SSZN SR Series User manual

SR Series 3D Camera

——Quick Start Guide

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

2/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Catalogue

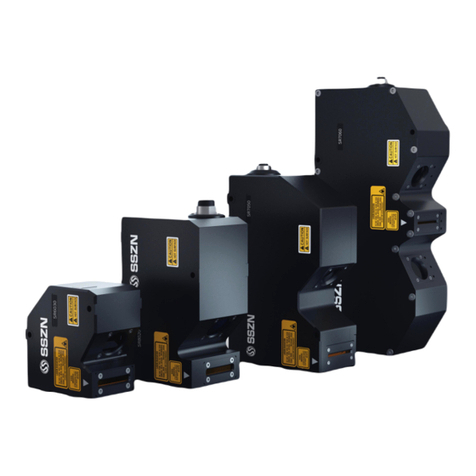

SR6000/SR7000/SR8000 Series 3D Camera...........................................................................................................1

——Quick Start Guide.....................................................................................................................................1

1 Preparation before Installation......................................................................................................................... 3

2 Camera Description..........................................................................................................................................4

2.1 Description of Camera SR6000........................................................................................................... 4

2.2 Description of Camera SR7000........................................................................................................... 5

2.3 Description of Camera SR8000........................................................................................................... 6

3 Controller Description......................................................................................................................................6

4 Precautions for Mounting the Camera............................................................................................................. 7

5 Precautions for cable use..................................................................................................................................8

6 Hardware Connection.....................................................................................................................................10

6.1 System Connecting Diagram............................................................................................................. 10

6.1.1 Connection method for continuous trigger mode.......................................................................... 12

6.1.2 Connection method for external trigger mode...............................................................................13

6.1.3 Connection method for encoder trigger mode............................................................................... 14

6.1.4 Cautions for wiring........................................................................................................................ 15

6.2 Connecting the controller and the Camera........................................................................................ 17

6.3 Connecting the Power Supply to the Controller................................................................................ 17

6.4 How to Use the Terminal Block.........................................................................................................18

7 Software Connection...................................................................................................................................... 20

7.1 Install EdgeImaging software............................................................................................................ 20

7.2 Connecting the controller and the PC................................................................................................ 21

8 Product Selection............................................................................................................................................23

9 Dimensions.....................................................................................................................................................27

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

3/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Be sure to read this guide before use.

This guide aims to provide instructions for user to use the SR series 3D cameras quickly.

For detailed user’s guide, you can download the Hardware Manual of SR Series 3D Camera from

SSZN official home page website at http://www.cnsszn.com.

Please read the detailed user’s guide to understand the SR series 3D camera fully.

This guide is subject to change without individual notice.

Do not tear up the label, otherwise,we are not responsible for warranty repair.

Do not disassemble the camera, or it will damage the camera, and cause the factory

calibration data error, must be returned to the manufacturer for repair.

Be sure to read this guide carefully, incorrect operation may cause damage to the

camera.

Environmental Requirements

Keep away from the strong electromagnetic noise source such as a high-power equipment and

high-voltage line.

Avoid sharing power source with the high-power equipment.

Avoid laying the Camera cable and the Ethernet cable in parallel with the power lines.

1 Preparation before Installation

Before installation, first, please prepare the following items:

Ethernet Cable (category 6 or higher or compatible with 10GBase-T)

Multimeter

Wire Stripping Plier

Wire Crimping plier

Flat Gasket, M4 x4

A set of Flathead Screwdrivers

A set of Cross Screwdrivers

A set of Hex Key Allen Wrench

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

4/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

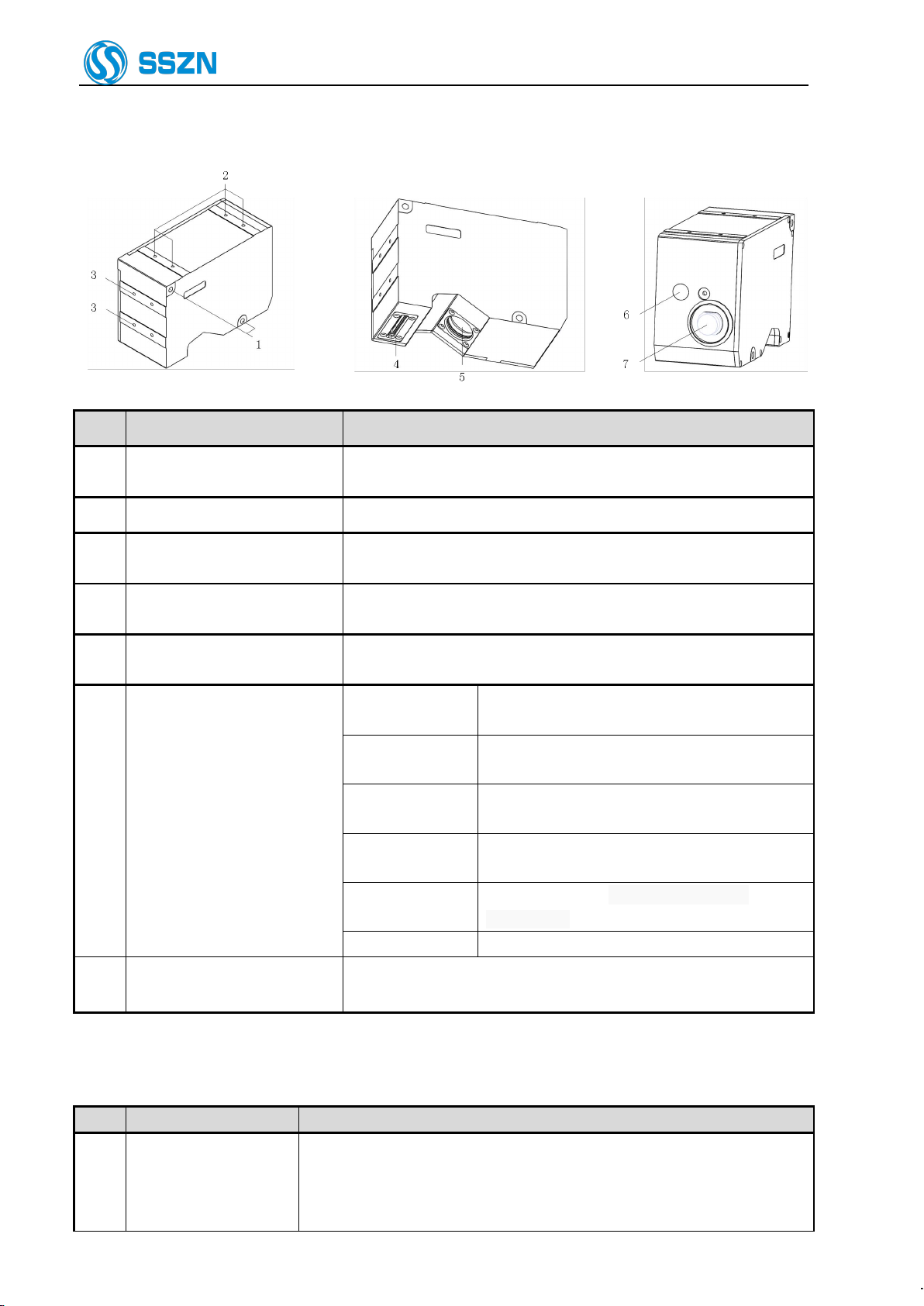

2 Camera Description

2.1 Description of Camera SR6000

Item

Name

Description

1

Laser-emitting LED

Lights green

The target object is at around the center of the Z

axis measurement area.

Lights orange

The target object is in the Z axis measurement

area.

Blinks orange

The target object is out of the specified Z axis

measurement area.

Lights green or

orange

The laser is working.

Lights off

Power off, or the power supply is failed

or abnormal.

Lights red

Any system error occurred at the camera.

2

Special mounting holes

The screw holes can be used to mount the camera.

3

Mounting holes

Use the hexagon socket bolt (included) to affix the camera.

Please refer to “4 Precautions for Mounting the Camera”.

4

Mounting holes for the stray

light shield

Use the holes to mount a plate for blocking stray light. Do not use for

mounting the camera.

5

Sensor (receiver)

Receive the laser beam for measurement.

Protected by a glass cover.

6

Sensor (transmitter)

Emit the laser beam for measurement.

Protected by a glass cover.

7

Cable connector

Connected with the camera cable.

Please refer to “6.2 Connecting the controller and the Camera”.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

5/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

2.2 Description of Camera SR7000

1

2

3

4

4

5

6

7

Item

Name

Description

1

Laser-emitting LED

Lights green

The target object is at around the center of the Z

axis measurement area.

Lights orange

The target object is in the Z axis measurement

area.

Blinks orange

The target object is out of the specified Z axis

measurement area.

Lights green or

orange

The laser is working.

Lights off

Power off, or the power supply is failed

or abnormal.

Lights red

Any system error occurred at the camera.

2

Special mounting holes

The screw holes can be used to mount the camera.

3

Mounting holes

Use the hexagon socket bolt (included) to affix the camera.

Please refer to “4Precautions for Mounting the Camera”.

4

Mounting holes for the stray

light shield

Use the holes to mount a plate for blocking stray light. Do not use for

mounting the camera.

5

Sensor (receiver)

Receive the laser beam for measurement.

Protected by a glass cover.

6

Sensor (transmitter)

Emit the laser beam for measurement.

Protected by a glass cover.

7

Cable connector

Connected with the camera cable.

Please refer to “6.2 Connecting the controller and the Camera”.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

6/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

2.3 Description of Camera SR8000

Item Name Description

1 Mounting holes Use the hexagon socket bolt (included) to affix the camera.

Please refer to “4Precautions for Mounting the Camera”.

2 Special mounting holes The screw holes can be used to mount the camera.

3Mounting holes for the stray

light shield

Use the holes to mount a plate for blocking stray light. Do not use for

mounting the camera.

4 Sensor (transmitter) Emit the laser beam for measurement.

Protected by a glass cover.

5 Sensor (receiver) Receive the laser beam for measurement.

Protected by a glass cover.

6 Laser-emitting LED

Lights green The target object is at around the center of the Z

axis measurement area.

Lights orange The target object is in the Z axis measurement

area.

Blinks orange The target object is out of the specified Z axis

measurement area.

Lights green or

orange The laser is working.

Lights off Power off, or the power supply is failed

or abnormal.

Lights red Any system error occurred at the camera.

7 Cable connector Connected with the camera cable.

Please refer to “6.2 Connecting the controller and the Camera”.

3 Controller Description

Item Name Description

1 I/O terminal block

Used for controlling signal input or output.

Used for pulse signal input from the encoder.

Used for RS-232 connection;

and used for power supply of I/O insulating part.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

7/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Please refer to “Hardware Manual of SR Series 3D Camera”.

2

24V power input

terminal block

Used for supply of the power source (DC24V).

Left: +24V, middle: 0V, right: Shell and GND

3

Ethernet port RJ45

connector

Connect to a personal computer or a switch with the Ethernet cable. (RJ-45

connector)

4

Camera connector

Connect to cameras with the camera cable, including camera-A connector

and camera-B connector.

Please refer to “6.2 Connecting the controller and the Camera”.

5

Reserved

Do not use, or it will damage the controller

6

USB2.0 port

Reserved

7

VGA port

Reserved

8

POWER ON LED

Showing the power

status, blue LED.

ON

The controller is powered on normally

OFF

Power off, or the power supply is

abnormal.

9

RUN LED

Showing the controller

works status, green

LED.

Blink

The controller is in the normal

operation state.

OFF

Power off, or the controller

is abnormal.

10

ERROR LED

Showing the controller

error status, red LED.

ON

Any error occurs.

OFF

The controller is normal.

Controller Model

Description

SR7001

Support SR6000 and SR7000 Camera

SR7002

Only support SR8000 Camera

4 Precautions for Mounting the Camera

Figure 4- 1 Dead Zone Arises

When installing the camera, make sure that the laser

beam irradiating the target object and the laser beam

reflected from the target object into the receiver, are

not obstructed by a wall surface, etc.

Figure 4- 2 Laser Beam Optical Path Obstructed

Depending on their shape, some target objects create a

dead zone in the measurement range. Make sure that the

dead zone does not affect the measurement result.

This unit features a fan shaped laser beam and receiver

system. For this reason, the dead zone will be smaller

near the center of the X-axis measurement range.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

8/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Stray light

Stray ligh

The laser reflected on the wall

will become stray light. Make

sure that the stray light will

not affect the measurement

Figure 4- 3 Generation of Stray light

Adjust the distance between the camera and

the target object, and then mount the camera

using the provided bolts.

For mounting dimensions, please refer to “9

Dimensions”

The tightening torque of the mounting screws

should be in the following ranges:

M4 screw: 1.2 ~1.8 N · m

Hexagon socket

head bolt

M4x55: 3 bolts

Figure 4- 4 Mounting the Camera

If you mount the camera on a plate made from material having poor heat

dissipation properties (such as resin), the camera surface may become hot, which

may cause a burn hazard.

Be sure to connect the camera to a metallic plate for better heat dissipation.

When using two cameras, pay attention to mutual interference area to prevent mutual interference from each

other. For more information, please refer to “Software Manual of SR Series 3D Camera” provided together

with the product.

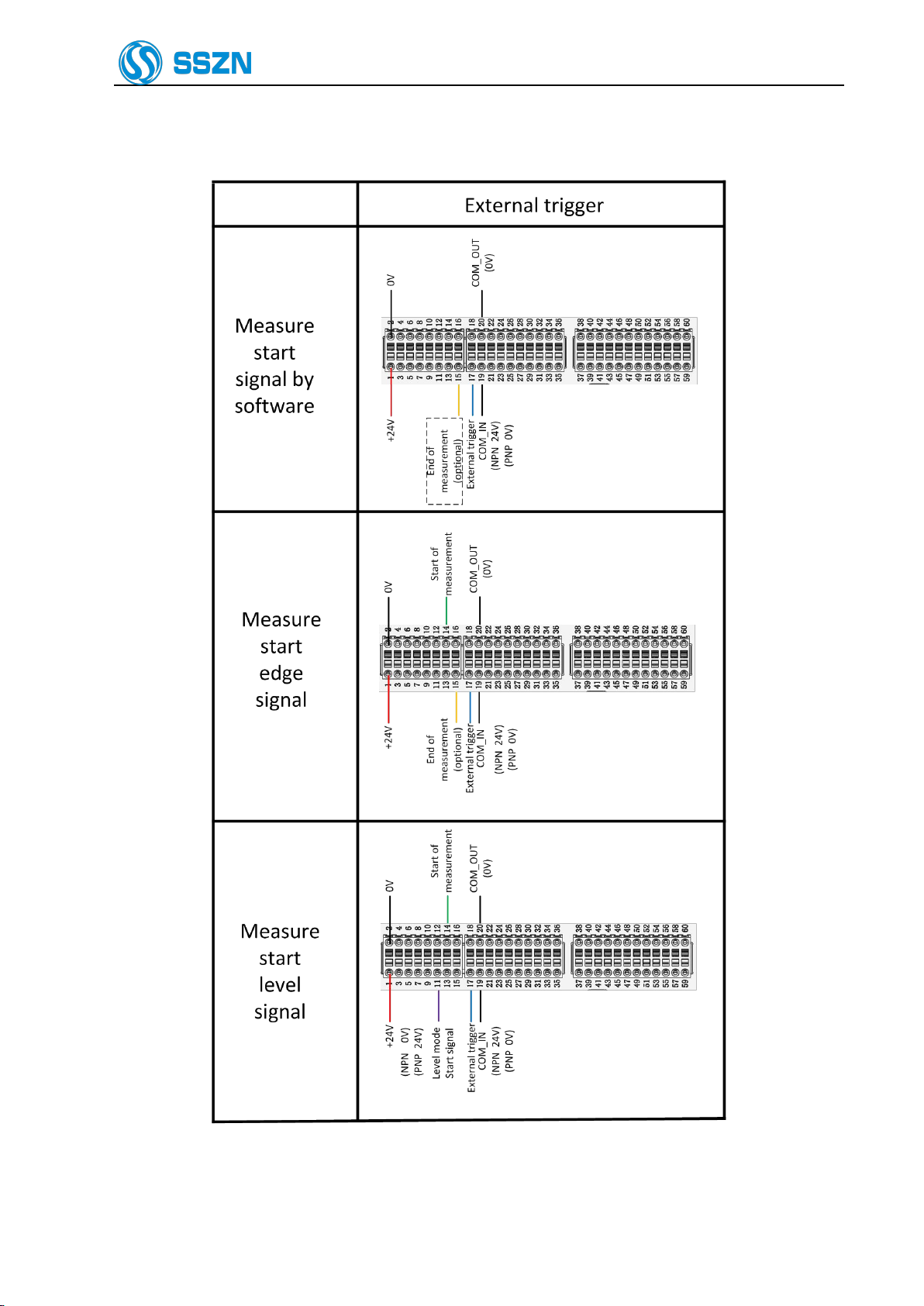

5 Precautions for cable use

Please ensure that the minimum

bending radius of the camera cable

is more than 30mm

Figure 5- 1 Schematic diagram of minimum bending radius of cable

When using cable connection,

the connector and the cable

within 70mm at both ends

must be kept relatively

stationary.

Figure 5- 2 Schematic diagram of cable connection

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

9/43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

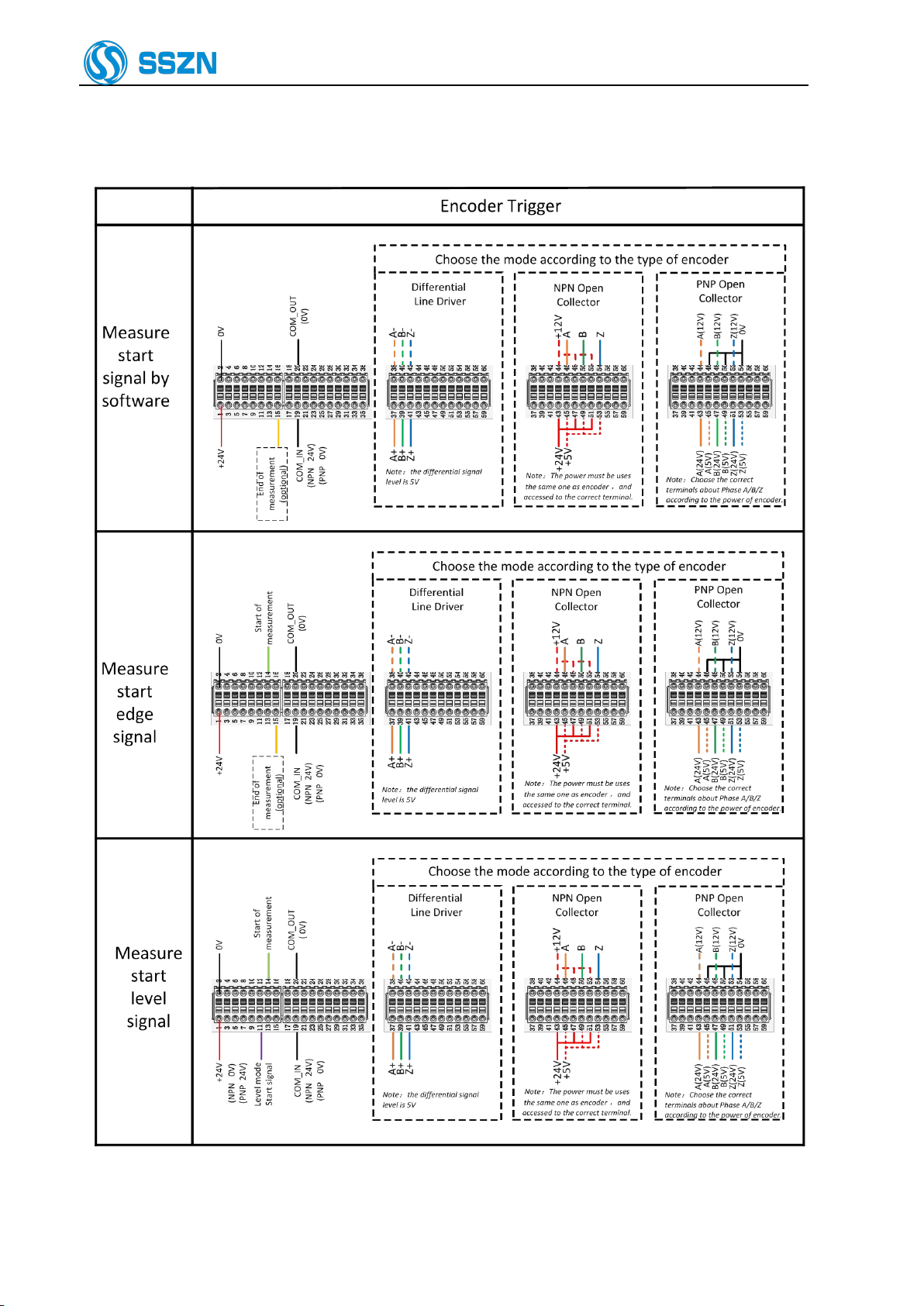

If there is no special specification

when using drag chain, please

select products above R100.

R100

Figure 5- 3 Schematic diagram of minimum bending radius of cable

Cables with connection points shall

not be used on the drag chain.

&

&

When using drag chains,

choose cables without

connection points

Figure 5- 4 Selection Diagram for Cable Drag Application

Figure 5- 5 Fixed Camera and Camera Cable Diagram

The cable must be fixed on the

same bracket as the camera about

70mm from the connector plug to

keep it relatively static with the

camera.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

10 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Make sure that the connector plug and the cable within a minimum of 70mm remain relatively

static with the camera.

6 Hardware Connection

6.1 System Connecting Diagram

Figure 6- 1 System Connecting Diagram

Always make sure to switch OFF the controller before connecting or removing

cables. Connecting or removing cables with the controller switched ON may

result in a malfunction.

Plug in the connector after making sure its orientation is correct. Inserting the

connector in the wrong orientation may break the connector pins and result in

a malfunction.

Only one camera controller can be connected to an encoder output; When

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

11 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

multiple camera controllers are required to share a single encoder, an Encoder

Pulse Signal Allocator is required to expand the encoder signal to multiple

outputs and then connect the corresponding camera controllers separately.

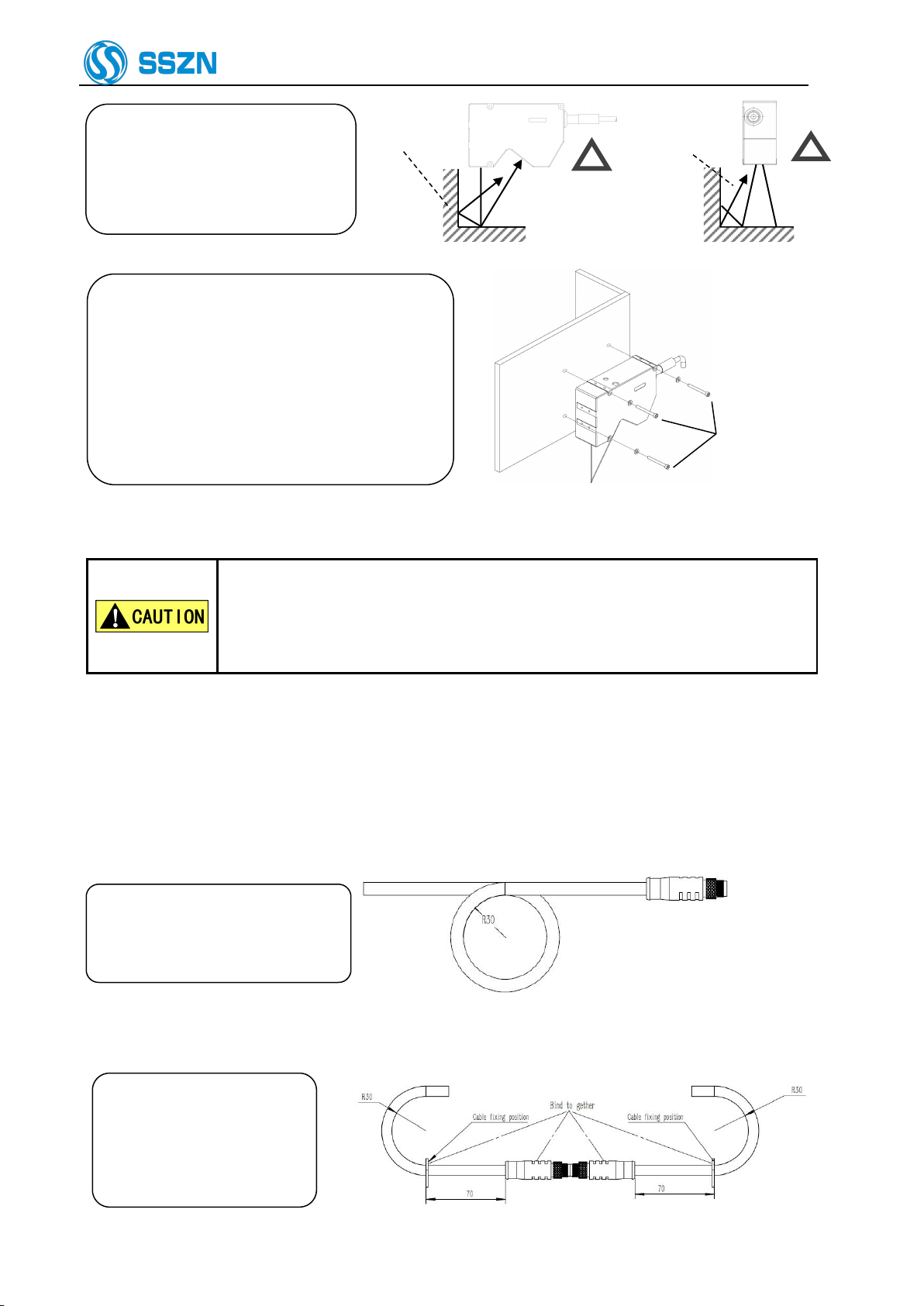

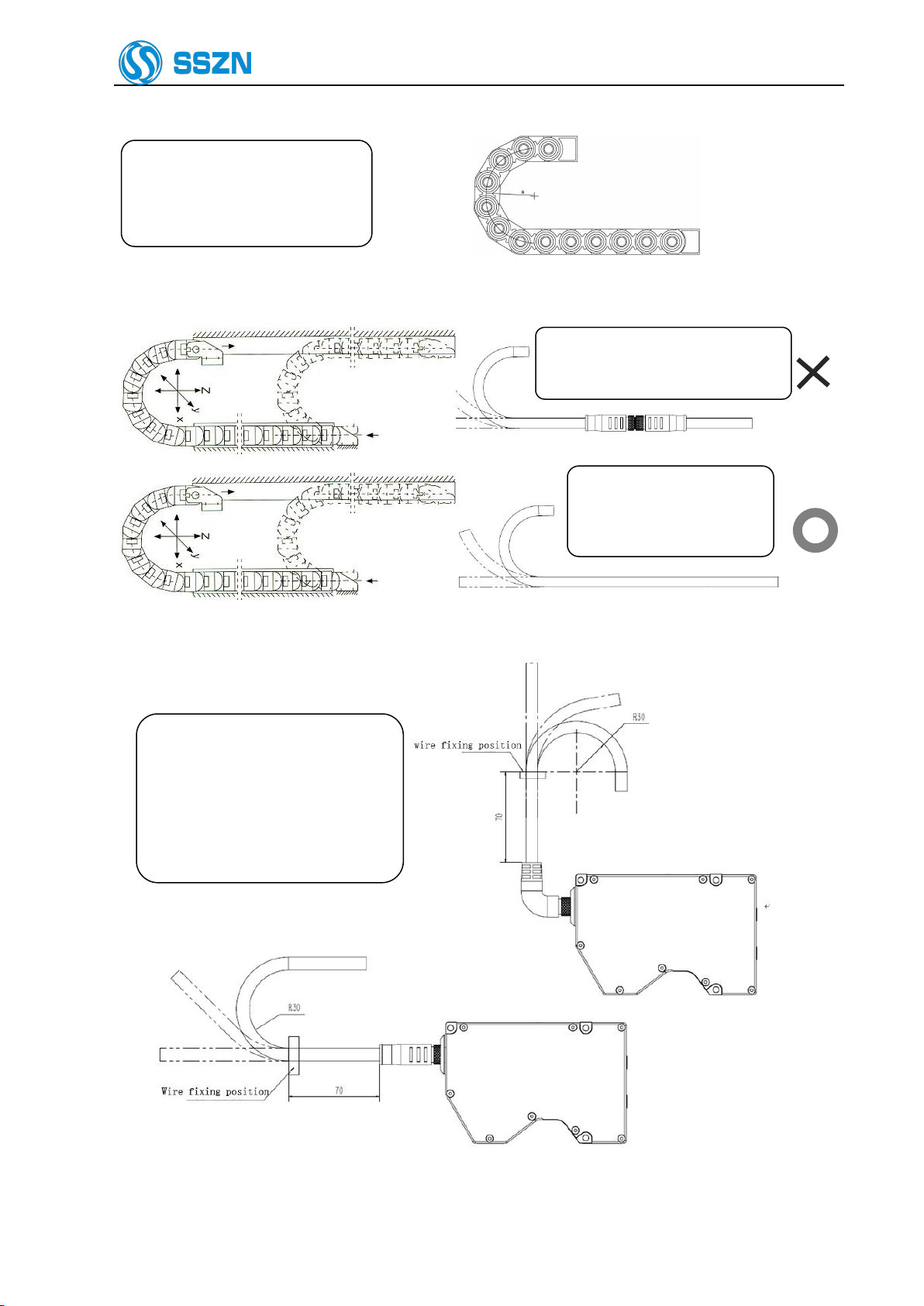

Different control requirements of the system correspond to different connection modes, select the

corresponding wiring diagram to connect on the basis of “Trigger mode” and “Batch start mode”, please refer

to “Figure 6 2 I/O Terminal Wiring Diagram 1”, “Figure 6 2 I/O Terminal Wiring Diagram 1” and “Figure 6 3

I/O Terminal Wiring Diagram 3”. For the “Trigger mode” Setting in EdgeImaging, please refer to “Software

Manual of SR Series 3D Camera”.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

12 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

6.1.1 Connection method for continuous trigger mode

Figure 6- 2 I/O Terminal Wiring Diagram 1

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

13 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

6.1.2 Connection method for external trigger mode

Figure 6- 3 I/O Terminal Wiring Diagram 2

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

14 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

6.1.3 Connection method for encoder trigger mode

Figure 6- 3 I/O Terminal Wiring Diagram 3

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

15 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

6.1.4 Cautions for wiring

1. Terminal connection must not be live operation, do not supply power to the controller, and ensure that the

PLC, servo driver, etc. are in power off status. Hot plug terminal stage will cause controller damage.

2. 3-17 PIN are input ports, combined with PIN19 "COM_IN"; 21~36 PIN are output ports, combined with

20 feet "COM_OUT".

a) Input port and PIN19 wiring instructions:

PLC Leakage Output (NPN) Local Input Circuit PLC Source Output(PNP) Local Input Circuit

b) Output port and PIN20 connection instructions:

Local Output Circuit PLC Input Circuit(Positive Common End)

3. In the connection method using edge signal, PIN14 and PIN15 need to connect to 0V in order to avoid

triggering by mistake when they are not used.

4. When there is no input in PIN11, the start of measurement (PIN14) and end of measurement (PIN15) work

in edge mode. Figure 65 shows the time sequence diagram for signals.

Figure 6- 5 Time sequence diagram for Edge Mode

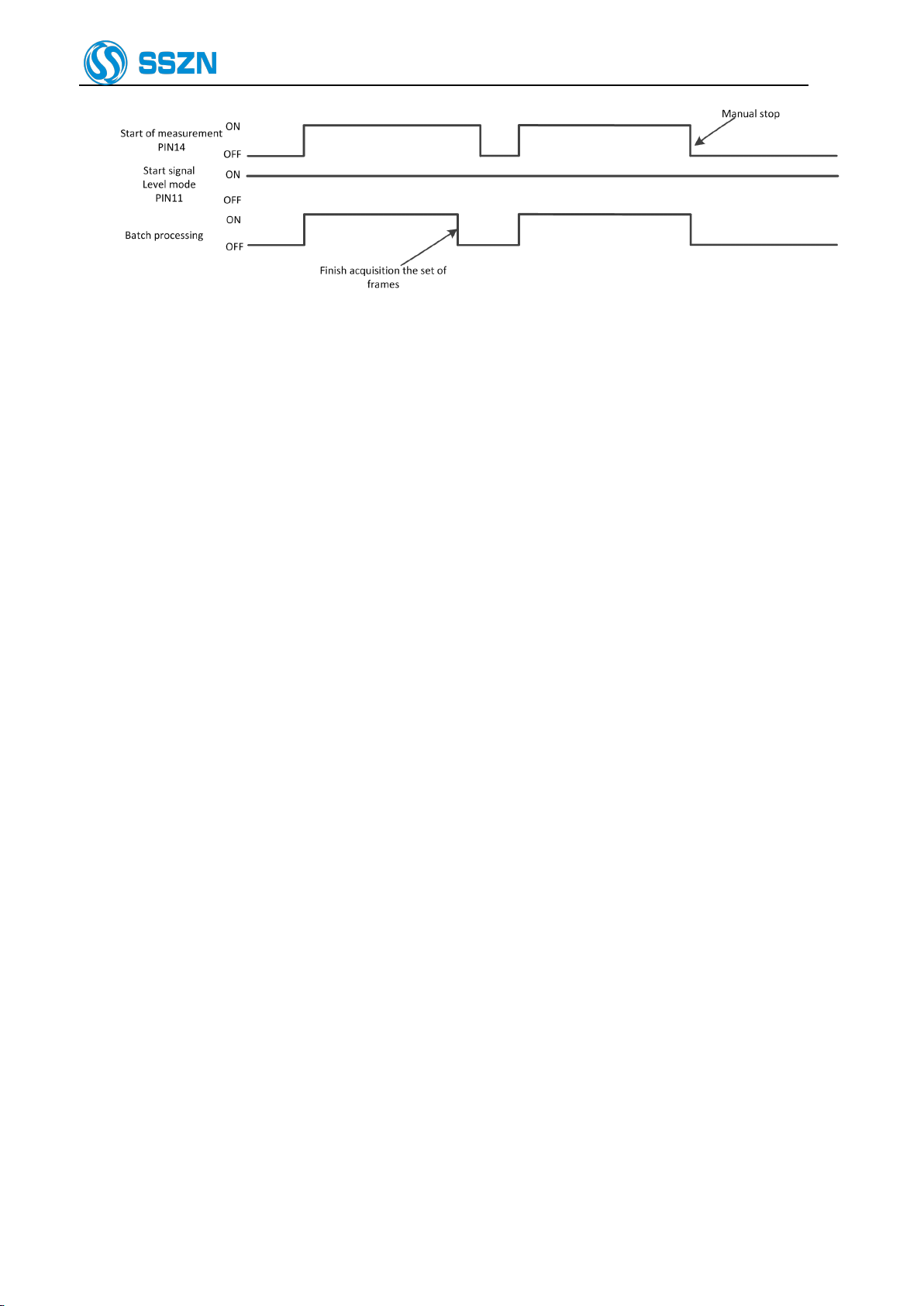

5. When there is a input signal in PIN11 all the time, the start of measurement (PIN14) works in level mode

and the end of measurement (PIN15) is invalid. Figure 6-6 shows the signal sequence diagram.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

16 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Figure 6- 6 Time sequence diagram for Level Mode

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

17 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

6.2 Connecting the controller and the Camera

This section explains the procedure for connecting the controller and the camera.

Do not supply power to the controller before connecting the camera cable.

Connecting the camera cable while the controller is switched ON may damage

the camera and/or the controller.

Maintain a minimum bend radius of 30 mm or more for the camera cable,

and the connectors at both ends should not be in tension state.

When using a cable tray, select a model with R100 or higher unless specified

otherwise.

Step1 Connect the camera cable to the camera connector of the controller.

Figure 6- 7 Connecting the Camera Cable to the Controller

Step2 Connect the camera cable and the camera.

Check the orientation of the

connector, and then insert it all the

way while slowly rotating it. Tighten

the screw with a tightening torque of

1 to 1.5 N·m.

Figure 6- 8 Connecting the camera cable and the camera

Plug in the connector after making sure its orientation is correct. Inserting the

connector in the wrong orientation may break the connector pins and result in

a malfunction.

Insert the connector without tilting it, and then tighten it firmly. If the

connector is not tightened enough, it may become loose due to vibration, etc.

resulting in poor contact.

Tighten it firmly by hand and then retighten approx. 45° to 60°.

6.3 Connecting the Power Supply to the Controller

This section explains the procedure for connecting the controller and the power supply.

Use a wire between AWG14 and AWG20.

If you are using a solderless terminal, use a terminal that has the following size

and suits the M3 screw:

If only one camera is used, connect it

to the CAM A connector. Tighten the

screws on both sides of the connector

with a flathead screwdriver. Make sure

it is fixed firmly.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

18 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

Y terminal

6.4mm or less

Tighten the screw firmly with a tightening torque of 0.5 to 0.75 [N·m].

The DC24V power supply must be 60W or more(include 2 cameras).

(notice :if only have one controller with one camera ,the power supply must be

30W or more ).

Step1 Connect the 24 V DC power supply to the 24 V power supply terminal of the controller.

6.4 How to Use the Terminal Block

This section explains how to use the terminal block.

IO power supply of controller terminal must share power supply with PLC and

servo driver.

Terminal block wiring should not be operated live, please do not supply power

to the controller, and ensure that the PLC, servo driver are in a power-off state.

Hot plug terminal stage will cause controller damage..

Use a wire between AWG16 and AWG28.

The end of the wire should be processed to the length approx. 8 mm.

Do not solder (pre-solder) the processed end of the wire.

The wire should be inserted all the way into the terminal block.

Step1 Insert the wire into “part b” while pushing in “part a” of the terminal block with a flathead

screwdriver.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

19 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

When the wire is inserted to

the end of “part b”, remove

the screwdriver. Then lightly

pull the wire to make sure it is

fixed firmly.

b

a

Terminal

block

Figure 6- 10 Terminal Block Wiring Diagram

Step 2 When the wire is inserted to the end, remove the screwdriver. Then lightly pull the wire to make

sure it is fixed firmly.

Shenzhen Sincevision Technology Co.Ltd

www.cnsszn.com

20 /43

Quick Start Guide of SR Series ©2021 SSZN All Right Reserved

7 Software Connection

7.1 Install EdgeImaging software

1. The required computer environment is as follows:

Hardware

requirements

CPU

Core i5 2.3 GHz or higher

Memory Size

8 GB or more

Level 2 cache

2 MB or more

Hard disk space

10GB or more

Interface

Ethernet 1000BASE-T/100BASE-TX

Displayer

XGA(1024*768 pixels)or more,256-color or more

Software

requirements

Operating system

Windows 10 32/64bit Professional/Enterprise

Windows 8.1 32/64bit Professional/Enterprise

Windows7 32/64bit Professional/Ultimate

2. Obtain the installation package of EdgeImaging software from the manufacturer.

3. Enter the windows system,double click the installation package of EdgeImaging.

4. Follow the steps in the installation wizard.

Figure 7- 1

5. On the Finish page, click Finish to exit.Then, the EdgeImaging software is installed successfully.

Figure 7- 2

Other manuals for SR Series

1

This manual suits for next models

16

Table of contents

Other SSZN 3D Camera manuals