SSV MLS/160A User guide

MLS/160A

Soft Sensor

System Reference

SSV Software Systems GmbH

Dünenweg 5

D-30419 Hannover

Phone: +49 (0)511/40 000-0

Fax: +49 (0)511/40 000-40

Document Revision: 1.1

Date: 2020-11-18

MLS/160A – System Reference

2

D oc u m e n t R e v i s i o n 1 . 1

CONTENT

1

INTRODUCTION ............................................................................................................... 3

1.1

Safety Guidelines ................................................................................................................... 3

1.2

Conventions .......................................................................................................................... 3

1.3

Block Diagram ....................................................................................................................... 4

1.4

Nameplate ............................................................................................................................. 4

1.

Features and Technical Data .................................................................................................

2

OVERVIEW ....................................................................................................................... 6

3

INTER ACES ................................................................................................................... 7

3.1

JTAG/Debug – J1.................................................................................................................... 7

3.2

Primary RS48 Screw Terminal – J2 ...................................................................................... 8

3.3

Power Connector – J4 ........................................................................................................... 8

3.4

Power/Status LED – D1 ......................................................................................................... 8

4

OPERATING SYSTEM ..................................................................................................... 9

4.1

A/B Boot Concept ................................................................................................................ 10

4.2

Secure Device Update (SDU) ............................................................................................... 11

5

PROTOCOL SPECI ICATION........................................................................................ 12

.1

Interface .............................................................................................................................. 12

.2

Operating states .................................................................................................................. 12

.3

Datagrams ........................................................................................................................... 13

6

MECHANICAL DIMENSIONS ......................................................................................... 19

7

CONNECTING TO AN RMG/941 .................................................................................... 20

8

HELP UL LITERATURE ................................................................................................ 21

CONTACT ............................................................................................................................. 21

DOCUMENT HISTORY ......................................................................................................... 21

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

3

1 INTRODUCTION

This document describes the basic hardware and software components of the soft sensor

MLS/160A.

1.1 Safety Guidelines

Please read the following safety guidelines carefully! In case of property or personal

damage by not paying attention to this document and/or by incorrect handling, we do

not assume liability. In such cases any warranty claim expires.

ATTE TIO !

Observe precautions for handling – electrostatic sensitive device!

• Please pay attention that the power cord or other cables are not s ueezed or dam-

aged in any way when you set up the device.

• Do NOT turn on the power supply while connecting any cables, especially the pow-

er cables. This could cause damaged device components! First connect the cables

and THEN turn the power supply on.

• The installation of the device should be done only by ualified personnel.

• Discharge yourself electrostatic before you work with the device, e.g. by touching a

heater of metal, to avoid damages.

• Stay grounded while working with the device to avoid damage through electrostat-

ic discharge.

• The case of the device should be opened only by ualified personnel.

1.2 Conventions

Convention

Usage

bold

Important terms

monospace

Pathnames, internet addresses and program code

Table 1: Conventions used in this document

MLS/160A – System Reference

4

D o c u m e n t R e v i s i o n 1 . 1

1.3 Block Diagram

Figure 1: Block diagram MLS/160A

1.4 Nameplate

Figure 2: ameplate MLS/160A

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

5

1. Features and Technical Data

Processor

Manufacturer/Type

STM32 micro controller

with ARM 32

-

bit Cortex

-

M3 Core

Clock speed

max. 72

MHz

Memory

RAM

20

KB SRAM

Flash

64

KB

Interfaces

Serial I/Os

1x RS485 half duplex, 115200

bps

JTAG/Debug

1x 18

-

pin connector (internal)

Inertial Measurement Unit osch MI160

3

-

Axis Acceler

ometer

max. sampling rate: 1600

Hz

max. analog band width:

684 Hz for x- and y-axis; 353 Hz for z-axis

Range: ±2 g (g = 9.81 m/s²)

Resolution: signed 16-bit integer

3

-

Axis Gyroscope

max. sampling rate: 1600

Hz

max. analog band width: 523.9 Hz

Range: ±2000°/s

Resolution: signed 16-bit integer

Environmental Sensor osch ME280

Humidity

Operating range 0 .. 100% rel. humidity

Pressure

Operating range 300 .. 1100

hPa

Temperature

Operating range

-

40 ..

85

°C

Software

Operating system

RIOT

2019.04

Protocol

s

RS48

5

to t

ransfer

the

measurement data

in a special

Data

Streaming Mode

Configuration

Via Datagram

s

Miscellaneous

Firmware upgrade via Secure Device Update app (A/B boot)

Displays/Control Elements

LEDs

1x Power/status

Electr

ical Characteristics

Power sup

ply

12 .. 24

VDC from external power supply

Current consumption

typ. 20

mA @12

V / typ. 10

mA @24

V

Mechanical Characteristics

Protection class

IP40/IP65

Mass

<

5

0

g

Dimensions

91.2

mm x 43.2

mm x 26

mm (without cable)

Operating temperature

-

2

0 ..

7

0

°C

Standards and Certifications

EMC

CE

Environmental

standards

RoHS, WEEE

Table 2: Features MLS/160A

MLS/160A – System Reference

6

D o c u m e n t R e v i s i o n 1 . 1

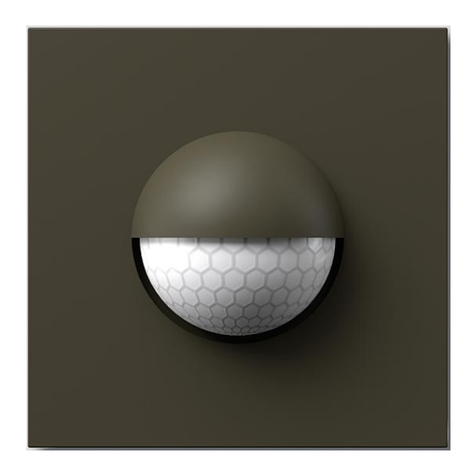

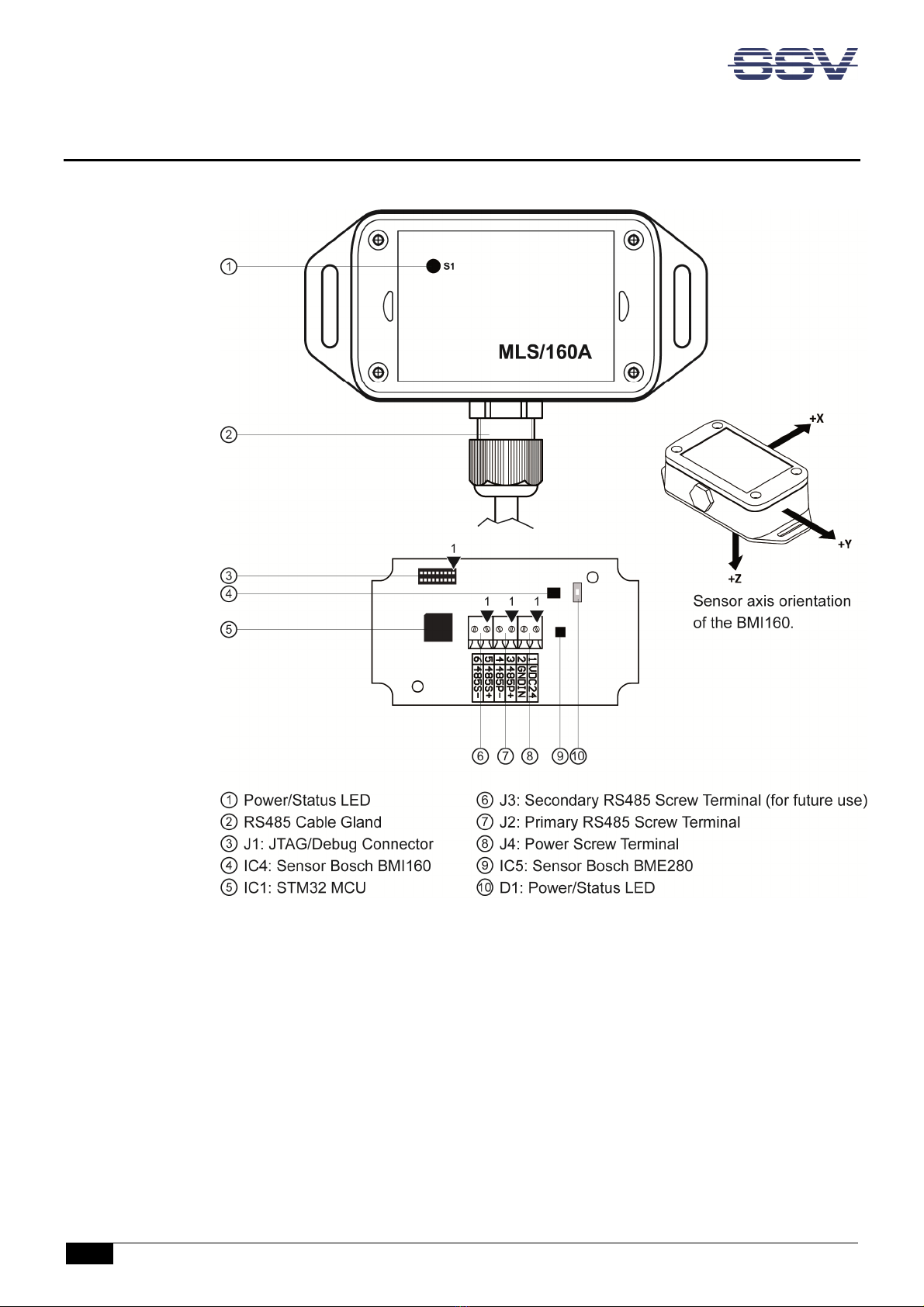

2 OVERVIEW

Figure 3: Overview MLS/160A

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

7

3 INTERFACES

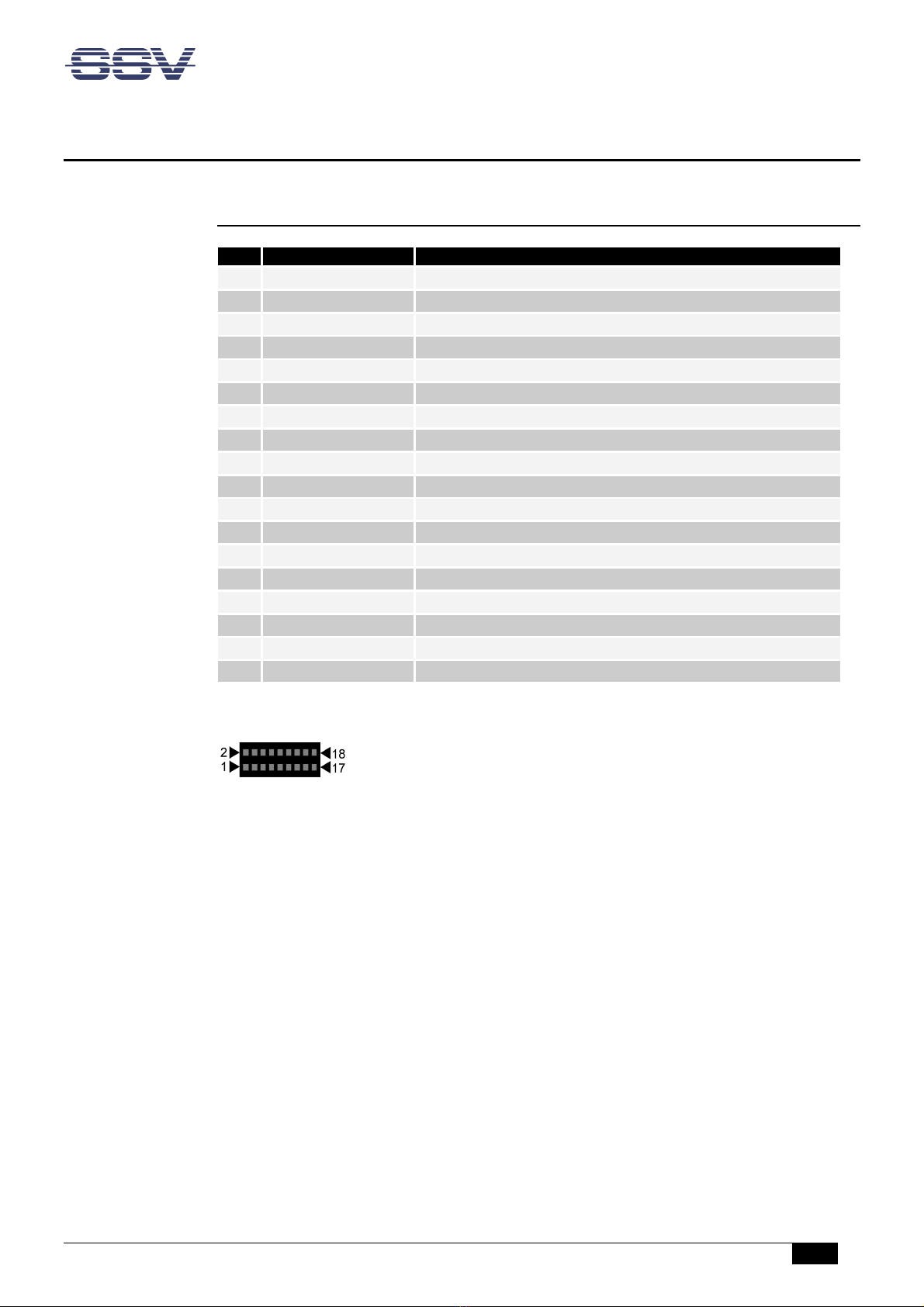

3.1 JTAG/Debug – J1

Pin

Name

Func

tion

1

VCC3

3.3 VDC

2

G D

Ground

3

TRST#

Test Reset

4

BOOT0

Boot0 Pin (please refer to STM32 datasheet)

5

TDI

Test Data In

6

TXD

1

Debug Port TXD

1

Pin

7

TMS

Test Mode Select

8

RXD

1

Debug Port RXD

1

Pin

9

TCK

Test Clock

10

G D

Ground

11

---

Reserv

ed. Do not use.

12

---

Reserved. Do not use.

13

TDO

Test Data Out

14

---

Reserved. Do not use.

15

RESET#

Reset

16

---

Reserved. Do not use.

17

G D

Ground

18

---

Reserved. Do not use.

Table 3: Pinout JTAG/Debug connector

MLS/160A – System Reference

8

D o c u m e n t R e v i s i o n 1 . 1

3.2 Primary RS48 Screw Terminal – J2

Pin

Name

Function

Wire color

3

RS485P+

COM2 Serial Port:

primary

RS485 RX /TX+

Green

4

RS485P

-

COM2 Serial Port:

primary RS485 RX /TX

-

Yellow

Table 4: Pinout primary RS485 screw terminal

3.3 Power Connector – J4

Pin

Name

Function

Wire color

1

VCC24

12

..

24

Volt

power input

White

2

G D

Ground

Brown

Table 5: Pinout power connector

CAUTIO !

Providing the MLS/160A with a higher voltage than the regular 12 .. 24 VDC ±10% could

cause damaged device components!

Do OT turn on the power supply while connecting any cables, especially the power ca-

bles. This could cause damaged device components! First connect the (power) cables and

THE turn the power supply on.

3.4 Power/Status LED – D1

Table 10 shows the two modes of the LED D1 on the MLS/160A’s front.

Mode

Function

On

O.K./Sampling

Blink

Waiting on

c

onfiguration/IDLE

Table 6: LED D1 modes

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

9

4 OPERATING SYSTEM

The MLS/160A’s firmware is built with the lightweight real time operating system RIOT.

RIOT is a free, open source operating system and is designed for the particular re uire-

ments of Internet of Things (IoT) scenarios. For more information please see:

https://riot-os.org/

RIOT offers a low memory footprint, high energy efficiency, real-time capabilities and a

modular and configurable communication stack. It provides a microkernel, utilities like

cryptographic libraries, data structures (bloom filters, hash tables, priority ueues), a shell,

various network stacks, and support for various microcontrollers, radio drivers, sensors,

and configurations for entire platforms, e.g. the STM32 MCU family.

The microkernel itself comprises thread management, a priority-based scheduler, a power-

ful API for inter-process communication (IPC), a system timer, and mutexes.

All this makes it an ideal OS for the MLS/160A and opens up versatile options for own de-

velopments, as well as benefiting from community driven enhancements.

In order to build an application or library with RIOT, you first need to download the source

code. You can obtain the latest firmware code from the SSV Github account:

https://github.com/SSV-embedded/fw-mls160a

To compile RIOT for the MLS/160A, you need to install the corresponding toolchain for

STM32 MCUs (ARM 32-bit Cortex-M3).

On a Linux host you may use the default GNU cross compiler for ARM architecture of your

Linux distribution. Please refer to the RIOT webpage to see how to set up a cross compiler

environment for a different operating system like Windows10.

Table 7 shows the STM32 GPIO mapping of the MLS/160A:

RIOT OS

STM32

GPIO line in use

MLS/160A

I2C

I2C1

PB6/7

BMI160/BME280

UART0

USART1

PA9/10

Debug Connector

UART1

USART2

PA2/3

J2 RS458P

Direction1

PortA1

PA1

IC2 RS485 Transceiver

UART2

USART3

PB10/11

J3 RS458S

Direction2

PortB14

PB14

IC3 RS485 Transceiver

LED0

PortC13

PC13

Power/Status

LED

Table 7: STM32 GPIO mapping of MLS/160A

MLS/160A – System Reference

10

D o c u m e n t R e v i s i o n 1 . 1

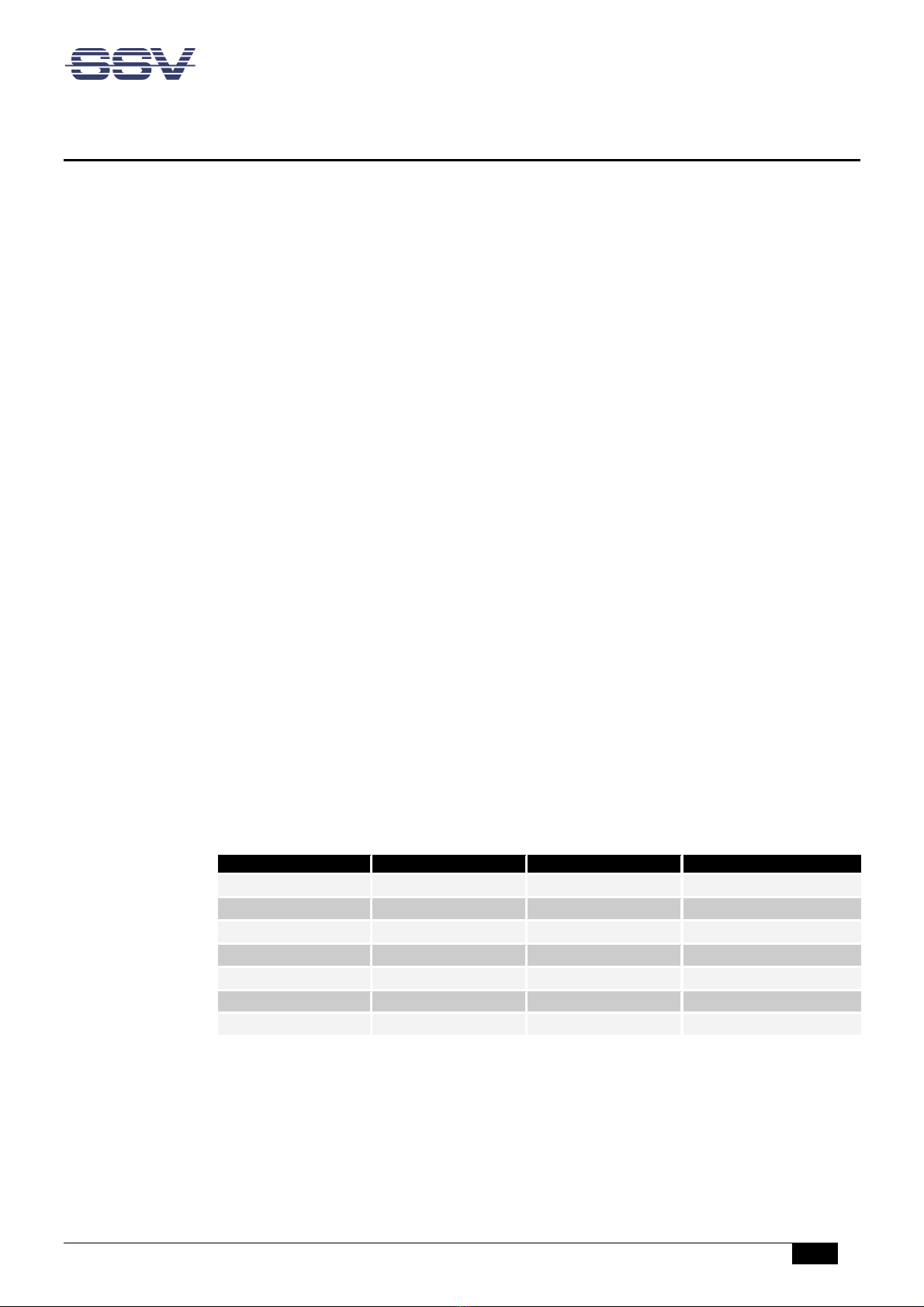

4.1 A/B Boot Concept

The MLS/160A has an A/B boot concept is based on the RIOTBOOT bootloader. It enables,

for instance, the Secure Device Update (SDU) function (please see chapter 4.2).

The Flash memory of the STM32 MCU is divided in two so-called boot slots ("A" and "B")

like shown in figure 4. Each of them may store the MLS/160A’s firmware.

Figure 4: Division of the MCU Flash memory

Header

Each boot slot has a header containing following information as 32-bit unsigned integer

(uint32):

• magic_number: header magic number ("RIOT")

• version: partition/boot slot version

• start_addr: memory address after the allocated space

• chksum: checksum of the header

Boot Process

First the boot loader checks the header checksum of each slot.

If both slots have a valid checksum, the boot loader uses the slot with the higher version

number to continue the boot process.

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

11

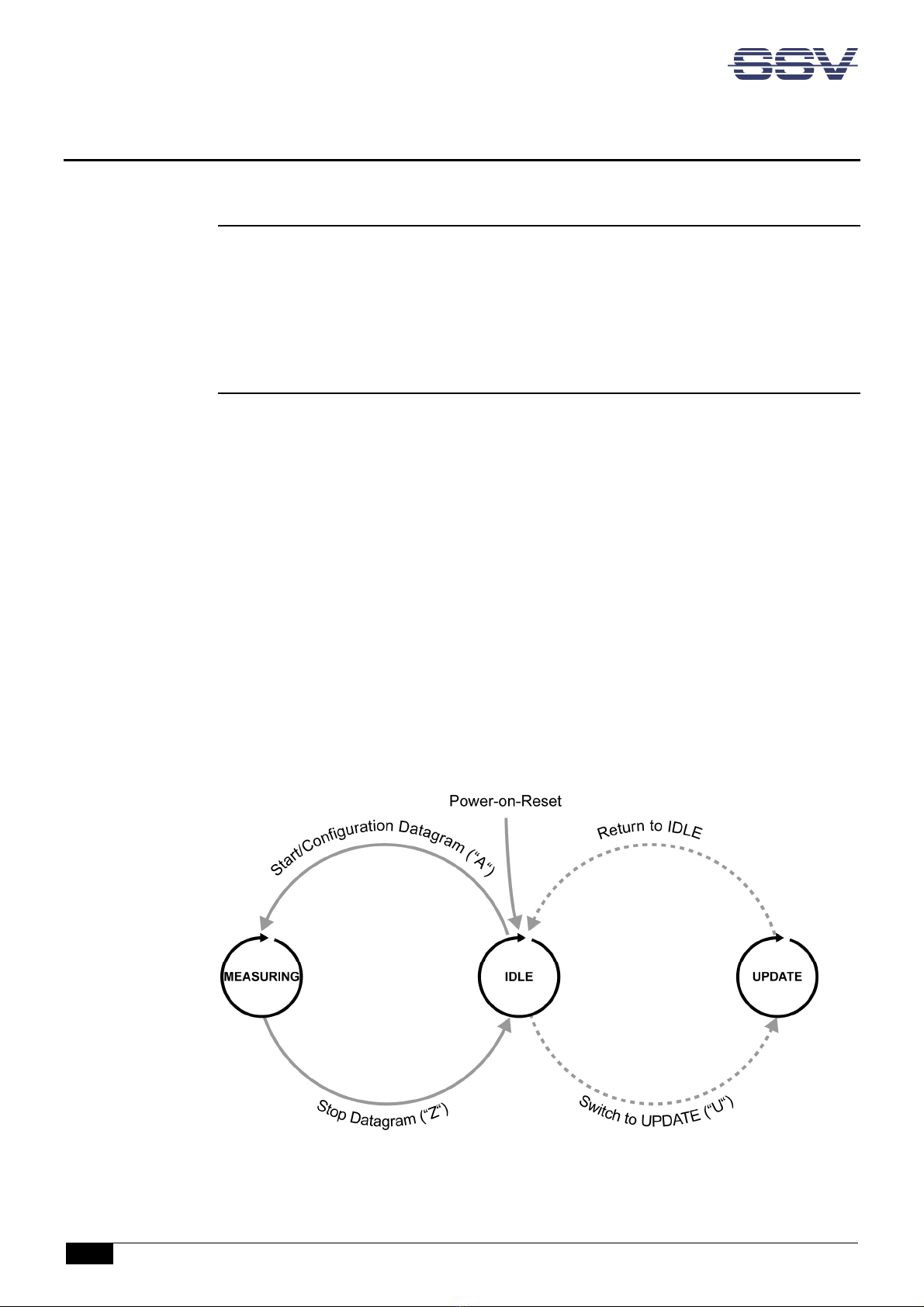

4.2 Secure Device Update (SDU)

The secure device update function allows the secure remote update of the MLS/160A’s

firmware. Therefore it uses the A/B boot concept (please see chapter 4.1).

To run a secure device update the SDU app must be installed on the remote station, e.g.

the remote maintenance gateway RMG/941. The SDU app contains an SDU agent, which

connects with the SDU device driver of the MLS/160A.

Figure 5: Diagram of the Secure Device Update

Update Process

The update process follows these steps:

• Invalidating the inactive slot by setting its magic number from "RIOT" to "0000".

• Writing the new header and firmware excluding the magic number into the inactive

slot. The slot remains invalid because its magic number is still "0000".

• Verifying the written slot by an SHA256 HMAC (Keyed-Hash Message Authentica-

tion Code).

If the HMAC is valid, the magic number is set back to "RIOT" and the slot is valid

again and ready to boot.

If the HMAC is invalid, the magic number is not changed and the slot remains inva-

lid.

• Resetting the MLS/160A and checking if the slots are valid. If both slots are valid,

the slot with the higher version number is used, which should be the updated one.

Please refer to chapter 5.3 for a detailed description of the update process.

MLS/160A – System Reference

12

D o c u m e n t R e v i s i o n 1 . 1

5 PROTOCOL SPECIFICATION

.1 Interface

The MLS/160A communicates via RS485 in half duplex mode with its remote station and

uses the following serial interface settings:

EIA/485, 115200 Baud, 8 data bits, 1 stop bit, no parity (8 1).

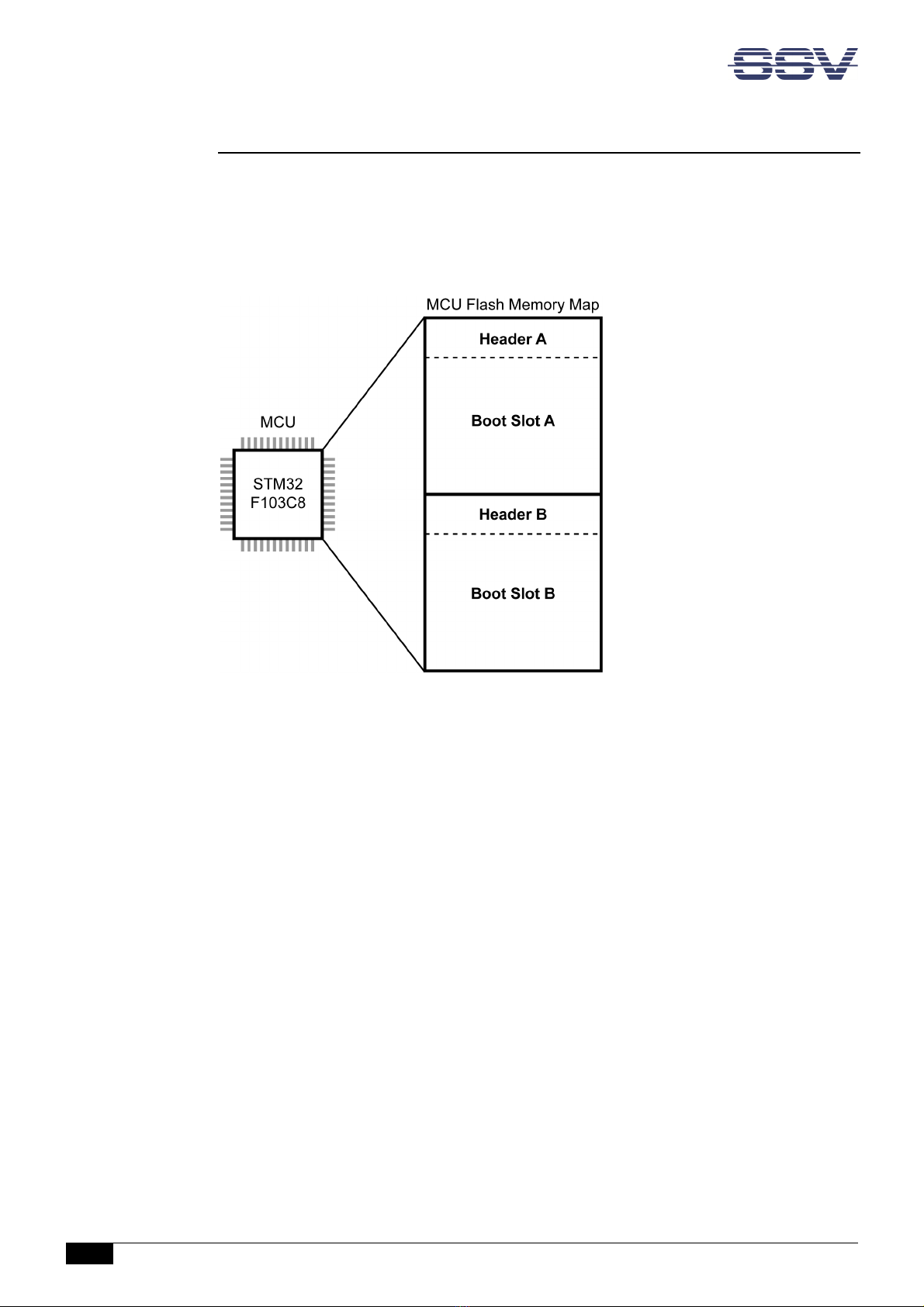

.2 Operating states

IDLE

This is the reset state of the MLS/160A. The MLS/160A waits for a configuration datagram

from the remote station. After receiving a valid configuration datagram the MLS/160A

switches to the MEASURING state. Invalid datagrams will be ignored.

MEASURING

The sensors of the MLS/160A are cyclically polled with the configured sample rate. The

measuring data is sent within a measuring datagram to the remote station. If the

MLS/160A receives a stop datagram during the time with no transmission it returns to the

IDLE state.

UPDATE

If the MLS/160A is in the IDLE state and receives the start update datagram from the re-

mote station, it switches to the UPDATE state and the update process begins. After the up-

date the MLS/160A returns to the IDLE state. Please refer to chapter 5.3 for a detailed de-

scription of the update process.

Figure 6: State machine diagram

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

13

.3 Datagrams

Configuration

This datagram has a fixed length of 5 bytes and is transferred at the beginning of the meas-

uring from the remote station to the MLS/160A.

Bit

7

6

5

4

3

2

1

0

Byte

0x41: A

0

HUM

TEMP

G

YRZ

GYRY

GYRX

ACCZ

ACCY

ACCX

1

SAMPLE RATE

2

…

3

CRC

4

Table 8: Configuration datagram

• A: The ASCII character A (0x41) is the identifier of the configuration datagram.

• ACCX .. Z, GYRX .. Z, TEMP, HUM: These enable bits define which measurement

values of the sensors are used. At least one value must be activated, otherwise the

configuration is invalid and will be ignored.

• SAMPLE RATE: Desired sample rate in Hz as 16-bit unsigned integer (uint16) in lit-

tle endian mode. The maximum rate is calculated with the following formula:

f

max

= 115200/2 +3 (N = number of active channels)

If the desired sample rate is higher than the maximum rate, the configuration is in-

valid and will be ignored.

• CRC: CRC8 checksum over all preceding bytes.

Polynom:

f(x) = x

8

+ x

2

+ x + 1 (The bits are processed from MSB to LSB)

Example: CRC8('A') = 0xC0.

MLS/160A – System Reference

14

D o c u m e n t R e v i s i o n 1 . 1

Measuring

This datagram is sent from the MLS/160A to the remote station after each measurement. It

has a variable length depending on the configuration. If the respective measurement value

is configured to be polled, the value will be transferred, otherwise the field is left out.

Bit

7

6

5

4

3

2

1

0

Byte

0x4D: M

0

READI G ACCX (opt. BMI160)

?

?

READI G ACCY (opt. BM

I160)

?

?

READI G ACCZ (opt. BMI160)

?

?

READI G GYRX (opt. BMI160)

?

?

READI G GYRY (opt. BMI160)

?

?

READI G GYRZ (opt. BMI160)

?

?

READI G TEMP (opt. BME280)

?

?

READI G HUM (opt. BME280)

?

?

CRC

?

Table 9: Measuring datagram

• M: The ASCII character M (0x4D) is the identifier of the measuring datagram.

• READI G ACCX .. Z, READI G GYRX .. Z: Measured value of the BMI160 sensor as

16-bit unsigned integer (uint16) in little endian format.

• READI G TEMP, READI G HUM: Measured value of the BME280 sensor as 16-bit

unsigned integer (uint16) in little endian format.

• CRC: CRC8 checksum over all preceding bytes. Polynom: see above.

Stop

This datagram with the ASCII character Z (0x5A) is sent from the remote station to stop the

measurement and has a length of 1 byte. Because the MLS/160A‘s RS485 interface works in

half duplex mode it receives incoming messages only during intermissions. Therefore the

stop datagram is sent sufficiently fre uent. The stop datagram has no effect in the IDLE

state and will be ignored.

Bit

7

6

5

4

3

2

1

0

Byte

0x5A: Z

0

Table 10: Stop datagram

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

15

Update

During the update process several datagrams are sent between the remote station and the

MLS/160A. Figure 7 shows the update process in a diagram.

Figure 7: Diagram of the update process

MLS/160A – System Reference

16

D o c u m e n t R e v i s i o n 1 . 1

startUpdate )

To initialize an update the remote station sends a start update datagram of 1 byte length

with the ASCII character U (0x55) to the MLS/160A.

Length in Bytes

1

0x55

:

U

Table 11: Start update datagram from the remote station

requestChunk )

The MLS/160A switches from the IDLE in the UPDATE state and answers with a request

datagram of 9 bytes length.

Length in Bytes

1

1

4

2

1

R

S

OFFSET

M

AX

C

L

CRC

Table 12: Request datagram from the MLS/160A

• R: The ASCII character R (0x52) is the identifier of the re uest datagram.

• S: This byte defines the boot slot to be updated.

• OFFSET: These 4 bytes define the offset of the firmware binary file in bytes (little

endian).

• MAXCL: These 2 bytes define the maximum chunk length of the firmware binary

file in bytes (little endian); in this case 128 bytes.

• CRC: This byte contains the CRC8 checksum over all preceding bytes.

pushChunk )

The remote station answers with a page datagram which contains the first chunk of the

new firmware binary file.

Length in

Byte

s

1

1

4

2

<

=

128

1

P

S

OFFSET

A

CT

C

L

DATA

CRC

Table 13: Page datagram from the remote station

• P: The ASCII character P (0x50) is the identifier of the page datagram.

• S: This byte defines the boot slot to be updated.

• OFFSET: These 4 bytes define the offset of the firmware binary file in bytes (little

endian).

• ACTCL: These 2 bytes contain the actual chunk length of the firmware binary file in

bytes (little endian).

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

17

• DATA: This part has a variable length and contains the chunk of the firmware bina-

ry file. Its maximum length is defined by the preceding re uest datagram.

• CRC: CRC8 checksum over all preceding bytes.

After receiving the page datagram the MLS/160A compares the MAXCL with the ACTCL. If

both lengths are e ual the MLS/160A sends a new re uest datagram with an adjusted OFF-

SET and the remote station sends a new page datagram with the next chunk of the firm-

ware binary file.

This loop runs until ACTCL is smaller than MAXCL which means that the firmware binary

file was transferred completely.

requestHMAC )

In this case the MLS/160A sends a verification datagram of 1 byte length with the ASCII

character V (0x56) to the remote station.

Length in Bytes

1

0x5

6

:

V

Table 14: Verification datagram from the MLS/160A

pushHMAC )

The remote station answers with the SHA256 HMAC (Keyed-Hash Message Authentication

Code) of the new firmware binary file.

Length in Bytes

1

256

1

H

HMAC

CRC

Table 15: HMAC datagram from the remote station

• H: The ASCII character H (0x48) is the identifier of the HMAC datagram.

• HMAC: This part contains the SHA256 HMAC of the new firmware binary file.

• CRC: CRC8 checksum over all preceding bytes.

The MLS/160A calculates the SHA256 HMAC of the new firmware (“CALC-HMAC”) and

compares it with the HMAC received from the remote station. The CALC-HMAC must be

identical with the received one in order to be valid.

MLS/160A – System Reference

18

D o c u m e n t R e v i s i o n 1 . 1

acceptUpdate )

If the HMAC is valid, the magic number of the updated slot is set back to "RIOT" and the

slot is valid again and ready to boot. The MLS/160A sends an okay datagram of 1 byte

length with the ASCII character Y (0x59) to the remote station.

Length in Bytes

1

0x59

: Y

Table 16: Okay datagram from the MLS/160A

denyUpdate )

If the HMAC is invalid, the magic number of the updated slot is not changed and the slot

remains invalid. The MLS/160A sends an error datagram of 1 byte length with the ASCII

character N (0x4E) to the remote station.

Length in Bytes

1

0x4E

:

Table 17: Error datagram from the MLS/160A

Reboot

The update process is finished and the state machine of the MLS/160A reboots and returns

to the IDLE mode.

MLS/160A – System Reference

D o c u m e n t R e v i s i o n 1 . 1

19

6 MECHANICAL DIMENSIONS

All length dimensions have a tolerance of 0.5 mm.

Figure 8: Mechanical dimensions of MLS/160A

MLS/160A – System Reference

20

D o c u m e n t R e v i s i o n 1 . 1

7 CONNECTING TO AN RMG/941

Connect the MLS/160A to an RMG/941 gateway like shown in figure 9.

Figure 9: Wiring diagram for the connection of the MLS/160A to an RMG/941

Wire color

Pin

MLS/160A

Pin

RMG/941

White

1 (Vin 24 VDC)

A3 (

Vin 24 VDC

)

Brown

2 (G Din)

A4 (Ground)

Green

3 (

485P+

)

A1 (

COM2 Serial Port: RS485 RX /TX+

)

Yellow

4 (

485P

-

)

A2 (

COM2 Serial Port: RS485 RX /TX

-

)

Table 18: Signal assignment of the wires

Table of contents