy Storage Inverting & Control All-In-One Machine 16

4. Operation Instruction for LCD Screen

4.1 Operation and display panel

4.2 Introduction to operation keys

Function Key Description

SET Enter/exit setting menu

UP Last option

DOWN Next option

ENT Confirm/enter option under setting menu

4.3 Introduction to indicator light

Indicator light Color Description

AC/INV Yellow

Constant on: mains supply output

Flashing: inverter output

CHARGE Green

Flashing: battery in charge

Constant on: charge completed

FAULT Red Constant on: fault state

Solar Energy Storage Inverting & Control All-In-One Machine 17

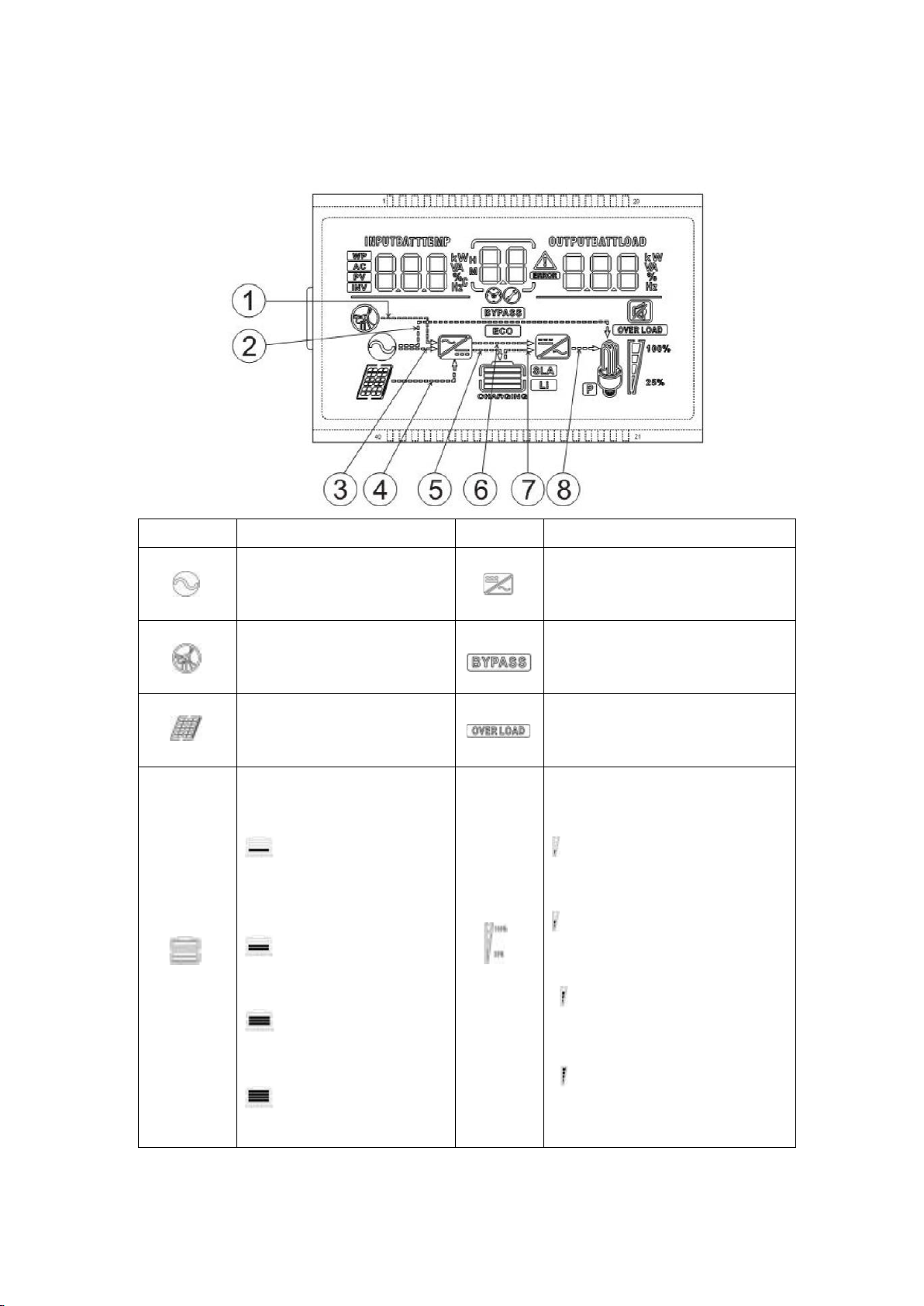

4.4 Introduction to LCD screen

Icon Function Icon Function

Indicating that AC input end

has been connected to

power grid Indicating that inverter circuit is in

working.

Indicates that the AC input

mode in APL mode (wide

voltage range) Indicating that the machine is in

mains supply bypass work mode

Indicating that PV input end

has been connected to solar

battery panel

Indicating that AC output is in

overload state

Indicating that machine has

been connected to battery,

indicating 0%~24%

battery remainin

capacity

indicating 25%~49%

battery remaining capacity

indicating 50%~74%

battery remaining capacity

indicating 75%~100%

battery remaining capacity

Indicating percentage of AC

output load,

indicating 0%~24% load

percentage,

indicating 25%~49% load

percentage,

indicating 50%~74% load

percentage,

indicating ≥75% load

percentage

Solar Energy Storage Inverting & Control All-In-One Machine 18

Indicating that present

battery type of the machine

is lithium battery Indicating that buzzer is not

enabled

Indicating that current

battery type of machine is

lead-acid battery Indicating alarm of machine

Indicating that the battery is

in charge state. Indicating that the machine is in

fault state.

Indicating that AC/PV

charge circuit is in working Indicating that the machine is in

setting mode.

Indicating that AC output

end has AC voltage output

Middle parameter display of screen,

1. In non-setting mode, displaying

alarm or fault code; 2. In setting

mode, displaying code of

parameter item under current

setting.

Parameter display at left side of screen: input parameter

Indicating AC input

Indicating PV input

Indicating inverter circuit

The icon is not displayed

Displaying battery voltage, total charge current of battery, charge power of

mains supply, AC input voltage, AC input frequency, PV input voltage,

temperature of internal radiator, software version

Parameter display at right side of screen: output parameter

Indicating output voltage, output current, output active power, output

apparent power, battery discharge current, software version; under setting mode,

displaying the setting parameter under the parameter item code set

currently

Arrow display

The arrow is not displayed ⑤Indicating charge from

charge circuit

to battery end

②Indicating power grid power supply

to load ⑥The arrow is not displayed

③Indicating power grid power supply

to charge circuit ⑦Indicating power supply

from battery

end to inverter circuit

④Indicating PV power supply to charge

circuit ⑧Indicating power supply

from inverter

circuit to load

Solar Energy Storage Inverting & Control All-In-One Machine 19

Real-time data view method

In LCD main screen, press keys “UP” and “DOWN” to turn page and view different realtime

data of the machine.

Page Left Parameter of Screen

Middle

Parameter of

Screen

Right Parameter of Screen

1 Battery input voltage

Fault code

Output voltage

2 PV temperature PV output KW

3 PV input voltage PV output current

4 Input battery current Output battery current

5 Input battery KW Output battery KW

6 AC input frequency AC output load frequency

7 AC input voltage AC output load current

8 Input voltage Output load KVA

9 INV temperature INV output load KW

10 APP software version Bootloader software version

11 Model Battery Voltage Rating Model Output Power Rating

12 Model PV Voltage Rating Model PV Current Rating

4.5 Setting parameter

Key operation description: to enter setting menu and exit from setting menu, please press key“SET”. After

entering the setting menu, parameter number【00】shall flash. At this time, press keys“ UP ”and“ DOWN ”

to select the parameter item code to be set. Afterwards, press key“ ENT” to enter parameter editing state. At

this moment, the parameter value can flash. The parameter values are adjusted through keys “UP” and

“DOWN”. In the end, press key“ENT” to complete parameter editing and return to parameter selection state.

Solar Energy Storage Inverting & Control All-In-One Machine 20

This manual suits for next models

3

Table of contents

Other Srne Batteries Charger manuals